In 2025, the demand for precision cutting tools is surging, driven by industries requiring high-quality acrylic cuts. This article provides an in-depth analysis of the key factors to consider when selecting an acrylic sheet cutter, covering aspects like types, performance, technical specs, and market trends. It offers valuable insights for professional buyers aiming to make informed purchasing decisions.

Sommaire :

-Acrylic Sheet Cutter Market Overview

-Detailed Analysis of the Acrylic Sheet Cutter Market

-Key Factors to Consider When Selecting an Acrylic Sheet Cutter

-Latest Technology Features in Acrylic Sheet Cutters

-Budget Considerations for Acrylic Sheet Cutters

-Understanding the Market and Future Trends

-En conclusion

Acrylic Sheet Cutter Market Overview

The global market for sawing and cutting tools was worth around USD 7 billion in 2023 and is projected to reach USD 9.4 billion by 2030, growing at a CAGR of 4.4% from 2023 to 2030. Within this market, the acrylic sheet cutter segment is gaining significant traction due to the rising demand for precision cutting tools across various industries. The industrial application segment is expected to reach USD 6.6 billion by 2030, growing at a CAGR of 4.7%, while the DIY application segment is projected to grow at a CAGR of 3.7% over the same period.

Regionally, the U.S. market was worth about USD 1.9 billion in 2023, with China forecasted to grow at an impressive CAGR of 7.4%, reaching USD 2 billion by 2030. Other key regions, such as Japan, Canada, Germany, and the Asia-Pacific, are also expected to witness substantial growth, driven by technological advancements and increased industrial activities.

Detailed Analysis of the Acrylic Sheet Cutter Market

Indicateurs clés de performance et dynamique des parts de marché

The acrylic sheet cutter market demands high precision and efficiency in cutting acrylic materials. Key players like Apex Tool Group, Atlas Copco, Hilti Corporation, and Makita Corporation dominate the market through continuous innovation and strategic partnerships. The market is highly competitive, focusing on advanced cutting technologies for industries such as automotive, construction, and electronics.

Influences économiques et changements de comportement des consommateurs

The economic landscape significantly impacts the acrylic sheet cutter market. Demand is closely tied to the growth of the construction and automotive industries, major consumers of acrylic materials. The shift towards sustainable and energy-efficient manufacturing processes has led to a preference for high-precision cutting tools that minimize material wastage.

Préférences en matière de canaux de distribution et innovations récentes

Distribution channels for acrylic sheet cutters include both online and offline platforms. The online segment is gaining popularity due to convenience and a wide range of options. Recent innovations include laser cutting machines and CNC (Computer Numerical Control) systems, offering enhanced accuracy and efficiency. These technologies are expected to drive market growth, providing new opportunities for manufacturers and distributors.

Product Lifecycle Stages and Digitalization

The product lifecycle of acrylic sheet cutters involves stages from design to distribution. Digitalization in manufacturing has streamlined these stages, improving efficiency and reducing production costs. The integration of IoT (Internet of Things) and AI (Artificial Intelligence) in cutting machines enhances performance, enabling real-time monitoring and predictive maintenance.

Points faibles des clients et stratégies de positionnement de la marque

Despite advancements, customers face challenges such as high initial investment costs and the need for skilled operators. Manufacturers are focusing on developing user-friendly and cost-effective solutions. Brand positioning strategies highlight unique features and benefits like precision, durability, and ease of use to differentiate from competitors.

Stratégies de différenciation et marchés de niche

Differentiation strategies include offering customized solutions for specific industry needs and comprehensive after-sales services. Niche markets, such as DIY enthusiasts and small-scale manufacturers, present growth opportunities for companies that offer affordable and efficient cutting tools tailored to their needs.

Key Factors to Consider When Selecting an Acrylic Sheet Cutter

Choosing the right acrylic sheet cutter is crucial for the efficiency and quality of your operations. Below, we explore key considerations in detail.

Types and Styles of Acrylic Sheet Cutters

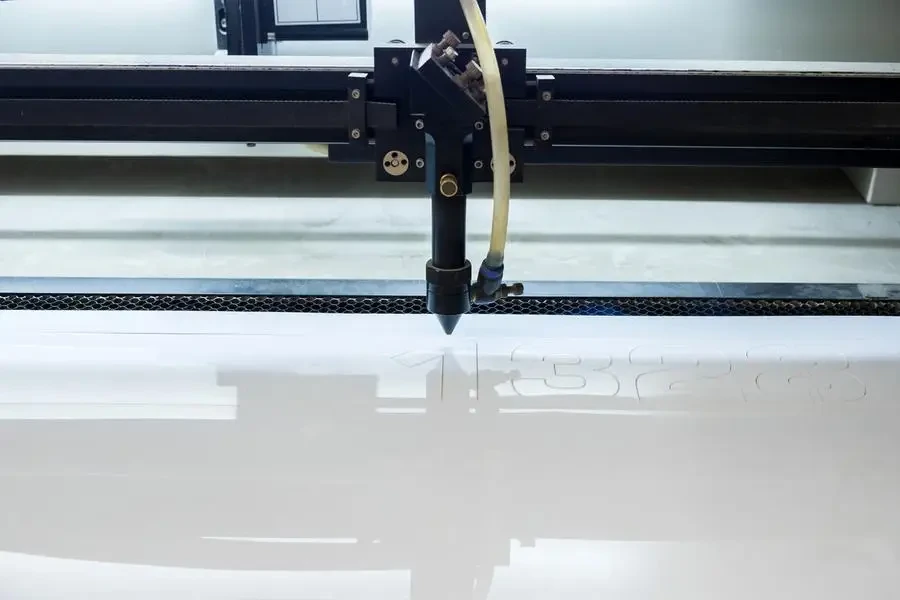

Acrylic sheet cutters come in various types and styles, each suited for different tasks and scales of operation. The most common types include manual cutters, laser cutters, and CNC (Computer Numerical Control) routers.

Manual cutters are typically used for small-scale projects or by hobbyists. They are cost-effective but require more physical effort and skill for precise cuts. Laser cutters offer high precision and are ideal for intricate designs, using a high-powered laser to cut through the acrylic, providing clean edges and reducing the need for post-processing. CNC routers are highly versatile and can handle large-scale production. They are controlled by computer software, allowing for complex shapes and designs to be cut with high accuracy and repeatability.

Performances et fonctionnalités

The performance of an acrylic sheet cutter is determined by its cutting speed, precision, and the quality of the cut edges. High-performance cutters can reduce production time and improve the quality of the final product.

For example, laser cutters can achieve cutting speeds of up to 120 inches per minute (IPM) and can cut acrylic sheets up to 1 inch thick with high precision. CNC routers, while slightly slower, can cut through thicker materials and handle larger sheets. The functionality of the cutter also includes its ability to handle different types of acrylic, such as cast or extruded acrylic, without compromising on the quality of the cut.

Spécifications techniques

When selecting an acrylic sheet cutter, consider its technical specifications. These include the cutting area, cutting depth, power requirements, and compatibility with various software and accessories.

The cutting area defines the maximum size of the acrylic sheet the cutter can handle. For large-scale operations, a cutter with a larger cutting area is preferable. Cutting depth is crucial for thicker acrylic sheets. Power requirements vary depending on the type of cutter; laser cutters typically require higher power inputs compared to manual or CNC cutters. Compatibility with design software like AutoCAD or Adobe Illustrator is also vital for seamless integration into your production workflow.

Normes de sécurité et certifications

Safety is a paramount concern when working with acrylic sheet cutters, especially those using high-powered lasers or rotating blades. Select cutters that comply with industry safety standards and certifications.

Laser cutters should comply with FDA regulations for laser products and have safety features such as enclosed cutting areas and interlock systems to prevent accidental exposure to the laser beam. CNC routers should have emergency stop buttons and protective guards to shield the operator from moving parts. Additionally, choose cutters that have received certifications from recognized bodies such as the International Organization for Standardization (ISO) or the Occupational Safety and Health Administration (OSHA).

Durabilité et qualité de fabrication

The durability and build quality of an acrylic sheet cutter affect its lifespan and maintenance requirements. High-quality cutters are typically constructed from robust materials such as steel or aluminum, which can withstand continuous use.

Laser cutters often feature sealed laser tubes that extend the life of the laser source, reducing the frequency of replacements. CNC routers with heavy-duty frames and high-quality spindles ensure stable and precise cutting over long periods. Regular maintenance, such as cleaning and lubricating moving parts, is essential to maintain the cutter’s performance and extend its lifespan. Investing in a cutter with solid build quality may involve higher upfront costs but can result in lower maintenance costs and longer operational life.

Latest Technology Features in Acrylic Sheet Cutters

The machinery industry continually evolves with advancements in technology, and acrylic sheet cutters are no exception.

Intégration de l'IA et de l'apprentissage automatique

Modern acrylic sheet cutters increasingly integrate artificial intelligence (AI) and machine learning to enhance precision and efficiency. These technologies enable the cutters to learn from previous cutting tasks, optimizing parameters such as cutting speed and laser power for future tasks. This improves the quality of cuts and reduces material wastage and operational costs.

Capacités logicielles avancées

Cutting-edge software capabilities are another significant advancement in acrylic sheet cutters. Many modern cutters come with proprietary software that offers features like real-time monitoring, automatic error detection, and remote operation capabilities. These software solutions often include advanced design tools that allow for complex and intricate patterns to be cut with ease. Integration with cloud-based platforms also enables seamless collaboration and data sharing across different departments and locations.

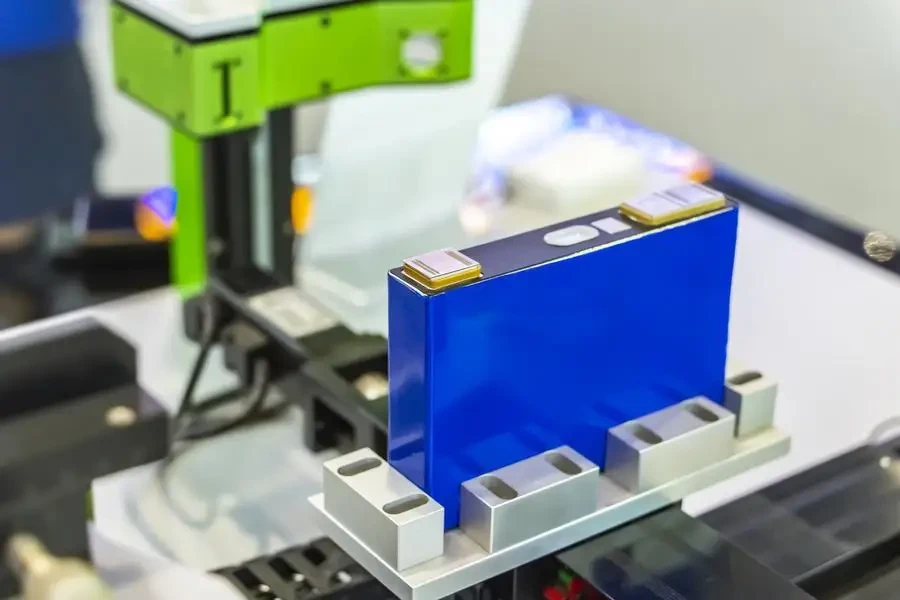

Automatisation et robotique améliorées

Automation and robotics have revolutionized the acrylic sheet cutting process, particularly in large-scale manufacturing environments. Automated acrylic sheet cutters can handle multiple sheets simultaneously, significantly increasing production throughput. Robotic arms can be integrated with CNC routers or laser cutters to automate the loading and unloading of sheets, further enhancing efficiency and reducing manual labor. This level of automation speeds up the production process and minimizes the risk of human error.

Budget Considerations for Acrylic Sheet Cutters

When investing in an acrylic sheet cutter, consider your budget and the total cost of ownership.

Coût d'achat initial

The initial purchase cost of an acrylic sheet cutter can vary widely depending on its type, features, and brand. Manual cutters are generally the most affordable, with prices ranging from $50 to $500. Laser cutters and CNC routers are more expensive, with prices ranging from $5,000 to $50,000 or more, depending on their capabilities and specifications. Balance your budget with the cutter’s performance and features to ensure you get the best value for your investment.

Coûts d'exploitation et de maintenance

Operating and maintenance costs are ongoing expenses that should be factored into your budget. Laser cutters, for instance, require regular replacement of laser tubes and lenses, which can be costly. CNC routers may need periodic spindle replacements and software updates. Additionally, energy consumption is a significant operating cost, particularly for high-powered laser cutters. Choose energy-efficient models to help reduce these costs over time.

Retour sur investissement (ROI)

Evaluating the return on investment (ROI) is essential when considering the purchase of an acrylic sheet cutter. A high-quality cutter that offers increased production efficiency, reduced material wastage, and lower maintenance costs can provide a higher ROI over its lifespan. Conduct a cost-benefit analysis to determine the potential savings and revenue generation the cutter can offer. This analysis should consider factors like increased production capacity, improved product quality, and reduced downtime.

Understanding the Market and Future Trends

The acrylic sheet cutter market is influenced by various factors, and staying abreast of future trends can help make informed purchasing decisions.

Demande et croissance du marché

The demand for acrylic sheet cutters is driven by various industries, including signage, automotive, construction, and interior design. As these industries continue to grow, the demand for high-quality acrylic sheet cutters is expected to rise. The increasing popularity of acrylic as a versatile and durable material for various applications further fuels this demand. Understanding market dynamics and growth trends can help in selecting a cutter that aligns with industry needs and future requirements.

Les avancées technologiques

Technological advancements play a crucial role in shaping the future of acrylic sheet cutters. Innovations such as AI, machine learning, and automation are expected to become more prevalent, enhancing the capabilities and efficiency of these cutters. Additionally, advancements in laser and CNC technologies will likely lead to more precise and faster cutting processes. Staying updated with these technological trends can help in selecting a cutter that is future-proof and capable of adapting to evolving industry standards.

Considérations environnementales et réglementaires

Environmental sustainability and regulatory compliance are becoming increasingly important in the machinery industry. Acrylic sheet cutters that incorporate eco-friendly features, such as energy-efficient operations and reduced emissions, are gaining popularity. Compliance with environmental regulations and certifications, such as ISO 14001, is also crucial for ensuring safe and sustainable operations. Considering these factors can help in selecting a cutter that meets both current and future regulatory requirements.

Récapitulation

Selecting the right acrylic sheet cutter involves careful consideration of various factors, including the type and style of the cutter, its performance and functionality, technical specifications, safety standards, durability, and budget. Additionally, staying informed about the latest technology features, market trends, and environmental considerations can help make a well-informed decision. With the right acrylic sheet cutter, businesses can achieve higher efficiency, improved product quality, and a competitive edge in the market.