In 2025, the food slicer machine market is booming with innovations like IoT-enabled devices and eco-friendly designs. This article delves into market drivers, essential features, and supplier tips, providing professional buyers with valuable insights to make informed decisions.

Table of Contents:

1. Understanding the Food Slicer Machine Market

2. Essential Features to Look for in a Food Slicer Machine

3. Evaluating the Different Types of Food Slicer Machines

4. Tips for Choosing the Right Supplier

5. Final Thoughts on Selecting the Ideal Food Slicer Machine

Understanding the Food Slicer Machine Market

Key Market Drivers

The food slicer machine market has been experiencing significant growth, driven by several key factors. The global market for food slicer machines was worth USD 1.16 billion in 2023 and is projected to reach USD 1.71 billion by 2030, growing at a CAGR of 5.66%. This growth is primarily fueled by the increasing demand for high-quality food products and the need for efficient food processing operations. The rising consumer preference for convenience foods and the expansion of the food service industry are also contributing to the market’s expansion.

Technological advancements in food slicer machines are another major driver of market growth. Innovations such as automated slicing systems, which enhance precision and reduce labor costs, are gaining popularity among food manufacturers. The integration of advanced imaging technology and machine learning algorithms in food slicer machines has significantly improved their efficiency and accuracy. These advancements enable the machines to handle a wide range of food products, including fruits, vegetables, meats, and cheeses, with minimal human intervention.

The growing emphasis on food safety and hygiene standards is also propelling the demand for food slicer machines. Regulatory authorities across the globe are imposing stringent food safety regulations, which necessitate the use of advanced food processing equipment. Food slicer machines equipped with features such as easy-to-clean components, antimicrobial surfaces, and automated cleaning systems are becoming increasingly popular. These machines help food manufacturers comply with hygiene standards and reduce the risk of contamination, thereby ensuring the safety of the end products.

Emerging Trends and Innovations

The food slicer machine market is witnessing several emerging trends and innovations that are shaping its future. One notable trend is the increasing adoption of smart and connected food slicer machines. These machines are equipped with IoT (Internet of Things) technology, which enables real-time monitoring and control of the slicing process. IoT-enabled food slicer machines can collect and analyze data on various parameters such as slicing speed, blade sharpness, and machine performance. This data can be used to optimize the slicing process, reduce downtime, and improve overall operational efficiency.

Another emerging trend in the food slicer machine market is the development of sustainable and eco-friendly slicing solutions. Manufacturers are focusing on designing machines that consume less energy and generate minimal waste. For instance, some food slicer machines are now equipped with energy-efficient motors and blades that reduce power consumption. Additionally, innovations in blade design and material are helping to extend the lifespan of the blades, thereby reducing the frequency of replacements and minimizing waste.

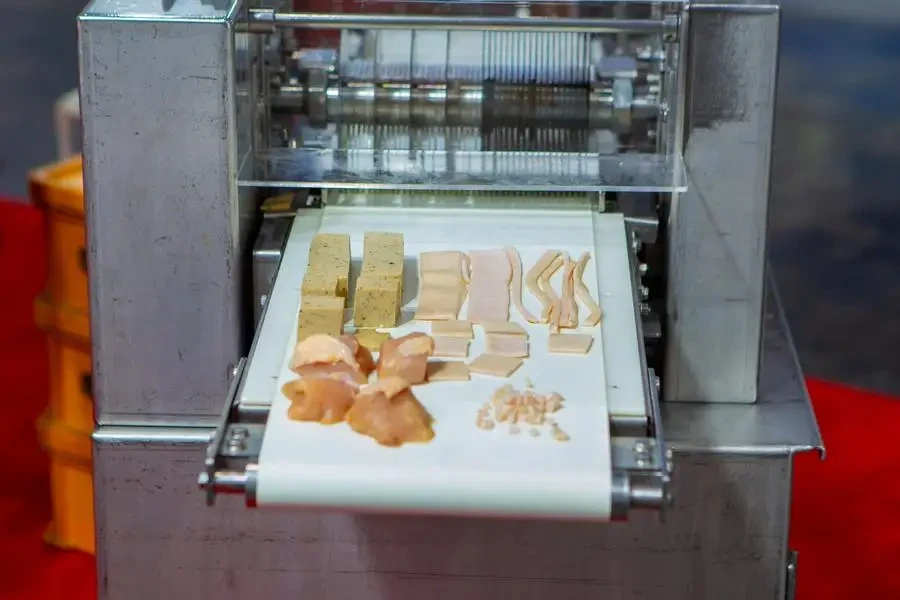

The increasing demand for customized and flexible food slicer machines is also driving innovation in the market. Food manufacturers are seeking machines that can handle a variety of slicing tasks and accommodate different product sizes and shapes. In response to this demand, manufacturers are developing modular food slicer machines that can be easily reconfigured to suit different slicing requirements. These machines offer greater flexibility and versatility, allowing food manufacturers to adapt to changing market demands and produce a wide range of sliced products.

Essential Features to Look for in a Food Slicer Machine

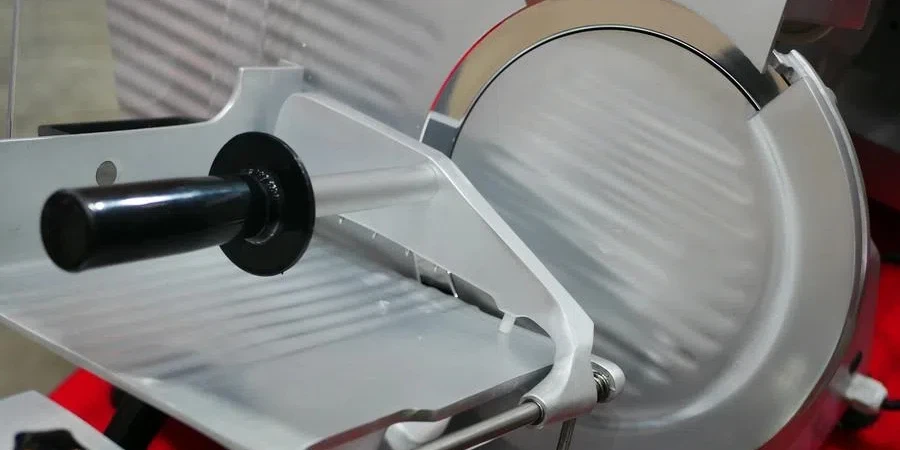

Blade Types and Materials

The blade is a critical component of a food slicer machine, and its type and material significantly impact the machine’s performance. Food slicer machines typically use stainless steel blades due to their durability, corrosion resistance, and ease of maintenance. High-carbon stainless steel blades are particularly popular as they offer a sharp edge and maintain their sharpness for a longer period. These blades are ideal for slicing a variety of food products, including meats, cheeses, and vegetables.

There are different types of blades used in food slicer machines, each designed for specific slicing tasks. Serrated blades are commonly used for slicing bread and other baked goods, as they can easily cut through crusty surfaces without crushing the soft interior. Smooth blades, on the other hand, are ideal for slicing meats and cheeses, as they provide clean and precise cuts. Some food slicer machines come with interchangeable blades, allowing users to switch between different blade types based on their slicing needs.

The material of the blade also plays a crucial role in determining the machine’s slicing efficiency and longevity. Blades made from high-quality stainless steel or carbon steel are preferred for their strength and resistance to wear and tear. Additionally, some blades are coated with non-stick materials to prevent food from sticking to the blade during slicing. This feature not only enhances the slicing performance but also makes cleaning the blade easier.

Adjustable Thickness Settings

Adjustable thickness settings are an essential feature to look for in a food slicer machine, as they provide versatility and precision in slicing. Food slicer machines with adjustable thickness settings allow users to customize the thickness of the slices according to their preferences. This feature is particularly important for food manufacturers and food service establishments that need to produce slices of varying thicknesses for different applications.

Most food slicer machines come with a thickness adjustment knob or lever that allows users to easily set the desired slice thickness. The adjustment range typically varies from very thin slices, suitable for deli meats and cheeses, to thicker slices, ideal for bread and vegetables. Some advanced food slicer machines offer digital thickness controls, which provide more precise and consistent slicing. These machines often come with a digital display that shows the selected thickness setting, making it easier for users to achieve the desired slice thickness.

The ability to adjust the slice thickness not only enhances the versatility of the food slicer machine but also improves the overall quality of the sliced products. Consistent slice thickness ensures uniform cooking and presentation, which is crucial for maintaining product quality and customer satisfaction. Additionally, adjustable thickness settings help reduce food waste by allowing users to slice products more efficiently and minimize off-cuts.

Safety Features

Safety is a paramount concern when it comes to operating food slicer machines, and manufacturers have incorporated various safety features to protect users from potential hazards. One of the most common safety features is the blade guard, which covers the exposed blade when the machine is not in use. The blade guard prevents accidental contact with the sharp blade, reducing the risk of injuries. Some food slicer machines also come with a blade lock mechanism that secures the blade in place during cleaning and maintenance.

Another important safety feature is the safety switch or interlock system, which prevents the machine from operating unless all safety components are properly engaged. For instance, some food slicer machines have a safety switch that ensures the machine only operates when the food carriage is in the correct position. This feature prevents accidental activation of the machine and enhances user safety. Additionally, some machines come with an automatic shut-off feature that turns off the machine after a certain period of inactivity, further reducing the risk of accidents.

Ergonomic design elements also contribute to the safety of food slicer machines. Machines with non-slip feet or suction cups provide stability during operation, preventing the machine from moving or tipping over. Additionally, food slicer machines with easy-to-grip handles and smooth-gliding food carriages reduce the effort required to operate the machine, minimizing the risk of strain or injury. These safety features ensure that users can operate the food slicer machine with confidence and peace of mind.

Ease of Cleaning and Maintenance

Ease of cleaning and maintenance is a crucial factor to consider when choosing a food slicer machine, as it directly impacts the machine’s hygiene and longevity. Food slicer machines that are easy to clean help prevent the buildup of food residues and bacteria, ensuring the safety and quality of the sliced products. Machines with removable and dishwasher-safe components, such as blades, food carriages, and blade guards, simplify the cleaning process and save time.

Some food slicer machines come with a quick-release mechanism that allows users to easily remove the blade for cleaning. This feature is particularly useful for thorough cleaning, as it provides access to hard-to-reach areas where food particles may accumulate. Additionally, machines with smooth and non-porous surfaces are easier to wipe down and sanitize, reducing the risk of contamination. Non-stick coatings on blades and other components also prevent food from sticking, making cleaning more efficient.

Regular maintenance is essential to keep the food slicer machine in optimal working condition and extend its lifespan. Machines with self-lubricating components or maintenance-free bearings require less frequent servicing, reducing downtime and maintenance costs. Some advanced food slicer machines come with built-in diagnostics or maintenance alerts that notify users when servicing is needed. These features help ensure that the machine operates smoothly and efficiently, minimizing the risk of breakdowns and prolonging its useful life.

Evaluating the Different Types of Food Slicer Machines

Manual vs. Electric Food Slicers

Manual food slicers are typically operated by hand, making them ideal for small-scale operations or home use. They are often more affordable and require no electricity, which can be advantageous in settings where power supply is a concern. However, manual slicers can be labor-intensive and may not provide the same level of precision and consistency as electric models. For example, the Avantco SL312 12″ manual gravity feed slicer, with its 1/3 hp motor and 12” stainless steel blade, is designed for light-duty operations and can handle slicing tasks for less than an hour per day.

Electric food slicers, on the other hand, are powered by motors, which significantly reduces the physical effort required to slice food. These machines are ideal for high-volume operations such as delis, butcher shops, and restaurants. Electric slicers can handle a variety of slicing tasks with greater speed and precision. For instance, the Hobart HS9-1 13″ heavy-duty automatic slicer features a 1/2 hp motor and an automatic cutting option, making it suitable for continuous use in busy commercial kitchens.

When choosing between manual and electric slicers, consider the volume of slicing required and the available budget. Manual slicers are cost-effective and suitable for low-volume tasks, while electric slicers offer efficiency and consistency for high-volume operations. The choice ultimately depends on the specific needs and constraints of the business.

Commercial vs. Home Use Slicers

Commercial food slicers are designed to withstand the rigors of high-volume use in professional kitchens. These slicers are built with durable materials such as stainless steel and anodized aluminum, ensuring longevity and reliability. They often come with advanced features like adjustable thickness settings, built-in sharpeners, and safety interlocks. For example, the Globe Chefmate C10 10″ manual gravity feed slicer, with its 1/4 hp motor and 10″ blade, is suitable for occasional slicing in commercial settings, offering 15 thickness options from the thinnest slices to 9/16″ cuts.

Home use slicers, in contrast, are typically smaller and less powerful than their commercial counterparts. They are designed for occasional use and are perfect for slicing meats, cheeses, and vegetables for family meals. These slicers are more affordable and easier to store, making them ideal for home kitchens. The Backyard Pro SL109E Butcher Series 9″ manual gravity feed meat slicer, for instance, is perfect for low-volume, light-duty applications, with a 9″ adjustable blade that can cut between 1/16″ to 5/8″ thick slices.

When selecting a slicer for home use, consider factors such as ease of use, storage space, and the types of food to be sliced. For commercial use, prioritize durability, power, and advanced features to ensure the slicer can handle the demands of a busy kitchen. The right choice will depend on the specific requirements and usage frequency.

Tips for Choosing the Right Supplier

Reputation and Reliability

When selecting a supplier for food slicer machines, it is crucial to consider their reputation and reliability. A reputable supplier will have a proven track record of providing high-quality products and excellent customer service. Look for suppliers with positive reviews and testimonials from other businesses in the industry. For instance, WebstaurantStore is known for its extensive range of commercial kitchen equipment and has garnered positive feedback for its reliable products and customer support.

Reliability also extends to the supplier’s ability to deliver products on time and provide consistent quality. A reliable supplier will have a robust supply chain and inventory management system to ensure that orders are fulfilled promptly. This is particularly important for businesses that rely on timely deliveries to maintain their operations. Checking the supplier’s history of on-time deliveries and their response to any issues can provide valuable insights into their reliability.

Additionally, consider the supplier’s experience and expertise in the industry. Suppliers with a long-standing presence in the market are more likely to have a deep understanding of the products and the needs of their customers. This expertise can be beneficial when seeking advice or support for selecting the right food slicer machine for your business.

Warranty and After-Sales Support

Warranty and after-sales support are critical factors to consider when choosing a supplier for food slicer machines. A comprehensive warranty provides peace of mind by covering potential defects and malfunctions that may occur after purchase. It is essential to understand the terms and duration of the warranty offered by the supplier. For example, high-end slicers like the Hobart HS7-1 13″ automatic slicer often come with extended warranties, reflecting the manufacturer’s confidence in the product’s durability and performance.

After-sales support is equally important, as it ensures that you have access to technical assistance and maintenance services when needed. A supplier with a dedicated support team can help troubleshoot issues, provide replacement parts, and offer guidance on proper maintenance and usage. This support can significantly extend the lifespan of your food slicer machine and minimize downtime in your operations.

When evaluating suppliers, inquire about their after-sales support policies and the availability of spare parts. Suppliers that offer comprehensive support services, including training and maintenance programs, can add significant value to your purchase. Ensuring that the supplier has a responsive and knowledgeable support team can make a substantial difference in the overall ownership experience.

Compliance with Safety Standards

Compliance with safety standards is a non-negotiable aspect when selecting a supplier for food slicer machines. Food slicers are powerful tools with sharp blades, and ensuring that they meet industry safety standards is crucial to prevent accidents and injuries. Look for suppliers that provide machines with safety features such as blade guards, no-volt release systems, and gauge plate interlocks. For instance, the Hobart HS9-1 slicer includes an automatic shutoff feature for enhanced safety.

Verify that the supplier’s products comply with relevant safety certifications and regulations, such as those set by the Occupational Safety and Health Administration (OSHA) or the National Sanitation Foundation (NSF). These certifications indicate that the machines have undergone rigorous testing and meet the required safety and hygiene standards. Suppliers that prioritize safety compliance demonstrate their commitment to providing safe and reliable equipment.

Additionally, consider the supplier’s track record in addressing safety concerns and their responsiveness to product recalls or safety updates. A supplier that proactively communicates and resolves safety issues can be trusted to prioritize the well-being of their customers. Ensuring that the food slicer machines meet safety standards not only protects your employees but also helps maintain a safe and compliant kitchen environment.

Final Thoughts on Selecting the Ideal Food Slicer Machine

Choosing the right food slicer machine involves evaluating various factors such as the type of slicer, supplier reputation, warranty, after-sales support, and compliance with safety standards. By carefully considering these aspects, businesses can select a slicer that meets their specific needs and ensures efficient and safe operations. Whether for commercial or home use, the ideal food slicer machine will enhance productivity and deliver consistent, high-quality results.

বাংলা

বাংলা Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português Русский

Русский Español

Español Kiswahili

Kiswahili ไทย

ไทย Türkçe

Türkçe اردو

اردو Tiếng Việt

Tiếng Việt isiXhosa

isiXhosa Zulu

Zulu