The global bench vice market is projected to grow significantly, reaching new heights in 2025 due to the rise in industrial demand. This article will cover critical aspects of selecting a bench vice, including types, build quality, and advanced features. Professional buyers will find valuable insights to make informed purchasing decisions.

Table of Contents:

1. Comprehensive Market Overview of Bench Vice Industry

2. In-Depth Analysis of Bench Vice Market Dynamics

3. Innovations and Future Trends in Bench Vice Market

4. Key Factors When Selecting a Bench Vice

5. Latest Technology Features in Bench Vices

6. Safety Standards and Certifications for Bench Vices

7. Regulatory Compliance and Environmental Considerations

8. Summing It Up

Comprehensive Market Overview of Bench Vice Industry

The global bench vice market has shown significant growth in recent years, driven by demand from both industrial and domestic sectors. In 2024, the market was worth around USD 1.2 billion, with a projected Compound Annual Growth Rate (CAGR) of 5.1% through 2030. This growth is due to the increasing need for precision and stability in applications such as metalworking, woodworking, and general maintenance.

Key regions contributing to this expansion include North America, Europe, and Asia-Pacific. North America held a significant market share, accounting for nearly 35% of global revenue in 2024. This is largely due to advanced manufacturing industries and high demand for reliable workholding tools. The Asia-Pacific region is expected to see the fastest growth, driven by rapid industrialization and the growing manufacturing sector in countries like China and India.

The bench vice market offers a diverse range of products, including heavy-duty, light-duty, and specialty vices for specific applications. Leading manufacturers such as Wilton Tools, Yost Vises, and Eclipse Tools dominate the market, continuously innovating to meet changing demands. The rise of eCommerce platforms has also made it easier to access a wider variety of products, boosting market growth.

In-Depth Analysis of Bench Vice Market Dynamics

Several key performance benchmarks influence the bench vice market, determining product quality and reliability. These include clamping force, jaw width, throat depth, and material composition. High-performance vices are typically made from robust materials like cast iron or forged steel, ensuring durability and resistance to wear. Advanced models often include features like quick-release mechanisms and swivel bases for enhanced user convenience and versatility.

Market share dynamics show that established brands like Wilton Tools and Yost Vises lead due to their reputation for quality and innovation. However, emerging players from the Asia-Pacific region are gaining ground by offering cost-effective solutions without compromising performance. The competitive landscape is also shaped by economic factors such as fluctuations in raw material prices and manufacturing costs, which can affect product pricing and profit margins.

Consumer behavior in the bench vice market has shifted towards digitalization and online purchasing. The convenience of comparing products, reading reviews, and accessing detailed specifications online has made eCommerce platforms increasingly popular. Recent innovations, such as ergonomic handles and adjustable jaws, have also improved ease of use and adaptability to various tasks.

Innovations and Future Trends in Bench Vice Market

The bench vice market is experiencing innovations aimed at enhancing functionality and user experience. One notable trend is the development of smart vices with digital sensors and IoT connectivity. These models provide real-time data on clamping force and jaw alignment, ensuring precision and reducing the risk of workpiece damage. The integration of AI algorithms also enables predictive maintenance, alerting users to potential issues before significant downtime occurs.

Another trend is the adoption of sustainable manufacturing practices. Manufacturers are increasingly using recycled materials and implementing energy-efficient production processes to reduce their environmental impact. This shift aligns with growing consumer demand for eco-friendly products and the global push towards sustainability in industrial operations.

The market is also seeing a rise in customized solutions tailored to specific industry requirements. For example, vices for aerospace applications offer enhanced clamping precision and resistance to high temperatures, while those for woodworking incorporate non-marring jaws to prevent surface damage. These niche markets provide lucrative opportunities for manufacturers to differentiate their offerings and capture a broader customer base.

Key Factors When Selecting a Bench Vice

Types of Bench Vices

When selecting a bench vice, understanding the different types available is crucial. The main types include the woodworking vice, metalworking vice, and multipurpose vice. Woodworking vices are designed specifically for holding wooden pieces securely. They often come with wooden or plastic jaws to avoid marring the wood’s surface. Metalworking vices are built to handle the rigors of metal fabrication. These vices typically feature hardened steel jaws to grip metal securely without slipping. Multipurpose vices combine features of both woodworking and metalworking vices, making them versatile tools for various applications.

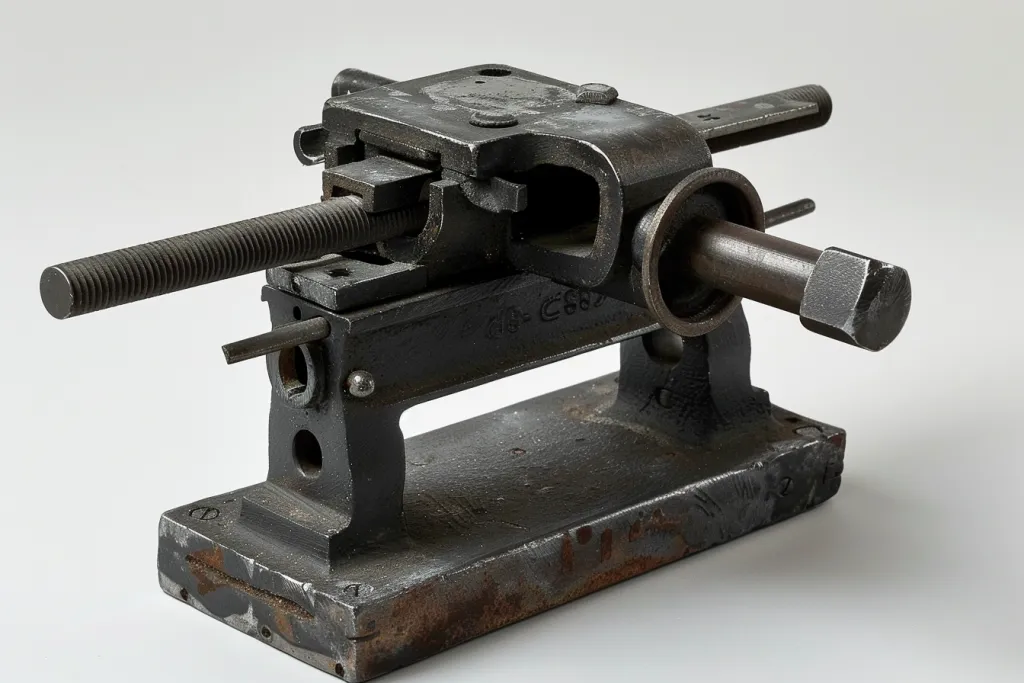

Build Quality and Materials

The build quality and materials used in constructing a bench vice are critical factors that influence its durability and performance. High-quality bench vices are typically made from cast iron or forged steel, providing superior strength and longevity. Cast iron vices are known for their rigidity and ability to withstand heavy-duty use, while forged steel vices offer excellent toughness and resistance to wear and tear. Additionally, the quality of the vice’s jaws and screws should be considered, as these components endure significant stress during use. Hardened steel jaws and precision-machined screws ensure a secure grip and smooth operation.

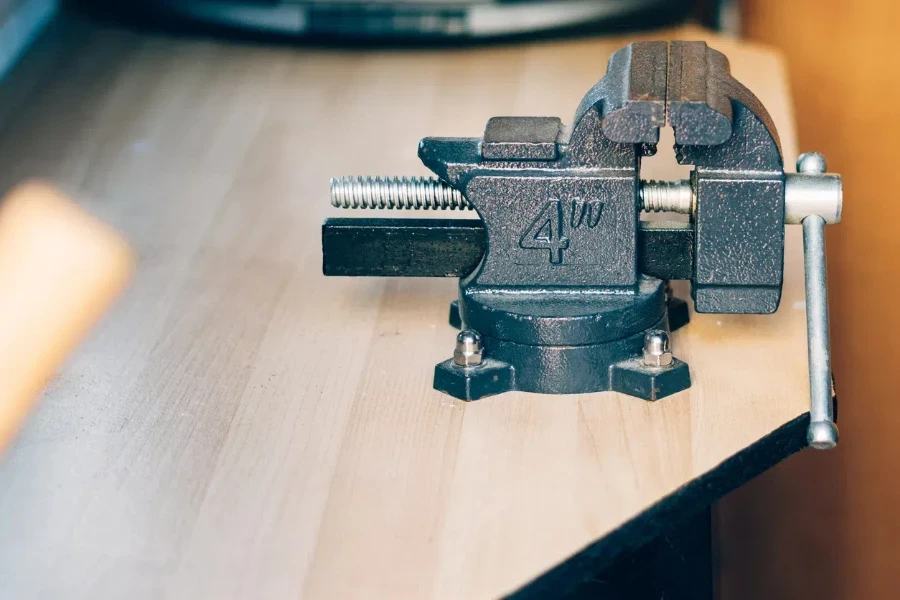

Jaw Width and Opening Capacity

The jaw width and opening capacity of a bench vice determine the size of the workpieces it can accommodate. Jaw width refers to the length of the vice’s jaws, while opening capacity indicates the maximum distance between the jaws when fully open. For general-purpose use, a jaw width of 4 to 6 inches and an opening capacity of 6 to 8 inches are typically sufficient. However, for specialized applications, such as working with larger materials, a vice with a wider jaw and greater opening capacity may be necessary. It’s essential to choose a bench vice that meets the specific requirements of your projects to ensure optimal performance and efficiency.

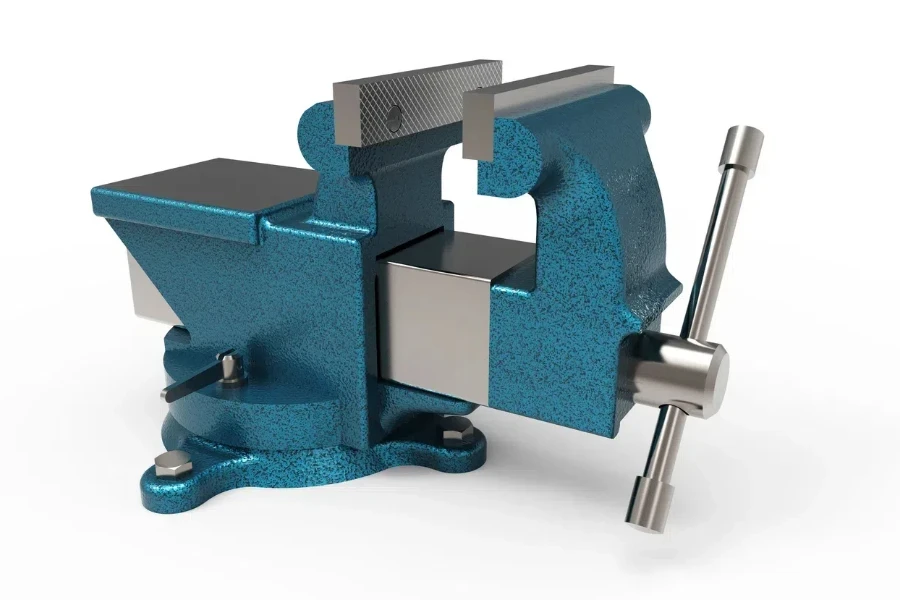

Swivel Base and Anvil Feature

A swivel base and anvil feature are additional considerations when selecting a bench vice. A swivel base allows the vice to rotate, providing greater flexibility in positioning the workpiece. This feature is particularly useful for tasks that require access to different angles without repositioning the entire vice. An anvil feature, often found on the back of the vice, provides a flat surface for hammering and shaping materials. This feature adds versatility to the bench vice, making it a valuable tool for a variety of applications in both woodworking and metalworking.

Price Range and Budget

The price range of bench vices can vary significantly based on factors such as build quality, materials, and additional features. Entry-level bench vices suitable for light-duty tasks can be found in the $50 to $100 range, while high-quality, heavy-duty vices can cost upwards of $200. It’s important to consider your budget and the specific requirements of your projects when selecting a bench vice. Investing in a high-quality vice can provide long-term value by ensuring reliable performance and durability, reducing the need for frequent replacements.

Latest Technology Features in Bench Vices

Advanced Clamping Mechanisms

Recent advancements in bench vice technology have introduced new clamping mechanisms that enhance performance and ease of use. One such innovation is the quick-release mechanism, which allows for rapid adjustment of the jaws without extensive turning of the handle. This feature is particularly beneficial for tasks that require frequent repositioning of the workpiece. Additionally, some modern bench vices incorporate self-centering jaws, which automatically align to the center of the workpiece, ensuring even pressure distribution and a secure grip.

Enhanced Durability with Composite Materials

The use of composite materials in bench vice construction is another noteworthy development. Composite materials, such as high-strength polymers and fiber-reinforced plastics, offer several advantages over traditional metals. These materials are lightweight, corrosion-resistant, and can withstand high levels of stress without deforming. As a result, bench vices made from composite materials provide enhanced durability and longevity, making them suitable for demanding industrial applications.

Integration with Digital Tools

The integration of digital tools and smart features in bench vices represents a significant leap forward in the industry. Some modern bench vices are equipped with digital readouts that display the exact clamping force applied, allowing for precise adjustments and consistent results. Additionally, smart bench vices can be connected to mobile devices via Bluetooth, enabling remote monitoring and control. These features not only improve accuracy and efficiency but also enhance safety by preventing over-tightening and potential damage to the workpiece.

Safety Standards and Certifications for Bench Vices

Compliance with Industry Standards

Ensuring that a bench vice complies with industry standards and certifications is crucial for safety and reliability. Reputable manufacturers adhere to standards set by organizations such as the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO). These standards specify the requirements for materials, design, and performance of bench vices, ensuring they meet stringent safety and quality criteria. When selecting a bench vice, it’s essential to verify that it complies with relevant standards to ensure safe and reliable operation.

Importance of Load Testing

Load testing is a critical aspect of bench vice safety. This process involves subjecting the vice to various loads and stresses to verify its strength and durability. Load testing helps identify potential weaknesses and ensures that the vice can withstand the demands of heavy-duty use. Manufacturers that conduct thorough load testing and provide certification of the results offer an added level of assurance regarding the safety and performance of their products.

Safety Features and Ergonomics

Modern bench vices are designed with safety features and ergonomic considerations to enhance user comfort and reduce the risk of injury. For example, some vices feature anti-pinch guards that prevent fingers from being caught between the moving parts. Additionally, ergonomic handles with cushioned grips reduce hand fatigue and provide better control during operation. These features contribute to a safer and more comfortable working environment, particularly during extended use.

Regulatory Compliance and Environmental Considerations

Adherence to Environmental Regulations

In today’s environmentally conscious market, regulatory compliance and environmental considerations are increasingly important. Manufacturers of bench vices are expected to adhere to environmental regulations, such as the Restriction of Hazardous Substances (RoHS) directive, which limits the use of certain hazardous materials in electronic and mechanical products. Compliance with these regulations ensures that bench vices are manufactured using environmentally friendly processes and materials, reducing their impact on the environment.

Sustainable Manufacturing Practices

Sustainable manufacturing practices are becoming a key focus for bench vice manufacturers. These practices include using recycled materials, reducing waste, and minimizing energy consumption during production. By adopting sustainable practices, manufacturers can reduce their carbon footprint and contribute to environmental conservation. When selecting a bench vice, it’s worth considering products from manufacturers that prioritize sustainability and environmental responsibility.

Product Lifecycle and Recyclability

The product lifecycle and recyclability of bench vices are important factors to consider from an environmental perspective. High-quality bench vices with a long lifespan reduce the need for frequent replacements, minimizing waste. Additionally, vices made from recyclable materials contribute to a circular economy by allowing the materials to be reused at the end of the product’s life. Choosing bench vices with a focus on durability and recyclability aligns with sustainable practices and supports environmental conservation efforts.

Summing It Up

Selecting the right bench vice involves considering various factors such as types, build quality, jaw width, additional features, and budget. Understanding the latest technology features, safety standards, and environmental considerations can further enhance the decision-making process. By prioritizing these aspects, buyers can ensure they choose a bench vice that meets their specific needs, offers reliable performance, and aligns with industry standards and environmental practices.