The global market for meat processing equipment, including meat slicers, was valued at USD 8.84 billion in 2023, and is projected to grow at a CAGR of 10.29% to reach USD 17.55 billion by 2030. This growth highlights the increasing importance of advanced meat processing tools in meeting the rising demand for processed meat products. As businesses look to enhance efficiency and maintain high standards of food safety, selecting the right meat slicer becomes crucial.

Table of Contents:

– The Role of Meat Slicers for Businesses

– Key Benefits of Using Meat Slicers

– Types of Meat Slicers Available

– Key Features to Consider When Selecting a Meat Slicer

– Evaluating the Cost and ROI of Meat Slicers

– Trends in Meat Slicer Technology

– Making the Final Decision on Your Meat Slicer Purchase

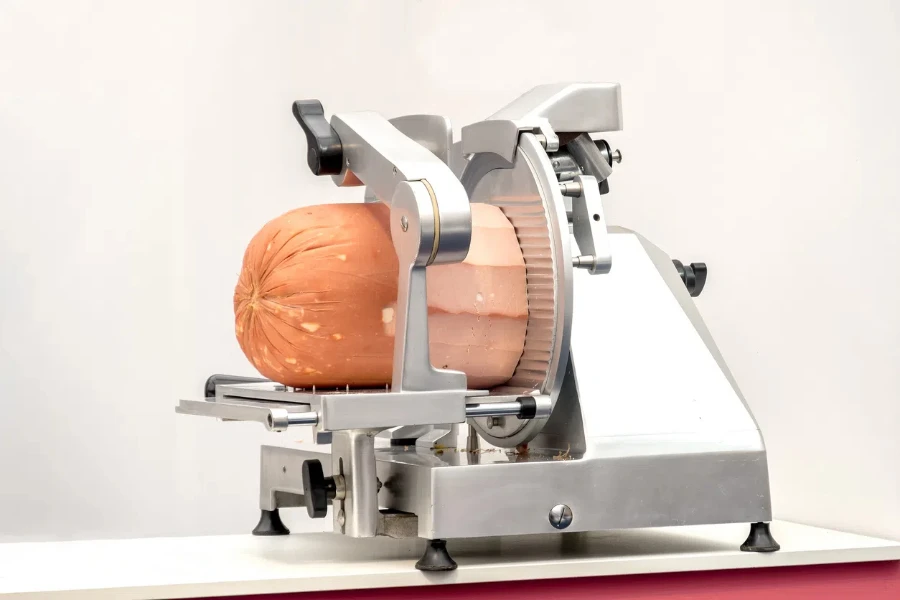

The Role of Meat Slicers for Businesses

Meat slicers are indispensable tools in the food industry, particularly for businesses involved in meat processing and retail. They enhance efficiency by enabling precise and consistent slicing of meat products, which is crucial for maintaining product quality and meeting customer expectations. According to the Global Slaughtering Equipment Market report, the market for meat processing equipment, including slicers, was valued at USD 8.84 billion in 2023 and is projected to grow at a CAGR of 10.29% to reach USD 17.55 billion by 2030. This growth underscores the increasing reliance on advanced meat processing tools to meet the rising demand for processed meat products.

The use of meat slicers also contributes to significant labor cost savings. Automated and semi-automated slicers reduce the need for manual labor, allowing businesses to allocate resources more efficiently. The integration of automation and robotics in meat processing equipment, as highlighted in the report, is transforming the industry by enhancing operational efficiency and precision. This trend is expected to continue, with the semi-automated equipment segment projected to reach USD 6.1 billion by 2030, growing at a CAGR of 3.9%.

Moreover, meat slicers play a critical role in ensuring food safety and hygiene. Consistent slicing reduces the risk of contamination and ensures that meat products are handled in a sanitary manner. The focus on food safety and hygiene is a key driver of growth in the slaughtering equipment market, as businesses strive to comply with stringent regulatory standards. The U.S. market, for instance, was estimated at USD 2.0 billion in 2023, reflecting the high demand for advanced meat processing equipment in regions with strict food safety regulations.

Key Benefits of Using Meat Slicers

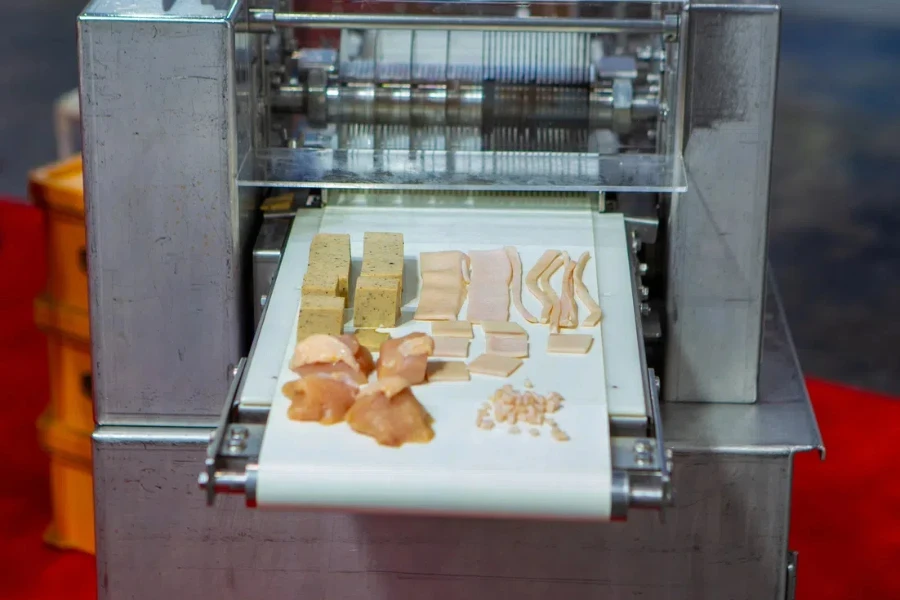

One of the primary benefits of using meat slicers is the ability to achieve uniform slices, which is essential for product consistency and customer satisfaction. Uniform slicing ensures that each piece of meat has the same thickness, which is particularly important for products like deli meats and steaks. This consistency not only enhances the visual appeal of the product but also ensures even cooking and flavor distribution. The global market for meat and poultry processing equipment, which includes slicers, is expected to grow significantly, driven by the increasing demand for high-quality meat products.

Another significant advantage of meat slicers is the reduction in meat wastage. Manual slicing often results in uneven cuts and higher wastage, whereas automated slicers can be programmed to minimize waste by making precise cuts. This efficiency translates into cost savings for businesses, as they can maximize the yield from each piece of meat. The report highlights that the adoption of advanced meat processing equipment, including slicers, is driven by the need to minimize wastage and improve yield, particularly in high-volume processing environments.

Additionally, meat slicers enhance operational efficiency by speeding up the slicing process. Manual slicing is time-consuming and labor-intensive, whereas automated slicers can process large quantities of meat quickly and with minimal human intervention. This increased efficiency is crucial for businesses looking to scale their operations and meet growing demand. The integration of IoT and data analytics in meat processing equipment further enhances efficiency by enabling real-time monitoring and process optimization, reducing downtime and operational costs.

Types of Meat Slicers Available

Manual Meat Slicers

Manual meat slicers are the most basic type of slicers, operated entirely by hand. They are typically used in smaller establishments where the volume of meat processing is relatively low. These slicers are favored for their simplicity, ease of use, and lower cost compared to automated models. Despite their manual operation, they can still provide precise cuts, making them suitable for businesses that prioritize control over automation. The market for manual meat slicers remains steady, particularly in regions where small-scale meat processing is prevalent.

One of the key features of manual meat slicers is their durability and low maintenance requirements. Since they do not rely on electrical components, they are less prone to mechanical failures and can be easily maintained with regular cleaning and sharpening of the blade. This makes them a cost-effective option for businesses with limited budgets. The report indicates that while the market is shifting towards automation, there is still a significant demand for manual equipment in certain segments of the meat processing industry.

However, manual meat slicers do have limitations in terms of speed and efficiency. They require significant physical effort and time to operate, which can be a drawback for businesses with high processing volumes. As a result, many businesses are transitioning to semi-automated or fully automated slicers to enhance productivity. The global trend towards automation in meat processing is expected to continue, with the fully automated equipment segment projected to grow at a CAGR of 2.5% over the analysis period.

Automatic Meat Slicers

Automatic meat slicers are designed to handle high volumes of meat with minimal human intervention. These slicers are equipped with advanced features such as programmable settings, automatic blade sharpening, and safety mechanisms to ensure efficient and safe operation. They are ideal for large-scale meat processing facilities that require consistent and high-speed slicing. The adoption of automatic meat slicers is driven by the need for increased productivity and precision in meat processing.

One of the main advantages of automatic meat slicers is their ability to produce uniform slices at a much faster rate compared to manual slicers. This not only improves efficiency but also ensures that the meat products meet the desired quality standards. The report highlights that the integration of automation and robotics in meat processing equipment is transforming the industry by enhancing operational efficiency and precision. The market for fully automated meat processing equipment is expected to grow significantly, driven by the increasing demand for high-quality meat products.

In addition to speed and precision, automatic meat slicers also offer enhanced safety features. These slicers are equipped with sensors and safety guards to prevent accidents and ensure safe operation. The focus on safety is a key driver of growth in the meat processing equipment market, as businesses strive to comply with stringent regulatory standards. The report indicates that the adoption of advanced meat processing equipment, including automatic slicers, is driven by the need to ensure food safety and hygiene in meat processing facilities.

Semi-Automatic Meat Slicers

Semi-automatic meat slicers offer a balance between manual and automatic operation, providing both control and efficiency. These slicers are equipped with motorized blades that reduce the physical effort required for slicing, while still allowing the operator to control the slicing process. They are ideal for medium-sized businesses that require a higher volume of meat processing than manual slicers can handle, but do not need the full automation of automatic slicers. The market for semi-automatic meat slicers is expected to grow, driven by the increasing demand for efficient and flexible meat processing solutions.

One of the key features of semi-automatic meat slicers is their versatility. They can be used for a wide range of meat products, from deli meats to steaks, and can be easily adjusted to achieve the desired thickness. This versatility makes them a popular choice for businesses that process a variety of meat products. The report highlights that the semi-automated equipment segment is expected to reach USD 6.1 billion by 2030, growing at a CAGR of 3.9%, reflecting the increasing demand for flexible and efficient meat processing solutions.

In addition to versatility, semi-automatic meat slicers also offer enhanced safety features compared to manual slicers. They are equipped with safety guards and sensors to prevent accidents and ensure safe operation. The focus on safety is a key driver of growth in the meat processing equipment market, as businesses strive to comply with stringent regulatory standards. The report indicates that the adoption of advanced meat processing equipment, including semi-automatic slicers, is driven by the need to ensure food safety and hygiene in meat processing facilities.

Key Features to Consider When Selecting a Meat Slicer

Blade Size and Material

The blade size and material are critical factors to consider when selecting a meat slicer. The size of the blade determines the thickness and size of the meat slices, with larger blades being suitable for thicker cuts and smaller blades for thinner slices. Common blade sizes range from 9 to 14 inches, with 12-inch blades being the most popular for commercial use. The material of the blade also affects its durability and performance, with stainless steel being the preferred choice due to its resistance to corrosion and ease of cleaning.

Stainless steel blades are known for their sharpness and ability to maintain an edge, which is essential for achieving precise cuts. They are also less prone to rust and corrosion, making them ideal for use in meat processing environments where hygiene is paramount. The report highlights that the focus on food safety and hygiene is a key driver of growth in the meat processing equipment market, with businesses increasingly opting for high-quality stainless steel blades to ensure compliance with regulatory standards.

In addition to size and material, the design of the blade also plays a role in its performance. Serrated blades are ideal for slicing tougher meats, while smooth blades are better suited for softer meats and deli products. The choice of blade design depends on the type of meat being processed and the desired thickness of the slices. The report indicates that the market for meat processing equipment, including slicers, is expected to grow significantly, driven by the increasing demand for high-quality meat products and the need for precise and efficient slicing solutions.

Motor Power and Speed

Motor power and speed are crucial factors that determine the efficiency and performance of a meat slicer. The motor power, measured in watts, affects the slicer’s ability to handle different types of meat and the volume of meat it can process. Higher motor power allows the slicer to cut through tougher meats and handle larger quantities, making it suitable for high-volume processing environments. Common motor power ratings for commercial meat slicers range from 200 to 500 watts, with higher power ratings being preferred for heavy-duty use.

The speed of the slicer, measured in revolutions per minute (RPM), also affects its efficiency and performance. Higher speeds allow for faster slicing, which is essential for businesses that need to process large volumes of meat quickly. The report highlights that the integration of automation and robotics in meat processing equipment is transforming the industry by enhancing operational efficiency and precision. The market for fully automated meat processing equipment, which includes high-speed slicers, is expected to grow significantly, driven by the increasing demand for high-quality meat products.

In addition to motor power and speed, the design of the slicer also affects its performance. Slicers with adjustable speed settings allow the operator to control the slicing process and achieve the desired thickness and consistency. This versatility is particularly important for businesses that process a variety of meat products. The report indicates that the adoption of advanced meat processing equipment, including high-speed slicers, is driven by the need to enhance productivity and meet the growing demand for processed meat products.

Safety Features

Safety features are a critical consideration when selecting a meat slicer, as they help prevent accidents and ensure safe operation. Common safety features include blade guards, safety switches, and non-slip feet. Blade guards protect the operator from accidental contact with the blade, while safety switches prevent the slicer from operating when the blade guard is not in place. Non-slip feet provide stability and prevent the slicer from moving during operation, reducing the risk of accidents.

In addition to these basic safety features, advanced meat slicers are equipped with sensors and automatic shut-off mechanisms that enhance safety. These features detect any irregularities in the slicing process and automatically shut off the slicer to prevent accidents. The report highlights that the focus on safety is a key driver of growth in the meat processing equipment market, as businesses strive to comply with stringent regulatory standards. The adoption of advanced meat processing equipment, including slicers with enhanced safety features, is driven by the need to ensure food safety and hygiene in meat processing facilities.

Moreover, training and proper usage are essential to ensure the safe operation of meat slicers. Operators should be trained on how to use the slicer correctly and follow safety protocols to prevent accidents. Regular maintenance and cleaning of the slicer also help ensure its safe operation and prolong its lifespan. The report indicates that the adoption of advanced meat processing equipment, including slicers with enhanced safety features, is driven by the need to ensure food safety and hygiene in meat processing facilities.

Ease of Cleaning and Maintenance

Ease of cleaning and maintenance is an important factor to consider when selecting a meat slicer, as it affects the slicer’s hygiene and longevity. Meat slicers should be easy to disassemble and clean to prevent the buildup of meat residues and bacteria. Stainless steel components are preferred for their resistance to corrosion and ease of cleaning. The report highlights that the focus on food safety and hygiene is a key driver of growth in the meat processing equipment market, with businesses increasingly opting for slicers that are easy to clean and maintain.

In addition to ease of cleaning, regular maintenance is essential to ensure the slicer’s optimal performance and longevity. This includes sharpening the blade, lubricating moving parts, and checking for any wear and tear. The report indicates that the adoption of advanced meat processing equipment, including slicers, is driven by the need to ensure food safety and hygiene in meat processing facilities. Businesses should follow the manufacturer’s maintenance guidelines and schedule regular inspections to keep the slicer in good working condition.

Moreover, some advanced meat slicers are equipped with self-cleaning and self-sharpening features that reduce the need for manual cleaning and maintenance. These features enhance the slicer’s efficiency and reduce downtime, making them ideal for high-volume processing environments. The report highlights that the integration of automation and robotics in meat processing equipment is transforming the industry by enhancing operational efficiency and precision. The market for fully automated meat processing equipment, which includes slicers with self-cleaning and self-sharpening features, is expected to grow significantly, driven by the increasing demand for high-quality meat products.

Size and Space Requirements

The size and space requirements of a meat slicer are important considerations, especially for businesses with limited space. Meat slicers come in various sizes, from compact models suitable for small kitchens to larger models designed for high-volume processing. The size of the slicer should be chosen based on the available space and the volume of meat processing required. The report highlights that the market for meat processing equipment, including slicers, is expected to grow significantly, driven by the increasing demand for high-quality meat products and the need for efficient and space-saving solutions.

In addition to the physical size, the weight of the slicer is also an important consideration. Heavier slicers are generally more stable and durable, but they may be difficult to move and require a dedicated space. Lighter slicers are more portable and can be easily moved, but they may not be as stable and durable. The choice of slicer depends on the specific needs and constraints of the business. The report indicates that the adoption of advanced meat processing equipment, including slicers, is driven by the need to enhance productivity and meet the growing demand for processed meat products.

Moreover, some advanced meat slicers are designed with space-saving features such as foldable components and compact designs. These features make them ideal for businesses with limited space and help maximize the use of available space. The report highlights that the integration of automation and robotics in meat processing equipment is transforming the industry by enhancing operational efficiency and precision. The market for fully automated meat processing equipment, which includes space-saving slicers, is expected to grow significantly, driven by the increasing demand for high-quality meat products.

Brand Reputation and Warranty

Brand reputation and warranty are important factors to consider when selecting a meat slicer, as they provide assurance of the slicer’s quality and reliability. Reputable brands are known for their high-quality products and excellent customer service, making them a preferred choice for businesses. The report highlights that the market for meat processing equipment, including slicers, is expected to grow significantly, driven by the increasing demand for high-quality meat products and the need for reliable and durable equipment.

In addition to brand reputation, the warranty offered by the manufacturer is also an important consideration. A good warranty provides protection against defects and ensures that the slicer can be repaired or replaced if it malfunctions. The length and coverage of the warranty vary by manufacturer, with some offering extended warranties for added peace of mind. The report indicates that the adoption of advanced meat processing equipment, including slicers, is driven by the need to ensure food safety and hygiene in meat processing facilities. Businesses should choose slicers from reputable brands that offer comprehensive warranties to ensure the slicer’s reliability and longevity.

Moreover, customer reviews and testimonials can provide valuable insights into the performance and reliability of the slicer. Businesses should research and compare different brands and models to find the best slicer that meets their specific needs and requirements. The report highlights that the integration of automation and robotics in meat processing equipment is transforming the industry by enhancing operational efficiency and precision. The market for fully automated meat processing equipment, which includes slicers from reputable brands, is expected to grow significantly, driven by the increasing demand for high-quality meat products.

Evaluating the Cost and ROI of Meat Slicers

Initial Purchase Cost

The initial purchase cost of meat slicers varies significantly based on the type and features of the machine. Entry-level models for small-scale operations can start at around $500, while high-end commercial slicers with advanced features can exceed $5,000. Factors influencing the cost include blade size, motor power, and additional functionalities such as automatic slicing and safety features.

When evaluating the initial cost, it’s essential to consider the specific needs of your operation. For instance, a deli requiring high-volume slicing will benefit from investing in a more robust, higher-capacity slicer. Conversely, a small butcher shop might find a mid-range model sufficient, balancing cost with necessary features.

Additionally, the brand and warranty offered can impact the initial investment. Reputable brands often provide longer warranties and better customer support, which can justify a higher upfront cost. It’s crucial to assess these factors to ensure the slicer meets your operational demands and budget constraints.

Operating and Maintenance Costs

Operating costs for meat slicers include electricity consumption, blade sharpening, and routine maintenance. High-powered slicers consume more electricity, which can increase operational costs, especially in high-usage environments. Regular blade sharpening is necessary to maintain slicing efficiency and can cost between $50 to $100 per session.

Maintenance costs also encompass parts replacement and potential repairs. Components such as belts, bearings, and motors may need periodic replacement, with costs varying based on the slicer model and usage intensity. For example, a commercial-grade slicer used continuously in a busy deli will incur higher maintenance costs compared to a slicer used sporadically in a small butcher shop.

To minimize downtime and extend the slicer’s lifespan, it’s advisable to follow the manufacturer’s maintenance schedule. Investing in a maintenance contract can provide peace of mind and potentially lower long-term costs by ensuring timely servicing and parts replacement.

Long-Term Savings and Efficiency

Investing in a high-quality meat slicer can lead to significant long-term savings and operational efficiency. Efficient slicers reduce product waste by ensuring consistent slice thickness, which is crucial for portion control and cost management. For instance, a slicer that minimizes meat waste by just 1% can save a business thousands of dollars annually.

Advanced slicers with automation features can also enhance productivity by reducing manual labor. Automated slicers can handle high volumes with minimal supervision, allowing staff to focus on other tasks, thereby improving overall workflow. This efficiency translates to labor cost savings and increased throughput.

Moreover, modern slicers with energy-efficient motors and smart features can lower electricity consumption. Over time, these savings can offset the higher initial purchase cost, making them a cost-effective investment. Evaluating the total cost of ownership, including potential savings, is crucial for making an informed purchasing decision.

Trends in Meat Slicer Technology

Innovations in Blade Technology

Recent advancements in blade technology have significantly improved the performance and longevity of meat slicers. High-carbon stainless steel blades are now standard, offering superior sharpness and durability compared to traditional steel blades. These blades maintain their edge longer, reducing the frequency of sharpening and associated downtime.

Ceramic-coated blades are another innovation, providing enhanced corrosion resistance and non-stick properties. This coating reduces friction during slicing, resulting in smoother cuts and less residue buildup. For example, ceramic-coated blades are particularly beneficial in environments where hygiene and ease of cleaning are paramount.

Additionally, some manufacturers are incorporating self-sharpening mechanisms into their slicers. These systems automatically sharpen the blade during operation, ensuring consistent cutting performance and extending the blade’s lifespan. This feature is especially useful in high-volume settings where maintaining peak efficiency is critical.

Advancements in Automation and Safety

Automation in meat slicers has revolutionized the industry, offering features such as automatic slicing, portion control, and programmable settings. These advancements reduce the need for manual intervention, increasing productivity and ensuring uniform slice thickness. For instance, automated slicers can be programmed to produce precise slices for different products, enhancing consistency and customer satisfaction.

Safety features have also seen significant improvements, with modern slicers incorporating advanced sensors and safety guards. These features prevent accidental injuries by automatically stopping the blade when obstructions are detected. For example, slicers with hand-guard sensors ensure that the machine ceases operation if the operator’s hand gets too close to the blade.

Emergency stop buttons and non-slip feet are additional safety enhancements that provide operators with greater control and stability. These features are crucial in busy commercial kitchens where safety and efficiency are top priorities. Investing in slicers with advanced safety features can reduce workplace accidents and associated costs.

Smart and IoT-Enabled Meat Slicers

The integration of smart technology and the Internet of Things (IoT) in meat slicers is an emerging trend that offers numerous benefits. IoT-enabled slicers can connect to a central management system, allowing for real-time monitoring and data analysis. This connectivity enables operators to track usage patterns, maintenance schedules, and performance metrics remotely.

Smart slicers can also provide predictive maintenance alerts, notifying operators of potential issues before they lead to downtime. For example, sensors can detect blade wear and send alerts when sharpening or replacement is needed. This proactive approach minimizes unexpected breakdowns and extends the equipment’s lifespan.

Furthermore, IoT-enabled slicers can integrate with inventory management systems, optimizing stock levels based on slicing activity. This integration ensures that businesses maintain optimal inventory levels, reducing waste and improving cost efficiency. As technology continues to evolve, the adoption of smart slicers is expected to increase, offering enhanced operational control and efficiency.

Making the Final Decision on Your Meat Slicer Purchase

When making the final decision on purchasing a meat slicer, it’s essential to consider both the initial and long-term costs. Evaluate the slicer’s features, including blade technology, automation, and safety enhancements, to ensure it meets your operational needs. Additionally, consider the potential savings and efficiency gains from investing in advanced, IoT-enabled slicers.

Afrikaans

Afrikaans አማርኛ

አማርኛ العربية

العربية বাংলা

বাংলা Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português Русский

Русский Español

Español Kiswahili

Kiswahili ไทย

ไทย Türkçe

Türkçe اردو

اردو Tiếng Việt

Tiếng Việt isiXhosa

isiXhosa Zulu

Zulu