The laser engraving machine market is rapidly evolving, driven by technological breakthroughs and surging demand across industries like automotive, aerospace, and consumer electronics. Valued at USD 1.92 billion in 2024, the market is expected to grow at a CAGR of 4.37%, reaching USD 2.48 billion by 2030. This article explores leading market players, rising trends, and critical factors to consider when selecting a laser engraving machine, offering professional buyers valuable insights for strategic decisions.

جدول المحتويات:

Understanding the Laser Engraving Machine Market

تحديد احتياجاتك الخاصة

أنواع آلات النقش بالليزر

الميزات الرئيسية التي يجب البحث عنها في آلة النقش بالليزر

اعتبارات الميزانية

Emerging Trends in Laser Engraving Technology

اتخاذ قرار مستنير

Understanding the Laser Engraving Machine Market

المُقدّمة

As of late 2024, the global laser engraving machine market is experiencing significant growth, driven by technological advancements and increasing demand across various industries. The market size was estimated at USD 1.84 billion in 2023 and is projected to reach USD 2.48 billion by 2030, growing at a CAGR of 4.37%. This article delves into the key market players, growth and demand, and technological advancements shaping the laser engraving machine market.

مفتاح لاعبين السوق

The laser engraving machine market is dominated by several key players who are driving innovation and market expansion. Companies such as Epilog Corporation, Gravotech Marking SAS, and Trotec Laser GmbH are at the forefront, offering advanced laser engraving solutions. Epilog Corporation, for instance, has been recognized for its high-quality CO2 and fiber laser systems, which cater to a wide range of applications from metal engraving to wood and plastic marking. Gravotech Marking SAS, another major player, specializes in providing comprehensive engraving solutions, including software and hardware integration, enhancing user experience and efficiency.

In addition to these established companies, new entrants like Hispeed Laser Technology Ltd. and Morn Laser Technology Co. Ltd. are making significant strides. Hispeed Laser Technology Ltd. has introduced innovative fiber laser systems that offer high precision and speed, making them ideal for industrial applications. Morn Laser Technology Co. Ltd. focuses on providing cost-effective solutions without compromising on quality, thereby expanding their market reach, especially in emerging economies.

نمو السوق والطلب

The demand for laser engraving machines is on the rise, driven by their versatility and precision. The market size was estimated at USD 1.92 billion in 2024 and is expected to grow at a CAGR of 4.37% to reach USD 2.48 billion by 2030. This growth is attributed to the increasing adoption of laser engraving technology in various industries such as automotive, aerospace, and electronics. The automotive industry, for example, utilizes laser engraving for marking parts and components, ensuring traceability and compliance with industry standards.

Moreover, the consumer electronics sector is witnessing a surge in demand for laser engraving machines due to the need for precise and intricate designs on devices such as smartphones and laptops. The ability of laser engraving machines to work on a variety of materials, including metals, plastics, and ceramics, further fuels their adoption. Additionally, the rise of e-commerce and personalized products has led to increased demand for laser engraving in the retail sector, where customization and branding are key differentiators.

تقدمات تكنولوجية

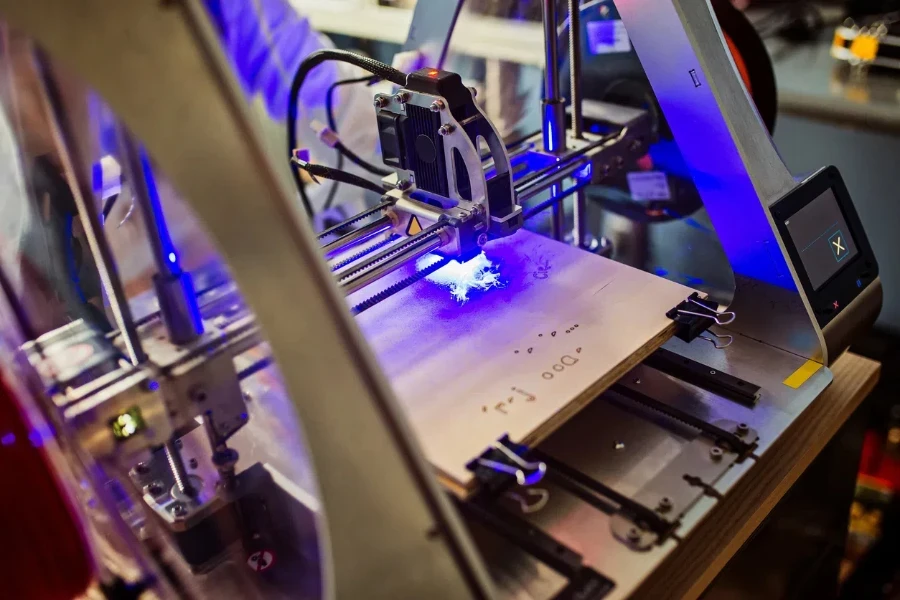

Technological advancements are playing a crucial role in the evolution of the laser engraving machine market. The development of fiber laser technology, for instance, has revolutionized the industry by offering higher efficiency, lower maintenance costs, and the ability to engrave on reflective materials such as aluminum and copper. Fiber lasers are now preferred in applications requiring high precision and speed, such as in the aerospace and electronics industries.

Another significant advancement is the integration of laser engraving machines with computer-aided design (CAD) and computer-aided manufacturing (CAM) software. This integration allows for more complex and precise engravings, enhancing the capabilities of laser systems. Additionally, the adoption of Industry 4.0 technologies, such as IoT and AI, is enabling real-time monitoring and predictive maintenance of laser engraving machines, thereby reducing downtime and increasing productivity.

تحديد احتياجاتك الخاصة

توافق المواد

When selecting a laser engraving machine, it is essential to consider the material compatibility to ensure optimal performance. Different laser types, such as CO2, fiber, and diode lasers, have varying capabilities in terms of the materials they can engrave. CO2 lasers are highly effective for non-metal materials like wood, acrylic, and glass, making them ideal for applications in the signage and arts and crafts industries. Fiber lasers, on the other hand, are better suited for metals and reflective materials, commonly used in the automotive and aerospace sectors.

Understanding the specific material requirements of your projects will help in choosing the right laser engraving machine. For instance, if your primary focus is on engraving metals, a fiber laser system would be more appropriate due to its high precision and efficiency. Conversely, for applications involving organic materials, a CO2 laser would be the preferred choice. Ensuring material compatibility not only enhances the quality of engravings but also extends the lifespan of the laser system.

Project Volume and Size

The volume and size of your projects are critical factors in determining the appropriate laser engraving machine. High-volume production environments, such as manufacturing plants, require robust and high-speed laser systems capable of handling continuous operations. Machines with higher wattage and advanced cooling systems are ideal for such settings, as they can operate for extended periods without overheating or losing efficiency.

For smaller-scale projects or businesses focusing on custom and personalized items, a compact and versatile laser engraving machine would be more suitable. These machines offer flexibility and ease of use, allowing for quick adjustments and changes in design. Additionally, considering the workspace and available area for the machine is important. Compact machines are advantageous for small workshops or retail environments where space is limited.

Precision and Detail Requirements

Precision and detail are paramount in laser engraving, especially for industries requiring intricate designs and fine markings. The resolution and accuracy of the laser system play a significant role in achieving the desired quality. High-resolution laser engravers, capable of producing detailed and sharp engravings, are essential for applications in the jewelry and electronics industries, where even the smallest imperfections can be unacceptable.

Evaluating the precision requirements of your projects will guide you in selecting a laser engraving machine with the appropriate specifications. For instance, if your work involves detailed artwork or fine text, a machine with a high DPI (dots per inch) rating and advanced focusing mechanisms would be necessary. Additionally, features such as autofocus and real-time monitoring can further enhance precision, ensuring consistent and high-quality results.

أنواع آلات النقش بالليزر

ماكينات النقش بالليزر ثاني أكسيد الكربون

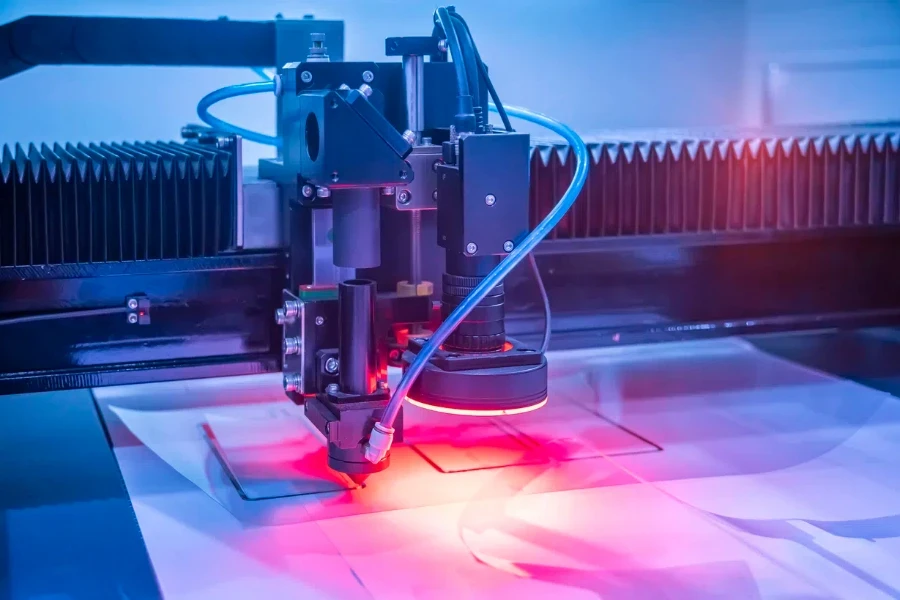

CO2 laser engraving machines are widely used due to their versatility and efficiency in engraving non-metal materials. These machines utilize a gas mixture, primarily carbon dioxide, to produce a laser beam that can cut and engrave materials such as wood, acrylic, glass, and leather. CO2 lasers are known for their high precision and ability to create intricate designs, making them popular in the signage, arts and crafts, and packaging industries.

One of the key advantages of CO2 laser engraving machines is their ability to handle a wide range of materials with varying thicknesses. This flexibility allows businesses to diversify their product offerings and cater to different market segments. Additionally, CO2 lasers are relatively cost-effective compared to other laser types, making them accessible to small and medium-sized enterprises. The maintenance of CO2 lasers is also straightforward, with readily available replacement parts and consumables.

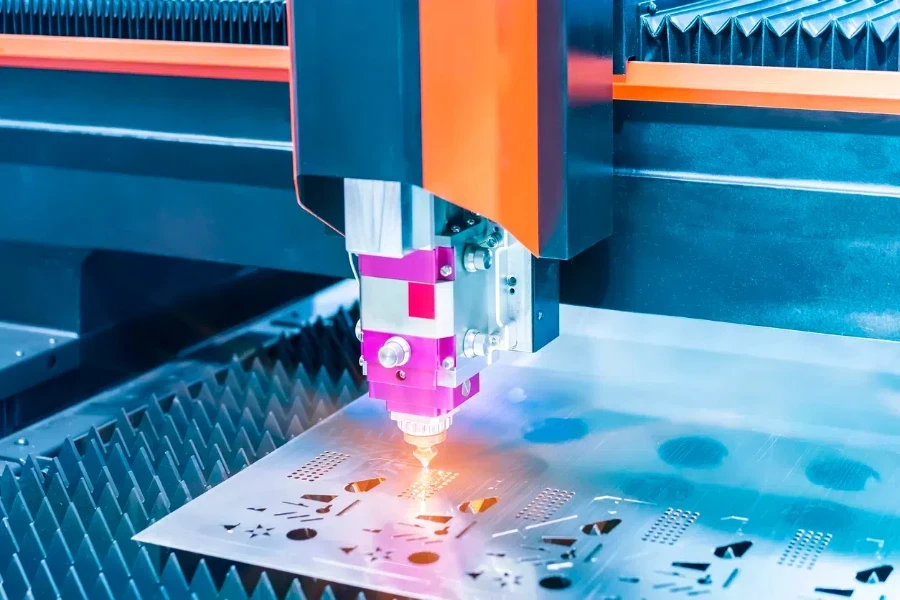

ماكينات النقش بالليزر

Fiber laser engraving machines are renowned for their high efficiency and precision in engraving metals and reflective materials. These machines use a solid-state laser source, which generates a laser beam through optical fibers doped with rare-earth elements. Fiber lasers are capable of producing high-quality engravings on materials such as stainless steel, aluminum, brass, and copper, making them ideal for applications in the automotive, aerospace, and electronics industries.

The advantages of fiber laser engraving machines include their high-speed operation, low maintenance requirements, and long lifespan. Fiber lasers have a higher energy conversion efficiency compared to CO2 lasers, resulting in lower operating costs and reduced energy consumption. Additionally, fiber lasers can achieve finer details and higher resolution engravings, which are essential for industries requiring precision and accuracy. The ability to engrave on reflective materials without compromising quality further enhances the versatility of fiber laser systems.

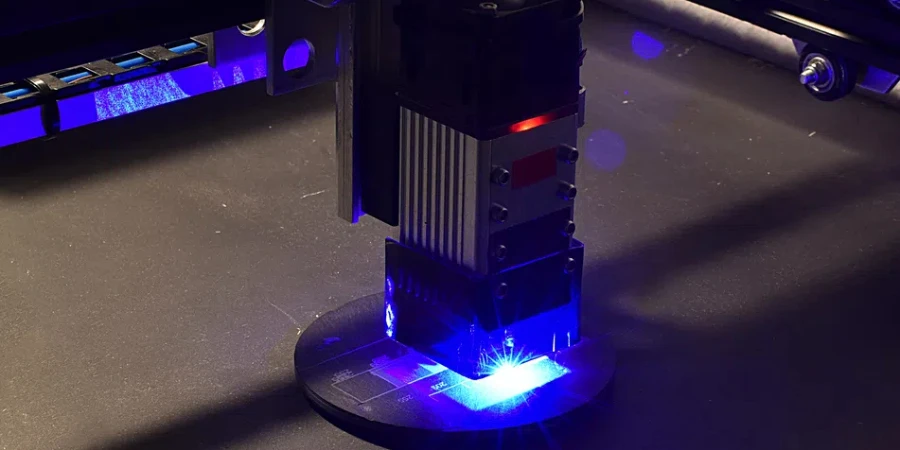

آلات النقش بالليزر الثنائي

Diode laser engraving machines are compact and cost-effective solutions for engraving a variety of materials. These machines use semiconductor diodes to generate a laser beam, which can be used for engraving materials such as wood, plastic, leather, and certain metals. Diode lasers are known for their portability and ease of use, making them suitable for small businesses, hobbyists, and educational institutions.

One of the main benefits of diode laser engraving machines is their affordability, making them accessible to a wide range of users. These machines are also energy-efficient and have a lower power consumption compared to CO2 and fiber lasers. Diode lasers are ideal for applications that do not require high power or deep engraving, such as creating custom gifts, promotional items, and educational projects. The compact size and lightweight design of diode lasers allow for easy transportation and setup, making them a versatile option for various engraving needs.

الميزات الرئيسية التي يجب البحث عنها في آلة النقش بالليزر

القوة والسرعة

When selecting a laser engraving machine, power and speed are critical factors. The power of the laser, measured in watts, determines the machine’s ability to cut through various materials. Higher wattage lasers, such as 100W or more, are suitable for cutting thicker materials like metals and hardwoods. Speed, measured in inches per second (IPS), affects the efficiency and productivity of the engraving process. Machines with higher IPS can complete tasks faster, which is essential for high-volume production environments. Balancing power and speed ensures optimal performance for specific applications.

برنامج التوافق

Software compatibility is another essential feature to consider in a laser engraving machine. The machine should support various design software, such as AutoCAD, CorelDRAW, and Adobe Illustrator. This compatibility allows users to import and edit designs seamlessly. Additionally, the machine’s software should offer user-friendly interfaces and advanced features like vector and raster engraving modes. Integration with popular file formats, such as DXF, SVG, and PDF, ensures flexibility and ease of use. Ensuring software compatibility can significantly enhance the machine’s functionality and user experience.

أنظمة التبريد

Effective cooling systems are vital for maintaining the longevity and performance of laser engraving machines. These systems prevent the laser tube from overheating, which can lead to reduced efficiency and potential damage. Water-cooled systems are commonly used in high-power lasers, providing consistent temperature control. Air-cooled systems, on the other hand, are suitable for lower-power lasers and offer easier maintenance. Choosing a machine with a reliable cooling system ensures stable operation and extends the lifespan of the laser components. Proper cooling is crucial for maintaining optimal engraving quality and machine durability.

ميزات السلامة

Safety features are paramount when operating laser engraving machines. These machines should include protective enclosures to shield users from laser exposure. Interlock systems that automatically shut off the laser when the enclosure is opened are essential for preventing accidents. Additionally, machines should have emergency stop buttons for immediate shutdown in case of emergencies. Proper ventilation systems are also necessary to remove fumes and particulates generated during engraving. Ensuring the machine complies with safety standards, such as CE or FDA certifications, provides peace of mind and a safer working environment.

اعتبارات الميزانية

الاستثمار الأولي

The initial investment for a laser engraving machine can vary significantly based on its features and capabilities. Entry-level machines suitable for hobbyists or small businesses may cost between $2,000 and $5,000. Mid-range machines with higher power and advanced features can range from $10,000 to $20,000. High-end industrial machines, designed for large-scale production, can exceed $50,000. It’s essential to consider the machine’s intended use and required specifications when determining the budget. Investing in a machine that meets current and future needs can provide better value and return on investment.

تكاليف الصيانة

Maintenance costs are an ongoing consideration for laser engraving machines. Regular maintenance includes replacing consumables such as laser tubes, lenses, and mirrors. Laser tubes typically last between 1,000 to 10,000 hours, depending on the type and usage, with replacement costs ranging from $200 to $2,000. Additionally, periodic cleaning and calibration are necessary to maintain optimal performance. Some machines may require professional servicing, adding to the overall maintenance expenses. Budgeting for these costs ensures the machine remains in good working condition and minimizes downtime.

كفاءة إستهلاك الطاقة

Energy efficiency is an important factor that can impact the long-term operating costs of a laser engraving machine. Machines with higher energy efficiency consume less power, reducing electricity bills and environmental impact. Look for machines with energy-saving features such as automatic power-off when idle and efficient cooling systems. Comparing the power consumption of different models can help identify the most cost-effective option. Investing in an energy-efficient machine not only lowers operational costs but also supports sustainable business practices.

Emerging Trends in Laser Engraving Technology

In 2025 and beyond, several emerging trends are expected to shape the laser engraving industry. One significant trend is the integration of artificial intelligence (AI) and machine learning (ML) to enhance precision and automation. AI-powered systems can optimize engraving paths and adjust parameters in real-time, improving efficiency and reducing errors. Another trend is the development of more compact and portable laser engraving machines, making them accessible for small businesses and hobbyists. Additionally, advancements in laser sources, such as fiber lasers, are expected to offer higher power and better beam quality, expanding the range of materials that can be engraved. These trends indicate a move towards more intelligent, versatile, and user-friendly laser engraving solutions.

اتخاذ قرار مستنير

Choosing the right laser engraving machine involves careful consideration of various factors. Assessing the machine’s power, speed, software compatibility, cooling systems, and safety features is crucial. Additionally, understanding the initial investment, maintenance costs, and energy efficiency helps in making a cost-effective choice. Staying informed about emerging trends ensures that the selected machine remains relevant and competitive in the future.