In 2025, the demand for precision metal shaping tools has surged, making the selection of the right English Wheel crucial for businesses. This article delves into the market dynamics, key factors, and innovations, providing valuable guidance for professional buyers in making informed decisions.

Sommaire :

-Market Overview of the English Wheel

-Detailed Analysis of the English Wheel Market

-Innovations and Market Trends

-Key Factors When Selecting an English Wheel

-Advanced Features and Accessories

-Practical Examples and Case Studies

-Summing It Up

Market Overview of the English Wheel

The global market for English Wheels has grown significantly due to the rising demand for precision metal shaping tools across various industries. As of 2024, the market’s value was around $1.5 billion, with projections suggesting it will reach $2.3 billion by 2030, growing at a compound annual growth rate (CAGR) of 6.5%. This growth is driven by the expanding automotive, aerospace, and custom metal fabrication sectors, where English Wheels are essential for producing complex curved surfaces and high-quality metal finishes.

North America holds the largest market share, accounting for 35% of the global market, followed closely by Europe with 30%. The Asia-Pacific region is expected to witness the fastest growth, with a CAGR of 7.2%, due to the burgeoning automotive and aerospace industries in countries like China, India, and Japan. The demand in these regions is fueled by increased investments in manufacturing infrastructure and the rise of skilled artisans and craftsmen.

Market segmentation shows that manual English Wheels dominate, comprising 60% of the total share, while powered English Wheels hold the remaining 40%. The preference for manual English Wheels is due to their affordability and versatility, making them suitable for both small-scale workshops and large manufacturing units. Key players in the market include MetalAce, Baileigh Industrial, and ProLine, known for their innovative designs and superior product quality.

Detailed Analysis of the English Wheel Market

The English Wheel market plays a critical role in metalworking industries, where precision and craftsmanship are essential. Key performance benchmarks include throat depth, wheel diameter, and the material of the anvils and wheels, typically hardened steel for durability. Market share dynamics are influenced by technological advancements, with companies investing in research and development to enhance the efficiency and ease of use of these tools.

Economic factors significantly impact the market’s growth. The global push for lightweight and aerodynamically efficient vehicles in the automotive and aerospace sectors has led to increased adoption of English Wheels for shaping aluminum and other lightweight metals. Consumer behavior is shifting towards customized and bespoke metal products, further driving the demand for high-quality metal shaping tools.

Distribution channels for English Wheels vary, with a notable preference for direct sales and online platforms. Direct sales, accounting for 55% of the market, allow manufacturers to offer tailored solutions and provide technical support, while online platforms cater to a broader audience, including hobbyists and small-scale workshops. Recent innovations include CNC-controlled English Wheels, offering automated precision shaping, and the integration of digital readouts for enhanced accuracy.

Innovations et tendances du marché

The English Wheel market is witnessing several innovations aimed at improving user efficiency and product quality. One notable trend is the integration of digital technologies, such as CNC controls and digital readouts, which enhance precision and reduce manual effort. These advancements cater to the growing demand for automation in metalworking processes, particularly in large manufacturing units.

Another significant trend is the development of lightweight and portable English Wheels. These models are designed for ease of transport and versatility, making them ideal for on-site repairs and custom metalwork projects. The use of advanced materials, such as carbon fiber in the construction of frames, has resulted in more durable and lightweight tools, further driving market growth.

Customer pain points, such as the high initial cost and the need for skilled operation, are being addressed through comprehensive training programs and financing options. Manufacturers are also focusing on brand positioning strategies that emphasize quality, durability, and innovation to differentiate their products in a competitive market. Niche markets, such as custom motorcycle and aircraft restoration, present lucrative opportunities for specialized English Wheels designed to meet the unique requirements of these applications.

Key Factors When Selecting an English Wheel

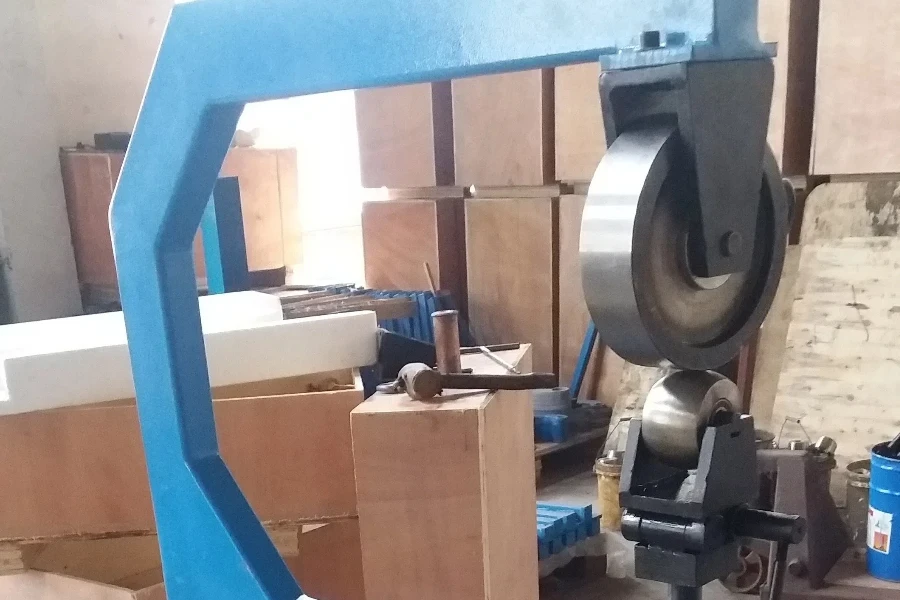

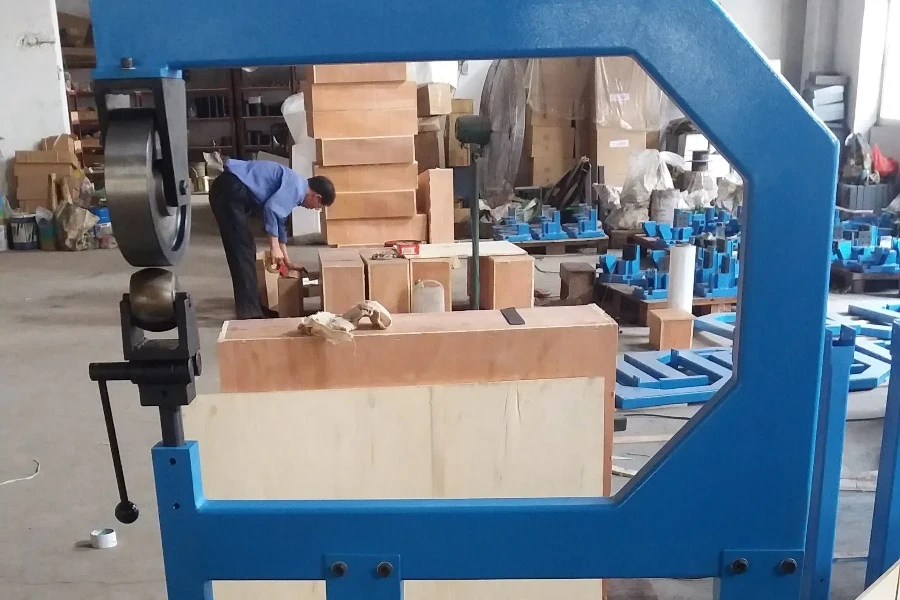

Types et styles

English wheels come in various types and styles, each suited for specific applications. The most common type is the traditional floor-standing model, which offers a robust and stable platform for shaping large metal sheets. These models typically have a throat depth ranging from 24 to 48 inches, providing ample space for maneuvering large workpieces. Another popular style is the benchtop English wheel, which is more compact and suited for smaller projects or workshops with limited space, usually having a throat depth of 18 to 24 inches. Additionally, there are portable English wheels that can be clamped to a workbench, offering flexibility for on-site work.

For specialized applications, some English wheels come with interchangeable anvils that allow for different radii and shapes. This versatility is crucial for custom metalworking projects that require precise curvature control. The choice of type and style should be based on the specific requirements of the project, available workspace, and desired outcomes.

Performances et fonctionnalités

The performance of an English wheel is primarily determined by its build quality and the materials used in its construction. High-performance models are typically made from heavy-duty steel, providing the necessary rigidity and stability for precise metal shaping. These models often feature precision-ground anvils and wheels, ensuring smooth operation and consistent results. The anvils are usually made from hardened steel to withstand continuous use.

Functionality is enhanced by features such as adjustable pressure settings, allowing the user to control the amount of force applied to the metal sheet. This is particularly important when working with different types of metals, as each material requires a specific pressure setting to achieve the desired shape without causing damage. Additionally, some models come with quick-release mechanisms for easy anvil changes, further increasing their versatility and efficiency.

Spécifications techniques

When selecting an English wheel, it is essential to consider its technical specifications. These include the throat depth, wheel diameter, and anvil radius. The throat depth determines the maximum size of the workpiece that can be accommodated, with larger depths allowing for greater versatility. Wheel diameter affects the smoothness of the shaping process, with larger wheels providing a more gradual curve.

Anvil radius is another critical specification, as it determines the curvature of the finished piece. Anvils with smaller radii are used for tighter curves, while larger radii are suited for gentle bends. It is also important to consider the weight of the machine, as heavier models offer more stability but may be challenging to move. Finally, the overall dimensions of the English wheel should be compatible with the available workspace, ensuring that it can be used effectively without causing obstructions.

Gamme de prix et budget

The price of an English wheel can vary significantly based on its type, build quality, and additional features. Entry-level models suitable for hobbyists or small workshops typically range from $500 to $1,000. These models offer basic functionality and are often made from lighter materials, making them less durable but more affordable. Mid-range models, suitable for more frequent use, usually cost between $1,000 and $3,000. These machines offer better build quality, more robust construction, and additional features such as adjustable pressure settings.

Professional-grade English wheels, designed for continuous use in industrial settings, can cost upwards of $3,000. These models are made from high-quality materials, offer precision-ground components, and include a range of interchangeable anvils and wheels. When setting a budget, it is important to consider the long-term investment, as higher-quality machines will offer better performance and durability, ultimately providing better value over time.

Advanced Features and Accessories

Dernières fonctionnalités technologiques

Modern English wheels are equipped with advanced technology features that enhance their functionality and ease of use. One notable advancement is the incorporation of digital pressure gauges. These gauges provide real-time feedback on the pressure being applied to the metal sheet, allowing for precise adjustments and consistent results. Another innovative feature is the use of motorized anvils, which automate the pressure application process, reducing the physical effort required from the user and increasing productivity.

Additionally, some high-end models come with integrated laser guides that project a visible line on the workpiece, helping users maintain a consistent path and achieve more accurate shapes. These technological enhancements not only improve the quality of the finished product but also make the shaping process more efficient and user-friendly.

Normes de sécurité et certifications

Safety is a paramount consideration when selecting an English wheel, especially for professional workshops where the equipment is used frequently. High-quality models are designed to meet stringent safety standards and often come with certifications from recognized organizations such as the Occupational Safety and Health Administration (OSHA) or the European Union’s CE Mark. These certifications ensure that the machine has been tested and meets specific safety criteria, providing peace of mind for users.

Safety features such as emergency stop buttons, protective covers for moving parts, and non-slip surfaces are also important. These features help prevent accidents and injuries, making the working environment safer for operators. It is crucial to choose a model that complies with relevant safety regulations and includes built-in safety mechanisms to protect users.

Durabilité et qualité de fabrication

The durability and build quality of an English wheel are critical factors that determine its longevity and performance. Machines made from high-grade steel or cast iron are more durable and can withstand the rigors of continuous use. These materials provide the necessary strength and stability to handle heavy workpieces without deforming or losing precision. Additionally, components such as wheels and anvils should be made from hardened steel to resist wear and tear.

High-quality English wheels are often precision-engineered, with tight tolerances and smooth finishes that ensure consistent performance. Investing in a well-built machine not only guarantees better results but also reduces the need for frequent maintenance and repairs, ultimately saving time and costs in the long run.

Exemples pratiques et études de cas

Custom Automotive Fabrication

In the automotive industry, English wheels are indispensable tools for custom fabrication and restoration projects. For example, a custom car builder may use an English wheel to create complex curves and shapes for body panels, fenders, and hoods. The ability to precisely control the curvature and smoothness of the metal allows for the creation of unique, high-quality components that enhance the overall aesthetics and performance of the vehicle.

Metal Art and Sculpture

Artists and sculptors also rely on English wheels to create intricate metal artworks. The tool’s versatility allows artists to shape metal sheets into various forms, from smooth, flowing curves to sharp, angular bends. This capability opens up endless possibilities for creative expression, enabling artists to bring their visions to life with precision and finesse.

Industrie aérospaciale

In the aerospace industry, English wheels are used to fabricate and repair aircraft components. The tool’s ability to shape lightweight yet durable metals such as aluminum and titanium is crucial for creating aerodynamic surfaces and structural parts. For instance, an aerospace engineer might use an English wheel to form the skin of an aircraft wing or fuselage, ensuring that the component meets strict performance and safety standards.

En résumé

When selecting an English wheel, several key factors should be considered, including types and styles, performance and functionality, design, technical specifications, and price range. Advanced features and accessories, safety standards and certifications, and durability and build quality also play crucial roles. By carefully evaluating these factors and considering practical examples and case studies, buyers can make informed decisions and choose the right English wheel for their specific needs.