في عام 2025، تشهد سوق ماكينات القطع بالليزر الأكريليكية ازدهارًا كبيرًا، بفضل التطورات في تكنولوجيا الليزر والتطبيقات المتنوعة. تقدم هذه المقالة تحليلًا متعمقًا للسوق، وتسلط الضوء على الاعتبارات الأساسية للمشترين المحترفين. كما تقدم رؤى قيمة حول اختيار الماكينة المناسبة، مع التأكيد على أهمية الدقة والسرعة والكفاءة. تم تصميم هذا الدليل لمساعدة المشترين من رجال الأعمال في اتخاذ قرارات مستنيرة، وضمان تخزينهم وبيع منتجات عالية الجودة.

جدول المحتويات:

– نظرة عامة على سوق ماكينات القطع بالليزر الأكريليكية

- مقدمة وتحليل تفصيلي لسوق آلة قطع الأكريليك بالليزر

– العوامل الرئيسية عند اختيار آلة قطع الأكريليك بالليزر

- التكنولوجيا المتقدمة في ماكينات قطع الأكريليك بالليزر

- كفاءة الطاقة والاعتبارات البيئية

- معايير السلامة والشهادات

- التوافق مع الترقيات المستقبلية

- ملخص

نظرة عامة على سوق قاطع الليزر الأكريليكي

يشهد سوق قواطع الليزر الأكريليكية العالمية نموًا كبيرًا، مدفوعًا بالتقدم في تكنولوجيا الليزر وتوسيع التطبيقات عبر مختلف الصناعات. بحلول عام 2030، من المتوقع أن يصل السوق إلى 10.22 مليار دولار أمريكي، بمعدل نمو سنوي مركب (CAGR) بنسبة 4.94٪ من 7.29 مليار دولار أمريكي في عام 2023. ويرجع هذا النمو إلى حد كبير إلى الطلب المتزايد على الدقة والكفاءة في التصنيع، وخاصة في قطاعات مثل السيارات والإلكترونيات الاستهلاكية والتصنيع الصناعي.

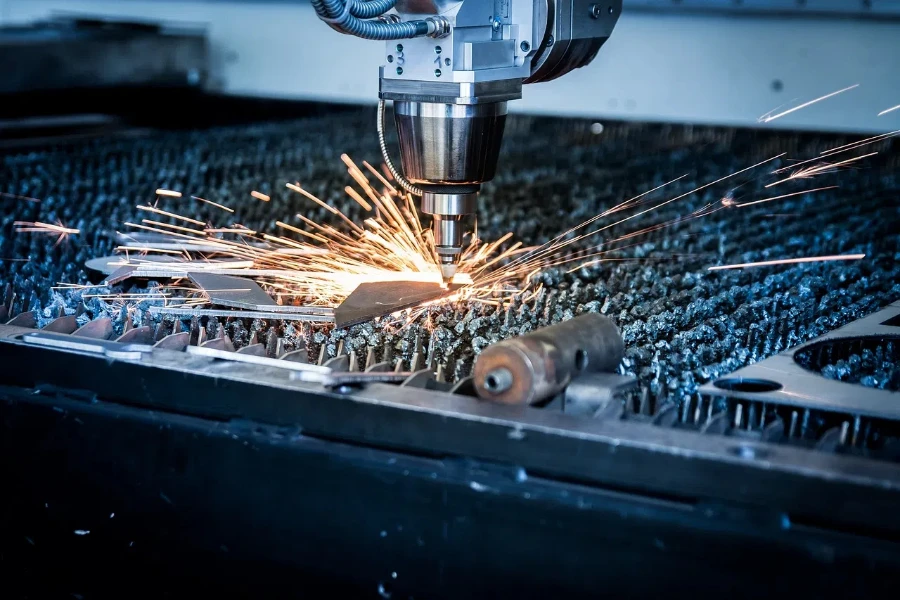

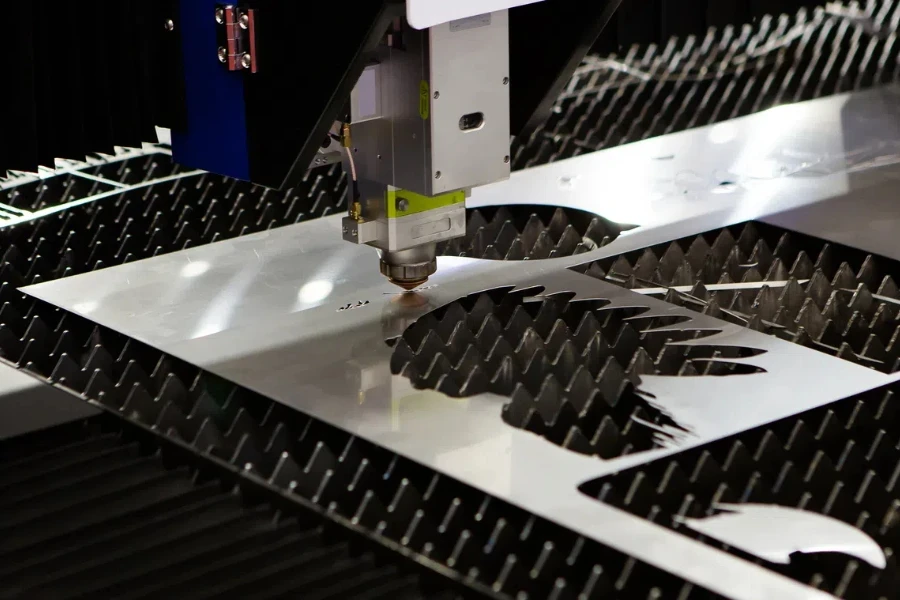

تُستخدم قواطع الليزر الأكريليكية بشكل أساسي لقطع ونقش المواد الأكريليكية، والتي تُستخدم على نطاق واسع في اللافتات وحوامل العرض والعناصر الزخرفية. إن تعدد استخدامات هذه الآلات، إلى جانب قدرتها على إنتاج تصميمات معقدة وعالية الجودة، يجعلها لا غنى عنها في التصنيع الحديث. يتم تقسيم السوق حسب التكنولوجيا، بما في ذلك الليزر الغازي والليزر أشباه الموصلات والليزر ذي الحالة الصلبة، مع اكتساب الليزر الليفي قوة جذب كبيرة بسبب كفاءته وانخفاض تكاليف التشغيل.

تهيمن منطقة آسيا والمحيط الهادئ على سوق قطع الليزر الأكريليكي، مدفوعة بالتصنيع السريع والتحضر والتقدم التكنولوجي في دول مثل الصين واليابان وكوريا الجنوبية. ومن المتوقع أن تحافظ المنطقة على مكانتها الرائدة، مع الاستثمارات الكبيرة في البنية التحتية للتصنيع والتركيز المتزايد على الأتمتة والهندسة الدقيقة. كما تمتلك أمريكا الشمالية وأوروبا حصصًا سوقية كبيرة، حيث تعد الولايات المتحدة وألمانيا مساهمين رئيسيين بسبب قطاعات التصنيع القوية وتبني التقنيات المتقدمة.

مقدمة وتحليل تفصيلي لسوق آلة قطع الأكريليك بالليزر

تتمتع ماكينات قطع الأكريليك بالليزر بتقدير كبير لدقتها وسرعتها وقدرتها على التعامل مع التصميمات المعقدة، مما يجعلها ضرورية في العديد من الصناعات. تشمل معايير الأداء الرئيسية لهذه الآلات سرعة القطع والدقة والقدرة على القطع عبر سماكات مختلفة من مواد الأكريليك. يتحول السوق نحو مصادر ليزر أكثر كفاءة وفعالية من حيث التكلفة، مثل ليزر الألياف، الذي يوفر سرعات قطع أعلى ومتطلبات صيانة أقل مقارنة بالليزر التقليدي ثاني أكسيد الكربون.

تتأثر ديناميكيات حصة السوق بالمشهد التنافسي، حيث تتصدر السوق شركات كبرى مثل TRUMPF SE + Co. KG وHan's Laser Technology Industry Group Co., Ltd. وEpilog Laser. تعمل هذه الشركات باستمرار على الابتكار لتعزيز عروض منتجاتها والحفاظ على ميزة تنافسية. أدت التطورات في تكنولوجيا الليزر إلى ظهور آلات تحقق دقة أعلى وسرعات قطع أسرع، مما يلبي الطلب المتزايد على منتجات الأكريليك عالية الجودة.

تلعب التأثيرات الاقتصادية، مثل التقلبات في أسعار المواد الخام والتغيرات في تكاليف التصنيع، دورًا حاسمًا في تشكيل السوق. بالإضافة إلى ذلك، فإن تحولات سلوك المستهلك، وخاصة الطلب المتزايد على المنتجات المخصصة والجذابة جماليًا، تدفع إلى تبني قواطع الليزر الأكريليكية. لقد تطورت قنوات التوزيع، حيث اكتسبت المنصات عبر الإنترنت مكانة بارزة كقنوات مبيعات رئيسية، مما يوفر سهولة الوصول إلى مجموعة أوسع من المنتجات وتمكين الشركات المصنعة من الوصول إلى قاعدة عملاء عالمية.

وتشمل الابتكارات الحديثة دمج الرقمنة والأتمتة، مما يعزز كفاءة التصنيع ومرونته. ويتيح دمج برامج التصميم بمساعدة الكمبيوتر والتصنيع بمساعدة الكمبيوتر إجراء عمليات قطع أكثر تعقيدًا ودقة، مما يدعم الاتجاه نحو الصناعة 4.0. كما تؤثر الاتجاهات الاجتماعية، مثل التركيز المتزايد على الاستدامة، على السوق، حيث يطور المصنعون آلات صديقة للبيئة تستهلك طاقة أقل وتنتج الحد الأدنى من النفايات.

تتم معالجة نقاط الألم لدى العملاء، مثل التكاليف الأولية المرتفعة ومتطلبات الصيانة، من خلال التقدم في التكنولوجيا وإدخال آلات أكثر بأسعار معقولة وسهلة الاستخدام. تركز استراتيجيات تحديد موقع العلامة التجارية على تسليط الضوء على موثوقية ودقة وتنوع قواطع الليزر الأكريليكية، في حين تؤكد استراتيجيات التمايز على الميزات الفريدة مثل سرعات القطع المحسنة وتحسين تكامل البرامج وانخفاض تكاليف التشغيل. توفر الأسواق المتخصصة، مثل إنتاج العناصر الزخرفية الراقية واللافتات المخصصة، فرص نمو كبيرة للمصنعين.

العوامل الرئيسية عند اختيار آلة قطع الأكريليك بالليزر

عند اختيار آلة قطع الأكريليك بالليزر، من الضروري مراعاة عوامل مختلفة لضمان تلبية الآلة لاحتياجاتك المحددة. تتضمن هذه العوامل نوع الليزر والقوة وسرعة القطع والدقة والميزات الإضافية. يلعب كل من هذه الجوانب دورًا حاسمًا في أداء آلة القطع بالليزر وملاءمتها لتطبيقات مختلفة.

نوع الليزر

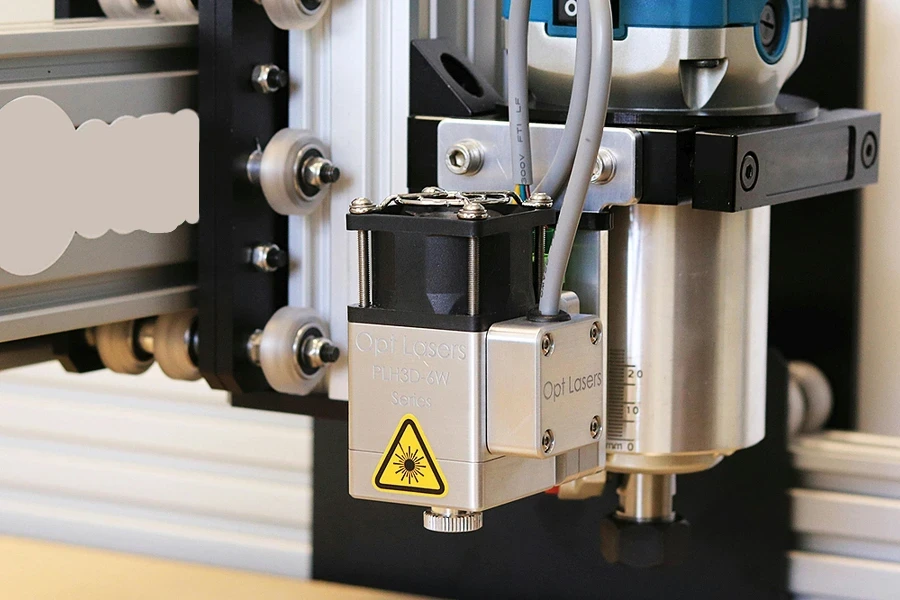

يؤثر نوع الليزر المستخدم في آلة قطع الأكريليك بالليزر بشكل كبير على أدائها ونطاق تطبيقها. أكثر أنواع الليزر شيوعًا المستخدمة في هذه الآلات هي ليزر ثاني أكسيد الكربون وليزر الألياف.

تُستخدم ليزرات ثاني أكسيد الكربون على نطاق واسع نظرًا لكفاءتها في قطع ونقش المواد الأكريليكية. تعمل عند طول موجي يبلغ حوالي 2 ميكرومتر، مما يجعلها فعالة للغاية للمواد غير المعدنية. تشتهر ليزرات ثاني أكسيد الكربون بقوتها المستمرة وقدرتها على إنتاج قطع عالية الجودة بحواف ناعمة.

من ناحية أخرى، تُستخدم ليزرات الألياف بشكل أقل شيوعًا لقطع الأكريليك ولكنها توفر مزايا من حيث كفاءة الطاقة وعمر أطول. تعمل ليزرات الألياف بطول موجي يبلغ حوالي 1.064 ميكرومتر، وهو أكثر ملاءمة لقطع المعادن. ومع ذلك، بالنسبة للتطبيقات المحددة التي تتطلب دقة عالية، مثل النقش التفصيلي، يمكن أن تكون ليزرات الألياف خيارًا.

الطاقة

تُعد قوة الليزر عاملاً حاسمًا في تحديد سرعة القطع وقدرات السُمك لقاطع الليزر للأكريليك. تُقاس قوة الليزر بالواط (W)، وتتراوح مستويات الطاقة النموذجية لقطع الأكريليك من 40 وات إلى 150 وات أو أكثر، حسب التطبيق.

عند قطع ألواح الأكريليك السميكة، يلزم وجود مستويات طاقة أعلى لضمان قطع نظيفة وفعالة. على سبيل المثال، يمكن لليزر ثاني أكسيد الكربون بقوة 100 وات قطع الأكريليك بسمك 2 مم بسهولة، بينما قد يواجه الليزر بقوة 10 وات صعوبة في التعامل مع مثل هذا السُمك. كما تترجم الطاقة الأعلى إلى سرعات قطع أسرع، مما قد يحسن الإنتاجية في البيئات الصناعية.

ومع ذلك، فإن مستويات الطاقة الأعلى تعني أيضًا زيادة استهلاك الطاقة ومخاوف السلامة المحتملة. ومن المهم موازنة متطلبات الطاقة مع التطبيق المقصود لتجنب التكاليف والمخاطر غير الضرورية.

سرعة القطع

تُعد سرعة القطع عاملاً بالغ الأهمية، وخاصةً في بيئات الإنتاج ذات الحجم الكبير. تتأثر سرعة قطع آلة قطع الأكريليك بالليزر بقوة الليزر ونوع مادة الأكريليك وسمك المادة.

توفر قواطع الليزر الأكريليك ذات مستويات الطاقة الأعلى عمومًا سرعات قطع أسرع، مما قد يقلل بشكل كبير من وقت الإنتاج. على سبيل المثال، يمكن لقاطعة الليزر ثاني أكسيد الكربون بقوة 100 وات تحقيق سرعات قطع تصل إلى 2 مم/ثانية للأكريليك بسمك 300 مم، بينما قد يصل الليزر بقوة 3 وات إلى 50 مم/ثانية فقط لنفس السُمك.

من المهم أيضًا مراعاة جودة القطع عند سرعات مختلفة. قد تؤدي السرعات العالية في بعض الأحيان إلى تقليل الدقة وظهور حواف أكثر خشونة، لذا فإن إيجاد التوازن الأمثل بين السرعة والجودة أمر ضروري.

الانضباط و الدقة

الدقة والإتقان من الأمور الأساسية عندما يتعلق الأمر بالقطع بالليزر، وخاصة للتطبيقات التي تتطلب تصميمات معقدة ونقوشًا تفصيلية. تتأثر دقة آلة قطع الأكريليك بالليزر بجودة شعاع الليزر والمكونات الميكانيكية للآلة وبرنامج التحكم.

تستطيع أشعة الليزر ثاني أكسيد الكربون عالية الجودة ذات قطر الشعاع الدقيق تحقيق قطع دقيقة بتفاوتات منخفضة تصل إلى 2 مم. كما تلعب المكونات الميكانيكية، مثل نظام الحركة ورأس القطع، دورًا مهمًا في الحفاظ على الدقة. يمكن للآلات ذات أنظمة التحكم في الحركة المتقدمة والبنية الصلبة تقديم نتائج متسقة وقابلة للتكرار.

علاوة على ذلك، يمكن لبرنامج التحكم المستخدم في آلة القطع بالليزر أن يعزز الدقة من خلال السماح بإجراء تعديلات دقيقة وتوفير ميزات مثل التركيز التلقائي والمراقبة في الوقت الفعلي. إن الاستثمار في آلة ذات قدرات برمجية متقدمة يمكن أن يحسن بشكل كبير من الدقة الشاملة وجودة القطع.

ميزات إضافية

عند اختيار قاطع ليزر الأكريليك، يمكن للميزات الإضافية تعزيز تنوع الماكينة وسهولة استخدامها. تتضمن بعض الميزات الرئيسية التي يجب البحث عنها التركيز التلقائي، والملحقات الدوارة، ومساعدة الهواء، وميزات السلامة. يضبط التركيز التلقائي تركيز شعاع الليزر تلقائيًا بناءً على سمك المادة، مما يضمن أداء القطع الأمثل. يمكن أن تكون الملحقات الدوارة مفيدة لقطع ونقش الأشياء الأسطوانية. تنفث مساعدة الهواء تيارًا من الهواء على سطح القطع لإزالة الحطام ومنع ارتفاع درجة الحرارة، مما يؤدي إلى قطع أنظف. تعد ميزات السلامة مثل أزرار التوقف في حالات الطوارئ، والأغطية الواقية، وأقفال الليزر ضرورية لضمان التشغيل الآمن.

إن مراعاة هذه الميزات الإضافية يمكن أن يساعدك في اختيار قاطع الليزر الأكريليكي الذي لا يلبي متطلبات القطع الخاصة بك فحسب، بل يعزز أيضًا الإنتاجية والسلامة.

التكنولوجيا المتقدمة في قواطع الليزر للأكريليك

شهدت صناعة قطع الأكريليك بالليزر تقدمًا كبيرًا في التكنولوجيا، مما أدى إلى تحسين الأداء والكفاءة والتنوع. تشمل هذه التطورات الابتكارات في مصادر الليزر وأنظمة التحكم في الحركة وواجهات المستخدم.

الابتكارات في مصادر الليزر

يعد تطوير مصادر الليزر عالية الطاقة والكفاءة أحد أبرز التطورات في ماكينات قطع الأكريليك بالليزر. أصبحت أجهزة الليزر الحديثة التي تعمل بغاز ثاني أكسيد الكربون أكثر كفاءة، حيث توفر طاقة أعلى مع استهلاك أقل للطاقة. لا يعمل هذا التحسن على تحسين أداء القطع فحسب، بل يقلل أيضًا من تكاليف التشغيل.

بالإضافة إلى ذلك، فإن التطورات في تكنولوجيا الليزر الليفي جعلت من الممكن استخدام هذه الليزرات لتطبيقات قطع الأكريليك المحددة. توفر الليزرات الليفية فوائد مثل عمر افتراضي أطول ومتطلبات صيانة أقل وكفاءة طاقة أعلى مقارنة بالليزر ثاني أكسيد الكربون التقليدي. يمكن لهذه الليزرات توفير قطع ونقوش دقيقة، مما يجعلها مناسبة للأعمال التفصيلية.

أنظمة التحكم في الحركة المحسّنة

شهدت أنظمة التحكم في الحركة في قواطع الليزر الأكريليكية أيضًا تحسينات كبيرة. تتضمن الأنظمة المتقدمة الآن أدلة خطية عالية الدقة ومحركات مؤازرة وآليات تحكم ذات حلقة مغلقة. تعمل هذه المكونات معًا لتوفير حركة سلسة ودقيقة، مما يؤدي إلى قطع ونقوش دقيقة.

لقد أدى دمج أنظمة الرافعات والأذرع الآلية إلى تعزيز تنوع قواطع الليزر الأكريليكية. تسمح هذه الأنظمة بالحركة متعددة المحاور، مما يتيح أنماط قطع معقدة ونقوش ثلاثية الأبعاد. بفضل القدرة على التعامل مع التصميمات المعقدة، يمكن لقواطع الليزر الأكريليكية الحديثة تلبية متطلبات الصناعات المختلفة، بما في ذلك اللافتات والإعلان والتصنيع.

واجهات وبرامج سهلة الاستخدام

أصبحت واجهة المستخدم وبرامج قواطع الليزر الأكريليكية أكثر سهولة في الاستخدام وغنية بالميزات. تأتي الآلات الحديثة مزودة بواجهات تعمل باللمس، مما يسمح بسهولة التنقل والتحكم. توفر البرامج المستخدمة في هذه الآلات ميزات متقدمة مثل المراقبة في الوقت الفعلي والتركيز التلقائي ومكتبات المواد.

توفر مكتبات المواد معلمات محددة مسبقًا لأنواع مختلفة من الأكريليك، مما يضمن أداء قطع مثاليًا دون الحاجة إلى تعديلات يدوية. تتيح المراقبة في الوقت الفعلي للمشغلين تتبع عملية القطع وإجراء التعديلات اللازمة أثناء التشغيل، مما يحسن الكفاءة ويقلل الأخطاء.

علاوة على ذلك، تتيح حلول البرامج المستندة إلى السحابة التشغيل عن بُعد ومراقبة قواطع الليزر الأكريليكية. هذه القدرة مفيدة بشكل خاص لمرافق الإنتاج واسعة النطاق، حيث يمكن إدارة العديد من الآلات ومراقبتها من موقع مركزي.

كفاءة الطاقة والاعتبارات البيئية

تُعد كفاءة الطاقة والتأثير البيئي من العوامل المهمة بشكل متزايد عند اختيار آلة قطع الأكريليك بالليزر. تم تصميم الآلات الحديثة لتقليل استهلاك الطاقة وتقليل النفايات، مما يساهم في عملية تصنيع أكثر استدامة.

كفاءة إستهلاك الطاقة

لقد أدى التقدم في تكنولوجيا الليزر إلى تطوير مصادر ليزر أكثر كفاءة في استخدام الطاقة. توفر الآن ليزر ثاني أكسيد الكربون عالي الطاقة كفاءة أفضل في استخدام الطاقة، مما يقلل من إجمالي استهلاك الطاقة للجهاز. يمكن أن تعمل ليزرات الألياف، المعروفة بكفاءتها العالية في استخدام الطاقة، على تقليل تكاليف التشغيل بشكل أكبر.

بالإضافة إلى مصادر الليزر الفعّالة، تشتمل قواطع الليزر الأكريليكية الحديثة على ميزات توفير الطاقة مثل أوضاع الاستعداد التلقائية وأنظمة إدارة الطاقة. تساعد هذه الميزات في تقليل استهلاك الطاقة أثناء فترات الخمول، مما يساهم في خفض فواتير الكهرباء وتقليل البصمة الكربونية.

الحد من النفايات

يعد تقليل النفايات جانبًا مهمًا آخر من جوانب التصنيع المستدام. تم تصميم قواطع الليزر الأكريليكية لتحقيق أقصى استفادة من المواد وتقليل النفايات. تعمل برامج التعشيش المتقدمة على تحسين ترتيب أنماط القطع، مما يقلل من هدر المواد ويضمن الاستخدام الفعال لألواح الأكريليك.

علاوة على ذلك، تساعد أنظمة مساعدة الهواء في ماكينات القطع بالليزر الحديثة على إزالة الحطام ومنع تراكم المواد، مما يؤدي إلى قطع أنظف وتقليل النفايات. كما تعمل هذه الأنظمة على تحسين الجودة الإجمالية للقطع، مما يقلل من الحاجة إلى إعادة العمل ويقلل من النفايات بشكل أكبر.

تأثير بيئي

إن التأثير البيئي لآلات قطع الأكريليك بالليزر يتجاوز استهلاك الطاقة والحد من النفايات. إن استخدام المواد والمكونات الصديقة للبيئة في تصنيع الآلات يلعب أيضًا دورًا في الاستدامة. يستخدم المصنعون بشكل متزايد المواد القابلة لإعادة التدوير ويتبنون ممارسات التصنيع الصديقة للبيئة.

بالإضافة إلى ذلك، تم تجهيز بعض ماكينات القطع بالليزر الأكريليكي بأنظمة استخلاص الدخان التي تلتقط وتصفي الانبعاثات الضارة الناتجة أثناء عملية القطع. تساعد هذه الأنظمة في الحفاظ على بيئة عمل آمنة والحد من إطلاق الملوثات في الغلاف الجوي.

معايير وشهادات السلامة

السلامة لها أهمية قصوى عند تشغيل ماكينات قطع الأكريليك بالليزر. الالتزام بمعايير السلامة والحصول على الشهادات ذات الصلة يضمن التشغيل الآمن للماكينات والامتثال للمتطلبات التنظيمية.

معايير السلامة

يجب أن تتوافق قواطع الليزر الأكريليكية مع معايير السلامة المختلفة لضمان التشغيل الآمن. في الولايات المتحدة، تنظم إدارة السلامة والصحة المهنية (OSHA) معايير السلامة لمعدات الليزر. كما تحكم سلسلة ANSI Z136 معايير سلامة الليزر لتطبيقات مختلفة، بما في ذلك الصناعية والطبية والبحثية.

يتضمن الامتثال لهذه المعايير تنفيذ ميزات السلامة مثل أزرار التوقف في حالات الطوارئ، والأغطية الواقية، وأقفال الليزر. تساعد هذه الميزات في منع الحوادث وحماية المشغلين من المخاطر المحتملة المرتبطة بالقطع بالليزر.

الشهادات

إن الحصول على شهادات من منظمات معترف بها يثبت التزام الشركة المصنعة بالسلامة والجودة. تشمل الشهادات الشائعة لآلات قطع الأكريليك بالليزر علامة CE (Conformité Européenne)، والتي تشير إلى الامتثال لمعايير السلامة والصحة وحماية البيئة الأوروبية.

وتشهد شهادات أخرى، مثل ISO 9001 وISO 14001، على التزام الشركة المصنعة بأنظمة إدارة الجودة وإدارة البيئة على التوالي. وتوفر هذه الشهادات ضمانًا بأن قاطعة الليزر الأكريليكية تلبي معايير السلامة والجودة الصارمة.

إجراءات التدريب والسلامة

بالإضافة إلى الامتثال لمعايير السلامة والشهادات، فإن التدريب المناسب وإجراءات السلامة ضرورية للتشغيل الآمن. يجب أن يتلقى المشغلون تدريبًا شاملاً على استخدام قواطع الليزر الأكريليكية، بما في ذلك بروتوكولات السلامة وتشغيل الماكينة وإجراءات الصيانة.

إن تنفيذ إجراءات السلامة، مثل عمليات التفتيش والصيانة المنتظمة، يمكن أن يساعد في تحديد المشكلات المحتملة ومنع الحوادث. كما أن تزويد المشغلين بمعدات الحماية الشخصية، مثل نظارات وقفازات السلامة الخاصة بالليزر، يعزز السلامة أثناء التشغيل.

التوافق مع الترقيات المستقبلية

يضمن الاستثمار في آلة قطع الأكريليك بالليزر المتوافقة مع الترقيات المستقبلية إمكانية الاستخدام على المدى الطويل والتكيف مع التكنولوجيا المتطورة. يمكن أن يؤدي التوافق مع الترقيات إلى إطالة عمر الآلة وتحسين أدائها بمرور الوقت.

تصميم وحدات

تتيح ماكينات القطع بالليزر الأكريليكية ذات التصميم المعياري إمكانية الترقيات والتخصيص بسهولة. يمكن استبدال المكونات المعيارية، مثل مصادر الليزر وأنظمة الحركة وبرامج التحكم، أو ترقيتها دون الحاجة إلى شراء آلة جديدة. تتيح هذه المرونة للشركات التكيف مع المتطلبات المتغيرة ودمج أحدث التقنيات.

ترقيات البرمجيات

تلعب ترقيات البرامج دورًا حاسمًا في الحفاظ على أداء ووظائف قواطع الليزر الأكريليكية. غالبًا ما يصدر المصنعون تحديثات للبرامج تتضمن ميزات جديدة وخوارزميات محسّنة وإصلاحات للأخطاء. إن التأكد من تحديث برنامج التحكم في قاطع الليزر بانتظام يمكن أن يعزز قدراته ويطيل عمره الافتراضي.

التكامل مع الأنظمة الأخرى

التوافق مع الأجهزة والأنظمة الأخرى هو اعتبار مهم آخر. توفر قواطع الليزر الأكريليكية التي يمكن دمجها مع برامج التصميم بمساعدة الكمبيوتر (CAD) وأنظمة تخطيط موارد المؤسسة (ERP) ومعدات التصنيع الأخرى تنوعًا وكفاءة أكبر. يعمل هذا التكامل على تبسيط عملية الإنتاج وتمكين الاتصال السلس بين الأنظمة المختلفة.

إثبات المستقبل

تتضمن عملية تأمين قاطعة الأكريليك بالليزر للمستقبل اختيار آلة يمكنها استيعاب التطورات التكنولوجية المتوقعة. على سبيل المثال، اختيار قاطعة ليزر ذات قوة ودقة كافيتين للتطبيقات المستقبلية المحتملة يمكن أن يمنع الحاجة إلى ترقيات أو استبدالات باهظة الثمن.

بالإضافة إلى ذلك، فإن النظر في الاتجاهات والتقنيات الناشئة، مثل الأتمتة والذكاء الاصطناعي، يمكن أن يساعد في تأمين الاستثمار في المستقبل. يمكن للآلات المجهزة بخصائص الأتمتة، مثل الأذرع الآلية وأنظمة النقل، أن تعزز الإنتاجية وتقلل من تكاليف العمالة.

الملخص

يتضمن اختيار قاطع الليزر الأكريليكي المناسب مراعاة عوامل مختلفة مثل نوع الليزر والقوة وسرعة القطع والدقة والميزات الإضافية. أدت التطورات في التكنولوجيا إلى تطوير آلات أكثر كفاءة وتنوعًا، مما يوفر أداءً محسنًا واستدامة. يضمن الالتزام بمعايير السلامة والحصول على الشهادات ذات الصلة التشغيل الآمن والامتثال للوائح. يعمل التوافق مع الترقيات المستقبلية على إطالة عمر الآلة ويسمح بالتكيف مع التكنولوجيا المتطورة. من خلال تقييم هذه العوامل بعناية، يمكن للشركات اتخاذ قرارات مستنيرة والاستثمار في قواطع الليزر الأكريليكية التي تلبي احتياجاتها ومتطلباتها المحددة.