في عام 2025، ستزدهر سوق آلات تعبئة الكبسولات، حيث تقدر قيمتها بنحو 1.36 مليار دولار أمريكي. تقدم هذه المقالة تحليلاً شاملاً لأحدث التطورات والعوامل الأساسية التي يجب على المشترين المحترفين مراعاتها عند اختيار آلة تعبئة الكبسولات. ستساعد الأفكار المقدمة في اتخاذ قرارات شراء مستنيرة، وضمان كفاءة الإنتاج المثلى والامتثال التنظيمي.

جدول المحتويات:

– نظرة عامة على سوق آلات تعبئة الكبسولات

- مقدمة وتحليل تفصيلي لسوق آلات تعبئة الكبسولات

- العوامل الرئيسية التي يجب مراعاتها عند اختيار آلة تعبئة الكبسولات

– أحدث ميزات التكنولوجيا في آلات تعبئة الكبسولات

- كفاءة الطاقة والاعتبارات البيئية

- اعتبارات التكلفة والميزانية

- الخلاصة

نظرة عامة على سوق آلات تعبئة الكبسولات

يشهد سوق آلات تعبئة الكبسولات نموًا كبيرًا، مدفوعًا بالطلب المتزايد في الصناعات الدوائية والغذائية. تقدر قيمة السوق العالمية بحوالي 1.36 مليار دولار أمريكي في عام 2025، مع معدل نمو سنوي مركب (CAGR) بنسبة 8.7٪ متوقعًا حتى عام 2035. ويرجع هذا النمو إلى الحاجة المتزايدة إلى حلول تعبئة فعالة ودقيقة، وخاصة للتركيبات المعقدة في المستحضرات الصيدلانية الحيوية.

يتم تقسيم السوق حسب نوع الحاوية الأساسية وحجم التشغيل وإنتاجية النظام والمستخدم النهائي. تعد الكبسولات حاويات أساسية رئيسية، إلى جانب القوارير والمحاقن والأمبولات. يتراوح نطاق التشغيل من السريري إلى التجاري، مع تفاوت إنتاجية النظام من المنخفض إلى المرتفع. يشمل المستخدمون النهائيون الأساسيون شركات الأدوية والتكنولوجيا الحيوية، بالإضافة إلى منظمات التصنيع التعاقدية.

من الناحية الجغرافية، تهيمن أمريكا الشمالية على السوق، تليها أوروبا ومنطقة آسيا والمحيط الهادئ. ويعد الانتشار المتزايد للأمراض المزمنة والطلب اللاحق على الأدوية الفعالة من العوامل الرئيسية الدافعة في هذه المناطق. بالإضافة إلى ذلك، من المتوقع أن تعمل التطورات في تكنولوجيا تعبئة الكبسولات، مثل دمج العوازل وأنظمة الحواجز ذات الوصول المحدود (RABS)، على تعزيز نمو السوق.

مقدمة وتحليل تفصيلي لسوق آلات تعبئة الكبسولات

تعد آلات تعبئة الكبسولات ضرورية في تصنيع الأدوية، حيث تضمن تعبئة الكبسولات بدقة ودون تلوث. وتتضمن معايير الأداء الرئيسية لهذه الآلات الدقة العالية والسرعة والمرونة في التعامل مع أحجام وصيغ مختلفة من الكبسولات. وتعمل الشركات الرائدة باستمرار على الابتكار للحفاظ على ميزة تنافسية، والاستثمار بشكل كبير في البحث والتطوير.

تؤثر التأثيرات الاقتصادية، مثل ارتفاع الإنفاق العالمي على الرعاية الصحية والتركيز المتزايد على الطب الشخصي، على سلوك المستهلك وتدفع الطلب على حلول التعبئة المتقدمة. تتطور تفضيلات قنوات التوزيع، مع ميل متزايد نحو المبيعات المباشرة والمنصات عبر الإنترنت، مما يوفر سهولة الوصول إلى الآلات وقطع الغيار.

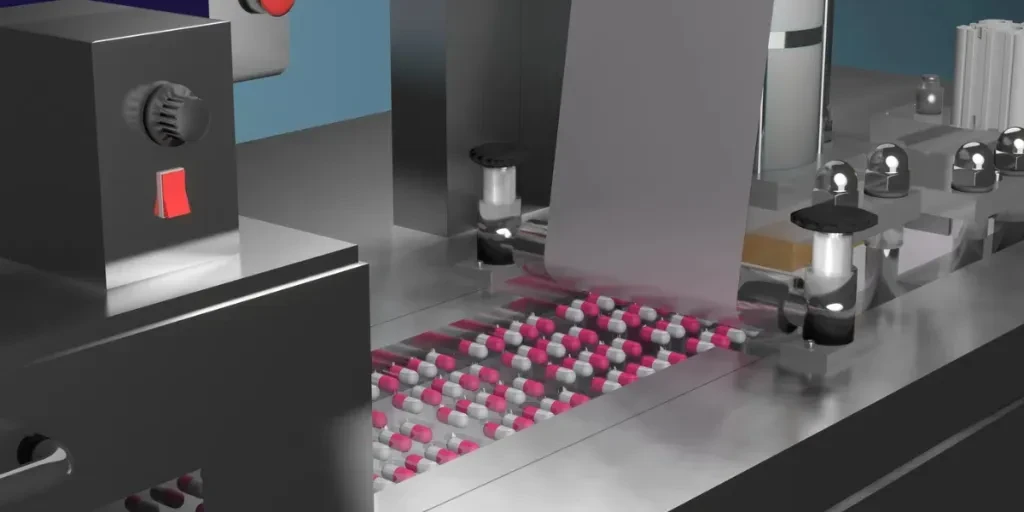

تتضمن الابتكارات الحديثة آلات تعبئة الكبسولات الآلية بالكامل والتي تقلل من التدخل البشري، وتقلل من مخاطر التلوث وتحسن الكفاءة التشغيلية. تتميز هذه الآلات بالمراقبة في الوقت الفعلي والصيانة التنبؤية وقدرات الرقمنة، بما يتماشى مع معايير الصناعة 4.0.

تشمل مراحل دورة حياة المنتج لآلات تعبئة الكبسولات التطوير والتقديم والنمو والنضج والانحدار. حاليًا، يمر السوق بمرحلة النمو، والتي تتميز بالتقدم التكنولوجي السريع والتبني المتزايد بين مختلف المستخدمين النهائيين. يتم التعامل مع مخاوف العملاء، مثل الاستثمارات الأولية المرتفعة وتكاليف الصيانة، من خلال خيارات التمويل المبتكرة والحلول الفعالة من حيث التكلفة.

إن جهود تحديد موقع العلامة التجارية والتمييز بينها تشكل أهمية بالغة بالنسبة للاعبين في السوق للاستحواذ على أسواق متخصصة. وتركز الشركات على تقديم حلول مخصصة مصممة لتلبية متطلبات العملاء المحددة، مما يعزز حضورها في السوق وقدرتها التنافسية. بالإضافة إلى ذلك، يتم تشكيل تعاونات وشراكات استراتيجية لتوسيع نطاق الوصول إلى السوق والاستفادة من الخبرات التكميلية.

العوامل الرئيسية التي يجب مراعاتها عند اختيار آلة تعبئة الكبسولات

يعد اختيار آلة تعبئة الكبسولات المناسبة أمرًا بالغ الأهمية لتحقيق إنتاج فعال ودقيق في الصناعات الدوائية والغذائية وغيرها من الصناعات ذات الصلة. فيما يلي العديد من العوامل الرئيسية التي يجب مراعاتها:

أنواع آلات تعبئة الكبسولة

هناك ثلاثة أنواع رئيسية من آلات تعبئة الكبسولات: يدوية وشبه آلية وأوتوماتيكية. تتطلب الآلات اليدوية تدخلًا كبيرًا من المشغل، مما يجعلها مناسبة للإنتاج على نطاق صغير أو للاستخدام في المختبرات. توفر الآلات شبه الآلية توازنًا بين اليدوي والأوتوماتيكي، مع بعض الوظائف الآلية ولكنها لا تزال تتطلب مشاركة المشغل. الآلات الأوتوماتيكية مؤتمتة بالكامل، مما يوفر قدرات إنتاج عالية السرعة وكبيرة الحجم مع الحد الأدنى من تدخل المشغل.

الأداء والوظيفة

تعتبر مقاييس الأداء مثل سرعة التعبئة والدقة والسعة بالغة الأهمية. يمكن للآلات عالية السرعة تعبئة ما يصل إلى 200,000 كبسولة في الساعة، بينما تضمن الدقة احتواء كل كبسولة على الجرعة الصحيحة. يجب أن تكون الآلات متعددة الاستخدامات أيضًا، وقادرة على التعامل مع أحجام وأنواع مختلفة من الكبسولات، بما في ذلك كبسولات الجيلاتين الصلبة والكبسولات النباتية. يمكن للميزات مثل الجرعات ودبابيس الدك وأنظمة التعبئة بالفراغ أن تعزز الأداء.

بناء الجودة والمواد

تؤثر جودة تصنيع آلة تعبئة الكبسولات بشكل كبير على متانتها وطول عمرها. تُفضَّل الآلات المصنوعة من الفولاذ المقاوم للصدأ عالي الجودة نظرًا لمقاومتها للتآكل وسهولة التنظيف. تضمن المواد عالية الجودة قدرة الآلة على تحمل التشغيل المستمر والحفاظ على الأداء بمرور الوقت. كما يقلل البناء القوي من وقت التوقف عن العمل وتكاليف الصيانة.

معايير وشهادات السلامة

يعد الالتزام بمعايير السلامة والشهادات أمرًا ضروريًا للامتثال للقواعد التنظيمية وضمان سلامة المشغل. يجب أن تتوافق الآلات مع ممارسات التصنيع الجيدة (GMP) وأن تكون معتمدة من قبل السلطات ذات الصلة مثل إدارة الغذاء والدواء أو الاتحاد الأوروبي. تعد ميزات السلامة مثل أزرار التوقف في حالات الطوارئ ووسائل الحماية وأقفال التشابك أمرًا بالغ الأهمية لمنع الحوادث.

سهولة الاستخدام والصيانة

إن التصميمات سهلة الاستخدام التي تبسط التشغيل والصيانة مرغوبة للغاية. إن الميزات مثل واجهات شاشة اللمس، وأدوات التحكم البديهية، وسهولة الوصول للتنظيف والصيانة يمكن أن تقلل بشكل كبير من وقت التوقف عن العمل وتحسن الإنتاجية. إن الآلات التي توفر عمليات تبديل بدون أدوات وتعديلات سهلة لأحجام الكبسولات المختلفة يمكن أن تعزز الكفاءة بشكل أكبر.

أحدث ميزات التكنولوجيا في آلات تعبئة الكبسولات

شهدت صناعة آلات تعبئة الكبسولات العديد من التطورات التكنولوجية التي تهدف إلى تحسين الكفاءة والدقة وسهولة الاستخدام.

التكامل مع أنظمة التحكم

غالبًا ما تتكامل آلات تعبئة الكبسولات الحديثة مع أنظمة التحكم لتوفير المراقبة في الوقت الفعلي وتسجيل البيانات. يسمح هذا التكامل بتحكم أفضل في العملية وإمكانية التتبع والامتثال للمتطلبات التنظيمية. يمكن لأنظمة التحكم المتقدمة أيضًا تسهيل الصيانة التنبؤية، مما يقلل من خطر التوقف غير المتوقع.

الأتمتة والروبوتات

لقد أحدث دمج الأتمتة والروبوتات ثورة في مجال تعبئة الكبسولات. حيث يمكن للأنظمة الآلية التعامل مع مهام مثل فرز الكبسولات وتعبئتها وختمها بدقة وسرعة عالية. كما يمكن للروبوتات تعزيز الكفاءة من خلال أتمتة تحميل وتفريغ الكبسولات، مما يقلل الحاجة إلى التدخل اليدوي ويزيد من الإنتاجية.

اتصال إنترنت الأشياء (IoT).

تتيح إمكانية الاتصال عبر إنترنت الأشياء لآلات تعبئة الكبسولات أن تكون جزءًا من بيئة إنتاج متصلة. يمكن للآلات المجهزة بأجهزة استشعار إنترنت الأشياء توفير بيانات في الوقت الفعلي حول الأداء واحتياجات الصيانة والمشكلات المحتملة. يتيح هذا الاتصال المراقبة والتشخيص عن بُعد، مما يحسن الكفاءة التشغيلية الإجمالية ويقلل من وقت التوقف عن العمل.

كفاءة الطاقة والاعتبارات البيئية

في سوق اليوم الذي يولي اهتمامًا بالبيئة، تعد كفاءة الطاقة والاستدامة من الاعتبارات الحاسمة بالنسبة لآلات تعبئة الكبسولات.

تصاميم موفرة للطاقة

لا تعمل الآلات الموفرة للطاقة على تقليل تكاليف التشغيل فحسب، بل تقلل أيضًا من التأثير البيئي. يمكن للميزات مثل المحركات منخفضة استهلاك الطاقة، وأنظمة معالجة الهواء الفعالة، وضوابط العمليات المحسّنة أن تقلل بشكل كبير من استخدام الطاقة. يركز المصنعون بشكل متزايد على تصميم الآلات التي توفر أداءً عاليًا مع استهلاك أقل للطاقة.

المواد والممارسات المستدامة

يكتسب استخدام المواد والممارسات المستدامة زخمًا متزايدًا في صناعة آلات تعبئة الكبسولات. تساهم الآلات المصنوعة من مواد قابلة لإعادة التدوير والمصممة لعمر خدمة طويل في الاستدامة. بالإضافة إلى ذلك، يتبنى المصنعون ممارسات مثل تقليل النفايات وتحسين استخدام الموارد أثناء الإنتاج.

اعتبارات التكلفة والميزانية

تعتبر تكلفة آلة تعبئة الكبسولات عاملاً مهمًا لأي مشتري.

الاستثمار الأولي مقابل الادخار طويل الأجل

في حين أن الاستثمار الأولي في آلة تعبئة الكبسولات عالية الجودة قد يكون كبيرًا، فمن المهم مراعاة المدخرات طويلة الأجل. يمكن للآلات التي توفر كفاءة عالية وتكاليف صيانة منخفضة ومتانة أن توفر وفورات كبيرة على مدار عمرها الافتراضي. يمكن للميزات التي تقلل من وقت التوقف عن العمل وتحسن الإنتاجية أن تعزز العائد على الاستثمار.

خيارات التمويل والتأجير

بالنسبة للشركات التي تعاني من قيود الميزانية، يمكن أن تجعل خيارات التمويل والتأجير شراء آلة تعبئة الكبسولات أكثر جدوى. تقدم العديد من الشركات المصنعة والموردين خطط دفع مرنة، مما يسمح للشركات بتوزيع التكلفة على مدار الوقت. يمكن أن توفر خيارات التأجير أيضًا إمكانية الوصول إلى أحدث التقنيات دون الحاجة إلى استثمار مقدمي كبير.

وفي الختام

يتضمن اختيار آلة تعبئة الكبسولات المناسبة مراعاة مجموعة من العوامل، بدءًا من نوع الآلة والأداء إلى جودة التصنيع ومعايير السلامة والتكلفة. ومن خلال مراعاة هذه العوامل، يمكن للشركات ضمان اختيار آلة تلبي احتياجات الإنتاج الخاصة بها، وتتوافق مع المتطلبات التنظيمية، وتوفر عائدًا جيدًا على الاستثمار. ومع التقدم التكنولوجي والتركيز على الاستدامة، يبدو مستقبل آلات تعبئة الكبسولات واعدًا، حيث توفر كفاءة محسنة وتأثيرًا بيئيًا أقل.