Bandsaws are a cornerstone in the world of machinery, offering unparalleled precision and efficiency in cutting various materials. This comprehensive guide delves into the essential aspects that make bandsaws a critical tool for professionals and hobbyists alike. From understanding their operational mechanics to exploring the latest technological advancements, this article aims to equip you with the knowledge to leverage bandsaws for your projects effectively.

Table of Contents:

– What makes bandsaws unique in machinery

– The anatomy of a bandsaw: Understanding its components

– The technological advancements in bandsaw design

– Selecting the right bandsaw for your needs

– Maintenance tips for prolonging the life of your bandsaw

What makes bandsaws unique in machinery

Bandsaws stand out in the machinery world for their ability to make precise cuts with minimal waste. Unlike other cutting tools, bandsaws use a thin, continuous loop of metal with teeth along one edge to slice through materials. This unique cutting action allows for intricate cuts, including curves and angles that would be challenging or impossible with other tools. The efficiency of a bandsaw is evident in its ability to cut faster while preserving material, making it a go-to choice for projects requiring precision and economy.

The versatility of bandsaws extends beyond just cutting shapes. They are capable of handling a wide range of materials, from wood and metal to plastics and composites. This adaptability is due to the variable speed settings and blade types available, allowing users to customize the saw’s performance to the task at hand. Whether it’s a fine, detailed cut in a delicate material or a straight cut through thick metal, bandsaws offer the flexibility to achieve the desired outcome.

Moreover, bandsaws are celebrated for their safety features. The design of the bandsaw minimizes the risk of kickback, a common hazard with other cutting tools. This safety aspect, combined with the precision and versatility of bandsaws, underscores their unique position in the machinery landscape, catering to both seasoned professionals and beginners.

The anatomy of a bandsaw: Understanding its components

At the heart of a bandsaw’s functionality are its components, each playing a crucial role in its operation. The blade, the soul of the bandsaw, comes in various widths, tooth designs, and materials, tailored to cut specific materials and shapes. Understanding the blade’s characteristics is key to maximizing the bandsaw’s capabilities and achieving clean, precise cuts.

The motor, another vital component, powers the bandsaw. Motors vary in horsepower, directly impacting the saw’s ability to cut through thicker or more resistant materials. A robust motor ensures smooth, uninterrupted operation, even under demanding conditions, highlighting the importance of selecting a bandsaw with the right motor for your needs.

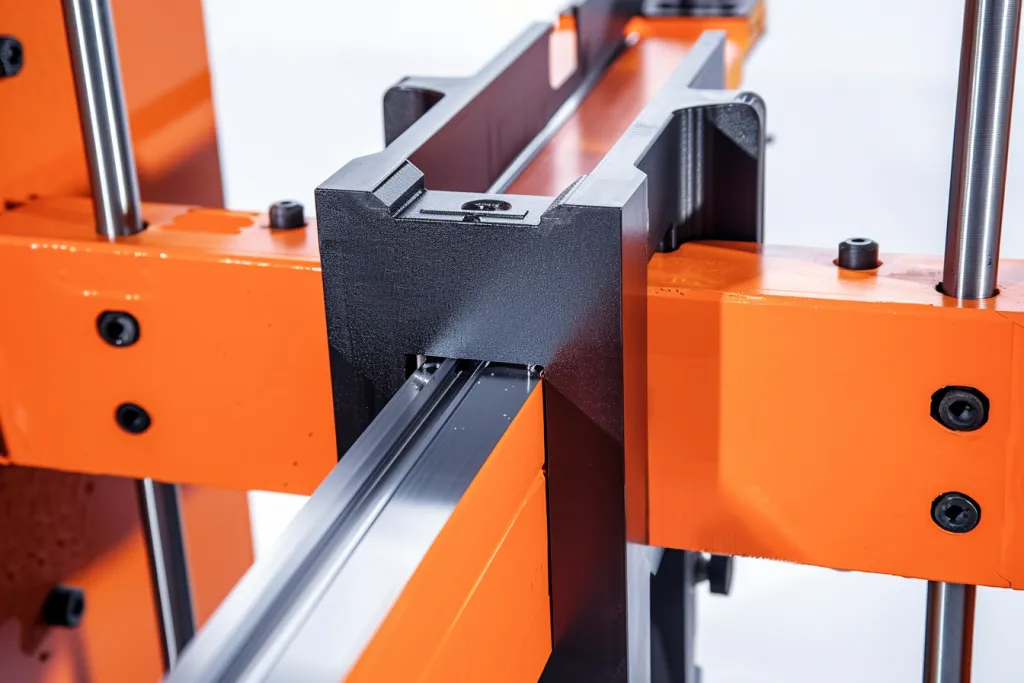

The bandsaw’s frame and table constitute its structural foundation, providing stability and support during cutting tasks. The frame’s design influences the bandsaw’s throat capacity — the distance from the blade to the frame — which determines the maximum width of material the saw can accommodate. An adjustable table enhances the bandsaw’s versatility, allowing for angled cuts and facilitating complex projects.

The technological advancements in bandsaw design

Technological advancements have significantly impacted bandsaw design, enhancing their performance and user experience. Modern bandsaws feature increased energy efficiency, reducing operational costs and environmental impact. Innovations in blade materials and tooth geometry have also improved cutting speed and longevity, allowing for smoother cuts and reduced blade replacements.

Digital controls and automation are transforming bandsaw operation, making precise cuts easier to achieve. Programmable settings for speed, pressure, and feed rate enable users to optimize the cutting process for different materials, improving efficiency and outcomes. These advancements not only enhance the bandsaw’s capabilities but also make them more accessible to users with varying levels of experience.

Moreover, the integration of safety features, such as blade guards and emergency stop functions, has made bandsaws safer to use. These features minimize the risk of accidents, ensuring a safer working environment. The evolution of bandsaw design demonstrates a commitment to meeting the needs of modern users, combining performance, efficiency, and safety.

Selecting the right bandsaw for your needs

Choosing the right bandsaw involves considering several factors to ensure it meets your specific requirements. The material you plan to cut most frequently is a primary consideration, as it determines the blade type and motor power needed. For heavy-duty cutting, a bandsaw with a high horsepower motor and a durable blade is essential.

The size of the bandsaw is another critical factor. The machine’s throat capacity should accommodate the maximum width of the material you intend to cut. Additionally, consider the bandsaw’s footprint and whether you have sufficient space in your workshop.

Finally, evaluate the bandsaw’s features and ease of use. Look for models with adjustable tables, variable speed settings, and easy blade change mechanisms. These features enhance the bandsaw’s versatility and make it more user-friendly, allowing you to tackle a wide range of projects with confidence.

Maintenance tips for prolonging the life of your bandsaw

Proper maintenance is crucial for keeping your bandsaw in optimal condition and extending its lifespan. Regularly cleaning the bandsaw, removing dust and debris, prevents buildup that can affect the machine’s performance. Lubricating the blade and other moving parts ensures smooth operation and protects against wear and tear.

Inspecting the blade for signs of dullness or damage and replacing it as needed is also essential. A sharp, intact blade is critical for making precise cuts and preventing strain on the bandsaw’s motor. Additionally, checking the bandsaw’s alignment and making adjustments as necessary ensures accurate cuts and reduces the risk of uneven wear on the blade.

Conclusion:

Bandsaws are a versatile and valuable tool in the machinery arsenal, offering precision, efficiency, and safety for a wide range of cutting tasks. Understanding the unique features of bandsaws, along with the latest technological advancements, can help you select the right bandsaw for your needs and maintain it for years of reliable service. By considering the aspects discussed in this guide, you can harness the full potential of bandsaws to elevate your projects to new heights.