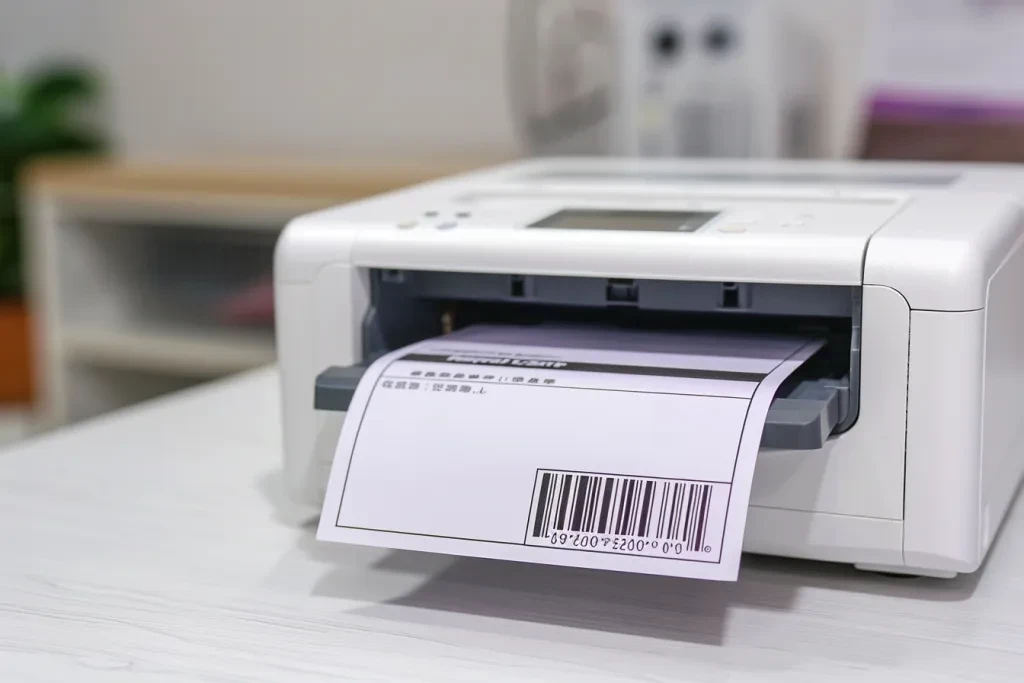

Recent advancements in thermal label printing technology are revolutionizing business operations in 2025. This article provides an in-depth analysis of the market, highlighting key factors and trends that professional buyers need to consider. By understanding these elements, businesses can make informed decisions that enhance efficiency and sustainability.

Table of Contents:

– Global Market Overview of Thermal Label Printers

– In-Depth Analysis of the Thermal Label Printer Market

– Innovations and Trends Shaping the Future

– Key Factors When Selecting a Thermal Label Printer

– Advanced Features in Modern Thermal Label Printers

– Energy Efficiency and Environmental Impact

– The Future of Thermal Label Printing

– Summing Up

Global Market Overview of Thermal Label Printers

The thermal label printer market is experiencing significant growth, driven by the demand for high-speed, cost-effective, and reliable printing solutions across various industries. Recent data suggests the global thermal printer market will exceed $5.5 billion by 2031, with a compound annual growth rate (CAGR) of 6.6%. This growth is mainly due to the rising need for barcode printing and related applications.

The expansion of the market is heavily influenced by the retail, logistics, and healthcare sectors, which require efficient and durable printing solutions. The Asia-Pacific (APAC) region, along with the Middle East & Africa (MEA) and Latin America, are emerging as key growth areas due to rapid industrialization and the adoption of advanced technologies. These regions are expected to significantly contribute to the market’s growth.

Thermal label printers are categorized based on product type, end-use, printing speed, and regional distribution. The primary product types are direct thermal printers and thermal transfer printers, with applications spanning retail, healthcare, manufacturing, and more. The market’s versatility and adaptability highlight its importance in streamlining global business operations.

In-Depth Analysis of the Thermal Label Printer Market

Thermal label printers are crucial in various industries due to their efficiency and reliability. Key performance benchmarks include printing speed, resolution, and durability. High-speed thermal printers can achieve speeds of up to 14 inches per second, essential for high-volume environments like logistics and retail. Advancements in printhead technology and connectivity options, such as wireless and Bluetooth, are enhancing these devices’ functionality.

Market share dynamics show that North America holds a significant portion of the market, thanks to its advanced retail and healthcare sectors. However, the APAC region is quickly catching up, driven by countries like China and India, where industrialization and technological adoption are accelerating. Economic factors, including rising disposable income and urbanization, also influence this shift.

Consumer behavior is moving towards more efficient and eco-friendly printing solutions. The demand for thermal printers using sustainable materials and energy-efficient technologies is increasing. This trend aligns with global environmental regulations aimed at reducing carbon footprints and promoting green technologies. Additionally, integrating Internet of Things (IoT) functionalities in thermal printers is opening new avenues for smart printing solutions, enabling real-time data monitoring and enhanced operational efficiency.

Innovations and Trends Shaping the Future

The thermal label printer market is characterized by continuous innovation. Companies are heavily investing in research and development to introduce state-of-the-art technologies that meet evolving industry demands. Innovations such as RFID-enabled printers and environmentally friendly printing solutions are gaining traction. For example, developing thermal printers that use linerless labels reduces waste and aligns with sustainability goals.

Digitalization is also playing a crucial role in market evolution. Integrating cloud-based systems with thermal printers allows for seamless data management and enhanced connectivity. This is particularly beneficial for retail and logistics sectors where real-time inventory tracking and management are critical. The adoption of mobile POS systems further emphasizes the need for compact and efficient thermal printers that can operate in diverse environments.

Customer pain points like high initial costs and the need for frequent maintenance are being addressed through innovative solutions. Companies are focusing on developing cost-effective and versatile printers that offer high durability and minimal downtime. The emphasis on user-friendly designs and easy integration with existing systems is enhancing the overall customer experience, making thermal label printers indispensable in modern business operations.

Key Factors When Selecting a Thermal Label Printer

When selecting a thermal label printer, several factors must be considered to ensure the device meets your business needs. These factors include types and styles, performance and functionality, technical specifications, ease of use, and budget considerations. Understanding these aspects will help you make an informed decision.

Types and Styles

Thermal label printers come in two main types: direct thermal and thermal transfer. Direct thermal printers use heat-sensitive paper, which darkens when heated. This method is suitable for short-term labeling as the labels can fade over time. Thermal transfer printers, on the other hand, use a ribbon to transfer ink onto the label, producing more durable prints that can withstand harsh environments.

The style of the printer also matters. Desktop thermal printers are compact and ideal for small to medium-sized businesses with moderate printing needs. Industrial thermal printers are larger and more robust, designed for high-volume printing in demanding environments such as warehouses and manufacturing plants. Mobile thermal printers offer portability and are perfect for on-the-go printing needs, such as in logistics and retail.

Performance and Functionality

Performance and functionality are critical when choosing a thermal label printer. Key performance indicators include print speed, resolution, and duty cycle. Print speed, measured in inches per second (IPS), determines how quickly the printer can produce labels. Higher speeds are beneficial for high-volume printing tasks. Print resolution, measured in dots per inch (DPI), affects the clarity and quality of the printed labels. Higher DPI values provide sharper and more detailed prints, which is essential for barcodes and small text.

Functionality features such as connectivity options, including USB, Ethernet, Wi-Fi, and Bluetooth, ensure seamless integration with your existing systems. Advanced functionality may include RFID encoding, allowing for the creation of smart labels, and direct integration with software applications for streamlined operations.

Technical Specifications

Understanding the technical specifications of a thermal label printer is crucial for matching it with your requirements. Specifications to consider include media compatibility, maximum print width, and memory capacity. Media compatibility pertains to the types of labels and ribbons the printer can handle, including various materials like paper, polyester, and polypropylene. This is important for ensuring the printer can produce labels suitable for your application.

The maximum print width determines the largest label size the printer can produce, which is crucial for applications needing wide labels. Memory capacity affects the printer’s ability to store label formats and graphics, influencing print speed and efficiency. Printers with higher memory can handle more complex designs and larger print jobs without slowing down.

Ease of Use

Ease of use is a significant factor, especially in environments where multiple users will operate the printer. User-friendly features such as intuitive interfaces, easy media loading, and minimal maintenance requirements can enhance productivity. Some printers come with touchscreens and guided instructions to simplify setup and operation.

Software compatibility is another aspect of ease of use. Ensure the printer is compatible with your existing label design software and that it supports common file formats. Additionally, printers with remote management capabilities allow for easier monitoring and troubleshooting, reducing downtime.

Budget Considerations

Budget is always a critical consideration. Thermal label printers come in a wide price range, from affordable desktop models to high-end industrial machines. It’s essential to balance cost with the features and capabilities you need. While it might be tempting to choose the cheapest option, investing in a higher-quality printer can lead to long-term savings through increased durability, lower maintenance costs, and better performance.

Consider the total cost of ownership, including the initial purchase price, cost of consumables (such as labels and ribbons), and maintenance expenses. Some printers might have a higher upfront cost but offer lower running costs, making them more economical in the long run.

Advanced Features in Modern Thermal Label Printers

Modern thermal label printers come equipped with advanced features that enhance their functionality and versatility. These features include connectivity options, RFID capabilities, and integration with software solutions.

Connectivity Options

Connectivity options in thermal label printers have evolved to meet the demands of modern business environments. USB and Ethernet ports are standard, allowing for direct connections to computers and networks. Wi-Fi and Bluetooth connectivity offer wireless printing capabilities, providing flexibility and reducing cable clutter.

Advanced models may support cloud printing, enabling remote printing from anywhere with an internet connection. This is particularly useful for businesses with multiple locations or remote operations. Additionally, some printers offer mobile app support, allowing for label design and printing directly from smartphones and tablets, further enhancing convenience and efficiency.

RFID Capabilities

RFID (Radio-Frequency Identification) capabilities in thermal label printers allow for the encoding of RFID tags, which can store information and be read remotely. This technology is particularly beneficial in inventory management, asset tracking, and supply chain logistics. RFID-enabled labels can be scanned without direct line-of-sight, speeding up processes and reducing errors.

Printers with integrated RFID modules can encode and print labels in a single pass, streamlining operations and improving accuracy. This feature is becoming increasingly important as businesses adopt RFID technology to enhance their tracking and management systems.

Software Integration

Integration with software solutions is a key feature of modern thermal label printers. These printers can connect with enterprise resource planning (ERP) systems, warehouse management systems (WMS), and other business applications, allowing for automated label printing based on real-time data. This integration reduces manual entry, minimizes errors, and speeds up processes.

Some printers come with their own label design software, offering a range of templates and design tools. Others are compatible with popular third-party software, providing flexibility and ensuring that businesses can continue using their preferred solutions. API support and SDKs (Software Development Kits) enable custom integrations, allowing businesses to tailor the printer’s functionality to their specific needs.

Energy Efficiency and Environmental Impact

Energy efficiency and environmental impact are increasingly important considerations for businesses when selecting thermal label printers. Modern printers are designed to minimize energy consumption and reduce waste, contributing to sustainability goals.

Energy Efficiency

Energy-efficient thermal label printers are designed to consume less power during operation and standby modes. Features such as automatic sleep mode, which powers down the printer when not in use, help reduce energy consumption. Some printers are ENERGY STAR certified, indicating they meet stringent energy efficiency guidelines set by the U.S. Environmental Protection Agency.

Using energy-efficient printers not only helps reduce operational costs but also supports corporate sustainability initiatives. Businesses can lower their carbon footprint and contribute to environmental conservation by choosing printers that use less energy.

Reduced Waste

Thermal label printers can contribute to waste reduction in several ways. Direct thermal printing eliminates the need for ink or toner, reducing the amount of consumable waste generated. Thermal transfer printers, while using ribbons, often come with ribbon-saving features that minimize waste by using only the necessary amount of ribbon for each print job.

Additionally, some printers are designed to work with eco-friendly label materials, such as recyclable or biodegradable substrates. By selecting printers that support these materials, businesses can further reduce their environmental impact.

Sustainable Manufacturing

Manufacturers of thermal label printers are increasingly adopting sustainable practices in their production processes. This includes using recycled materials, reducing harmful emissions, and implementing energy-efficient manufacturing techniques. Choosing printers from manufacturers committed to sustainability can support broader environmental goals and demonstrate corporate responsibility.

The Future of Thermal Label Printing

The future of thermal label printing is marked by advancements in technology, increased automation, and a focus on sustainability. These trends are shaping the development of next-generation printers that offer enhanced capabilities and improved efficiency.

Technological Advancements

Technological advancements are driving the evolution of thermal label printers. Innovations such as high-resolution printing, faster print speeds, and improved connectivity are enhancing the performance and functionality of these devices. Future printers are expected to incorporate more advanced sensors and artificial intelligence (AI) to optimize printing processes and improve accuracy.

Augmented reality (AR) and virtual reality (VR) technologies may also play a role in the future of thermal label printing. These technologies can provide interactive training and support, making it easier for users to operate and maintain printers. Additionally, AR and VR can assist in troubleshooting and repairs, reducing downtime and improving productivity.

Increased Automation

Automation is a key trend in the future of thermal label printing. Automated label printers can streamline workflows, reduce manual intervention, and increase efficiency. Features such as automatic label dispensing, cutting, and application are becoming more common, allowing for fully automated labeling processes.

Integration with robotic systems and conveyor belts can further enhance automation, enabling seamless label printing and application in high-volume production environments. This level of automation can significantly reduce labor costs and improve operational efficiency.

Focus on Sustainability

Sustainability will continue to be a major focus in the future of thermal label printing. Manufacturers are expected to develop printers that are even more energy-efficient and environmentally friendly. This includes using sustainable materials, reducing waste, and implementing greener manufacturing processes.

Businesses will increasingly seek out printers that align with their sustainability goals, driving demand for eco-friendly solutions. The development of new materials and technologies that support sustainable printing will be a key area of innovation in the coming years.

Summing Up

In conclusion, selecting the right thermal label printer involves considering various factors such as types and styles, performance and functionality, technical specifications, ease of use, and budget. Advanced features like connectivity options, RFID capabilities, and software integration enhance the printer’s versatility. Energy efficiency and environmental impact are also important considerations, while future trends point towards technological advancements, increased automation, and a focus on sustainability.

বাংলা

বাংলা Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português Русский

Русский Español

Español Kiswahili

Kiswahili ไทย

ไทย Türkçe

Türkçe اردو

اردو Tiếng Việt

Tiếng Việt isiXhosa

isiXhosa Zulu

Zulu