The concrete sander market is evolving rapidly in 2025, with innovations in technology and a growing emphasis on efficiency. This article provides a comprehensive analysis of the latest trends, performance benchmarks, and essential factors for selecting the ideal concrete sander. Professional buyers will find valuable insights to make informed decisions and enhance their product portfolios.

Sommaire :

-Concrete Sander Market Overview

-In-Depth Analysis of the Concrete Sander Market

-Key Factors When Selecting a Concrete Sander

-Advanced Features in Modern Concrete Sanders

-Tendances du marché et évolutions futures

-Wrapping Up the Key Points

Concrete Sander Market Overview

The global market for concrete sanders has seen substantial growth, with a market size estimated at USD 1.15 billion in 2024. This market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5%, reaching approximately USD 1.58 billion by 2030. The increasing demand for efficient and high-performance concrete finishing tools in construction and renovation projects is a primary driver of this market. The Asia-Pacific region, particularly China and India, holds the largest market share due to rapid urbanization and infrastructure development.

In 2024, the industrial segment accounted for the largest share of the concrete sander market, driven by the need for precision and efficiency in large-scale construction projects. Additionally, the residential segment has shown significant growth due to the rising trend of DIY home improvement activities. Innovations in sander technology, such as the integration of dust collection systems and enhanced ergonomic designs, are contributing to market expansion. Furthermore, the adoption of eco-friendly materials and energy-efficient technologies is expected to boost market growth in the coming years.

The distribution of concrete sanders is primarily through offline channels, including specialty stores and retail outlets, which accounted for 65% of the market share in 2024. However, the online segment is gaining traction, with a CAGR of 8.1%, as consumers increasingly prefer the convenience of online shopping. Key players in the market include Bosch, Makita Corporation, and Hitachi, Ltd., which are focusing on expanding their product portfolios and enhancing their distribution networks to capture a larger market share.

In-Depth Analysis of the Concrete Sander Market

Indicateurs clés de performance et dynamique des parts de marché

Concrete sanders are evaluated based on several performance benchmarks, including power efficiency, dust collection capability, and user ergonomics. High-performance models typically feature variable speed controls, brushless motors, and advanced dust extraction systems, which significantly enhance user productivity and safety. The market is highly competitive, with leading manufacturers like Bosch and Makita Corporation leveraging their technological capabilities to maintain a dominant market position. These companies have substantial market shares due to their extensive product lines and robust distribution channels.

Influences économiques et changements de comportement des consommateurs

The economic landscape plays a crucial role in shaping the concrete sander market. Economic growth in emerging markets, coupled with increased government spending on infrastructure projects, has led to higher demand for construction tools, including concrete sanders. Additionally, shifts in consumer behavior, such as the growing popularity of DIY home improvement projects, have driven demand in the residential segment. Consumers are increasingly seeking high-quality, durable tools that offer enhanced performance and ease of use, influencing manufacturers to innovate and improve their product offerings.

Préférences en matière de canaux de distribution et innovations récentes

While traditional brick-and-mortar stores remain the primary distribution channel, the rise of e-commerce has significantly impacted the concrete sander market. Online platforms offer a wide range of products, competitive pricing, and the convenience of home delivery, attracting a growing number of consumers. Recent innovations in the market include the development of cordless concrete sanders, which provide greater mobility and ease of use. Additionally, advancements in dust collection technology have led to the creation of more efficient and environmentally friendly sanders, addressing consumer concerns about health and safety.

Points faibles des clients et stratégies de positionnement de la marque

Common customer pain points in the concrete sander market include issues related to dust generation, tool weight, and operational noise. Manufacturers are addressing these concerns by incorporating advanced dust collection systems, lightweight materials, and noise reduction technologies into their products. Brand positioning strategies focus on highlighting these innovative features, along with durability and reliability, to differentiate products in a competitive market. Leading brands are also investing in customer education and support services to enhance user experience and build brand loyalty.

Stratégies de différenciation et marchés de niche

Differentiation in the concrete sander market is achieved through technological innovation, product quality, and customer service. Companies are developing specialized sanders tailored to specific applications, such as high-performance models for industrial use and compact, user-friendly designs for residential projects. Niche markets, such as the restoration and refurbishment sector, offer significant growth opportunities for manufacturers. By focusing on these specialized areas and continuously improving their product offerings, companies can achieve a competitive edge and drive market growth.

Key Factors When Selecting a Concrete Sander

Choosing the right concrete sander for your business involves several critical considerations. These include the type and size of the sander, its performance specifications, design features, and compliance with safety standards. Below are the primary aspects to evaluate.

Types of Concrete Sanders

Concrete sanders come in several types, each designed for specific tasks and environments. The most common types include handheld sanders, walk-behind sanders, and edge sanders.

Handheld sanders are typically used for smaller jobs or areas where larger machines cannot reach. Their portability makes them ideal for residential projects or detailed work. They usually have a smaller motor, providing adequate power for precision tasks.

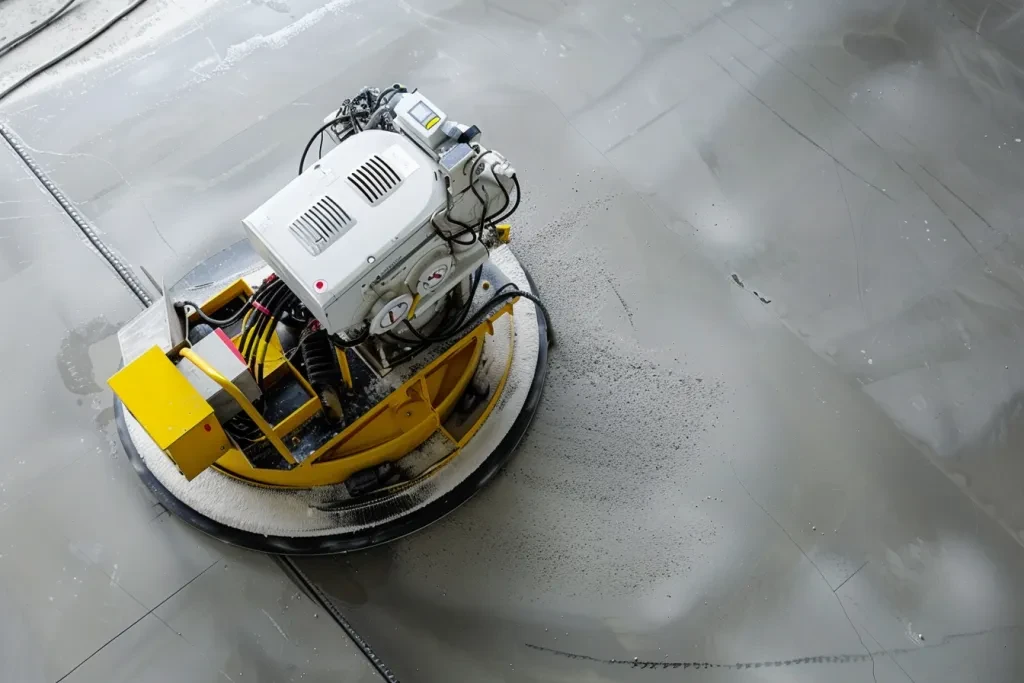

Walk-behind sanders are used for larger surface areas such as commercial floors. They are equipped with powerful motors and larger sanding discs or belts, allowing them to cover more ground efficiently. Walk-behind sanders are preferred for their ability to maintain consistent pressure over extensive surfaces.

Edge sanders are specifically designed to work along the edges of walls and other obstacles. They provide the precision needed to sand hard-to-reach areas that larger machines might miss. Edge sanders are essential for achieving a uniform finish throughout a project.

Caractéristiques de performances

Performance specifications determine a concrete sander’s efficiency and suitability for your needs. These include motor power, speed settings, and dust collection capabilities.

Motor power, typically measured in horsepower (HP) or watts (W), directly impacts the sander’s ability to handle tough surfaces. Higher power ratings facilitate faster and more efficient sanding, especially on dense concrete.

Variable speed settings allow operators to adjust the sander’s performance according to the task’s specific requirements. This flexibility is crucial for achieving different finishes, from rough to smooth, and for working with various types of concrete.

Efficient dust collection systems are critical for maintaining a clean work environment and ensuring operator safety. Integrated dust collection systems or the ability to connect to external vacuums help minimize airborne dust, which can be harmful when inhaled.

Conception et construction de qualité

The design and build quality of a concrete sander affect both its longevity and ease of use. Key aspects include the materials used, ergonomic design, and overall durability.

High-quality materials such as hardened steel and durable plastics enhance the sander’s lifespan and resistance to wear and tear. Robust components ensure that the sander can withstand heavy use.

Ergonomic design features such as adjustable handles, cushioned grips, and balanced weight distribution reduce operator fatigue and increase precision. These features are particularly important for prolonged use and detailed work.

The overall durability of a concrete sander is influenced by its construction quality. Machines with reinforced frames and high-grade components are more likely to provide reliable performance over time, reducing maintenance costs and downtime.

Normes de sécurité et certifications

Compliance with safety standards and certifications is essential when selecting a concrete sander. Look for machines that meet or exceed industry safety standards, such as those set by OSHA or other relevant bodies.

Important safety features include emergency stop buttons, overload protection, and guards to prevent accidental contact with moving parts. These features help protect operators from potential hazards during operation.

Certifications from recognized organizations provide assurance that the sander has been tested for safety and performance. Common certifications include CE marking for European markets and UL listing for North American markets.

Considérations de coût et de budget

The price range of concrete sanders varies significantly based on their type, features, and brand. Budget considerations should include the initial purchase price, maintenance costs, potential downtime, and the availability of replacement parts.

While higher-end models with advanced features may come at a premium, they often offer better performance and durability, which can justify the investment in the long run.

Consider the ease of maintenance and availability of spare parts. Machines that require frequent repairs or have hard-to-find parts can lead to higher long-term costs and operational interruptions.

High-quality, well-maintained sanders typically retain better resale value. This can be an important factor for businesses that plan to upgrade their equipment periodically.

Advanced Features in Modern Concrete Sanders

Technological advancements have led to the development of concrete sanders with enhanced features that improve efficiency, ease of use, and safety.

Capteurs intelligents et automatisation

Modern concrete sanders often incorporate smart sensors and automation features that optimize performance and reduce manual intervention.

Load sensors detect resistance and adjust the motor speed accordingly to maintain consistent performance. This feature helps prevent motor overload and ensures smooth operation.

Automated features such as programmable settings and self-adjusting sanders enhance productivity by allowing operators to set specific parameters for different tasks. Automation reduces the need for constant manual adjustments, leading to more efficient workflows.

Connectivité et surveillance à distance

Connectivity options such as Bluetooth and Wi-Fi allow for remote monitoring and control of concrete sanders.

Operators can monitor the sander’s performance, receive maintenance alerts, and adjust settings remotely. This feature is particularly useful for large-scale operations where multiple machines are in use simultaneously.

Advanced models can log operational data, providing insights into usage patterns, maintenance needs, and performance metrics. This data can be used to optimize operations and extend the machine’s lifespan.

Enhanced Dust Management Systems

Improved dust management systems in modern concrete sanders ensure a cleaner and safer work environment.

High-Efficiency Particulate Air (HEPA) filters capture fine dust particles, reducing the amount of airborne dust and improving air quality. HEPA filtration is essential for compliance with stringent health and safety regulations.

Sealed dust collection systems prevent dust from escaping during operation. These systems handle the high volume of dust generated by concrete sanding, ensuring efficient collection and disposal.

Tendances du marché et développements futurs

The concrete sander market continues to evolve, with several trends shaping the future of this essential construction tool.

Increasing Demand for Eco-Friendly Solutions

There is a growing demand for eco-friendly concrete sanders that minimize environmental impact.

Manufacturers are focusing on developing energy-efficient sanders that reduce power consumption without compromising performance. Energy-efficient models help lower operational costs and reduce carbon footprints.

The use of sustainable and recyclable materials in the construction of sanders is becoming more prevalent. This trend aligns with the broader industry push towards sustainability and environmental responsibility.

Intégration avec la modélisation des informations du bâtiment (BIM)

The integration of concrete sanders with Building Information Modeling (BIM) systems represents a significant advancement in construction technology.

BIM integration allows for seamless coordination between the sander and other construction tools and systems. This integration enhances project planning, execution, and management, leading to improved efficiency and accuracy.

Real-time data sharing between the sander and BIM systems enables better decision-making and project tracking. This capability ensures that all stakeholders have access to up-to-date information, facilitating smoother project workflows.

Adoption of Robotics and AI

The adoption of robotics and artificial intelligence (AI) in concrete sanding is set to revolutionize the industry.

Robotic sanders can perform tasks autonomously, reducing the need for manual labor and increasing precision. These machines are particularly useful for large-scale projects and repetitive tasks.

AI algorithms can analyze data from sensors and adjust the sander’s performance in real-time. This capability enhances efficiency, reduces errors, and extends the lifespan of the machine by optimizing its operation based on the specific requirements of each task.

Wrapping Up the Key Points

Selecting the right concrete sander is a multifaceted decision that requires careful consideration of various factors. From the type and performance specifications to design features and safety standards, each aspect plays a crucial role in ensuring that the sander meets your operational needs. Furthermore, staying abreast of market trends and technological advancements can provide a competitive edge, allowing you to leverage the latest innovations for improved efficiency and sustainability. By taking a comprehensive approach to selection, you can ensure that your investment in a concrete sander yields optimal results for your business.