Los recientes avances en la tecnología láser de fibra han revolucionado las industrias, lo que hace que 2025 sea un año crucial para los compradores comerciales. Este artículo profundiza en los aspectos críticos de la selección del grabador láser de fibra ideal, ofreciendo un análisis profundo y una guía práctica. Los compradores profesionales obtendrán información valiosa para tomar decisiones informadas y optimizar sus estrategias de adquisición.

Índice:

-Descripción general del mercado de grabadores láser de fibra

-Análisis detallado y conocimientos técnicos sobre grabadores láser de fibra

- Factores clave a la hora de seleccionar un grabador láser de fibra

-Tamaños y modelos disponibles

-Características de última tecnología

-Consideraciones sobre rango de precios y presupuesto

-Calidad de construcción y durabilidad

-Consideraciones similares para los equipos de procesamiento láser

-Cumplimiento normativo y estándares de la industria

-Complejidad de configuración inicial

-Compatibilidad con futuras actualizaciones

-Reflexiones finales

Descripción general del mercado de grabadores láser de fibra

El mercado de grabadores láser de fibra ha crecido significativamente en los últimos años y se espera que mantenga su tendencia al alza. Para 2025, se proyecta que el tamaño del mercado global de grabadores láser de fibra alcance los USD 5.8 mil millones, con una tasa de crecimiento anual compuesta (CAGR) del 9.8% entre 2020 y 2025. Este crecimiento está impulsado por la creciente demanda en sectores como el automotriz, aeroespacial, electrónico y de atención médica.

La región de Asia y el Pacífico lidera el mercado y representa alrededor del 40% de los ingresos globales. Este crecimiento se debe a la rápida industrialización, los avances tecnológicos y las importantes inversiones en infraestructura de fabricación. América del Norte y Europa también tienen cuotas de mercado sustanciales, impulsadas por las altas tasas de adopción de tecnologías de fabricación avanzadas y una fuerte presencia de actores clave del mercado.

La expansión del mercado se ve respaldada por el aumento de las aplicaciones de grabadores láser de fibra en la fabricación de precisión y el procesamiento de materiales. Las industrias que requieren diseños intrincados y marcas duraderas, como la electrónica y los dispositivos médicos, han impulsado especialmente la demanda de soluciones de grabado de alta velocidad y alta precisión.

Análisis detallado y conocimientos técnicos sobre los grabadores láser de fibra

Los grabadores láser de fibra producen grabados precisos y de alta calidad en diversos materiales, incluidos metales, plásticos y cerámicas. Los parámetros de rendimiento clave incluyen una alta calidad del haz (M² < 1.1), una potencia de salida que varía de 20 W a 100 W y longitudes de onda operativas de alrededor de 1064 nm. Estas especificaciones permiten que los grabadores láser de fibra alcancen una precisión y una velocidad superiores en comparación con los láseres de CO2 tradicionales.

El mercado es competitivo y cuenta con empresas líderes como IPG Photonics, TRUMPF y Coherent Corp. Estas empresas se centran en la innovación continua y en el desarrollo de sistemas láser avanzados. Por ejemplo, IPG Photonics ha introducido láseres de fibra de alta potencia con una calidad y una eficiencia de haz mejoradas para satisfacer la demanda de soluciones de grabado de alto rendimiento.

Las influencias económicas, como el impulso hacia la automatización y la Industria 4.0, han tenido un impacto significativo en el mercado de grabadores láser de fibra. Las empresas están adoptando cada vez más sistemas de grabado automatizados para mejorar la eficiencia de la producción y reducir los costos laborales. Además, el cambio hacia la sostenibilidad ha llevado al desarrollo de sistemas láser energéticamente eficientes que minimizan el impacto ambiental.

Las tendencias de comportamiento de los consumidores muestran una preferencia creciente por productos personalizables y de alta precisión, lo que impulsa la demanda de grabadores láser de fibra en mercados especializados. Por ejemplo, la industria de la joyería depende de estos grabadores para diseños intrincados y grabados personalizados. De manera similar, la industria de dispositivos médicos utiliza láseres de fibra para marcar y grabar componentes críticos con alta precisión y confiabilidad.

Las innovaciones recientes en el mercado incluyen la integración de algoritmos de inteligencia artificial (IA) y aprendizaje automático (ML) para optimizar los procesos de grabado. Estos avances permiten realizar ajustes y monitoreo en tiempo real, lo que mejora la precisión y reduce el desperdicio de material. Además, la digitalización y los sistemas láser habilitados para IoT permiten una integración perfecta con los flujos de trabajo de fabricación, lo que mejora la eficiencia operativa y las capacidades de análisis de datos.

A medida que el mercado evoluciona, sigue siendo crucial abordar los problemas de los clientes, como los altos costos iniciales y los requisitos de mantenimiento. Las empresas se están centrando en ofrecer paquetes de servicios integrales y opciones de financiación para que los grabadores láser de fibra avanzados sean más accesibles para una gama más amplia de empresas. El desarrollo de sistemas láser compactos y portátiles satisface las necesidades de las pequeñas y medianas empresas (PYME), lo que impulsa aún más el crecimiento del mercado.

Factores clave a la hora de seleccionar un grabador láser de fibra

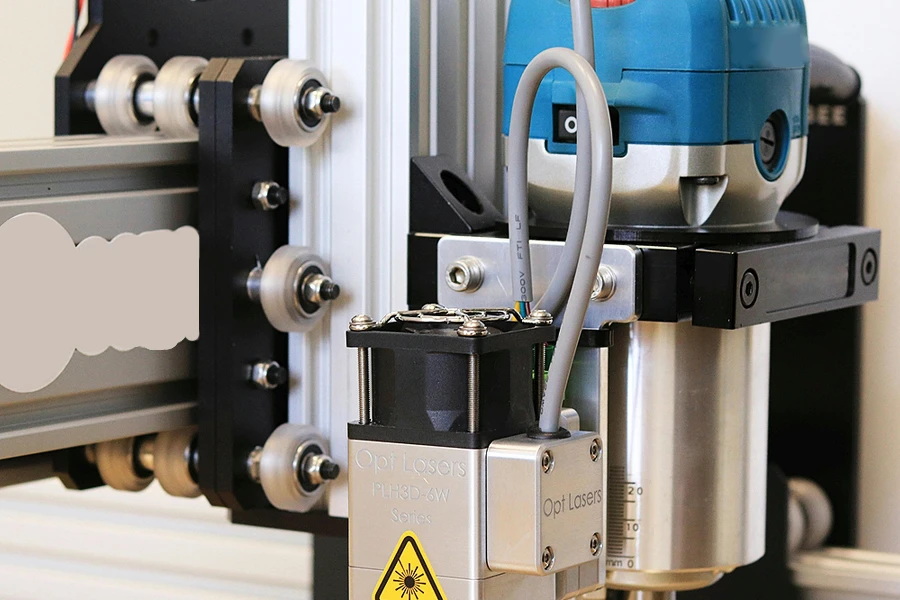

Tipos y Estilos

Al seleccionar un grabador láser de fibra, tenga en cuenta los diferentes tipos y estilos disponibles. Los grabadores láser de fibra se pueden clasificar en modelos portátiles, de sobremesa e industriales. Los modelos portátiles son ligeros y compactos, ideales para operaciones in situ donde la movilidad es crucial. Los modelos de sobremesa ofrecen un equilibrio entre portabilidad y potencia, adecuados para talleres pequeños y medianos. Los modelos industriales están diseñados para entornos de producción de gran volumen, proporcionando un rendimiento sólido y durabilidad.

La elección del tipo y el estilo influyen en la eficiencia operativa y el rango de aplicación del grabador. Por ejemplo, los modelos industriales suelen tener funciones avanzadas como sistemas automáticos de manipulación de materiales, lo que mejora la productividad y reduce los costos de mano de obra. Los modelos de sobremesa pueden incluir interfaces y software fáciles de usar para un control preciso de los parámetros de grabado, mientras que los modelos portátiles están optimizados para facilitar su uso y su configuración rápida.

Rendimiento y funcionalidad

Las métricas de rendimiento, como la potencia de salida, la velocidad de grabado y la precisión, son fundamentales a la hora de evaluar un grabador láser de fibra. La potencia de salida, medida en vatios, determina la capacidad del grabador para manejar diversos materiales y espesores. Los modelos de mayor potencia pueden grabar materiales más gruesos y duros, como metales, mientras que los modelos de menor potencia son adecuados para materiales más blandos, como plásticos y madera.

La velocidad de grabado, medida en milímetros por segundo (mm/s), afecta el rendimiento y la eficiencia del proceso de grabado. Los modelos avanzados ofrecen capacidades de grabado de alta velocidad, esenciales para cumplir con plazos de producción ajustados. La precisión es otro factor vital, ya que los modelos de alta gama brindan una precisión de nivel micrométrico, lo que garantiza que los diseños detallados e intrincados se reproduzcan fielmente.

Design

El diseño de un grabador láser de fibra puede influir en su integración en los flujos de trabajo existentes y en la experiencia del usuario. Los diseños ergonómicos que facilitan el acceso al área de trabajo, los paneles de control intuitivos y las configuraciones personalizables pueden mejorar significativamente la comodidad y la productividad del usuario.

Los grabadores láser de fibra modernos suelen tener diseños compactos que minimizan el espacio que ocupan en un taller. Esto es especialmente importante en entornos con espacio limitado. Algunos modelos están diseñados con componentes modulares, lo que permite realizar actualizaciones y realizar tareas de mantenimiento con facilidad.

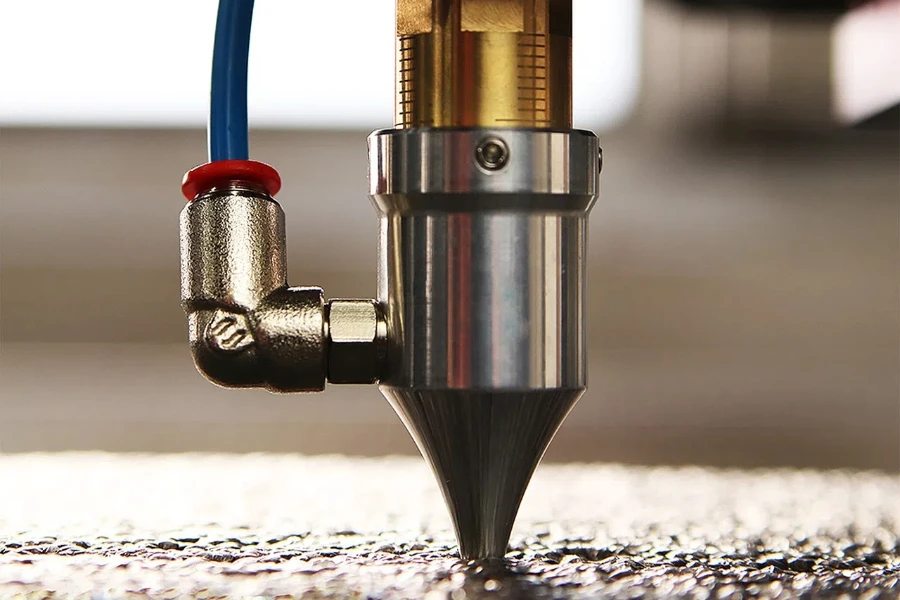

Especificaciones técnicas

Las especificaciones técnicas, como la longitud de onda, la calidad del haz y los sistemas de refrigeración, desempeñan un papel crucial en el rendimiento y la fiabilidad de un grabador láser de fibra. La longitud de onda del láser, que suele rondar los 1064 nm en el caso de los láseres de fibra, afecta a las características de absorción de los distintos materiales, lo que influye en la calidad y la eficiencia del proceso de grabado.

La calidad del haz, a menudo representada por el factor M2, determina la capacidad de enfoque del haz láser. Un valor M2 más bajo indica un haz de mayor calidad que se puede enfocar en un tamaño de punto más pequeño, lo que da como resultado detalles de grabado más finos. Los sistemas de refrigeración eficientes, ya sea por aire o por agua, son esenciales para mantener un funcionamiento estable y prolongar la vida útil de los componentes del láser.

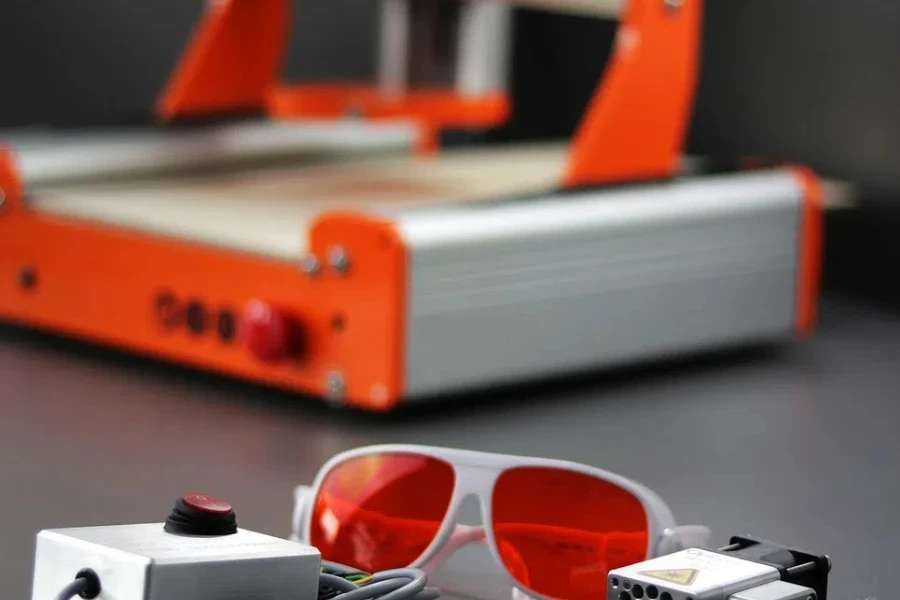

Normas de seguridad y certificaciones

El cumplimiento de las normas y certificaciones de seguridad es fundamental a la hora de seleccionar un grabador láser de fibra. Estas máquinas se clasifican en función de sus posibles peligros: la clase 1 es la más segura y la clase 4 requiere medidas de seguridad estrictas. Es fundamental garantizar que el grabador cumpla con las normas internacionales, como la IEC 60825 para la seguridad del láser y las certificaciones ISO pertinentes para la calidad de fabricación.

Las características de seguridad, como los sistemas de interbloqueo, los gabinetes de protección y los botones de parada de emergencia, son fundamentales para prevenir accidentes y garantizar un funcionamiento seguro. Los manuales de usuario completos y los recursos de capacitación proporcionados por el fabricante pueden ayudar a los operadores a comprender y mitigar los posibles riesgos.

Tallas y modelos disponibles

Los grabadores láser de fibra vienen en varios tamaños y modelos, para satisfacer diferentes necesidades operativas. Los modelos compactos están diseñados para operaciones a pequeña escala y espacios de trabajo limitados, y ofrecen portabilidad y facilidad de uso. Estos modelos son ideales para pequeñas empresas, aficionados o talleres con limitaciones de espacio. A pesar de su pequeño tamaño, muchos modelos compactos no comprometen el rendimiento, ya que ofrecen alta precisión y potencia adecuada para una variedad de materiales.

Los modelos de tamaño mediano son adecuados para empresas que requieren un equilibrio entre potencia y espacio. Estos modelos suelen incluir características mejoradas, como áreas de trabajo más grandes, mayor potencia de salida y funciones de software avanzadas. Son versátiles y pueden manejar una gama más amplia de materiales y aplicaciones, lo que los convierte en una opción popular para las empresas de tamaño mediano.

Los modelos industriales de gran tamaño están diseñados para entornos de producción de gran volumen. Estos modelos cuentan con amplias áreas de trabajo, salidas de alta potencia y una construcción robusta para soportar un funcionamiento continuo. Están equipados con funciones de automatización avanzadas, como sistemas de transporte y brazos robóticos, para mejorar la productividad y reducir la intervención manual. Los modelos industriales son ideales para grandes instalaciones de fabricación que requieren un grabado uniforme y de alta calidad en diversos materiales.

Características de la última tecnología

Los grabadores láser de fibra más modernos incorporan tecnología de vanguardia para mejorar el rendimiento, la precisión y la experiencia del usuario. Los sistemas de control de movimiento avanzados, como los escáneres galvanométricos, ofrecen un posicionamiento preciso y de alta velocidad del haz láser, lo que permite realizar diseños intrincados y complejos. Estos sistemas son fundamentales para aplicaciones que requieren alta precisión y velocidad, como el micromecanizado y el grabado detallado.

La integración con el software CAD/CAM permite procesos de diseño y grabado sin inconvenientes. Los grabadores modernos cuentan con interfaces fáciles de usar y son compatibles con el software de diseño más conocido, lo que permite a los operadores importar y editar diseños fácilmente. Esta integración agiliza el flujo de trabajo y reduce el tiempo necesario para la configuración y los ajustes de diseño.

Algunos modelos cuentan con sistemas de monitoreo y diagnóstico en tiempo real. Estos sistemas brindan información continua sobre el rendimiento de la máquina y alertan a los operadores sobre posibles problemas antes de que se vuelvan críticos. Esta capacidad de mantenimiento predictivo ayuda a minimizar el tiempo de inactividad y a extender la vida útil de la grabadora.

Rango de precios y consideraciones presupuestarias

El rango de precios de los grabadores láser de fibra varía significativamente en función de su tamaño, potencia, características y marca. Los modelos básicos adecuados para pequeñas empresas o aficionados pueden oscilar entre $5,000 y $15,000 XNUMX. Estos modelos ofrecen una funcionalidad básica y son ideales para un uso ligero a moderado. Proporcionan una solución rentable para las empresas que buscan incorporar el grabado láser sin una inversión significativa.

Los modelos de gama media, cuyo precio oscila entre 15,000 y 50,000 dólares, ofrecen características mejoradas, como mayor potencia de salida, áreas de trabajo más amplias y funciones de software avanzadas. Estos modelos son adecuados para empresas medianas que requieren un equilibrio entre coste y rendimiento. Ofrecen una mayor durabilidad y pueden manejar una gama más amplia de materiales y aplicaciones.

Los modelos industriales de alta gama pueden tener un precio que va desde los 50,000 dólares hasta los 200,000 dólares. Estos modelos están diseñados para entornos de producción de gran volumen y cuentan con funciones de automatización avanzadas, salidas de alta potencia y una construcción robusta. Ofrecen el más alto nivel de rendimiento y confiabilidad, lo que los hace adecuados para grandes instalaciones de fabricación que requieren un grabado consistente y de alta calidad.

Calidad y durabilidad de construcción

La calidad de construcción y la durabilidad de un grabador láser de fibra son factores críticos que influyen en su rendimiento y longevidad. Los materiales de construcción de alta calidad, como el acero y el aluminio de calidad industrial, garantizan que el grabador pueda soportar los rigores del funcionamiento continuo. Una calidad de construcción robusta reduce el riesgo de fallas mecánicas y extiende la vida útil de la máquina.

La durabilidad también depende de la calidad de los componentes utilizados en el grabador. Las fuentes láser, los sistemas ópticos y de control de movimiento de alta calidad contribuyen a un rendimiento constante y reducen los requisitos de mantenimiento. El mantenimiento regular y el uso adecuado pueden mejorar significativamente la durabilidad del grabador.

Los fabricantes suelen ofrecer garantías y acuerdos de servicio que cubren las piezas y la mano de obra durante un período determinado. Estas garantías ofrecen tranquilidad y protección frente a costes de reparación inesperados. Además, los fabricantes con reputación de calidad y fiabilidad tienen más probabilidades de producir grabadores duraderos y de larga duración.

Consideraciones similares para los equipos de procesamiento láser

Al considerar el equipo de procesamiento láser, factores similares como el rendimiento, la funcionalidad y la calidad de construcción son cruciales. El equipo de procesamiento láser, incluidas las máquinas de corte y soldadura, también requiere una evaluación cuidadosa de la potencia de salida, la velocidad y la precisión. La elección del tipo de láser, como CO2 o Nd:YAG, afecta la idoneidad del equipo para diferentes materiales y aplicaciones.

Las funciones de automatización, como los controladores CNC y los brazos robóticos, mejoran la productividad y reducen la intervención manual. Estas funciones son especialmente importantes para entornos de producción de gran volumen donde la eficiencia y la consistencia son fundamentales. Las normas y certificaciones de seguridad también son esenciales para garantizar un funcionamiento seguro y el cumplimiento de las normas de la industria.

Cumplimiento normativo y estándares industriales

El cumplimiento normativo y las normas de la industria son fundamentales para garantizar la seguridad, el rendimiento y la fiabilidad de los grabadores láser de fibra. El cumplimiento de normas como la IEC 60825 para la seguridad del láser y las certificaciones ISO para la calidad de fabricación garantiza que el grabador cumpla con estrictos criterios de seguridad y rendimiento. Los fabricantes que cumplen estas normas ofrecen garantía de calidad y fiabilidad.

Los estándares de la industria también influyen en el diseño y la funcionalidad del grabador. Por ejemplo, el cumplimiento de los requisitos de marcado CE indica que el grabador cumple con los estándares de seguridad, salud y protección ambiental de la Unión Europea. Estas certificaciones son importantes para las empresas que operan en mercados regulados y requieren el cumplimiento de estándares internacionales.

Complejidad de la configuración inicial

La complejidad de la configuración inicial puede variar según el modelo y las características del grabador láser de fibra. Los modelos básicos suelen estar diseñados para facilitar su uso y su configuración rápida, lo que los hace adecuados para pequeñas empresas y aficionados. Estos modelos suelen venir con instrucciones de configuración detalladas e interfaces fáciles de usar que simplifican el proceso de instalación.

Los modelos de gama media y alta pueden requerir procedimientos de configuración más complejos, que incluyen calibración, instalación de software e integración con sistemas existentes. Los fabricantes suelen proporcionar asistencia técnica y recursos de formación para ayudar con el proceso de configuración. Una configuración adecuada es esencial para garantizar un rendimiento óptimo y evitar posibles problemas durante el funcionamiento.

Compatibilidad con futuras actualizaciones

La compatibilidad con futuras actualizaciones es un factor importante para las empresas que buscan invertir en grabadores láser de fibra. A medida que avanza la tecnología, la capacidad de actualizar los componentes y el software puede extender la vida útil del grabador y mejorar sus capacidades. Los diseños modulares que permiten un reemplazo y actualización sencillos de los componentes son particularmente beneficiosos.

Los fabricantes que ofrecen actualizaciones de software periódicas y soporte para nuevas funciones garantizan que el grabador se mantenga actualizado con la última tecnología. La compatibilidad con futuras actualizaciones también brinda flexibilidad a las empresas para adaptarse a los requisitos de producción cambiantes e incorporar nuevas funcionalidades según sea necesario.

Reflexiones Finales:

En conclusión, la selección del grabador láser de fibra adecuado implica una consideración cuidadosa de factores como los tipos, el rendimiento, el diseño, las especificaciones técnicas, los estándares de seguridad y el cumplimiento normativo. La evaluación de estos factores garantiza que el grabador elegido satisfaga las necesidades específicas de la empresa y ofrezca resultados consistentes y de alta calidad. Invertir en un grabador duradero y de alta calidad con funciones avanzadas y potencial de actualización proporcionará beneficios a largo plazo y mejorará la productividad general.