En 2025, el mercado de las cortadoras de carne comerciales está en auge gracias a los avances tecnológicos y al aumento del consumo de carne. Este artículo ofrece un análisis en profundidad de los factores clave que se deben tener en cuenta al seleccionar una cortadora de carne comercial, ofreciendo información valiosa y asistencia para los compradores profesionales que buscan tomar decisiones de compra informadas.

Índice:

– Panorama del mercado de las cortadoras de carne comerciales

– Análisis detallado y perspectivas del mercado

– Factores clave a la hora de seleccionar una cortadora de carne comercial

– Evaluación del rango de precios y presupuesto

– Evaluación de la durabilidad y la calidad

– Considerando estándares de seguridad y certificaciones

– Mantenimiento y limpieza de cortadoras de carne comerciales

- Pensamientos finales

Descripción general del mercado de cortadoras de carne comerciales

El mercado mundial de cortadoras de carne comerciales está experimentando un crecimiento significativo, impulsado por la creciente demanda de productos cárnicos procesados y los avances en las tecnologías de procesamiento de carne. En 2023, el tamaño del mercado de equipos de sacrificio, que incluye cortadoras de carne, se estimó en 7.5 millones de dólares. Se proyecta que alcance los 9.4 millones de dólares en 2030, con un crecimiento de CAGR del 3.4%. Este crecimiento se atribuye al aumento del consumo de productos cárnicos en todo el mundo, en particular en regiones como América del Norte y Europa, donde prevalecen el consumo de carne y la infraestructura avanzada de procesamiento de carne.

Norteamérica y Europa son los mercados más grandes para las cortadoras de carne comerciales debido a las estrictas normas regulatorias, el alto consumo de carne y la infraestructura avanzada de procesamiento de carne. Se estima que solo el mercado estadounidense alcanzaría los 2.0 millones de dólares en 2023. Mientras tanto, la región de Asia y el Pacífico está surgiendo como un área de alto crecimiento, impulsada por la expansión de la producción de carne, el aumento de la urbanización y el aumento de los ingresos disponibles. Se prevé que el mercado de China, por ejemplo, crezca a una impresionante tasa compuesta anual del 5.9% para alcanzar los 2.1 millones de dólares en 2030.

El mercado de las cortadoras de carne comerciales también se está beneficiando de los avances tecnológicos, en particular en automatización y robótica. El desarrollo de equipos de sacrificio inteligentes con capacidades de IoT e IA está mejorando la eficiencia y precisión operativas, reduciendo los costos laborales y asegurando una calidad y un rendimiento consistentes. Esto es particularmente importante en entornos de procesamiento de gran volumen, como plantas de procesamiento de carne y mataderos, donde la eficiencia y la productividad son fundamentales.

Análisis detallado y perspectivas del mercado

El mercado de las cortadoras de carne comerciales se caracteriza por varios parámetros de rendimiento clave y dinámicas de mercado que influyen en su crecimiento. Un factor principal es la creciente demanda de productos cárnicos procesados, que se espera que genere un volumen de mercado de 49.40 2029 millones de dólares en 15.86, con una tasa de crecimiento anual (CAGR) del 2024 % entre 2029 y XNUMX. Esta demanda se ve impulsada por factores como el crecimiento de la población, los cambios en los hábitos alimentarios y la comodidad que ofrecen los productos cárnicos procesados.

El comportamiento de los consumidores está cambiando hacia soluciones alimentarias más convenientes, lo que genera una mayor demanda de cortadoras de carne que puedan ofrecer cortes uniformes y precisos. Esto es particularmente relevante en la industria de servicios de alimentos, donde la eficiencia y la consistencia son primordiales. Se espera que el ingreso promedio por usuario (ARPU) en el mercado de carne procesada ascienda a $570.30 para 2029, lo que destaca la creciente disposición de los consumidores a invertir en productos cárnicos de alta calidad.

Los canales de distribución de las cortadoras de carne comerciales están evolucionando, con un cambio significativo hacia la digitalización. Se proyecta que el mercado de comercio electrónico de carne, incluida la carne fresca y procesada, alcance los 74.38 millones de dólares en 2024, con una CAGR del 13.55 % entre 2024 y 2029. Este cambio hacia las ventas en línea está impulsado por la creciente penetración de las plataformas digitales y la comodidad que ofrecen tanto a los consumidores como a las empresas. Empresas como Amazon, Tmall y JD son actores clave en este espacio, facilitando la compra y entrega en línea de productos cárnicos.

Las innovaciones recientes en el mercado de las cortadoras de carne comerciales incluyen la integración de tecnologías de IoT e IA, que permiten monitorear en tiempo real el rendimiento del equipo y programar el mantenimiento. Esto no solo reduce el tiempo de inactividad, sino que también optimiza el flujo de trabajo general de procesamiento de carne. Además, el desarrollo de sistemas energéticamente eficientes y tecnologías ambientalmente sostenibles está ganando terreno, lo que responde al creciente enfoque en la sostenibilidad en la industria de procesamiento de carne.

Factores clave a la hora de elegir una cortadora de carne comercial

Al elegir una cortadora de carne comercial, tenga en cuenta varios factores para asegurarse de que el equipo satisfaga sus necesidades. Esta sección explora los aspectos críticos que debe evaluar.

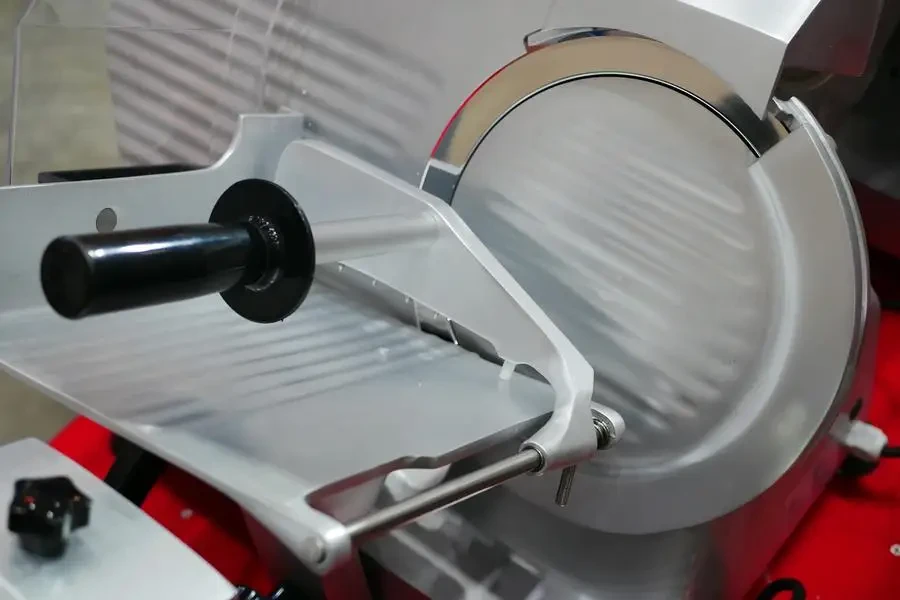

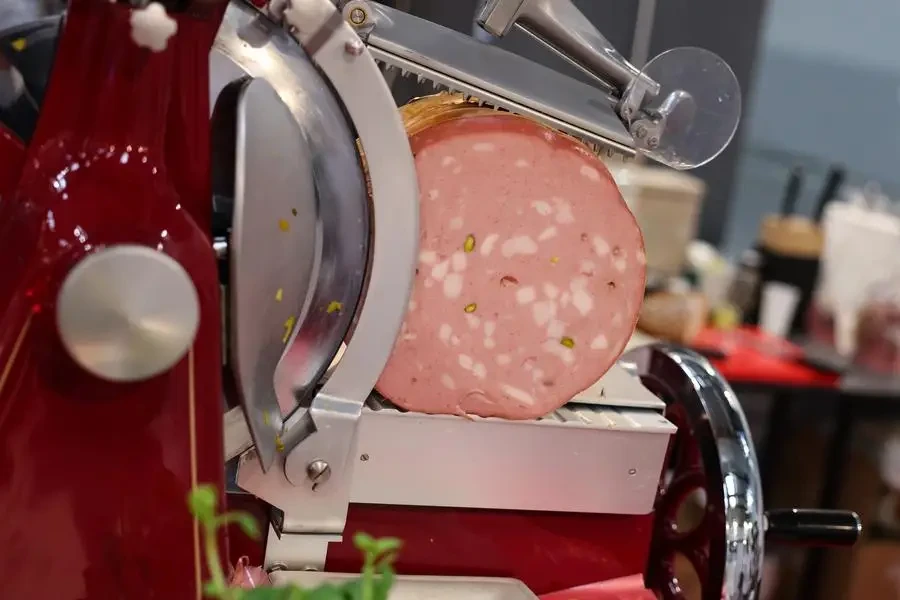

Tipos y estilos de cortadoras de carne

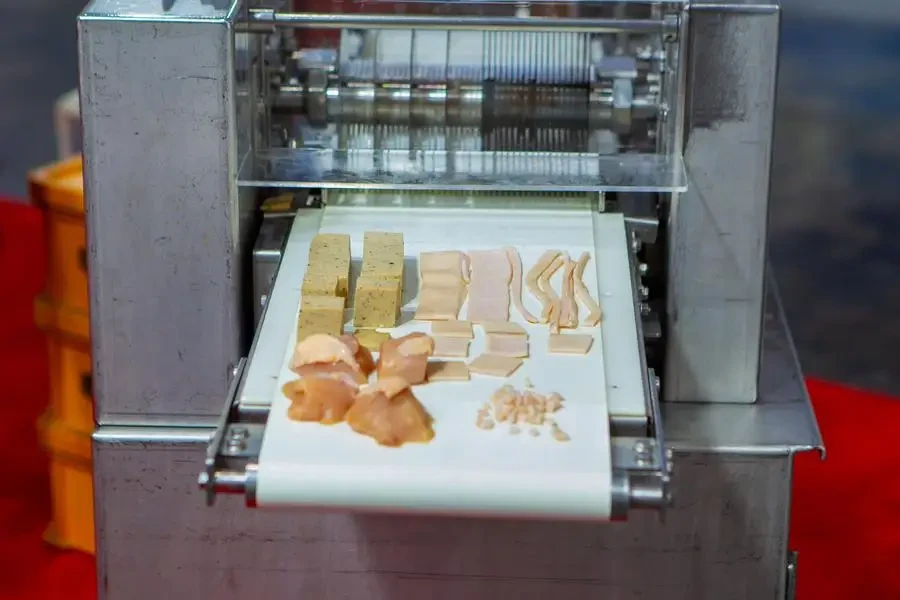

Las cortadoras de carne comerciales vienen en diferentes tipos y estilos, cada uno adecuado para aplicaciones específicas.

Las cortadoras manuales requieren que el operador mueva la bandeja de producto hacia adelante y hacia atrás, lo que ofrece control sobre el proceso de corte. Las cortadoras automáticas utilizan un motor para mover la bandeja, lo que las hace ideales para operaciones de gran volumen. Por ejemplo, la Hobart HS9-1 es una cortadora automática con una cuchilla de 13” y cuatro velocidades de corte, perfecta para tiendas de delicatessen concurridas.

Las cortadoras de alimentación por gravedad, como la Globe Chefmate C10, tienen una bandeja en ángulo que utiliza la gravedad para alimentar el producto hacia la cuchilla, lo que facilita el corte. Las cortadoras de alimentación vertical, por otro lado, requieren una alimentación manual, lo que ofrece más precisión para tareas de corte delicadas.

Rendimiento y funcionalidad

El rendimiento es un factor crítico, que abarca la potencia de la cortadora, el tamaño de la cuchilla y las capacidades de corte.

La potencia del motor (HP) determina la eficiencia con la que la cortadora puede manejar distintos volúmenes y tipos de productos. Por ejemplo, la Hobart HS9-1 cuenta con un motor de 1/2 HP adecuado para uso continuo, mientras que la Avantco SL713MAN tiene un motor de 3/4 HP para aplicaciones de uso medio.

El tamaño de la cuchilla afecta la capacidad de la cortadora para manejar productos más grandes. Las cortadoras con cuchillas de 13”, como la Centerline de Hobart EDGE-13, pueden adaptarse a cortes de carne más grandes en comparación con aquellas con cuchillas de 9” o 10”.

Los ajustes de grosor son esenciales para lograr precisión. El Globe G10, por ejemplo, ofrece grosores de corte de 0 a 9/16”, lo que permite opciones de corte versátiles.

Materiales y calidad de construcción

La durabilidad y la higiene de una cortadora de carne están influenciadas por los materiales utilizados en su construcción.

Las cortadoras de alta calidad suelen tener cuerpos de aluminio anodizado y hojas de acero inoxidable, que son resistentes a la corrosión y fáciles de limpiar. La Avantco SL713MAN, por ejemplo, combina una hoja de acero inoxidable con un cuerpo de aluminio anodizado para una mayor durabilidad.

Los afiladores incorporados, como el conjunto de afilador de piedra Borazon en el Hobart HS9-1, garantizan que la hoja se mantenga afilada, lo que reduce el tiempo de inactividad y mantiene la eficiencia del corte.

Normas de seguridad y certificaciones

Las características de seguridad son primordiales en las cortadoras de carne comerciales para evitar lesiones.

La mayoría de las cortadoras incluyen un protector de cuchillas para proteger al operador. La Globe Chefmate C10 incluye un protector de cuchillas para mejorar la seguridad del usuario.

Características como apagado automático y bloqueos, que se encuentran en el Hobart HS9-1, evitan que la cortadora funcione si ciertas piezas no están colocadas correctamente, lo que minimiza el riesgo de accidentes.

Este sistema, presente en el Globe G10, garantiza que la cortadora no se reinicie automáticamente después de un corte de energía, requiriendo que el usuario la reinicie manualmente, mejorando aún más la seguridad.

Facilidad de uso y mantenimiento

Los diseños fáciles de usar y el mantenimiento sencillo son cruciales para un funcionamiento eficiente.

Las cortadoras con componentes extraíbles, como la cubierta de la cuchilla y el afilador del Globe G10, facilitan una limpieza y un mantenimiento exhaustivos.

La limpieza regular es esencial para evitar la contaminación de los alimentos. La estructura de aluminio anodizado de la Avantco SL713MAN facilita su limpieza, mientras que los lubricantes de grado alimenticio garantizan el funcionamiento suave de las piezas móviles.

Evaluación del rango de precios y presupuesto

El precio de las cortadoras de carne comerciales varía significativamente según sus características, calidad de construcción y reputación de la marca.

Los modelos básicos son adecuados para un uso ligero y suelen costar entre 250 y 1,000 dólares. Por ejemplo, el Backyard Pro SL109E, con un precio de 249.99 dólares, es ideal para rebanar ocasionalmente en establecimientos pequeños.

Los modelos de gama media, con un precio de entre 1,000 y 5,000 dólares, ofrecen mayor durabilidad y características adicionales. El Avantco SL713MAN, a 1,199.00 dólares, es una excelente opción para trabajos medianos.

Las cortadoras de alta gama, como la Hobart HS9-1, pueden costar más de 10,000 XNUMX dólares. Están diseñadas para un uso intensivo y continuo y cuentan con funciones avanzadas de seguridad y rendimiento.

Evaluación de la durabilidad y la calidad

La longevidad de una cortadora de carne está determinada por su calidad de construcción y los materiales utilizados.

Las cuchillas fabricadas en acero inoxidable, como las del Avantco SL713MAN, son más duraderas y resistentes al óxido, lo que garantiza una vida útil más larga.

Las cortadoras con cuerpos de aluminio anodizado, como la Centerline de Hobart EDGE-13, ofrecen mayor durabilidad y facilidad de mantenimiento.

Tenga en cuenta la garantía y el servicio posventa que ofrece el fabricante. Marcas como Hobart y Globe son conocidas por su servicio de atención al cliente confiable y sus amplias garantías, que pueden ser cruciales para una inversión a largo plazo.

Considerando estándares de seguridad y certificaciones

El cumplimiento de las normas y certificaciones de seguridad es esencial para los equipos de cocina comerciales.

Busque cortadoras con certificación NSF, lo que garantiza que cumplen con los estrictos estándares de salud y seguridad pública. La Hobart HS9-1, por ejemplo, cuenta con certificación NSF, lo que garantiza que cumple con estos requisitos.

La certificación de Underwriters Laboratories (UL) indica que la cortadora ha sido sometida a pruebas de seguridad. Muchas cortadoras de alta calidad, incluidas las de Globe y Hobart, cuentan con esta certificación.

Mantenimiento y limpieza de cortadoras de carne comerciales

El mantenimiento y la limpieza adecuados son vitales para garantizar la longevidad y la higiene de una cortadora de carne.

Las cortadoras deben limpiarse a diario para evitar la acumulación de bacterias. Modelos como el Globe G10, con componentes extraíbles, simplifican este proceso.

Es necesario afilar la cuchilla con regularidad para mantener la eficiencia del corte. Los afiladores incorporados, como los de la Hobart HS9-1, facilitan esta tarea.

Utilice lubricantes de grado alimenticio para mantener las partes móviles de la cortadora, garantizando un funcionamiento suave y prolongando su vida útil.

Reflexiones Finales:

Para seleccionar la cortadora de carne comercial adecuada, es necesario evaluar diversos factores, como los tipos y estilos, el rendimiento, los materiales, la seguridad y la facilidad de uso. Si tiene en cuenta estos aspectos y comprende las necesidades específicas de su operación, podrá elegir una cortadora que mejore la eficiencia, la seguridad y la productividad en su cocina comercial.