Auch im Jahr 2025 wird die Präzisionsfertigung die industrielle Landschaft dominieren und die Entwicklung von Technologien zum Laserschneiden von Rohren vorantreiben. Dieser Artikel bietet eine eingehende Analyse des Marktes, wichtige Faktoren, die bei der Auswahl von Maschinen zu berücksichtigen sind, und wie diese Fortschritte professionellen Einkäufern und ihren Betrieben zugute kommen können. Im Übergang zum Haupttext untersuchen wir die kritischen Aspekte, die Ihre Kaufentscheidungen leiten werden.

Table of Contents:

– Der globale Markt für Rohrlaserschneiden: Ein umfassender Überblick

– Eingehende Analyse des Marktes für Rohrlaserschneiden

– Schlüsselfaktoren bei der Auswahl von Rohrlaserschneidmaschinen

– Steigerung der Produktionseffizienz durch Rohrlaserschneiden

– In die Zukunft der Fertigung investieren

- Abschließende Gedanken

Der globale Markt für Rohrlaserschneiden: Ein umfassender Überblick

Der Markt für das Laserschneiden von Rohren hat aufgrund der steigenden Nachfrage nach Präzisionsfertigung in verschiedenen Branchen ein deutliches Wachstum gezeigt. Der globale Markt für Laserschneidmaschinen, einschließlich des Laserschneidens von Rohren, war im Jahr 35.4 2023 Milliarden USD wert und wird bis 49.3 voraussichtlich 2030 Milliarden USD erreichen und mit einer durchschnittlichen jährlichen Wachstumsrate von 4.9 % wachsen. Dieses Wachstum wird durch Fortschritte in der Lasertechnologie und den zunehmenden Bedarf an Präzision in Herstellungsprozessen, insbesondere in der Automobil-, Luft- und Raumfahrt- und Elektronikbranche, vorangetrieben.

Der asiatisch-pazifische Raum dominiert den Markt für Laserschneidmaschinen, einschließlich des Rohrlaserschneidens. Dieser Markt wird voraussichtlich mit einer durchschnittlichen jährlichen Wachstumsrate von 4.6 % wachsen, angetrieben durch die schnelle Industrialisierung und die Einführung fortschrittlicher Fertigungstechnologien. China spielt eine entscheidende Rolle, da sein Markt bis 7.8 voraussichtlich 2030 Milliarden USD erreichen wird. Auch die Vereinigten Staaten stellen einen bedeutenden Markt dar, der im Jahr 9.6 auf 2023 Milliarden USD geschätzt wird, was die hohe Nachfrage nach Laserschneidtechnologien in Nordamerika widerspiegelt.

Zu den wichtigsten Akteuren auf dem Markt für das Laserschneiden von Rohren zählen Alpha Laser GmbH, AMADA WELD TECH Inc., Bystronic Group, Coherent Corp. und TRUMPF SE + Co. KG. Diese Unternehmen sind Innovationsführer, entwickeln kontinuierlich neue Technologien und erweitern ihre Produktlinien, um den Marktanforderungen gerecht zu werden.

Eingehende Analyse des Marktes für Rohrlaserschneiden

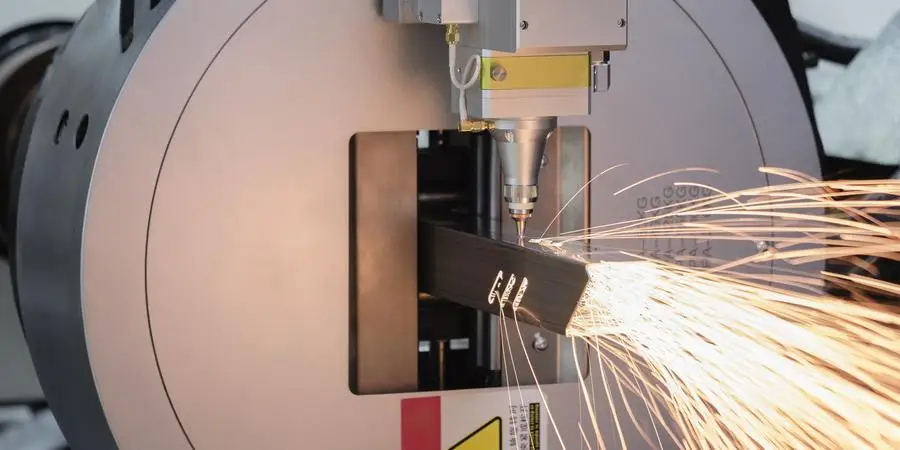

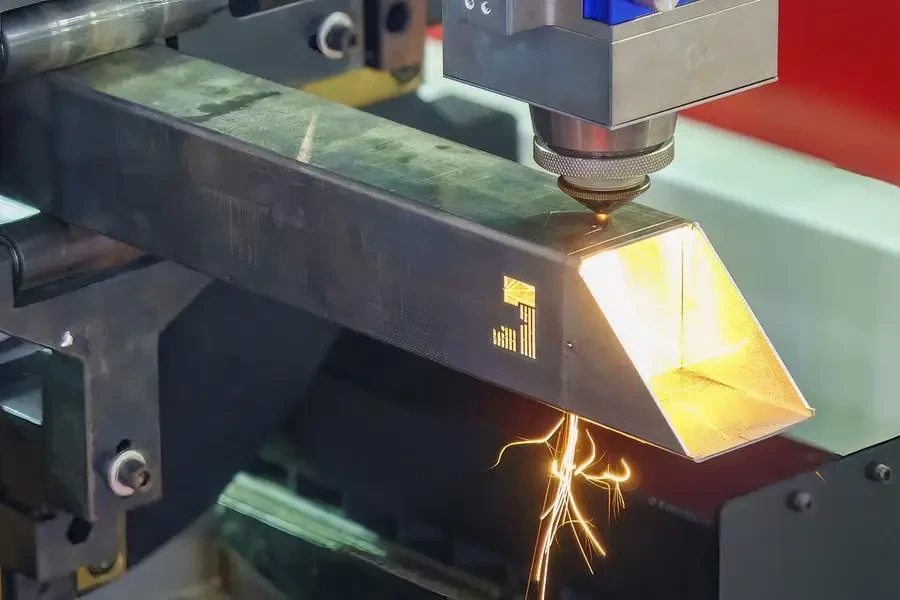

Der Markt für das Laserschneiden von Rohren zeichnet sich durch hohe Präzision und Effizienz beim Schneiden verschiedener Materialien wie Metalle und Kunststoffe aus. Zu den wichtigsten Leistungskriterien für Laserschneidmaschinen gehören Schnittgeschwindigkeit, Genauigkeit und Materialvielfalt. Faserlaser sind besonders beliebt, da sie im Vergleich zu herkömmlichen CO2-Lasern eine höhere Effizienz, schnellere Schnittgeschwindigkeiten und geringere Betriebskosten aufweisen.

Der Markt ist hart umkämpft, und verschiedene Anbieter leisten einen wesentlichen Beitrag. Die FPNV-Positionierungsmatrix kategorisiert diese Anbieter basierend auf ihren Geschäftsstrategien und Produktzufriedenheitsniveaus in vier Quadranten – Forefront, Pathfinder, Niche und Vital. Dies hilft Unternehmen bei der Auswahl der Laserschneidlösungen, die ihren Anforderungen am besten entsprechen.

Zu den jüngsten Innovationen gehört die Integration von Laserschneidmaschinen in CAD- und CAM-Software, wodurch komplexere und präzisere Schnitte möglich werden. Dies unterstützt den Industrie 4.0-Trend. Die Entwicklung von Faserlaserschneidmaschinen hat neue Anwendungsgebiete erschlossen, insbesondere in der Automobil- und Elektronikindustrie, wo Materialien wie Aluminium und Kupfer häufig verwendet werden.

Zu den wirtschaftlichen Faktoren, die den Markt beeinflussen, gehört die steigende Nachfrage nach hochwertigen, komplexen Teilen in verschiedenen Branchen. Der Trend hin zu Leichtbaumaterialien in der Automobil- und Luftfahrtindustrie treibt auch den Einsatz von Laserschneidmaschinen voran. Darüber hinaus erhöht der Trend zur Automatisierung und intelligenten Fertigung die Nachfrage nach Laserschneidmaschinen, die in automatisierte Produktionslinien integriert werden können, wodurch die Produktivität gesteigert und die Arbeitskosten gesenkt werden.

Das Verbraucherverhalten zeigt eine wachsende Vorliebe für digitale Fertigung und kundenspezifische Kleinserienproduktion. Laserschneidmaschinen bieten die Flexibilität, schnell zwischen verschiedenen Schneidaufgaben zu wechseln, ohne dass umfangreiche Umrüstungen notwendig sind. Zu den Vertriebskanälen für diese Maschinen zählen Direktvertrieb, Distributoren und Online-Plattformen, wobei umfassende Lösungen bevorzugt werden, die Installation, Schulung und After-Sales-Support umfassen.

Die Herausforderungen für Kunden im Markt für Rohrlaserschneiden liegen häufig in den hohen Anschaffungskosten der Ausrüstung und dem Bedarf an qualifizierten Bedienern. Anbieter begegnen diesen Problemen, indem sie benutzerfreundliche Schnittstellen entwickeln und umfassende Schulungen und Support anbieten. Der Trend zur Digitalisierung und zu fortschrittlichen Softwarelösungen trägt ebenfalls dazu bei, Abläufe zu rationalisieren und die Lernkurve für neue Benutzer zu verkürzen.

Schlüsselfaktoren bei der Auswahl von Rohrlaserschneidmaschinen

Bei der Auswahl der richtigen Rohrlaserschneidmaschine müssen mehrere wichtige Faktoren berücksichtigt werden, um sicherzustellen, dass sie Ihren spezifischen Betriebsanforderungen entspricht. Zu diesen Faktoren gehören Lasertyp, Leistungskapazität, Schnittgeschwindigkeit, Abmessungen und zusätzliche Funktionen, die die Funktionalität und Benutzerfreundlichkeit verbessern. Im Folgenden werden wir diese wichtigsten Überlegungen im Detail untersuchen.

Laser-Art

Der verwendete Lasertyp hat erhebliche Auswirkungen auf die Leistung der Maschine und ihre Eignung für unterschiedliche Materialien. Die beiden Haupttypen von Lasern sind CO2-Laser und Faserlaser.

CO2-Laser: CO2-Laser verwenden ein Gasgemisch, das hauptsächlich aus Kohlendioxid besteht. Aufgrund ihrer langen Wellenlänge (ca. 10.6 µm) sind sie äußerst effektiv zum Schneiden von nichtmetallischen Materialien und dicken Metallrohren. Diese Laser halten kontinuierliche und hohe Leistungsniveaus aufrecht und eignen sich daher für Anwendungen, die große Schnitttiefen erfordern. Sie sind ideal für Materialien wie Holz, Glas und bestimmte Kunststoffe.

Faserlaser: Faserlaser verwenden optische Fasern, die mit Seltenerdelementen wie Ytterbium dotiert sind. Sie emittieren Licht mit kürzeren Wellenlängen (ca. 1.064 µm), was sie zum Schneiden von Metallen wie Edelstahl, Aluminium und Kupfer äußerst effizient macht. Faserlaser sind für ihre hohe Präzision, schnellere Schnittgeschwindigkeiten und niedrigeren Wartungskosten im Vergleich zu CO2-Lasern bekannt. Aufgrund ihrer kompakten Größe und Energieeffizienz werden sie in industriellen Anwendungen immer beliebter.

Leistungskapazität

Die Leistungskapazität einer Rohrlaserschneidmaschine, gemessen in Kilowatt (kW), bestimmt ihre Schneidfähigkeit und -geschwindigkeit.

Laser mit geringer Leistung (1-3 kW): Diese eignen sich für dünnere Materialien und weniger anspruchsvolle Anwendungen. Sie bieten hohe Präzision und sind für kleine bis mittelgroße Betriebe kostengünstig.

Mittelleistungslaser (3-6 kW): Diese bieten ein Gleichgewicht zwischen Schnittgeschwindigkeit und Präzision und sind daher für eine größere Bandbreite an Materialien und Stärken geeignet. Sie sind ideal für mittelgroße Fertigungsanlagen.

Hochleistungslaser (6-12 kW und mehr): Hochleistungslaser sind für das Schneiden dicker Materialien und die Produktion großer Stückzahlen konzipiert. Sie bieten die höchsten Schneidgeschwindigkeiten und sind für anspruchsvolle Industrieanwendungen unverzichtbar. Allerdings sind ihre Betriebskosten höher und sie erfordern anspruchsvollere Kühlsysteme.

Schneidgeschwindigkeit

Die Schneidgeschwindigkeit ist entscheidend für die Produktivität und Betriebseffizienz. Sie wird von der Leistung des Lasers, dem zu schneidenden Material und der Gesamtkonstruktion der Maschine beeinflusst.

Medientyp: Verschiedene Materialien reagieren unterschiedlich auf das Laserschneiden. Metalle wie Aluminium und Kupfer, die eine hohe Wärmeleitfähigkeit haben, erfordern im Vergleich zu Stahl langsamere Schnittgeschwindigkeiten.

Dicke: Dickere Materialien erfordern im Allgemeinen langsamere Schnittgeschwindigkeiten, um einen sauberen und präzisen Schnitt zu gewährleisten. Hochleistungslaser können dickere Materialien schneller schneiden, dies hängt jedoch auch von den spezifischen Fähigkeiten der Maschine ab.

Präzision und Qualität: Höhere Schnittgeschwindigkeiten können manchmal die Qualität und Präzision des Schnitts beeinträchtigen. Es ist wichtig, ein Gleichgewicht zu finden, das Ihren Produktionsanforderungen entspricht, ohne die Qualität des fertigen Produkts zu beeinträchtigen.

Abmessungen und Größe Kapazität

Wichtige Überlegungen sind die Größe der Rohr-Laserschneidmaschine und ihre Fähigkeit, unterschiedliche Rohrdurchmesser und -längen zu verarbeiten.

Rohrdurchmesser: Stellen Sie sicher, dass die Maschine für die verschiedenen Rohrdurchmesser geeignet ist, mit denen Sie arbeiten. Maschinen mit verstellbaren Spannfuttern und Vorrichtungen können verschiedene Größen verarbeiten und bieten so mehr Flexibilität.

Schnittlänge: Die maximale Schnittlänge der Maschine sollte Ihren Produktionsanforderungen entsprechen. Einige Maschinen verfügen über verlängerte Betten für längere Rohre, was für Branchen wie das Baugewerbe sowie die Öl- und Gasindustrie von entscheidender Bedeutung ist.

Stellfläche der Maschine: Berücksichtigen Sie den verfügbaren Platz in Ihrer Einrichtung. Größere Maschinen bieten möglicherweise mehr Funktionen, benötigen aber mehr Stellfläche. Stellen Sie sicher, dass Sie über ausreichend Platz für einen sicheren Betrieb und eine sichere Wartung verfügen.

Zusätzliche Funktionen

Moderne Rohrlaserschneidmaschinen verfügen über zahlreiche Funktionen, die ihre Funktionalität und Benutzerfreundlichkeit verbessern.

Automation: Automatisierte Be- und Entladesysteme können die Produktivität deutlich steigern und die Arbeitskosten senken. Suchen Sie nach Maschinen mit integrierten Automatisierungslösungen für einen reibungslosen Betrieb.

Software und Steuerungssysteme: Moderne CNC-Systeme (Computer Numerical Control) ermöglichen eine präzise Steuerung des Schneidevorgangs. Benutzerfreundliche Schnittstellen und Softwarekompatibilität können die Effizienz steigern und den Lernaufwand für die Bediener verkürzen.

Sicherheitsvorrichtungen: Stellen Sie sicher, dass die Maschine den Sicherheitsstandards der Branche entspricht und über Funktionen wie Schutzgehäuse, Not-Aus-Schalter und Laser-Sicherheitsverriegelungen zum Schutz der Bediener verfügt.

Wartung und Support: Berücksichtigen Sie die Verfügbarkeit von Wartungsdiensten und technischem Support. Maschinen mit leicht zugänglichen Komponenten und umfassenden Supportpaketen können Ausfallzeiten minimieren und einen reibungslosen Betrieb gewährleisten.

Verbesserung der Produktionseffizienz durch Rohrlaserschneiden

Der Einsatz von Rohrlaserschneidtechnologie kann die Produktionseffizienz in verschiedenen Branchen erheblich steigern. Wenn Unternehmen die Vorteile und potenziellen Herausforderungen verstehen, können sie diese Technologie besser nutzen, um optimale Ergebnisse zu erzielen.

Präzision und Genauigkeit

Rohrlaserschneidmaschinen bieten beispiellose Präzision und Genauigkeit, die für eine qualitativ hochwertige Produktion entscheidend sind. Die Fähigkeit, komplizierte Schnitte und komplexe Formen mit minimalen Fehlern zu erzeugen, reduziert den Materialabfall und gewährleistet eine konsistente Produktion.

Reduzierter Materialabfall: Präzise Schnitte bedeuten weniger Materialabfall, was zu Kosteneinsparungen und einer effizienteren Nutzung der Ressourcen führt. Diese Präzision ist besonders in Branchen wichtig, in denen die Materialkosten hoch sind.

Durchgehende Qualität: Eine gleichbleibende Schnittqualität stellt sicher, dass jedes Stück die erforderlichen Spezifikationen erfüllt. Dadurch wird der Nacharbeitsbedarf verringert und die Gesamtproduktqualität verbessert.

Geschwindigkeit und Produktivität

Die hohen Schneidgeschwindigkeiten von Lasermaschinen führen zu einer höheren Produktivität. Schnellere Schneidzeiten ermöglichen einen höheren Durchsatz, sodass Unternehmen enge Termine einhalten und ihre Produktionskapazität steigern können.

Hoher Durchsatz: Höhere Schnittgeschwindigkeiten bedeuten, dass mehr Teile in kürzerer Zeit hergestellt werden können, was den Gesamtdurchsatz erhöht und die Vorlaufzeiten verkürzt.

Effizienz in der Produktion: Automatisierte Funktionen und fortschrittliche Steuerungssysteme steigern die Effizienz zusätzlich und ermöglichen einen Dauerbetrieb mit minimalen Ausfallzeiten.

Vielseitigkeit

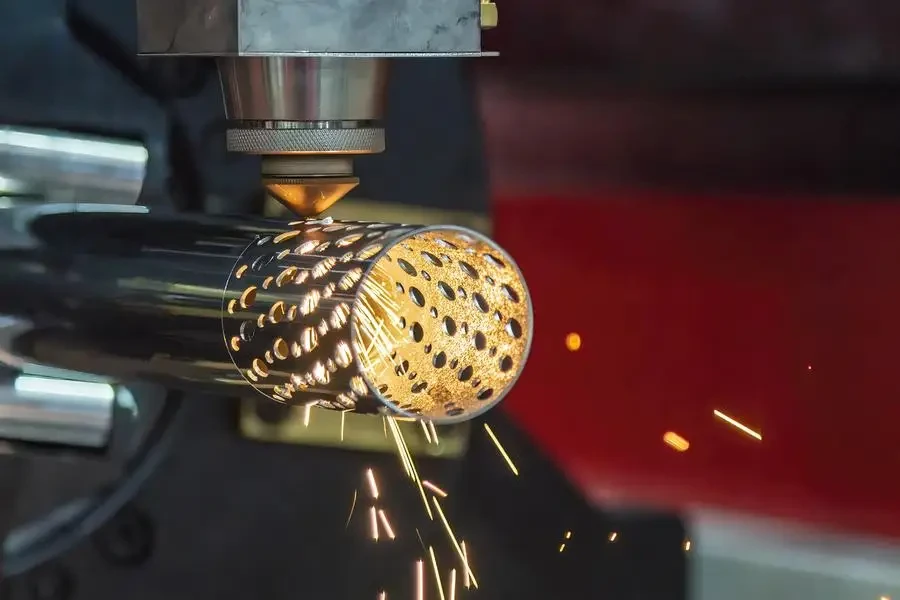

Rohrlaserschneidmaschinen sind vielseitig einsetzbar und können mit einer breiten Palette an Materialien und Anwendungen umgehen. Diese Vielseitigkeit macht sie für verschiedene Branchen geeignet, von der Automobil- und Luftfahrtindustrie bis hin zu Bau und Fertigung.

Handhabung mehrerer Materialien: Die Fähigkeit, verschiedene Materialien, darunter Metalle, Kunststoffe und Verbundwerkstoffe, zu schneiden, macht diese Maschinen für vielfältige Fertigungsanforderungen von unschätzbarem Wert.

Flexibilität: Maschinen mit anpassbaren Einstellungen und austauschbaren Komponenten können sich schnell an unterschiedliche Produktionsanforderungen anpassen und bieten so mehr Flexibilität im Betrieb.

Investition in die Zukunft der Fertigung

Die Einführung der Rohrlaserschneidtechnologie stellt eine bedeutende Investition in die Zukunft der Fertigung dar. Indem Unternehmen den technologischen Fortschritten und Branchentrends immer einen Schritt voraus sind, können sie ihren Wettbewerbsvorteil wahren und Innovationen vorantreiben.

Technologische Fortschritte

Kontinuierliche Fortschritte in der Lasertechnologie führen zu Verbesserungen bei Effizienz, Präzision und Kosteneffizienz. Wenn Unternehmen über die neuesten Entwicklungen auf dem Laufenden bleiben, können sie modernste Lösungen für ihre Produktionsanforderungen nutzen.

Emerging Technologies: Technologien wie KI und maschinelles Lernen werden in Laserschneidsysteme integriert und ermöglichen vorausschauende Wartung, Echtzeitüberwachung und Optimierung der Schneidparameter.

Nachhaltigkeit: Neuere Laserschneidmaschinen werden mit Blick auf Energieeffizienz entwickelt, wodurch die Umweltbelastung und die Betriebskosten reduziert werden. Investitionen in nachhaltige Technologie entsprechen dem globalen Trend hin zu umweltfreundlichen Herstellungsverfahren.

Branchentrends

Um fundierte Investitionsentscheidungen treffen zu können, ist es wichtig, Branchentrends und Marktanforderungen zu verstehen. Die wachsende Nachfrage nach maßgeschneiderten Produkten und der Übergang zu intelligenter Fertigung sind wichtige Trends, die die Zukunft der Branche prägen.

Maßgeschneidert: Die Fähigkeit, schnell und effizient kundenspezifische Teile und Komponenten herzustellen, wird immer wichtiger. Die Laserschneidtechnologie unterstützt diesen Trend, indem sie hohe Präzision und Flexibilität bietet.

Smart Manufacturing: Die Integration von IoT (Internet of Things) und Industrie 4.0-Prinzipien verändert Fertigungsprozesse. Intelligente Laserschneidmaschinen mit erweiterter Konnektivität und Datenanalysefunktionen sind bei dieser Transformation führend.

Abschließende Überlegungen

Bei der Auswahl der richtigen Rohrlaserschneidmaschine müssen verschiedene Faktoren sorgfältig berücksichtigt werden, von Lasertyp und Leistungskapazität bis hin zu Schnittgeschwindigkeit und Zusatzfunktionen. Durch das Verständnis dieser kritischen Aspekte können Unternehmen fundierte Entscheidungen treffen, die ihre Produktionseffizienz steigern und zukünftiges Wachstum fördern.