Los recientes avances en herramientas para trabajar la madera están revolucionando la industria en 2025. Este artículo ofrece una guía completa sobre cómo seleccionar cepillos de banco, que abarca el rendimiento, la funcionalidad, la calidad de construcción y más. Los compradores profesionales encontrarán información valiosa y asistencia para tomar decisiones informadas.

Índice:

1. Descripción general del mercado: cepilladora de banco

2. Información y análisis detallados

3. Factores clave a la hora de seleccionar una cepilladora de banco

4. Avances tecnológicos en las cepilladoras de banco

5. Consideraciones ambientales y eficiencia energética

6. Mantenimiento y cuidado para la longevidad

7. Pensamientos finales

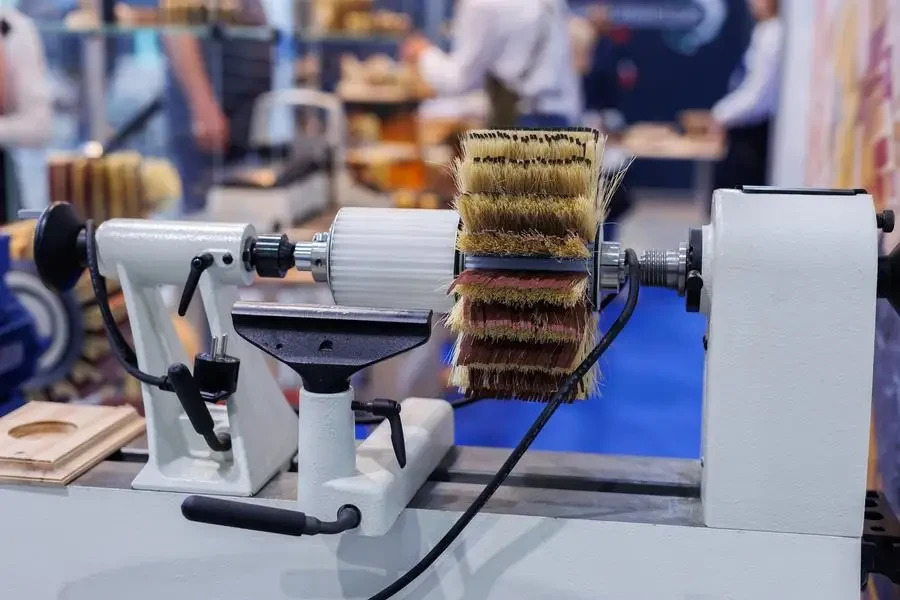

Descripción general del mercado: cepilladora de banco

El mercado mundial de cepilladoras de banco se está expandiendo de manera constante, impulsado por la creciente demanda de herramientas de carpintería de precisión. El tamaño del mercado se estimó en USD 1.5 mil millones en 2024 y se proyecta que alcance los USD 2.1 mil millones para 2030, creciendo a una CAGR del 5.8%. Este crecimiento está impulsado por la creciente adopción de maquinaria avanzada para trabajar la madera tanto en los segmentos profesionales como de bricolaje. El continente americano tiene una participación significativa del mercado, y Estados Unidos es un contribuyente importante debido a su sólida industria de carpintería. La región de Asia y el Pacífico, en particular China e India, también está experimentando un crecimiento sustancial debido a la rápida industrialización y al aumento de la renta disponible.

Los avances tecnológicos desempeñan un papel crucial en la expansión del mercado de las cepilladoras de banco. La integración de la tecnología de control numérico por computadora (CNC) y las capacidades de IoT en las cepilladoras de banco ofrece una mayor precisión, eficiencia y facilidad de uso. Esta tendencia es particularmente prominente en los mercados desarrollados donde la demanda de soluciones de carpintería automatizadas de alta calidad es alta. Además, el enfoque en modelos energéticamente eficientes y ecológicos está ganando terreno, en consonancia con los objetivos globales de sostenibilidad.

El mercado está segmentado en diferentes tipos según el tamaño y la funcionalidad, incluidas las cepilladoras de banco compactas, estándar y grandes. Las cepilladoras de banco compactas están ganando popularidad entre los aficionados y los pequeños talleres debido a su asequibilidad y diseño que ahorra espacio. Las cepilladoras de banco estándar y grandes son las preferidas en entornos industriales por su alta capacidad y características avanzadas. Los actores clave en el mercado incluyen Makita Corporation, DeWalt, Bosch e Hitachi, que innovan continuamente para mantener su ventaja competitiva.

Información y análisis detallados

El mercado de las cepilladoras de banco se caracteriza por varios parámetros de rendimiento clave que definen su trayectoria de crecimiento. La demanda de precisión y acabado de alta calidad en proyectos de carpintería es un factor impulsor principal que impulsa a los fabricantes a mejorar el rendimiento y la fiabilidad de sus productos. La dinámica de la cuota de mercado revela que marcas consolidadas como DeWalt y Makita dominan el mercado, aprovechando sus amplias redes de distribución y su sólida reputación de marca.

Las influencias económicas, como las fluctuaciones en los precios de las materias primas y los costos laborales, afectan significativamente el mercado. El aumento del costo del acero de alta calidad y otros materiales utilizados en la fabricación de cepilladoras de banco puede afectar las estrategias de precios de los fabricantes. Sin embargo, aumentar la inversión en automatización y digitalización ayuda a mitigar algunas de estas presiones de costos al mejorar la eficiencia operativa y reducir la dependencia de la mano de obra.

El comportamiento de los consumidores está cambiando hacia herramientas multifuncionales y fáciles de usar. Esta tendencia es evidente en la creciente demanda de cepillos de banco con características como profundidad de corte ajustable, sistemas de recolección de polvo y diseños ergonómicos. Las preferencias de los canales de distribución también están evolucionando, con un aumento notable en las ventas en línea. Las plataformas de comercio electrónico ofrecen una amplia gama de productos, precios competitivos y la comodidad de la entrega a domicilio, lo que las convierte en la opción preferida tanto para los usuarios profesionales como para los aficionados.

Entre las innovaciones recientes en el mercado se incluye el desarrollo de cepilladoras de banco inteligentes equipadas con sensores y funciones de conectividad. Estos modelos avanzados pueden monitorear y ajustar los parámetros de rendimiento en tiempo real, lo que garantiza una calidad constante y reduce el riesgo de errores. El ciclo de vida del producto de las cepilladoras de banco suele durar varios años, y los fabricantes introducen actualizaciones y mejoras periódicas para mantenerse competitivos.

La digitalización está transformando la industria de la maquinaria para trabajar la madera, con la adopción de tecnologías de la Industria 4.0. La integración de IoT e IA en las cepilladoras de banco permite el mantenimiento predictivo, la monitorización en tiempo real y el análisis de datos, mejorando la productividad y la eficiencia generales de las operaciones de carpintería. Las tendencias sociales como el movimiento DIY y la creciente popularidad de la carpintería como pasatiempo también están contribuyendo al crecimiento del mercado.

Los puntos débiles de los clientes incluyen el alto costo inicial de las cepilladoras de banco avanzadas, los requisitos de mantenimiento y la necesidad de una capacitación adecuada para operar modelos sofisticados. Los fabricantes abordan estos problemas ofreciendo opciones de financiamiento, garantías extendidas y programas de capacitación integrales. Las estrategias de posicionamiento de marca se centran en destacar la durabilidad, precisión y facilidad de uso de sus productos, diferenciándolos de la competencia.

Los nichos de mercado, como la fabricación de muebles a medida y la carpintería artesanal a pequeña escala, están surgiendo como segmentos lucrativos. Estos mercados demandan cepilladoras de banco especializadas capaces de ofrecer alta precisión y detalles intrincados. Las empresas están explorando estrategias de diferenciación, como ofrecer características personalizables, materiales ecológicos y un mejor servicio posventa para atender a estos segmentos de nicho.

Factores clave a la hora de elegir una cepilladora de banco

Seleccionar la cepilladora de banco adecuada es crucial para lograr acabados de alta calidad y operaciones eficientes. Se deben tener en cuenta varios factores, incluidos el rendimiento, la funcionalidad, el diseño y las especificaciones técnicas. A continuación, profundizamos en los aspectos clave que se deben tener en cuenta al elegir una cepilladora de banco.

Rendimiento y potencia

El rendimiento es fundamental a la hora de seleccionar una cepilladora de banco. La potencia del motor, medida en caballos de fuerza (HP), afecta directamente la eficiencia y la capacidad de la máquina. Por ejemplo, una cepilladora de banco con un motor de 1.5 HP puede trabajar con maderas más duras y cargas de trabajo mayores en comparación con un motor de 1 HP. La velocidad de avance, o la velocidad a la que pasa la madera por la cepilladora, es esencial. Las velocidades de avance más altas, que normalmente se miden en pies por minuto (FPM), permiten un procesamiento más rápido de los materiales, lo que mejora la productividad.

Otro factor crítico es la velocidad del cabezal de corte, medida en revoluciones por minuto (RPM). Un RPM más alto garantiza acabados más suaves y reduce la probabilidad de desgarros. Lo ideal es que una cepilladora de banco tenga una velocidad del cabezal de corte de al menos 10,000 XNUMX RPM para obtener resultados óptimos.

Funcionalidad y características

La funcionalidad de una cepilladora de banco está determinada por sus características. Una característica clave es el mecanismo de ajuste de profundidad, que permite un control preciso del grosor de la madera que se está cepillando. Las cepilladoras de banco modernas suelen venir con medidores de profundidad digitales para lecturas precisas y facilidad de uso.

Otra característica importante es el sistema de recolección de polvo. La recolección de polvo eficiente no solo mantiene limpio el espacio de trabajo, sino que también prolonga la vida útil de la máquina al evitar la acumulación de polvo en el motor y otros componentes. Algunas cepilladoras de banco están equipadas con puertos de recolección de polvo incorporados que se pueden conectar a extractores de polvo externos para una mayor eficiencia.

Además, busque cepilladoras con cuchillas de doble filo, ya que ofrecen una vida útil más larga y se pueden invertir cuando un lado se desafila. Algunos modelos también incluyen un sistema de cambio rápido de cuchillas, lo que reduce el tiempo de inactividad para el reemplazo de cuchillas y el mantenimiento.

Calidad y durabilidad de construcción

La calidad de construcción y los materiales utilizados en la fabricación de una cepilladora de banco afectan significativamente su durabilidad y rendimiento. Los modelos de alta calidad suelen estar hechos de hierro fundido o acero de alta resistencia, lo que proporciona estabilidad y reduce las vibraciones durante el funcionamiento. Esta construcción garantiza una vida útil más prolongada y un rendimiento constante, incluso con un uso intensivo.

Además, la calidad del cabezal de corte y de las cuchillas es crucial. Las cuchillas de acero rápido (HSS) o con punta de carburo son las preferidas por su filo y durabilidad. Las cuchillas con punta de carburo, en particular, son conocidas por su rendimiento duradero y su capacidad para mantener el filo, incluso al cepillar maderas duras.

Normas de seguridad y certificaciones

La seguridad es un factor primordial a tener en cuenta a la hora de seleccionar una cepilladora de banco. Asegúrese de que la máquina cumpla con las normas y certificaciones de seguridad pertinentes, como las de la Administración de Seguridad y Salud Ocupacional (OSHA) o el Comité Europeo de Normalización (CEN). Estas certificaciones indican que la cepilladora ha sido sometida a pruebas rigurosas y cumple con los requisitos de seguridad.

Busque características como mecanismos de apagado automático, que detienen la máquina en caso de sobrecarga o mal funcionamiento. Además, los dedos antirretroceso y las protecciones de seguridad alrededor del cabezal de corte son esenciales para evitar accidentes durante el funcionamiento.

Rango de precios y presupuesto

El precio de las cepilladoras de banco puede variar significativamente en función de sus características, calidad de construcción y marca. Los modelos básicos adecuados para aficionados y tareas livianas pueden costar alrededor de $300, mientras que las cepilladoras de nivel profesional con características avanzadas y mayor durabilidad pueden costar más de $1,500. Es importante equilibrar su presupuesto con las especificaciones requeridas y el uso previsto.

Invertir en una cepilladora de mayor calidad puede resultar en menores costos a largo plazo debido a un menor mantenimiento y una vida útil más larga. Además, considere la disponibilidad de repuestos y accesorios, ya que estos pueden afectar el costo total de propiedad.

Avances tecnológicos en cepilladoras de banco

En los últimos años, la industria de las cepilladoras de banco ha experimentado importantes avances tecnológicos que han mejorado tanto el rendimiento como la experiencia del usuario. Una de esas innovaciones es la integración de tecnología inteligente. Las cepilladoras de banco modernas ahora vienen equipadas con controles digitales y configuraciones programables, lo que permite a los usuarios guardar perfiles personalizados para diferentes tipos y espesores de madera. Esta característica ahorra tiempo y garantiza la uniformidad en la producción.

Otro avance destacable es el desarrollo de los motores sin escobillas. Estos motores ofrecen una mayor eficiencia, una vida útil más larga y un mantenimiento reducido en comparación con los motores con escobillas tradicionales. Además, generan menos calor y ruido, lo que hace que el entorno de trabajo sea más cómodo.

Además, algunos modelos avanzados ahora incluyen sensores integrados que monitorean el contenido de humedad de la madera y ajustan la velocidad de alimentación y del cabezal de corte en consecuencia. Este ajuste inteligente garantiza un rendimiento óptimo y evita daños tanto a la madera como a la máquina.

Consideraciones ambientales y eficiencia energética

En el mercado actual, consciente del medio ambiente, la eficiencia energética y la sostenibilidad son consideraciones importantes. Las cepilladoras de banco con motores de bajo consumo energético consumen menos energía, lo que reduce los costos operativos y el impacto ambiental. Busque modelos con calificaciones y certificaciones de eficiencia energética, como Energy Star.

Además, algunos fabricantes están utilizando materiales sostenibles y procesos de fabricación respetuosos con el medio ambiente, como el uso de metales reciclados para la construcción y la adopción de prácticas que reducen los residuos y las emisiones. La elección de estos productos favorece la sostenibilidad medioambiental y se alinea con los objetivos de responsabilidad social corporativa.

Mantenimiento y cuidado para la longevidad

El mantenimiento adecuado es esencial para la longevidad y el rendimiento óptimo de una cepilladora de banco. La limpieza regular, especialmente del sistema de recolección de polvo, evita la acumulación y posibles daños al motor y otros componentes. La lubricación de las piezas móviles, como los rodillos de alimentación y los cojinetes del cabezal de corte, garantiza un funcionamiento suave y reduce el desgaste.

El mantenimiento de las cuchillas es otro aspecto fundamental. Inspeccione y afile o reemplace las cuchillas periódicamente según sea necesario. Algunos modelos vienen con cuchillas autoafilables o sistemas de cuchillas fáciles de reemplazar, lo que simplifica las tareas de mantenimiento.

Además, mantener la cepilladora en un entorno seco y sin polvo cuando no esté en uso puede evitar la oxidación y otros daños ambientales. Seguir las pautas de mantenimiento del fabricante y programar un servicio profesional regular puede prolongar significativamente la vida útil de la máquina.

Reflexiones Finales:

En resumen, para seleccionar la cepilladora de banco adecuada es necesario tener en cuenta diversos factores, como el rendimiento, la funcionalidad, la calidad de fabricación, los estándares de seguridad y el presupuesto. Los avances tecnológicos y las consideraciones medioambientales también desempeñan un papel fundamental en las cepilladoras de banco modernas. Si se comprenden estos aspectos y se realiza el mantenimiento adecuado del equipo, los usuarios pueden garantizar un rendimiento óptimo y una larga vida útil de sus cepilladoras de banco.