En 2025, el mercado mundial de esterilizadores seguirá expandiéndose, impulsado por las innovaciones y la creciente demanda. Este artículo ofrece un análisis profundo del mercado de esterilizadores, que abarca los tipos, el rendimiento, las especificaciones técnicas, los estándares de seguridad y más. Ofrece información valiosa para ayudar a los compradores profesionales a tomar decisiones informadas.

Índice:

– El mercado de esterilizadores: una visión general completa

– Análisis en profundidad del mercado de esterilizadores

– Factores clave a la hora de seleccionar un esterilizador

– Avances en la tecnología de esterilización

– Cumplimiento Normativo en Esterilización

- Pensamientos finales

El mercado de esterilizadores: una visión general completa

El mercado mundial de esterilizadores ha experimentado un crecimiento significativo, impulsado por la creciente demanda en el ámbito sanitario y en diversas aplicaciones industriales. En 2024, el tamaño del mercado se estimó en 2.5 millones de dólares y se prevé que alcance los 3.3 millones de dólares en 2030, creciendo a una tasa de crecimiento anual compuesta (CAGR) del 4.1 %. Los esterilizadores son fundamentales para mantener la higiene y prevenir la contaminación, especialmente en entornos médicos y de laboratorio. El mercado incluye diferentes tipos de esterilizadores, como autoclaves, esterilizadores de calor seco y equipos de esterilización por microondas.

América del Norte posee la mayor participación de mercado debido a la alta prevalencia de infecciones asociadas a la atención médica y a las estrictas normas regulatorias. Europa le sigue de cerca, con importantes inversiones en infraestructura de atención médica y avances en métodos de esterilización. Se espera que la región de Asia y el Pacífico registre la tasa de crecimiento más alta, impulsada por el aumento del gasto en atención médica, la creciente conciencia sobre la higiene y la expansión de las instalaciones médicas. Factores como la creciente demanda de esterilización en los sectores farmacéutico y biotecnológico y el desarrollo de tecnologías de esterilización avanzadas influyen en la dinámica del mercado.

Las recientes innovaciones en tecnología de esterilización han impulsado aún más el crecimiento del mercado. Por ejemplo, los equipos de esterilización por microondas han ganado popularidad debido a su eficiencia y seguridad. Esta tecnología utiliza radiación de microondas para esterilizar dispositivos e instrumentos médicos, ofreciendo una alternativa más rápida y eficaz a los métodos tradicionales. La adopción de soluciones digitales y procesos de esterilización automatizados también está aumentando, mejorando la eficiencia operativa y garantizando el cumplimiento de estrictas normas de higiene.

Análisis en profundidad del mercado de esterilizadores

El mercado de esterilizadores se caracteriza por parámetros de rendimiento clave que definen su panorama competitivo. Los principales actores como Getinge AB, STERIS Corporation y Belimed AG dominan el mercado y representan una parte importante de los ingresos generales. Estas empresas han establecido un sólido posicionamiento de marca a través de la innovación continua, adquisiciones estratégicas y expansiones de la cartera de productos. Por ejemplo, la adquisición de Cantel Medical por parte de STERIS Corporation en 2021 impulsó significativamente su presencia en el mercado y su oferta de productos.

Los factores económicos, como el aumento del gasto sanitario y las iniciativas gubernamentales para mejorar el saneamiento y la higiene, han tenido un impacto positivo en el mercado de los esterilizadores. La pandemia de COVID-19 puso de relieve la importancia de una esterilización eficaz, lo que provocó un aumento de la demanda de equipos de esterilización en hospitales, laboratorios y clínicas. El comportamiento de los consumidores también ha cambiado, ya que una mayor conciencia sobre la higiene y el control de infecciones ha impulsado la adopción de esterilizadores en entornos residenciales y comerciales.

Los canales de distribución de esterilizadores varían, con una preferencia por las ventas directas y las plataformas en línea. Los canales de venta directa permiten a los fabricantes construir relaciones sólidas con los usuarios finales, brindando soluciones personalizadas y soporte posventa. Las plataformas en línea ofrecen conveniencia y accesibilidad, lo que permite a los clientes comparar productos y tomar decisiones de compra informadas. Las innovaciones en el mercado incluyen el desarrollo de esterilizadores portátiles y compactos, que atienden la creciente demanda de soluciones de esterilización flexibles y móviles.

Las etapas del ciclo de vida de los esterilizadores varían: algunos productos se encuentran en la etapa de madurez, mientras que otros se encuentran en la fase de crecimiento. Los autoclaves y los esterilizadores de calor seco se consideran productos maduros, con una presencia establecida en el mercado y una demanda estable. Por el contrario, los equipos de esterilización por microondas y los esterilizadores inteligentes se encuentran en la fase de crecimiento, impulsados por los avances tecnológicos y la creciente adopción en varios sectores. La digitalización y la automatización son tendencias clave que dan forma al mercado, y los fabricantes integran IoT y tecnologías inteligentes para mejorar la funcionalidad y la eficiencia de los esterilizadores.

Factores clave a la hora de elegir un esterilizador

Al seleccionar un esterilizador, se deben considerar cuidadosamente varios factores clave para garantizar que satisfaga las necesidades específicas de la aplicación. Estos factores incluyen tipos y estilos, rendimiento y funcionalidad, especificaciones técnicas, estándares y certificaciones de seguridad y características o accesorios adicionales.

Tipos y estilos de esterilizadores

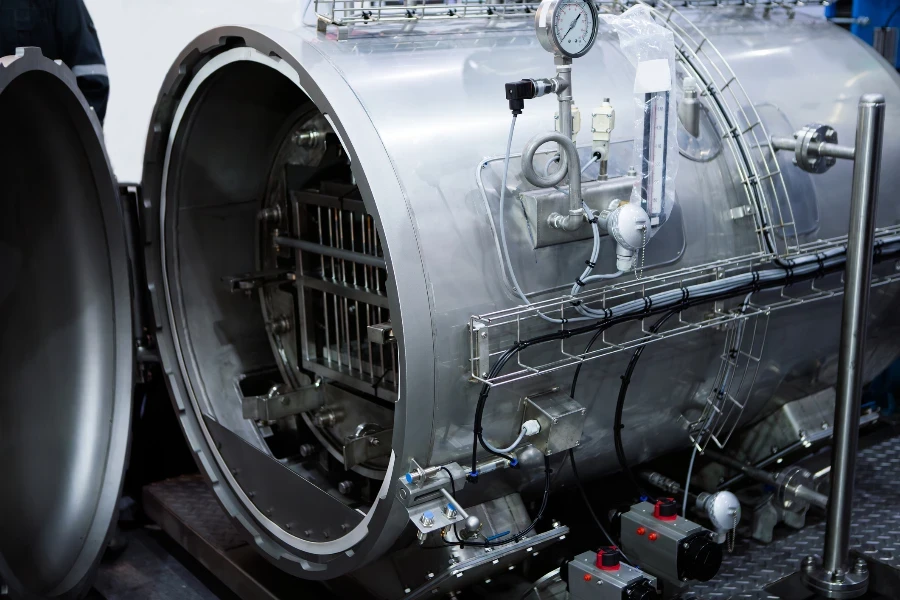

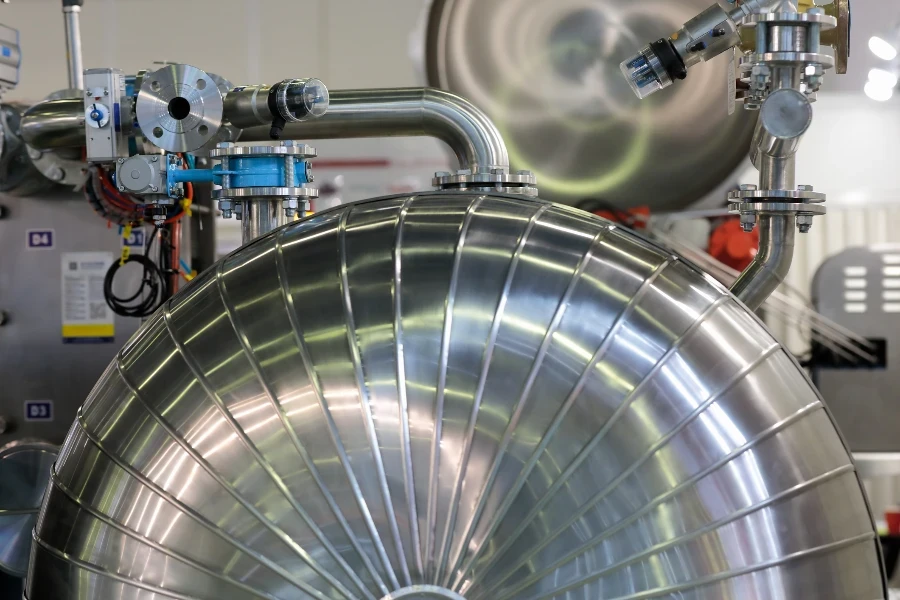

El tipo y estilo de esterilizador son consideraciones fundamentales, ya que determinan su idoneidad para diferentes aplicaciones. Existen varios tipos de esterilizadores, incluidos los esterilizadores a vapor, los esterilizadores de óxido de etileno (EO) y los esterilizadores ultravioleta (UV). Los esterilizadores a vapor, o autoclaves, se utilizan comúnmente en entornos médicos y de laboratorio debido a su capacidad para esterilizar una amplia gama de materiales utilizando vapor saturado a alta presión. Son muy eficaces contra bacterias, virus y esporas.

Los esterilizadores de EO utilizan gas de óxido de etileno para lograr la esterilización. Son ideales para materiales sensibles al calor y a la humedad, como ciertos plásticos y productos electrónicos. Los esterilizadores de EO se utilizan ampliamente en la industria de dispositivos médicos para artículos que no pueden soportar las altas temperaturas de la esterilización con vapor.

Los esterilizadores UV emplean radiación germicida ultravioleta (UVGI) para desinfectar el aire, el agua y las superficies. Son cada vez más populares en los entornos sanitarios por su capacidad para inactivar microorganismos sin productos químicos. Los esterilizadores UV son adecuados para la desinfección continua de superficies y aire en zonas de mucho tráfico.

Rendimiento y funcionalidad

El rendimiento y la funcionalidad son fundamentales a la hora de seleccionar un esterilizador. El tiempo de ciclo, la capacidad y la eficiencia del esterilizador deben estar en consonancia con las necesidades operativas. Por ejemplo, en un entorno hospitalario de gran volumen, un esterilizador con un tiempo de ciclo corto y una gran capacidad puede procesar numerosos instrumentos rápidamente, lo que garantiza un suministro continuo de equipo estéril.

La eficiencia del esterilizador en términos de consumo de energía y agua también es importante. Los esterilizadores modernos están diseñados para ser energéticamente eficientes, lo que reduce los costos operativos y el impacto ambiental. Características como los ciclos de prevacío y el secado posterior al vacío mejoran el rendimiento general al garantizar una esterilización y un secado completos de los instrumentos.

La funcionalidad también incluye facilidad de uso y mantenimiento. Los esterilizadores con interfaces fáciles de usar, ciclos programables y procesos automatizados reducen la probabilidad de error humano y mejoran la eficiencia del flujo de trabajo. Además, el mantenimiento y el servicio sencillos prolongan la vida útil del equipo y garantizan un rendimiento constante.

Especificaciones técnicas

Las especificaciones técnicas brindan información detallada sobre las capacidades del esterilizador. Las especificaciones clave incluyen el rango de temperatura, los niveles de presión y los ciclos de esterilización. En el caso de los esterilizadores a vapor, la temperatura suele oscilar entre 121 °C y 134 °C, con niveles de presión entre 15 y 30 psi. Estos parámetros garantizan la eliminación eficaz de todas las formas de vida microbiana.

El tamaño y las dimensiones del esterilizador también son cruciales, sobre todo en instalaciones con espacio limitado. Existen modelos compactos para clínicas y laboratorios más pequeños, mientras que las unidades más grandes son adecuadas para hospitales y aplicaciones industriales. Los materiales de construcción, como el acero inoxidable, garantizan durabilidad y resistencia a la corrosión, lo que es esencial para mantener los estándares de higiene.

Otra especificación importante es el cumplimiento de los estándares regulatorios por parte del esterilizador. Los esterilizadores deben cumplir con las estrictas pautas establecidas por organizaciones como la FDA, la CE y la ISO. Estas certificaciones garantizan que el esterilizador ha sido probado y aprobado en términos de seguridad y eficacia.

Normas de seguridad y certificaciones

Las normas y certificaciones de seguridad no son negociables a la hora de seleccionar un esterilizador. Los esterilizadores deben cumplir con las normas de seguridad nacionales e internacionales para garantizar que funcionen de forma segura y eficaz. Es fundamental cumplir con las normas establecidas por organizaciones como la Organización Internacional de Normalización (ISO) y la Administración de Alimentos y Medicamentos (FDA).

Estas normas cubren diversos aspectos, como el proceso de esterilización, los materiales de construcción y la seguridad operativa. Por ejemplo, la certificación ISO 13485 garantiza que el esterilizador cumple con los requisitos del sistema de gestión de calidad para dispositivos médicos, mientras que la aprobación de la FDA indica que el esterilizador es seguro para su uso en entornos sanitarios.

Las características de seguridad, como válvulas de alivio de presión, apagado automático y sistemas de alarma, mejoran la seguridad del esterilizador. Estas características evitan accidentes y garantizan que el esterilizador funcione dentro de parámetros seguros. El mantenimiento y la calibración regulares también son necesarios para mantener el cumplimiento de las normas de seguridad.

Funciones y accesorios adicionales

Las características y accesorios adicionales pueden mejorar la funcionalidad y la comodidad de un esterilizador. Algunos esterilizadores vienen con impresoras integradas o puertos USB para el registro de datos y el seguimiento de los ciclos de esterilización. Esta característica es particularmente útil para mantener registros y garantizar la trazabilidad en entornos de atención médica y de laboratorio.

Otros accesorios incluyen bandejas, contenedores y bastidores de esterilización que optimizan la carga y la disposición de los instrumentos. Estos accesorios mejoran la eficiencia del proceso de esterilización al garantizar la exposición adecuada al agente esterilizante. Algunos esterilizadores también ofrecen capacidades de control y monitoreo remoto, lo que permite a los operadores administrar el proceso de esterilización a distancia.

Los esterilizadores avanzados pueden incluir funciones como bombas de vacío, sistemas de ahorro de agua y opciones de enfriamiento rápido. Estas funciones no solo mejoran el rendimiento del esterilizador, sino que también contribuyen a la conservación de energía y agua. Al seleccionar un esterilizador con la combinación adecuada de funciones y accesorios, los usuarios pueden lograr resultados de esterilización óptimos y mejorar la eficiencia general.

Avances en la tecnología de esterilización

Los recientes avances en la tecnología de esterilización han mejorado significativamente la eficiencia, la seguridad y la eficacia de los esterilizadores. Innovaciones como la esterilización por plasma, la esterilización con vapor de peróxido de hidrógeno (HPV) y la esterilización con ozono ofrecen métodos alternativos para lograr una desinfección de alto nivel.

La esterilización por plasma utiliza gas de peróxido de hidrógeno a baja temperatura para esterilizar instrumentos y dispositivos médicos. Este método es particularmente eficaz para artículos sensibles al calor y a la humedad, ya que proporciona un proceso de esterilización rápido y sin residuos. Los esterilizadores de plasma se utilizan cada vez más en hospitales y centros de atención médica por su capacidad de lograr una desinfección de alto nivel sin el uso de productos químicos tóxicos.

La esterilización por VPH implica el uso de peróxido de hidrógeno vaporizado para lograr la esterilización. Este método es muy eficaz contra un amplio espectro de microorganismos, incluidas bacterias, virus y esporas. Los esterilizadores por VPH se utilizan habitualmente en entornos hospitalarios para la desinfección de salas terminales y la esterilización de dispositivos médicos complejos.

La esterilización con ozono emplea gas ozono para lograr la esterilización. El ozono es un poderoso agente oxidante que destruye eficazmente los microorganismos. Los esterilizadores de ozono son adecuados para una amplia gama de aplicaciones, incluida la esterilización de instrumentos médicos, equipos de laboratorio y productos farmacéuticos. Este método es respetuoso con el medio ambiente, ya que el ozono se descompone en oxígeno y no deja residuos nocivos.

Cumplimiento normativo en esterilización

El cumplimiento normativo es un aspecto fundamental de la esterilización en entornos industriales y sanitarios. Los esterilizadores deben cumplir con las estrictas pautas y normas establecidas por organismos reguladores como la FDA, la CE y la ISO. Estas normas garantizan que los esterilizadores sean seguros, eficaces y fiables para su uso en diversas aplicaciones.

La FDA proporciona pautas para la validación y verificación de los procesos de esterilización, garantizando que los esterilizadores alcancen constantemente el nivel requerido de desinfección. El cumplimiento de las normas de la FDA es obligatorio para los esterilizadores utilizados en entornos médicos y de atención de la salud en los Estados Unidos.

La marca CE indica que el esterilizador cumple con los requisitos de seguridad, salud y protección del medio ambiente de la Unión Europea. Los esterilizadores con certificación CE están aprobados para su uso en países de la UE, lo que garantiza que cumplen con los estándares necesarios de rendimiento y seguridad.

Las normas ISO, como la ISO 13485, proporcionan directrices para los sistemas de gestión de calidad de los dispositivos médicos, incluidos los esterilizadores. El cumplimiento de las normas ISO garantiza que los esterilizadores se fabriquen y mantengan de acuerdo con rigurosos procedimientos de control de calidad, lo que garantiza su fiabilidad y eficacia.

Reflexiones Finales:

La selección del esterilizador adecuado implica una evaluación exhaustiva de diversos factores, incluidos los tipos y estilos, el rendimiento y la funcionalidad, las especificaciones técnicas, los estándares de seguridad y las características adicionales. Los avances en la tecnología de esterilización y el cumplimiento normativo mejoran aún más la eficacia y la seguridad de los esterilizadores. Al considerar estos factores, las empresas y los centros de atención médica pueden asegurarse de elegir el esterilizador más adecuado para sus necesidades específicas, logrando resultados de esterilización óptimos y manteniendo altos estándares de higiene y seguridad.

বাংলা

বাংলা Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português Русский

Русский Español

Español Kiswahili

Kiswahili ไทย

ไทย Türkçe

Türkçe اردو

اردو Tiếng Việt

Tiếng Việt isiXhosa

isiXhosa Zulu

Zulu