The heavy-duty sewing machine market is booming in 2025, driven by advancements in technology and increasing demand in various industries. This article provides an in-depth analysis of the key factors to consider when selecting a heavy-duty sewing machine, offering valuable insights for professional buyers to make informed decisions. From build quality to energy efficiency, this guide covers everything needed to ensure optimal performance and durability in sewing operations.

Sommaire :

– Heavy Duty Sewing Machine Market Overview

– Detailed Analysis of the Heavy Duty Sewing Machine Market

– Key Factors When Selecting a Heavy Duty Sewing Machine

– Exploring Advanced Features in Heavy Duty Sewing Machines

– Ensuring Compatibility with Accessories and Add-Ons

– Considering Energy Efficiency and Sustainability

- Dernières pensées

Heavy Duty Sewing Machine Market Overview

The global heavy-duty sewing machine market is experiencing significant growth, driven by increasing demand in various industries, including automotive, upholstery, and apparel manufacturing. As of 2024, the market size for sewing machines, encompassing both household and industrial applications, reached USD 5.34 billion, up from USD 5.08 billion the previous year. The market is forecasted to grow at a compound annual growth rate (CAGR) of 5.75%, potentially reaching USD 7.51 billion by 2030. This growth is supported by technological advancements, such as computerized and automated sewing machines, which enhance productivity and precision.

The Asia-Pacific region, particularly China, Japan, and India, dominates the market in both production and consumption. China remains the largest producer and exporter, accounting for a significant proportion of the global supply. Meanwhile, North America and Europe exhibit strong demand for high-quality, durable machines, with a preference for advanced features and environmental sustainability. The market offers a diverse range of products, including electronic, mechanical, and embroidery sewing machines, catering to both professional and hobbyist users.

In terms of distribution channels, the market is split between offline and online sales. Offline channels, such as specialty stores and dealerships, continue to hold a substantial share due to the need for hands-on demonstrations and after-sales services. However, online sales are rapidly gaining traction, supported by e-commerce platforms and the growing trend of DIY fashion and home decor. Innovations in product design, including user-friendly interfaces and enhanced stitch options, are further driving market growth.

Detailed Analysis of the Heavy Duty Sewing Machine Market

Heavy-duty sewing machines are designed to handle thick fabrics and multiple layers, making them essential for industrial applications. Key performance benchmarks for these machines include stitch speed, stitch quality, durability, and ease of maintenance. High-end models can achieve speeds of up to 1,500 stitches per minute, significantly boosting production efficiency. The market is segmented into electronic, mechanical, and embroidery machines, each with distinct capabilities tailored to specific user needs.

Established brands like Brother, JUKI, and Singer dominate the market, thanks to their extensive product portfolios and strong brand reputations. These companies continually invest in research and development to introduce innovative features, such as automated threading, digital stitch selection, and integrated embroidery functions. Economic factors, including fluctuations in raw material prices and labor costs, also impact market dynamics. For instance, the rising cost of electronic components has led to increased prices for advanced sewing machines.

Consumer behavior is shifting towards more versatile and user-friendly machines. There is a growing demand for multifunctional devices that can perform a variety of tasks, from basic stitching to complex embroidery. This trend is particularly evident in the DIY and home decor segments, where consumers seek machines that offer creative flexibility. Distribution channel preferences are also evolving, with a noticeable shift towards online platforms. E-commerce giants like Amazon and specialized online retailers are expanding their product offerings, providing consumers with a wider selection and competitive pricing.

Recent innovations in the market include the integration of Internet of Things (IoT) technology, enabling remote monitoring and control of sewing machines. This digitalization enhances operational efficiency and reduces downtime by allowing real-time diagnostics and maintenance alerts. Social trends, such as the increasing popularity of upcycling and sustainable fashion, are driving demand for heavy-duty sewing machines capable of handling a variety of materials. Customer pain points, such as the complexity of machine operation and maintenance, are being addressed through user-friendly designs and comprehensive support services.

Brand positioning strategies focus on highlighting the reliability, durability, and advanced features of heavy-duty sewing machines. Differentiation strategies include offering extended warranties, superior customer service, and exclusive online tutorials. Niche markets, such as bespoke tailoring and custom upholstery, present significant opportunities for growth. Companies are increasingly targeting these segments with specialized machines that offer high precision and customization capabilities. As the market continues to evolve, manufacturers must stay attuned to technological advancements and consumer preferences to maintain a competitive edge.

Key Factors When Selecting a Heavy Duty Sewing Machine

Qualité de construction et matériaux

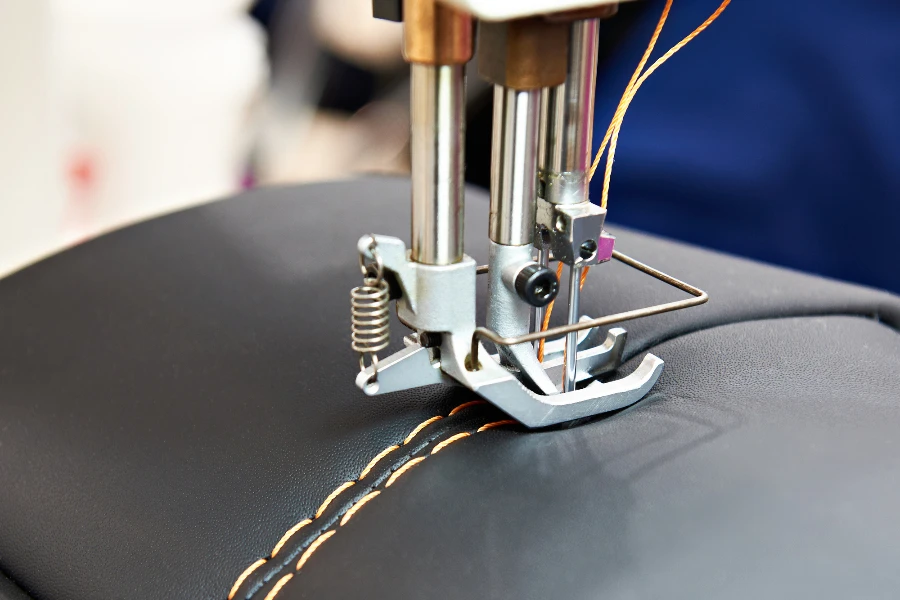

When choosing a heavy-duty sewing machine, the quality of construction and materials used are paramount. These machines are typically built with robust components to withstand rigorous use. High-quality materials such as cast iron and heavy-duty steel are often used in the frame and internal mechanisms to ensure durability and longevity. For instance, internal parts like the needle bar, presser foot, and feed dogs should be made from stainless steel to resist wear and tear. Additionally, using high-grade plastics in non-critical areas can help reduce weight without compromising structural integrity.

The build quality also extends to the machine’s finish. A powder-coated or anodized finish can protect the exterior from rust and corrosion, which is essential for machines used in humid or industrial environments. Heavy-duty sewing machines should be designed to handle continuous operation without overheating or breaking down.

Performances et fonctionnalités

Performance is a critical factor when selecting a heavy-duty sewing machine. These machines should handle thick fabrics and multiple layers with ease. Look for a machine with a high-power motor, typically ranging from 0.5 to 1.5 horsepower, to ensure it can sew through dense materials like leather, canvas, and denim. The motor’s power directly influences the machine’s ability to maintain consistent stitching speed and force, even when dealing with tough fabrics.

Functionality is equally important. A heavy-duty sewing machine should offer a range of stitch options, including straight, zigzag, and overlock stitches, to accommodate various sewing tasks. Features such as adjustable presser foot pressure, automatic needle threading, and a reverse stitch function enhance usability and efficiency. For instance, a machine with a built-in thread cutter and an automatic bobbin winding system can significantly reduce setup time and improve workflow.

Spécifications techniques

Technical specifications provide a clear picture of a sewing machine’s capabilities. Key specs to consider include stitch speed, stitch length, and needle size compatibility. A high stitch speed, typically between 1,000 to 1,500 stitches per minute (SPM), is essential for high-volume sewing projects. Stitch length should be adjustable, ranging from 0 to 5 millimeters, to allow for fine-tuning based on the fabric and project requirements.

Needle size compatibility is another crucial specification. Heavy-duty sewing machines should support a wide range of needle sizes, from size 16 to 22, to handle various fabric thicknesses. Additionally, the machine should have a large throat space, at least 7 inches, to accommodate bulky projects and provide ample workspace.

Normes de sécurité et certifications

Safety is a critical consideration, especially for industrial-grade sewing machines. Ensure that the machine complies with relevant safety standards and certifications. Look for machines tested and certified by organizations such as UL (Underwriters Laboratories) or CE (Conformité Européenne) to guarantee they meet stringent safety and performance criteria. These certifications ensure that the machine has undergone rigorous testing for electrical safety, mechanical integrity, and overall reliability.

In addition to certifications, consider safety features such as needle guards, emergency stop buttons, and automatic shutoff mechanisms. A heavy-duty sewing machine should have built-in safety measures to prevent accidents and ensure safe operation, especially in high-speed and high-volume environments.

Gamme de prix et budget

The price range for heavy-duty sewing machines can vary significantly based on features, brand, and build quality. Entry-level models may start around $500, while high-end industrial machines can exceed $2,000. When setting a budget, consider the machine’s intended use and the volume of work it will handle. Investing in a higher-priced model with advanced features and superior build quality can be cost-effective in the long run, as it will likely require fewer repairs and have a longer lifespan.

Prioritize machines that offer a good balance of price and performance, ensuring that you get the best value for your budget without compromising on essential features and build quality.

Exploring Advanced Features in Heavy Duty Sewing Machines

Automatic Thread Cutting and Needle Positioning

One of the most sought-after features in modern heavy-duty sewing machines is automatic thread cutting. This feature allows the machine to cut the thread automatically at the end of a seam, saving time and improving efficiency. It eliminates the need for manual thread trimming, which can be time-consuming and prone to errors.

Needle positioning is another advanced feature that significantly improves sewing accuracy. Machines with automatic needle positioning can stop the needle in either the up or down position, depending on the user’s preference. This feature is particularly useful for pivoting corners, quilting, and other detailed sewing tasks. It ensures consistent stitch placement and reduces the risk of skipped stitches or fabric shifting.

Programmable Stitch Patterns and Memory Functions

Programmable stitch patterns and memory functions are becoming increasingly popular in heavy-duty sewing machines. These features allow users to save custom stitch patterns and settings for future use, streamlining the sewing process and ensuring consistent results. A machine with a wide range of built-in stitch patterns, including decorative, utility, and stretch stitches, provides greater versatility for various sewing projects. Memory functions enable users to store frequently used stitches and settings, reducing setup time and minimizing errors.

Enhanced Durability and Maintenance Features

Durability is a critical factor for heavy-duty sewing machines, as they are often used in demanding environments. Machines constructed with high-quality materials and reinforced components are more likely to withstand continuous use and harsh conditions. Maintenance features such as self-lubricating mechanisms, easy-to-access oil ports, and removable parts for cleaning can significantly extend the machine’s lifespan. Machines with built-in diagnostic systems can alert users to potential issues before they become major problems, reducing downtime and maintenance costs.

Ensuring Compatibility with Accessories and Add-Ons

Presser Feet and Attachments

Compatibility with various presser feet and attachments is essential for maximizing the functionality of a heavy-duty sewing machine. Different presser feet, such as walking feet, zipper feet, and quilting feet, enable users to perform a wide range of sewing tasks with precision and ease. Ensure that the machine is compatible with industry-standard presser feet and attachments, as this allows for greater flexibility and customization. Look for machines that offer easy attachment and detachment mechanisms, reducing setup time and enhancing user convenience.

Extension Tables and Workspaces

Extension tables and workspaces are valuable accessories for heavy-duty sewing machines, providing additional support and stability for large or bulky projects. These accessories extend the machine’s working area, making it easier to handle large pieces of fabric and reducing the risk of fabric bunching or shifting. When selecting a heavy-duty sewing machine, consider models that offer compatible extension tables or workspaces as optional add-ons. Ensure that the extension table is sturdy and easy to attach and detach, providing a seamless transition between different sewing tasks.

Compatibility with Industrial Sewing Systems

For businesses that require integration with industrial sewing systems, compatibility with automated sewing and cutting systems is a crucial consideration. Machines that can be integrated into automated production lines offer significant advantages in terms of efficiency, precision, and consistency. Ensure that the heavy-duty sewing machine is compatible with industry-standard automation systems and software, allowing for seamless integration into existing production workflows. Compatibility with automated systems can significantly reduce labor costs, increase production speed, and improve overall product quality.

Considering Energy Efficiency and Sustainability

Moteurs et composants économes en énergie

Energy efficiency is an important consideration for heavy-duty sewing machines, particularly for businesses looking to reduce operational costs and minimize their environmental impact. Machines equipped with energy-efficient motors and components consume less power while maintaining high performance. Look for machines with energy-saving features such as automatic power-off functions, which reduce energy consumption when the machine is not in use. Additionally, consider models that use LED lighting instead of traditional incandescent bulbs, as LED lights are more energy-efficient and have a longer lifespan.

Programmes de réduction et de recyclage des déchets

Waste reduction and recycling programs are essential components of a sustainable sewing operation. Choose heavy-duty sewing machines that are designed for easy disassembly and recycling at the end of their lifecycle. Machines with modular components can be repaired or replaced individually, reducing the need for full machine replacement and minimizing waste. Additionally, consider manufacturers that offer take-back or recycling programs for old or damaged machines. These programs ensure that machines are disposed of responsibly and that valuable materials are recovered and reused. Supporting manufacturers with strong waste reduction and recycling initiatives can help promote a more sustainable industry and reduce the environmental impact of sewing operations.

Réflexions finales

Selecting the right heavy-duty sewing machine requires careful consideration of various factors, including build quality, performance, technical specifications, safety standards, and budget. By focusing on these key aspects, businesses can make informed decisions and invest in machines that meet their specific needs and requirements. Advanced features, compatibility with accessories, and energy efficiency also play crucial roles in enhancing the machine’s functionality and sustainability. Prioritizing these factors ensures that businesses can achieve optimal performance, durability, and efficiency in their sewing operations.