Laser engraving machines have revolutionized the way we etch designs onto various materials. These sophisticated pieces of machinery offer precision, efficiency, and versatility, making them indispensable in both industrial and creative settings. This article aims to demystify the technology behind laser engraving machines, explore their benefits, delve into the considerations for selecting the right machine, and provide insights into maintenance practices and future trends in the industry. Whether you’re a seasoned professional or a curious newcomer, this guide will equip you with the knowledge to navigate the world of laser engraving.

Table of Contents:

– Understanding laser engraving technology

– Key benefits of using laser engraving machines

– How to choose the right laser engraving machine

– Maintenance tips for laser engraving machines

– Future trends in laser engraving technology

Understanding laser engraving technology

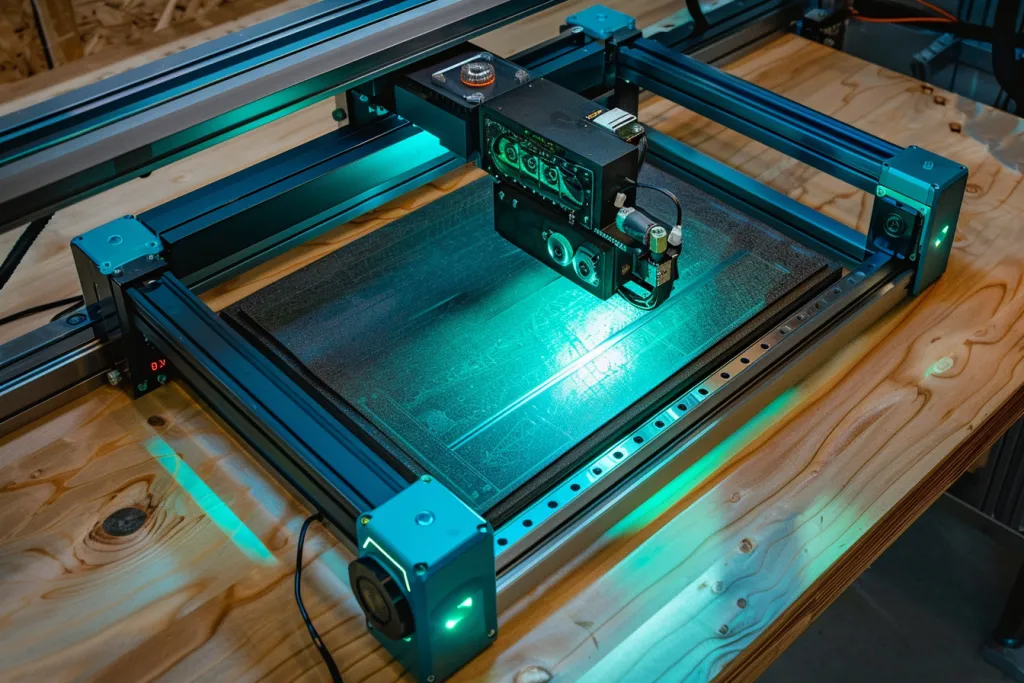

Laser engraving is a non-contact process that uses a laser to etch or mark the surface of various materials. The technology hinges on the use of a laser beam, which is focused onto the material’s surface, removing a portion of it to create a design. This process can be controlled with high precision, allowing for intricate designs on metals, plastics, wood, glass, and more. The core components of a laser engraving machine include a laser source, a controller, and a surface for the material being engraved.

The technology behind laser engraving machines is constantly evolving, with advancements aimed at increasing speed, efficiency, and the quality of the engravings. Modern machines come equipped with sophisticated software that allows users to create or upload designs, which are then precisely replicated by the machine. Understanding the basic principles of laser technology is crucial for anyone looking to utilize these machines effectively.

Key benefits of using laser engraving machines

Laser engraving machines offer a plethora of advantages over traditional engraving methods. First and foremost, their precision is unparalleled. The ability to create highly detailed and consistent engravings makes them ideal for applications requiring intricate designs. Furthermore, the non-contact nature of the process minimizes the risk of material damage or deformation, ensuring the integrity of the final product.

Another significant benefit is the versatility laser engraving machines offer. They can work with a wide array of materials and surfaces, from metal and wood to plastic and glass. This flexibility opens up a world of possibilities for customization and creativity. Additionally, laser engraving is a relatively fast process, especially when compared to manual engraving methods, leading to increased productivity and the ability to meet tight deadlines.

How to choose the right laser engraving machine

Selecting the appropriate laser engraving machine for your needs requires careful consideration of several factors. The type of material you plan to engrave is paramount, as different machines are optimized for different materials. For instance, CO2 lasers are generally better suited for engraving non-metal materials, while fiber lasers are ideal for metals.

The size of the engraving area is another critical factor. It’s important to choose a machine that can accommodate the largest piece you plan to engrave. Additionally, consider the machine’s power, measured in watts. Higher power allows for faster engraving and the ability to work with thicker materials. Lastly, software compatibility should not be overlooked, as it affects the ease of use and the complexity of designs you can create.

Maintenance tips for laser engraving machines

Maintaining your laser engraving machine is essential for ensuring its longevity and performance. Regular cleaning of the machine’s components, such as the lens and mirrors, is crucial for preventing damage and maintaining engraving quality. It’s also important to check and adjust the alignment of the laser beam periodically.

Furthermore, the cooling system, whether air or water-based, should be monitored and maintained to prevent overheating. Lastly, keeping the software updated ensures that you have access to the latest features and improvements. Adhering to a regular maintenance schedule can prevent costly repairs and downtime.

Future trends in laser engraving technology

The future of laser engraving looks promising, with technological advancements aimed at increasing efficiency, precision, and accessibility. One trend is the development of more compact and user-friendly machines, making laser engraving more accessible to small businesses and hobbyists. Additionally, advancements in software are making the design process more intuitive and flexible.

Sustainability is also becoming a focus, with efforts to reduce energy consumption and the environmental impact of laser engraving processes. As the technology continues to evolve, we can expect laser engraving machines to become even more versatile and integral to various industries.

Conclusion:

Laser engraving machines represent a pinnacle of precision and versatility in the world of material processing. Understanding the technology, benefits, and considerations for choosing the right machine is crucial for anyone looking to leverage the power of laser engraving. By following maintenance best practices and staying informed about future trends, users can ensure their laser engraving endeavors are successful and sustainable.