Obwohl moderne Technologien unser Leben prägen, fühlen sich manche Dinge oder Erlebnisse einfach besser an, wenn man sie in der Hand hält oder selbst sieht. So haben beispielsweise physische Kartendrucker, egal wie weit verbreitet virtuelle Alternativen werden, in unserer Welt immer noch ihren Platz, um wertvolle Dinge wie Mitarbeiterausweise, Geschäftspässe oder Mitgliedskarten zu drucken.

In diesem Artikel erfahren Sie, was ein Plastikkartendrucker leisten kann, welches globale Marktpotenzial er hat und wie Sie den richtigen Kartendruckertyp für den Verkauf im Jahr 2025 auswählen.

Inhaltsverzeichnis

Der weltweite Marktausblick für Plastikkartendrucker

Auswahl der richtigen Plastikkartendrucker zum Verkauf

Aufrüstbarkeit und verschiedene Budgetoptionen

Sicherheitsmerkmale und Haltbarkeit

Konnektivität und Benutzerfreundlichkeit

Top Plastikkartendrucker

Direct-to-Card (DTC)-Drucker

Retransferdrucker

Tintenstrahlkartendrucker

Kartendruck richtig gemacht

Der weltweite Marktausblick für Plastikkartendrucker

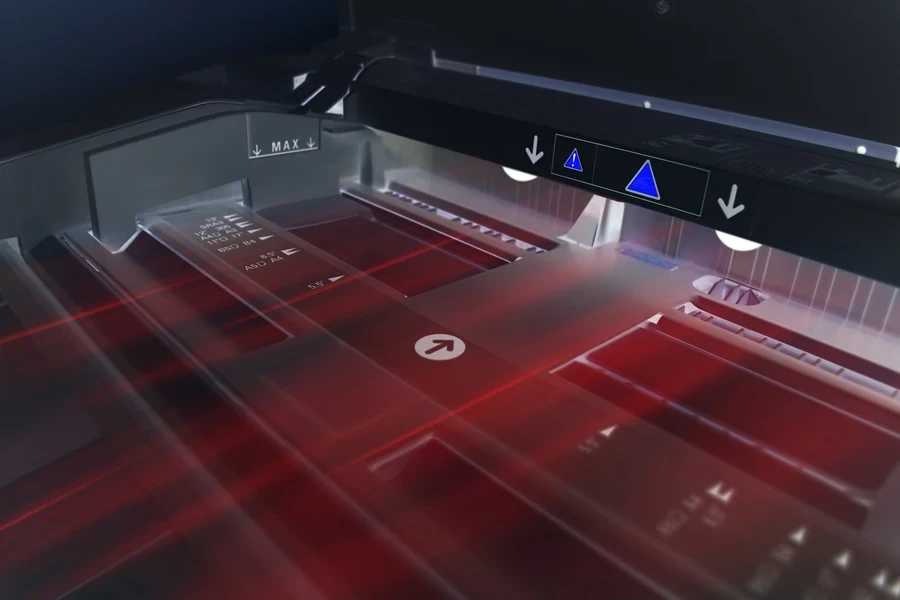

Plastikkartendrucker, manchmal einfach als Kartendrucker oder Plastikkartendrucker bezeichnet, sind Spezialdrucker, die für die Verarbeitung von Plastikoberflächen statt herkömmlichem Papier konzipiert sind. Da sie mit starren Plastikkarten arbeiten können, sind sie auch als ID-Kartendrucker oder Ausweisdrucker bekannt. Durch den Einsatz spezieller Drucktechniken wie Farbsublimation und Retransferdruck sorgen diese Drucker dafür, dass die Tinte richtig auf der Plastikoberfläche haftet und so ein langlebiges, hochwertiges Finish entsteht.

Gleichzeitig verfügen viele dieser Drucker auch über Kodierfunktionen, mit denen sie Daten und Informationen über Magnetstreifen, Barcodes, Smartchips, kontaktlose Chips oder RFID-Tags auf Karten einbetten können. Diese Kodiertechnologien sind mehr als nur der Druck einfacher Lichtbildausweise; sie ermöglichen auch datenintensive Anwendungen wie Zugangskontrolle und sichere Identifizierung.

In puncto Sicherheit bieten Plastikkartendrucker häufig auch erweiterte visuelle Sicherheitsfunktionen, die einen zusätzlichen Schutz gegen Fälschungen bieten und die Echtheit der Karte verbessern. Insgesamt ermöglichen diese Kodierungs- und Sicherheitsfunktionen es Plastikkartendruckern, sichere Mehrzweckkarten wie Mitarbeiterausweise, Zugangskontrollausweise, Fahrkarten, Mitgliedskarten und sogar Debit- und Kreditkarten von Banken zu produzieren.

Angesichts derart vielfältiger Anwendungen ist es klar, dass Plastikkartendrucker auch weiterhin eine wesentliche Rolle bei der Herstellung hochwertiger Ausweise mit sicheren Identifikations- und Verifizierungslösungen spielen können. Der globale Markt für Kartendrucker wird voraussichtlich mit einer durchschnittlichen jährlichen Wachstumsrate (CAGR) von etwa 4.3 % von 2023 bis 2030 und wird am Ende dieses Zeitraums 177 Millionen US-Dollar erreichen, gegenüber 117 Millionen US-Dollar im Jahr 2022. Dieses stabile Wachstum unterstreicht die steigende Nachfrage nach sicheren und vielseitigen Kartendrucklösungen in allen Branchen.

Auswahl der richtigen Plastikkartendrucker zum Verkauf

Aufrüstbarkeit und verschiedene Budgetoptionen

Da Plastikkartendrucker im Allgemeinen höhere Preise haben, einschließlich der laufenden Versorgung mit anderen zugehörigen Materialien, neigen Kunden dazu, eher auf die langfristigen Gesamtkosten zu achten als nur auf den einmaligen Kaufpreis der Hardware. Zu den wiederkehrenden Kosten gehören auf lange Sicht der leere Kartenvorrat und die Ersatzfarbbänder. Daher ist es für Verkäufer äußerst vorteilhaft, eine Auswahl sowohl hinsichtlich verschiedener budgetfreundlicher Druckermodelle als auch hinsichtlich der Optionen für leere Karten und Farbbänder anzubieten.

In der Zwischenzeit ist das Angebot von Druckern mit modularem Design und Upgrade-Optionen eine weitere wichtige Überlegung für Verkäufer. Eine solche Flexibilität ermöglicht es Benutzern beispielsweise, ihre relativ einfachen, einseitige Kartendrucker zu vielseitiger beidseitige Kartendrucker jederzeit. Diese Upgrade-Funktion ist besonders attraktiv für Benutzer, die planen, ihre Betriebsabläufe in naher Zukunft zu erweitern, insbesondere wenn solche Upgrades ganz einfach durch die Bereitstellung eines Kartendruckermodul or Upgrade-Kit für beidseitigen Kartendrucker.

Es ist auch sinnvoll, aktualisierbare Optionen für magnetische Kodierung und andere Kodierungsfunktionen bereitzustellen. Hardware wie Barcodes und Chipkartenleser oder -schreiber erfordern häufig diese anpassbaren Kodierungsfunktionen. Daher ist es für Verkäufer wichtig, bei der Beschaffung von Produkten die Marktrichtung zu bewerten. Diese Strategie trägt dazu bei, Hardwareabhängigkeiten zu minimieren und die Produktvielseitigkeit zu stärken.

Sicherheitsmerkmale und Haltbarkeit

Ein weiteres bemerkenswertes Merkmal von ID-Druckern sind ihre verbesserten visuellen Sicherheitsmerkmale, wie Hologramme oder Wasserzeichen-Overlays, die einen zusätzlichen Schutz gegen Fälschungen bieten. Darüber hinaus gibt es zwei weitere, weniger visuell auffällige Sicherheitsmerkmale, darunter taktile Präger, die erhabene, geprägte Designs erzeugen, und UV-Druckelemente, die nur unter UV-Licht sichtbar sind, wenn die Drucker mit UV-fähigen Farbbändern ausgestattet sind. Diese erweiterten Sicherheitsfunktionen können besonders für Benutzer interessant sein, die Zugangskontrollkarten, sichere ID-Karten und praktisch alle Karten mit solchen zusätzlichen Sicherheitsanforderungen erstellen.

Ein Nebeneffekt der Integration dieser Sicherheitsmerkmale ist, dass Overlays oder geprägte Designs oft auch als Laminierung dienen. Mit zusätzlichen Overlays (einer zusätzlichen Kunststoffschicht) dienen diese Merkmale sowohl als Schutz- als auch als Sicherheitsschicht und schützen die gedruckten Karten vor Abnutzung, Verblassen und Kratzern. Alternativ können Sie Kartendrucker mit eingebauten Laminiermodulen kann durch den integrierten Laminierungsprozess ebenfalls solche haltbarkeitssteigernden Eigenschaften bieten. Normalerweise ist der laminierungsfähige Drucker in höherwertigen Modellen erhältlich, um eine lange Haltbarkeit der gedruckten Karten zu gewährleisten.

Konnektivität und Benutzerfreundlichkeit

Neben vielseitigen Funktionen wie Aufrüstbarkeit und verbesserten Sicherheitslösungen sind Netzwerkkonnektivität und multifunktionale Konnektivitätsoptionen ebenso wichtige Überlegungen für Unternehmen, insbesondere solche mit Mehrbenutzer-Setups. Die meisten Kartendrucker können über USB, Ethernet oder WLAN verbunden werden. Daher ist es für Verkäufer wichtig, sicherzustellen, dass sie Drucker anbieten, die diese gängigen Konnektivitätsoptionen unterstützen, um Benutzerfreundlichkeit und Zugänglichkeit zu gewährleisten.

Darüber hinaus sollten sich Verkäufer auch auf andere benutzerfreundliche Funktionen von Kartendruckern konzentrieren, um die Attraktivität für ihren Zielmarkt zu steigern. Einfache Plug-and-Play-Einrichtung und modulare Designs für Upgrades sind einige praktische Aspekte, die Verkäufer anbieten können, damit Benutzer bei Bedarf schnell erweiterte Funktionen einrichten und erweitern können.

Gleichzeitig vereinfachen bestimmte scheinbar kleine, aber zeitsparende Funktionen wie die automatische Kartenzufuhr und -umdrehung für optimierten beidseitigen Druck sowie ein einfaches Ladesystem für Farbbandkassetten die Wartung und reduzieren Ausfallzeiten. Diese Funktionen sind besonders nützlich bei der Verwaltung von Druckern mit hohem Volumen.

Top Plastikkartendrucker

Direct-to-Card (DTC)-Drucker

Direct-to-Card (DTC)-Drucker sind eine der am weitesten verbreiteten und am häufigsten vorkommenden Grundtypen von Plastikkartendruckern, die derzeit auf dem Markt erhältlich sind. Diese Kartendrucker, die manchmal auch als Thermosublimationsdruck bezeichnet werden, verwenden die Thermosublimationsdrucktechnologie Thermosublimationskartendrucker, drucken Sie direkt auf die Karte für schnelle und zuverlässige Ergebnisse. Sie erfüllen alle Standardanforderungen für den Kartendruck und bieten eine kostengünstige Lösung für Unternehmen mit einfacheren, grundlegenden Kartendruckanforderungen.

Neben den Basistypen der Direct-to-Card-Drucker gibt es auch Varianten wie beidseitige Direct-to-Card-Drucker und hochauflösende DTC-Drucker, die eine verbesserte Bildqualität und Auflösung liefern und sich ideal für Anwendungen wie Lichtbildausweise oder Werbematerialien eignen, bei denen visuelle Details im Vordergrund stehen. Es gibt auch kompakte und mobile DTC-Drucker, die für den mobilen Einsatz oder platzsparende Nutzung konzipiert sind und sich für den Einsatz unterwegs oder an Arbeitsplätzen mit eingeschränktem Platzangebot eignen.

Retransferdrucker

Reverse-Transfer-Plastikkartendrucker, oft angerufen Retransfer-Kartendrucker, beziehen sich auf Drucker, die auf einen separaten Film statt direkt auf die leere Karte drucken. Dieser bedruckte Film wird dann mithilfe einer Wärmeübertragungstechnologie auf die Karte geklebt. Das Endergebnis von Retransferdruckern ist oft ein hochwertiges, randloses Finish, das durch seine nahtlose Ästhetik besticht.

Retransferdrucker liefern nicht nur erstklassige Qualität, sie sind auch für den Druck auf unebenen Oberflächen geeignet und daher ideal für Chipkarten mit eingebetteter Technologie. Diese Vielseitigkeit ist der Grund, warum Reverse-Transfer-Kartendrucker werden trotz ihres im Vergleich zu Direct-to-Card (DTC)-Druckern im Allgemeinen höheren Preises häufig im professionellen Umfeld und von Hochsicherheitsorganisationen gewählt.

Reverse-Transfer-Drucker, ähnlich wie DTC-Modelle, sind in verschiedenen Konfigurationen erhältlich. Einige sind mit Laminierungsfunktionen ausgestattet, während andere Kodierungs- und erweiterte Sicherheitsfunktionen bieten. Dazu gehören hochauflösende Reverse-Transfer-Drucker mit einer Auflösung von 600 DPI werden besonders für ihre Fähigkeit geschätzt, außergewöhnlich scharfe Bilder zu erzeugen und komplizierte Designs und feine Details festzuhalten.

Dies liegt daran, dass eine Auflösung von 600 DPI allgemein als höchste Druckqualität beim Kartendruck gilt und jede Standardauflösung von 300 DPI übertrifft, die lediglich die Anforderungen einfacher Ausweise und Standard-Retransferdrucker erfüllt. Retransferdrucker mit hoher Auflösung sind ideal für Anwendungen, die hohe Detailgenauigkeit und Präzision erfordern, wie z. B. Führerscheine oder sichere Zugangskarten, bei denen Genauigkeit von entscheidender Bedeutung ist.

Tintenstrahlkartendrucker

Tintenstrahl-Ausweisdrucker bringen einen neuen Ansatz für den Kartendruck im Vergleich zu den etablierteren Direct-to-Card (DTC)- und Reverse-Transfer-Druckern. Anstatt das traditionelle Farbbandsystem anderer Drucker zu verwenden, Tintenstrahl-Plastikkartendrucker verwenden „einfach zu installierende Patronen“, sodass es keine Probleme mit Farbbandrissen oder -knicken gibt. Dieses Design macht Tintenstrahldrucker viel einfacher zu handhaben und im täglichen Gebrauch wesentlich zuverlässiger.

Eine der herausragendsten Eigenschaften von Tintenstrahl-Kartendrucker ist ihre Fähigkeit, gestochen scharfe, randlose, qualitativ hochwertige Bilder direkt auf die Karte zu drucken, ohne dass eine Filmschicht erforderlich ist. Diese Funktion verschafft ihnen einen Vorteil gegenüber DTC-Druckern, wenn es um randlosen Druck geht, und sie sind im Allgemeinen kostengünstiger als Retransfermodelle.

Allerdings sollte man bedenken, dass Tintenstrahlkartendrucker normalerweise keine erweiterten Kodierungs- oder Sicherheitsfunktionen bieten, weshalb sie sich weniger für Anwendungen eignen, die zusätzliche Sicherheitsebenen oder benutzerdefinierte Kodierung erfordern. Für schnelle, optisch beeindruckende Karten bieten Tintenstrahldrucker jedoch eine perfekte Lösung ohne diese Komplexität.

Kartendruck richtig gemacht

Plastikkartendrucker sind speziell für den Druck auf starre Karten konzipiert und verfügen häufig über optionale Funktionen wie Datenspeicherung, Kodierung und zusätzliche Sicherheit. Diese Funktionen sind normalerweise als Upgrades oder als Teil modularer Designs erhältlich, was bei diesen Druckern eine gängige Konfiguration ist. Aus diesem Grund ist es für Verkäufer ratsam, eine Reihe von Modellen auf Lager zu haben, um unterschiedlichen Budgetanforderungen gerecht zu werden. Die Aufrüstbarkeit ist hier ein großes Plus; indem Sie modulare Designs oder Drucker anbieten, die mit Upgrade-Kits kompatibel sind, stellen Sie sicher, dass Kunden mit dem Wachstum ihres Unternehmens aufrüsten können.

Die drei Haupttypen von Plastikkartendruckern auf dem Markt sind derzeit Direct-to-Card (DTC)-Drucker, Retransferdrucker und Tintenstrahldrucker – jeder dieser Typen hat einzigartige Eigenschaften, die seine eigenen Vorteile und Spezialfunktionen haben.

Suchen Sie nach weiteren Ideen zu Produktoptionen oder Beschaffung? Bleiben Sie auf dem Laufenden über die neuesten Trends in der Logistik und im Großhandels-Sourcing unter Chovm.com Reads. Regelmäßige Updates sorgen dafür, dass Sie immer informiert sind und effizient arbeiten.

বাংলা

বাংলা Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português Русский

Русский Español

Español Kiswahili

Kiswahili ไทย

ไทย Türkçe

Türkçe اردو

اردو Tiếng Việt

Tiếng Việt isiXhosa

isiXhosa Zulu

Zulu