The Heat Transfer Printer market has been booming with recent technological advancements and the rise of e-commerce. This article delves into crucial factors such as printing width, resolution, media compatibility, and more. Professional buyers will find valuable insights to aid their purchasing decisions. Transitioning to the main text, these highlights will guide you in choosing the best heat transfer printer for your business needs.

Table of Contents:

1. Market Overview of Heat Transfer Printer

2. In-Depth Analysis of the Heat Transfer Printer Market

3. Key Factors When Selecting a Heat Transfer Printer

4. Advanced Features and Technologies in Heat Transfer Printers

5. Future Trends in Heat Transfer Printing Technology

6. Comprehensive Evaluation of Heat Transfer Printers

Market Overview of Heat Transfer Printer

The Heat Transfer Printer market has seen significant growth in recent years. By 2030, the market size is projected to reach $58.59 billion, growing at a Compound Annual Growth Rate (CAGR) of 5.27%. This growth is driven by the increasing demand for efficient printing solutions across sectors such as retail, logistics, manufacturing, and healthcare. Technological advancements, the rise of e-commerce, and the need for high-quality, durable printing outputs also fuel this expansion.

Regionally, the Asia-Pacific region is expected to experience the highest growth, followed by North America and Europe. The adoption of heat transfer printers in emerging markets is accelerating due to rapid industrialization and the uptake of advanced printing technologies. Key players in the market include Zebra Technologies, Honeywell International, and Seiko Epson Corporation, which continue to innovate and expand their product offerings to meet the evolving needs of various industries.

The market is segmented by product type, application, and end-user. The primary product types are direct thermal printers, thermal transfer printers, and dye diffusion thermal transfer printers. These printers are used in applications such as barcode printing, card printing, and point-of-sale receipt printing. End-users include the retail, healthcare, manufacturing, and transportation sectors, all of which require reliable and efficient printing solutions.

In-Depth Analysis of the Heat Transfer Printer Market

The Heat Transfer Printer market is dynamic, driven by continuous innovation and technological advancements. Key performance benchmarks like printing speed, print quality, and durability are critical factors influencing consumer preferences and market dynamics. Economic influences also shape the market, with businesses seeking cost-effective and high-efficiency printing solutions to boost productivity.

Consumer behavior is shifting towards cloud-based POS systems and mobile printing solutions, which offer flexibility and real-time data management. This trend is evident in the retail sector, where businesses are increasingly integrating thermal printers with their digital transaction systems. The rise of e-commerce has further fueled the demand for heat transfer printers, as efficient inventory management and order fulfillment processes become essential.

Recent innovations include the development of eco-friendly thermal papers and IoT-enabled printers, which offer enhanced connectivity and energy efficiency. These advancements address customer pain points such as high operational costs and the environmental impact of traditional printing methods. Companies are also focusing on brand positioning strategies that emphasize sustainability and technological prowess to stand out in a competitive market.

The product lifecycle of heat transfer printers involves continuous upgrades and enhancements to meet evolving end-user demands. Digitalization and the integration of smart technologies are expected to play a significant role in the market’s future. As businesses prioritize efficiency and sustainability, the adoption of advanced heat transfer printing solutions is likely to increase, driving further growth and innovation in the industry.

Key Factors When Selecting a Heat Transfer Printer

Printing Width and Rate

When selecting a heat transfer printer, consider the printing width and rate. The printing width is the maximum width of the substrate the printer can handle. This ensures the printer can accommodate the size of your materials. For example, if you need to print on wide textiles or large banners, a printer with a broader printing width is necessary.

The printing rate is the speed at which the printer produces prints, measured in linear inches or centimeters per second. A higher printing rate benefits high-volume production environments where efficiency is critical. For instance, a printer with a rate of 10 inches per second is more suitable for large-scale manufacturing than one with a rate of 5 inches per second.

Resolution and Color Capabilities

Printer resolution, measured in dots per inch (dpi), is crucial. Higher resolution printers, like those with 1200 dpi, produce sharper images, essential for detailed designs on apparel or promotional materials. Lower resolution printers might suffice for simpler designs or large text.

Color capabilities are also important. Some printers can print in multiple colors, vital for vibrant, multi-colored designs. These printers use various inks, including durable, vivid resin-based inks. A printer capable of CMYK (cyan, magenta, yellow, black) color printing is ideal for full-color graphics.

Medienkompatibilität

Heat transfer printers must be compatible with the media you plan to use, including textiles, plastics, metals, ceramics, and more. Each material has specific requirements for ink adhesion and heat resistance. For example, printing on textiles might require a printer that handles heat transfer vinyl, while ceramics need a printer using sublimation inks.

The thickness and texture of the media also affect printer choice. Printers for thicker materials, like cardstocks or heavy fabrics, often have adjustable platen heights and robust feeding mechanisms. Ensuring your printer can handle your specific media types will prevent production issues and ensure high-quality prints.

Haltbarkeit und Verarbeitungsqualität

Durability and build quality are critical for long-term reliability. Printers with sturdy frames and high-quality components are less prone to breakdowns and can withstand continuous use in industrial environments. For example, printers with metal housings and reinforced feeding systems are better for heavy-duty applications than those with plastic components.

Consider the printer’s lifespan. Manufacturers often provide operational life estimates, which help in planning maintenance and budgeting for replacements. A printer with a longer lifespan and lower maintenance needs offers better value over time, even with a higher initial investment.

Energieeffizienz und Umweltverträglichkeit

Energy efficiency is important for reducing operational costs and minimizing environmental impact. Look for printers with energy-saving modes and certifications like Energy Star, indicating compliance with energy efficiency standards.

Consider the environmental impact of inks and consumables. Eco-friendly inks and recyclable media options reduce waste and make printing operations more sustainable. For example, water-based inks are less harmful to the environment than solvent-based inks and are preferable for eco-conscious businesses.

Advanced Features and Technologies in Heat Transfer Printers

Automatisierte Wartungssysteme

Modern heat transfer printers often feature automated maintenance systems to reduce downtime and ensure consistent print quality. These systems include automatic nozzle cleaning, ink replenishment, and printhead alignment. Such features are beneficial in high-volume production settings where manual maintenance can be time-consuming.

Automated maintenance systems help keep the printer in optimal condition, extending its lifespan and reducing service interventions. This results in significant cost savings over the printer’s operational life. For instance, a printer with an automated cleaning cycle can prevent ink clogs and ensure smooth operation, reducing the need for costly repairs.

Konnektivität und Integration

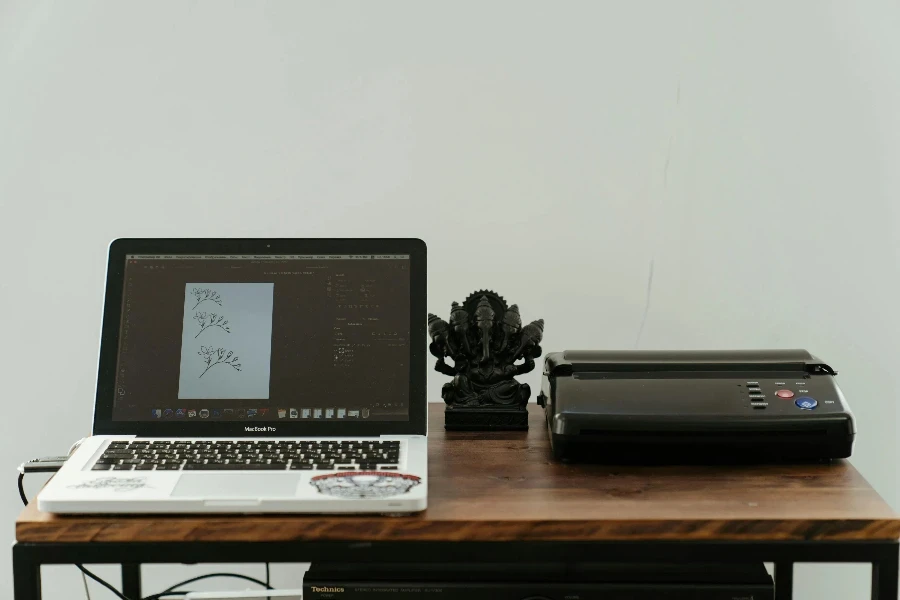

Connectivity options are crucial for heat transfer printers. Printers with multiple interface options, such as USB, Ethernet, and Wi-Fi, offer greater flexibility. Network-enabled printers can integrate into existing workflows, allowing remote operation and monitoring.

Integration with design software and production management systems is also essential. Printers that support popular file formats and have robust driver support can seamlessly integrate with design tools like Adobe Illustrator or CorelDRAW. This ensures a smooth transition from design to print, improving efficiency and reducing errors.

Sicherheitsstandards und Zertifizierungen

Compliance with safety standards and certifications ensures safe operation and regulatory compliance. Heat transfer printers should meet industry-specific safety standards, such as CE or UL certifications, indicating the equipment has been tested and meets safety requirements.

Certifications related to environmental and health standards, such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), are also important. These certifications ensure the printer and its consumables do not contain harmful substances, protecting operators and the environment.

Future Trends in Heat Transfer Printing Technology

Erhöhte Automatisierung und KI-Integration

The future of heat transfer printing technology will likely see more automation and AI integration. AI-driven printers can optimize print settings in real-time, adjusting parameters like temperature, pressure, and speed based on the specific media and design. This results in higher quality prints and reduced waste.

Automation technologies, such as robotic arms for media handling and automated inspection systems, can further streamline production. These advancements will enable businesses to achieve higher productivity and efficiency, reducing labor costs and improving competitiveness.

Verbesserte Materialkompatibilität

Advancements in ink formulations and printing technologies will enhance material compatibility, allowing printers to work with more substrates, including eco-friendly and recyclable materials, advanced composites, and smart textiles.

For example, developments in nanotechnology could create inks that bond more effectively with difficult substrates like glass or metal, without additional primers or treatments. This will expand the application possibilities for heat transfer printing, making it a more versatile tool in various industries.

Sustainability and Green Printing Solutions

Sustainability will remain a significant focus in the heat transfer printing industry. Manufacturers are likely to develop more eco-friendly printing solutions, including biodegradable inks, recyclable media, and printers with lower energy consumption.

Innovations like waterless printing technologies and zero-waste production processes will become more prevalent, reducing environmental impact. These sustainable practices will benefit the environment and appeal to eco-conscious consumers, enhancing brand reputation.

Comprehensive Evaluation of Heat Transfer Printers

When evaluating heat transfer printers, consider a comprehensive set of criteria that align with your needs and goals. Assess the printer’s technical specifications, such as printing width, rate, resolution, and color capabilities, and its compatibility with various media types.

Also, consider factors like durability, build quality, energy efficiency, and environmental impact. Advanced features, such as automated maintenance systems and connectivity options, can enhance the printer’s performance and workflow integration. Ensuring compliance with safety and environmental standards is crucial for safe and responsible operation.

By thoroughly evaluating these factors and staying informed about future trends and advancements, you can make an informed decision and select a heat transfer printer that meets your production needs and supports your business growth.