In 2025, the demand for vinyl sticker printers has surged, driven by the need for high-quality labeling and customization across various industries. This article provides an in-depth analysis of the latest trends, technological advancements, and essential factors to consider when selecting a vinyl sticker printer. Professional buyers will find valuable insights to make informed purchasing decisions, ensuring they invest in the best equipment for their business needs.

Índice:

- Visión general del mercado

-In-Depth Market Analysis

-Key Factors When Selecting a Vinyl Sticker Printer

-Technological Advancements in Vinyl Sticker Printers

-Industry Standards and Certifications

-Reflexiones finales

Visión general del mercado

The global vinyl sticker printer market has seen substantial growth due to the rising demand for high-quality labeling and customization in various industries. By 2025, the market is expected to reach USD 1.8 billion, growing at a CAGR of 6.5% from 2023. This growth is driven by the increasing use of vinyl sticker printers in sectors like retail, logistics, manufacturing, and healthcare. North America holds the largest market share at approximately 35%, followed by Europe and the Asia-Pacific region.

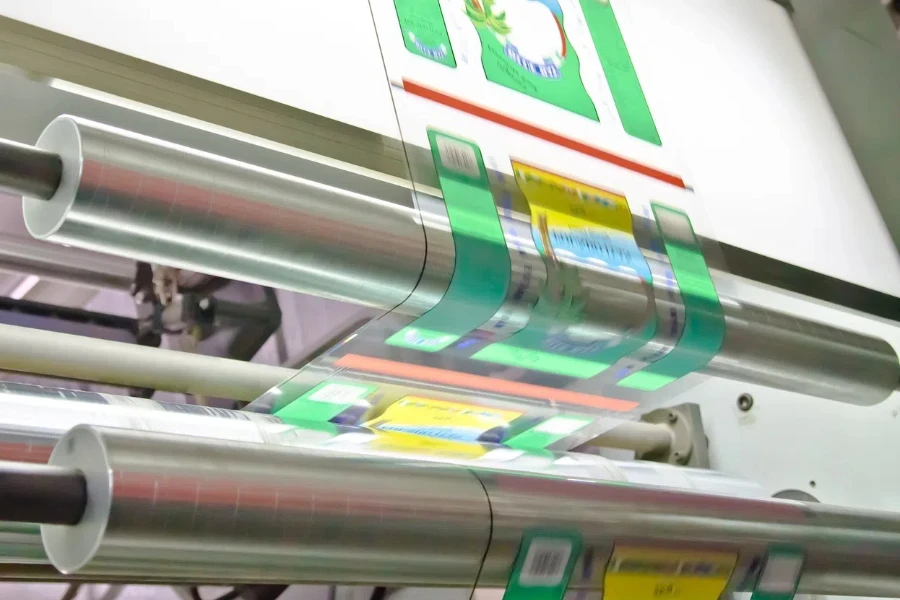

The rise of e-commerce has significantly boosted the demand for vinyl sticker printers, as businesses need efficient labeling solutions for packaging and shipping. Technological advancements in digital printing have made vinyl sticker printers more versatile and efficient. The integration of mobile applications and cloud-based printing solutions has further streamlined the printing process, benefiting small and medium-sized enterprises (SMEs).

Sustainability trends are also impacting the market, with manufacturers focusing on eco-friendly printing solutions. The use of biodegradable materials and eco-inks in vinyl sticker printing is gaining popularity, aligning with global environmental regulations and consumer preferences. This shift towards sustainable practices is expected to drive demand for vinyl sticker printers in the coming years.

Análisis de mercado en profundidad

Parámetros clave de rendimiento

Vinyl sticker printers are evaluated based on print quality, speed, durability, and versatility. High-resolution printing, typically ranging from 1200 to 2400 dpi, is crucial for producing detailed and vibrant stickers. Advanced models can achieve print speeds of up to 60 square meters per hour, making them suitable for high-volume production.

Dinámica de la cuota de mercado

The market is highly competitive, with key players like HP Inc., Epson, Canon, and Roland DG Corporation holding over 60% of the market share. HP Inc. leads with a 25% share. Continuous innovation and new models with enhanced features, such as wireless connectivity and automated cutting systems, drive the competitive landscape.

Influencias económicas

Economic factors, including fluctuating raw material prices and trade policies, impact the vinyl sticker printer market. The cost of vinyl materials and inks can affect production costs and pricing strategies. Additionally, the trend of reshoring manufacturing to reduce dependency on international supply chains is influencing market dynamics.

Cambios en el comportamiento del consumidor

Consumer preferences are shifting towards personalized and customized products, driving demand for vinyl sticker printers. Businesses use these printers to offer bespoke labeling solutions, enhancing brand identity and customer engagement. The rise of social media and online platforms has further fueled this trend, as consumers seek unique and visually appealing products.

Preferencias de canales de distribución

Vinyl sticker printers are primarily distributed through direct sales and online channels. Direct sales, including company-owned stores and authorized dealers, account for 55% of the market. Online channels, such as e-commerce platforms and company websites, are gaining popularity, especially among SMEs and individual users, due to their convenience and wider reach.

Innovaciones recientes

Recent innovations in vinyl sticker printing technology include UV-curable inks and advanced printhead designs. UV-curable inks offer superior durability and resistance to environmental factors, making them ideal for outdoor applications. Advanced printhead designs enhance print speed and precision, reducing downtime and maintenance costs.

Etapas del ciclo de vida del producto

Vinyl sticker printers are in the growth stage of their product lifecycle, with increasing adoption across various industries. Continuous technological advancements and new features drive market growth. However, the market is expected to reach maturity in the next decade, with a focus on product differentiation and value-added services.

Digitalización y tendencias sociales

The digitalization of printing processes, including IoT and cloud-based solutions, is transforming the vinyl sticker printer market. IoT-enabled printers allow for real-time monitoring and remote management, enhancing operational efficiency. Social trends, such as the demand for eco-friendly products and the rise of the gig economy, also influence market dynamics.

Puntos débiles del cliente

Common customer pain points include high initial investment costs, maintenance requirements, and the need for specialized training. Manufacturers address these issues by offering cost-effective models, extended warranties, and comprehensive training programs. User-friendly interfaces and automated features simplify the printing process for users.

Estrategias de Posicionamiento de Marca

Leading brands position themselves as providers of high-quality, innovative, and sustainable printing solutions. Marketing strategies emphasize the superior print quality, durability, and versatility of their products. Collaborations with key industry players and participation in trade shows and exhibitions enhance brand visibility and credibility.

Estrategias de diferenciación

Differentiation strategies include offering a wide range of customization options, such as various printing materials, finishes, and cutting capabilities. Companies invest in research and development to introduce unique features, such as wireless connectivity, mobile app integration, and automated maintenance systems. Providing exceptional customer service and support is another key differentiator in the competitive market.

Nichos De Mercado

Niche markets for vinyl sticker printers include the automotive, fashion, and interior design industries. In the automotive sector, vinyl stickers are used for vehicle wraps and decals. The fashion industry uses these printers for creating custom labels and tags. In interior design, vinyl stickers are popular for wall decals and decorative elements. These niche markets offer significant growth opportunities for manufacturers, driven by the demand for unique and customized products.

Key Factors When Selecting a Vinyl Sticker Printer

Printing Width and Resolution

Printing width is crucial when selecting a vinyl sticker printer. It determines the maximum size of the stickers you can produce. For instance, a printer with a width of up to 13 inches can handle larger stickers, ideal for industrial applications requiring high visibility. Higher-end models offer widths of up to 24 inches or more, catering to specialized needs like vehicle wraps and large-format decals.

Resolution, measured in dots per inch (dpi), is another important specification. Higher resolution printers, such as those offering 1200 dpi or more, ensure sharp, clear images and text. This is particularly important for intricate designs and detailed graphics. A higher dpi also means better color gradients and smoother edges, essential for professional-grade stickers.

The combination of printing width and resolution significantly impacts the printer’s versatility. A wider printer with high resolution adapts to various projects, from small, detailed stickers to large, vibrant graphics. This flexibility can be a decisive factor for businesses looking to cater to diverse clientele.

Compatibilidad con medios

The types of media a vinyl sticker printer can handle are paramount. Printers supporting various media, including vinyl, polyester, and other synthetic materials, offer greater flexibility. For example, a printer that manages both adhesive and non-adhesive media allows for a broader range of applications, from stickers to signage and labels.

Media thickness is another aspect to consider. Printers that handle thicker materials, up to 10 mil or more, are suitable for heavy-duty stickers that need to withstand harsh environments, ideal for industrial settings where durability is crucial. Conversely, printers designed for thinner media are better suited for everyday office use or consumer products.

The ability to print on different media sizes enhances the printer’s versatility. Some models accommodate roll-to-roll printing, efficient for large production runs, while others support sheet-fed printing, convenient for smaller batches. This adaptability can streamline operations and reduce material waste.

Rapidez y eficiencia

Printing speed is vital for businesses with high production demands. Printers capable of producing up to 60 inches per second can significantly boost productivity. This speed ensures large orders are completed promptly, reducing turnaround times and increasing customer satisfaction.

Efficiency is influenced by the printer’s ability to operate continuously without frequent interruptions. Features like automatic media loading and built-in cutters streamline the printing process, minimizing downtime. For instance, a printer with an automated cutting mechanism can produce ready-to-use stickers directly, eliminating the need for manual trimming.

Energy efficiency is also important. Modern vinyl sticker printers often come with energy-saving modes and low power consumption designs. These features reduce operational costs and align with sustainable business practices. Selecting an energy-efficient model can lead to significant savings over time, particularly for high-volume operations.

Software e interfaz

The software accompanying a vinyl sticker printer greatly impacts its usability. Printers with advanced design software compatibility, like Adobe Illustrator or CorelDRAW, offer extensive design capabilities. These programs allow precise control over sticker layouts, colors, and effects, enabling the creation of professional-quality products.

User interface is equally important. Printers with intuitive touchscreen controls and user-friendly interfaces simplify the printing process. Features like pre-set printing modes, customizable templates, and real-time print previews enhance efficiency and reduce the learning curve for new users. For instance, a printer with a large, responsive touchscreen facilitates quick adjustments and streamlines workflow.

Connectivity options, including USB, Ethernet, and wireless capabilities, also play a role. Printers with multiple connectivity options are easier to integrate into existing networks and support remote printing. This flexibility is particularly beneficial for businesses with multiple workstations or those requiring mobile printing capabilities.

Durabilidad y calidad de construcción

The build quality of a vinyl sticker printer is critical for long-term reliability. Printers constructed with robust materials, like metal frames and high-quality components, are more likely to withstand daily use. This durability is essential for industrial environments where equipment is subject to constant use and potential physical impacts.

Certification and compliance with industry standards, like ISO and CE, can indicate a printer’s build quality. These certifications ensure the printer meets stringent quality and safety requirements, providing peace of mind to users. For example, a printer that complies with ISO 9001 standards is likely to offer consistent performance and reliability.

Maintenance requirements are another aspect of durability. Printers designed with easy access to key components, like print heads and ink cartridges, simplify maintenance tasks. Features like self-cleaning print heads and automated maintenance cycles reduce downtime and extend the printer’s lifespan. This ease of maintenance is crucial for minimizing disruptions and ensuring continuous production.

Technological Advancements in Vinyl Sticker Printers

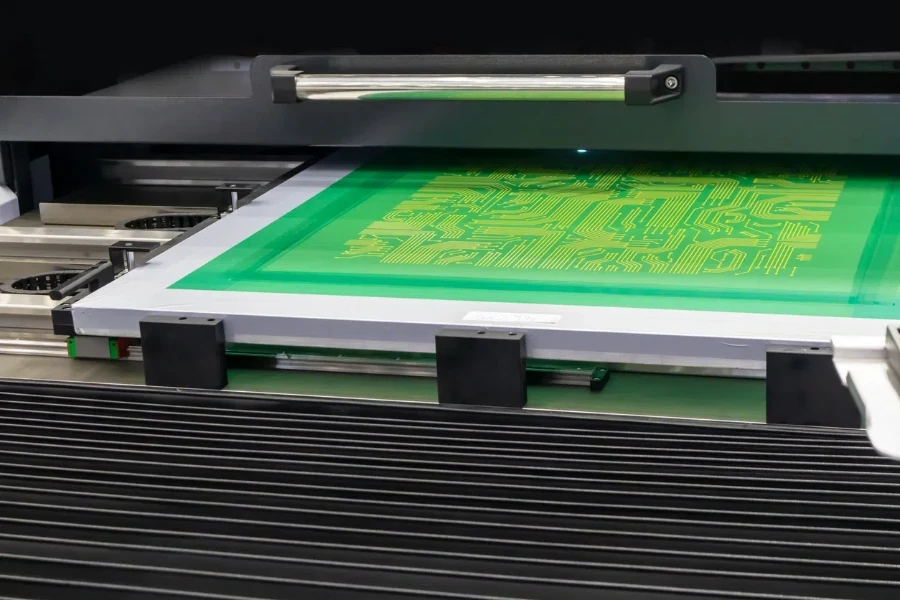

Tecnología de impresión UV

UV printing technology is a significant advancement in vinyl sticker printers. UV printers use ultraviolet light to cure or dry the ink as it is printed. This technology allows immediate handling of the printed stickers, as the ink is instantly cured, resulting in higher productivity and faster turnaround times.

UV printing also offers superior print quality compared to traditional methods. The cured ink provides vibrant colors and sharp details, ideal for high-resolution graphics. Additionally, UV printers can print on a wider range of materials, including non-porous surfaces like glass and metal. This versatility expands the applications of vinyl sticker printers beyond just vinyl stickers.

Furthermore, UV printing is more environmentally friendly. The inks used in UV printers are free from volatile organic compounds (VOCs), reducing harmful emissions. This makes UV printers a more sustainable choice for businesses looking to minimize their environmental impact.

Eco-Solvent Inks

Eco-solvent inks are another technological advancement in vinyl sticker printers. These inks are made from biodegradable solvents, making them less harmful to the environment compared to traditional solvent-based inks. Eco-solvent inks produce minimal odor and emissions, making them suitable for indoor environments.

In terms of performance, eco-solvent inks offer excellent adhesion to vinyl and other synthetic materials. They are also resistant to water and UV light, ensuring that the printed stickers are durable and long-lasting. This makes them ideal for outdoor applications where exposure to the elements is a concern.

Moreover, eco-solvent inks provide a wide color gamut, resulting in vibrant and accurate colors. This is particularly important for businesses that require precise color matching for branding purposes. The combination of environmental benefits and high performance makes eco-solvent inks a popular choice for modern vinyl sticker printers.

Wireless and Cloud Connectivity

Wireless and cloud connectivity in vinyl sticker printers have revolutionized business operations. Wireless connectivity allows seamless printing from multiple devices, including smartphones and tablets. This flexibility is particularly beneficial in dynamic work environments where mobility is essential.

Cloud connectivity enables remote printing and management. Users can upload designs to the cloud and print them from any location with an internet connection. This capability is ideal for businesses with multiple locations or remote teams. It also simplifies the process of updating designs and managing print jobs.

Cloud-based software often includes advanced features like analytics and reporting. These tools provide insights into printer usage, maintenance needs, and production efficiency. By leveraging cloud connectivity, businesses can optimize their printing operations and reduce downtime.

Normas y certificaciones de la industria

ISO 9001

ISO 9001 is an international standard specifying requirements for a quality management system (QMS). Vinyl sticker printers that are ISO 9001 certified consistently provide products meeting customer and regulatory requirements. This certification is a testament to the printer’s quality and reliability.

Choosing an ISO 9001 certified printer ensures businesses invest in a high-quality product. It also assures that the manufacturer follows rigorous quality control processes, reducing the risk of defects and malfunctions. This is particularly important for industrial applications where reliability is crucial.

ISO 9001 certification can enhance a business’s reputation. Customers and partners are more likely to trust and collaborate with companies that prioritize quality and adhere to international standards. This can lead to increased business opportunities and competitive advantage.

Marcado CE

The CE marking is a certification mark indicating conformity with health, safety, and environmental protection standards for products sold within the European Economic Area (EEA). Vinyl sticker printers with CE marking meet high safety, health, and environmental protection requirements.

For businesses operating in or exporting to Europe, CE marking is essential. It ensures the printer complies with European regulations, allowing for legal sale and distribution within the EEA. This certification also signifies that the product has undergone rigorous testing and meets stringent safety standards.

In addition to regulatory compliance, CE marking can be a mark of quality. It indicates that the manufacturer has taken steps to ensure the product’s safety and performance. This can provide peace of mind to users, knowing they are using a certified and reliable printer.

Energy Star

Energy Star is a government-backed program certifying products for energy efficiency. Vinyl sticker printers that have earned the Energy Star label meet strict energy efficiency guidelines set by the U.S. Environmental Protection Agency (EPA). These printers consume less energy, reducing operational costs and environmental impact.

Investing in Energy Star certified printers can lead to significant cost savings. Lower energy consumption translates to reduced utility bills, particularly beneficial for high-volume printing operations. Additionally, energy-efficient printers often have longer lifespans and lower maintenance costs.

Using Energy Star certified products can enhance a business’s sustainability efforts. It demonstrates a commitment to reducing environmental impact and promoting energy efficiency. This can improve a company’s reputation and appeal to environmentally conscious customers and partners.

Reflexiones Finales:

In summary, selecting the right vinyl sticker printer involves considering various factors such as printing width, resolution, media compatibility, speed, efficiency, software, interface, durability, and build quality. Technological advancements such as UV printing, eco-solvent inks, and wireless connectivity have significantly enhanced the capabilities of modern printers. Adhering to industry standards and certifications like ISO 9001, CE marking, and Energy Star ensures quality, safety, and energy efficiency. By carefully evaluating these aspects, businesses can invest in a vinyl sticker printer that meets their specific needs and supports their operational goals.