En 2025, le marché des imprimantes à tampons est en plein essor, porté par les progrès de la technologie d'impression et de l'automatisation. Cet article fournit une analyse approfondie des facteurs critiques à prendre en compte lors de la sélection d'une imprimante à tampons, notamment les spécifications de performances, la qualité de fabrication et les considérations de coût. Les acheteurs professionnels trouveront des informations précieuses pour prendre des décisions d'achat éclairées, garantissant que leurs sélections répondent aux exigences opérationnelles et améliorent la productivité.

Sommaire :

-Aperçu du marché de l'industrie des imprimantes à tampons en 2025

-Analyse approfondie et informations sur le marché des imprimantes à tampons

-Facteurs clés à prendre en compte lors de la sélection d'une imprimante à tampons

-Fonctionnalités avancées des imprimantes à tampon modernes

-Applications des imprimantes à tampon dans diverses industries

- Tendances futures de la technologie de tampographie

-Réflexions finales

Aperçu du marché des imprimantes à tampons en 2025

Le marché mondial des imprimantes à tampon a connu une croissance substantielle, la taille du marché atteignant environ 1.2 milliard USD en 2024. Il devrait croître à un taux de croissance annuel composé (TCAC) de 5.3 % au cours de la période de prévision, pour atteindre environ 1.56 milliard USD d'ici 2029. Cette croissance est tirée par la demande croissante d'industries telles que l'électronique, l'automobile, les appareils médicaux et les produits promotionnels. La capacité de la technologie de tampographie à imprimer sur des surfaces irrégulières et à traiter divers substrats, notamment les plastiques, les métaux, la céramique et le verre, en a fait un choix privilégié pour les fabricants.

L'Asie-Pacifique détient la plus grande part de marché, représentant 45 % du marché mondial des imprimantes à tampons. Cette domination est due au secteur manufacturier solide de pays comme la Chine, le Japon et la Corée du Sud. L'Amérique du Nord et l'Europe suivent, avec des parts de marché de 25 % et 20 %, respectivement. Les 10 % restants sont répartis entre d'autres régions, notamment l'Amérique latine et le Moyen-Orient et l'Afrique. L'adoption croissante de l'automatisation et les progrès des technologies d'impression sont des facteurs clés contribuant à l'expansion du marché.

Le marché des imprimantes à tampons compte plusieurs acteurs clés, dont Teca-Print AG, TAMPOPRINT AG et Inkcups. Ces entreprises investissent massivement dans la recherche et le développement pour introduire des produits innovants et renforcer leur présence sur le marché. Le marché est modérément fragmenté, les cinq principaux acteurs détenant environ 60 % des parts de marché. Le paysage concurrentiel est façonné par la différenciation des produits, les avancées technologiques et les collaborations stratégiques.

Analyse approfondie et informations sur le marché des imprimantes à tampons

Les imprimantes à tampon sont essentielles pour diverses applications, notamment l'impression sur des appareils médicaux, des pièces automobiles et des produits électroniques grand public. Les critères de performance clés des imprimantes à tampon comprennent une précision d'impression élevée, une vitesse et une capacité à gérer des motifs complexes. Le marché a connu une évolution vers des systèmes d'impression à tampon automatisés, qui offrent une efficacité accrue et des coûts de main-d'œuvre réduits. Ces systèmes sont dotés de fonctionnalités avancées telles que des bras robotisés, un mélange d'encre automatisé et des systèmes de contrôle qualité intégrés.

Les influences économiques, telles que les fluctuations des prix des matières premières et les politiques commerciales, ont un impact sur le marché des imprimantes à tampon. La hausse des coûts des encres et des solvants préoccupe les fabricants, ce qui les incite à développer des alternatives rentables et respectueuses de l'environnement. Le comportement des consommateurs a également changé, avec une demande croissante de produits personnalisés. Cette tendance a favorisé l'adoption des imprimantes à tampon dans le secteur des produits promotionnels, où les entreprises cherchent à différencier leurs offres grâce à une image de marque unique.

Les préférences en matière de canaux de distribution varient selon les régions. En Amérique du Nord et en Europe, les ventes directes et les canaux de distribution en ligne sont prédominants, tandis qu'en Asie-Pacifique, une combinaison de ventes directes, de distributeurs et de canaux en ligne est courante. Les innovations récentes en matière de tampographie comprennent le développement de systèmes hybrides numériques qui combinent la tampographie et les technologies d'impression numérique, offrant une plus grande flexibilité et une meilleure qualité d'impression. Les étapes du cycle de vie du produit pour les tampographes impliquent des améliorations et des mises à niveau continues, axées sur l'allongement de la durée de vie des équipements d'impression et la réduction des coûts de maintenance.

La digitalisation et l'Industrie 4.0 transforment le marché de la tampographie, les fabricants adoptant des pratiques de fabrication intelligentes. L'intégration de l'IoT et de l'IA dans les systèmes de tampographie permet une surveillance en temps réel et une maintenance prédictive, améliorant ainsi l'efficacité opérationnelle. Les tendances sociales, telles que l'accent croissant mis sur la durabilité, ont conduit au développement d'encres et de processus d'impression respectueux de l'environnement. Les problèmes des clients, notamment les coûts opérationnels élevés et les options de couleurs limitées, sont résolus grâce à une innovation continue et à l'introduction de solutions rentables.

Les stratégies de positionnement de marque sur le marché des imprimantes à tampons mettent l'accent sur la fiabilité des produits, les avancées technologiques et les services d'assistance à la clientèle. Les stratégies de différenciation incluent l'offre de solutions personnalisées, de services après-vente et de programmes de formation pour les opérateurs. Les marchés de niche, tels que l'impression de dispositifs médicaux et l'impression de pièces automobiles de haute précision, présentent des opportunités de croissance importantes pour les fabricants d'imprimantes à tampons. Les entreprises se concentrent sur ces segments de niche pour tirer parti de leur expertise et acquérir un avantage concurrentiel.

Facteurs clés à prendre en compte lors de la sélection d'une imprimante à tampons

Le choix de la machine à tamponner adaptée à votre activité implique l'évaluation de plusieurs facteurs essentiels. Ces facteurs garantissent que la machine répond à vos besoins spécifiques et à vos exigences opérationnelles. Vous trouverez ci-dessous des explications détaillées sur les considérations essentielles.

technologie d'impression

Les imprimantes à tampon utilisent différentes technologies d'impression pour répondre à différentes applications. Les principales technologies d'impression comprennent l'impression à tampon conventionnelle, l'impression à tampon rotative, les systèmes à godets fermés et les systèmes à encriers ouverts.

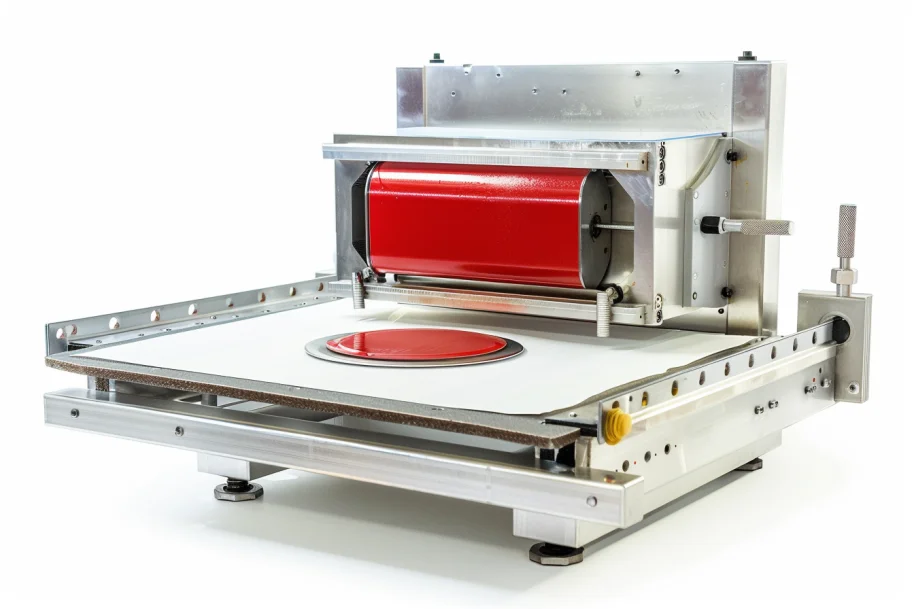

La tampographie conventionnelle utilise un tampon en silicone pour transférer l'encre d'une plaque gravée sur le substrat. Elle convient à l'impression sur des surfaces irrégulières et est largement utilisée dans les industries de fabrication et de produits promotionnels. La flexibilité du tampon en silicone lui permet de s'adapter à diverses formes et textures.

Dans la tampographie rotative, le substrat et le tampon se déplacent de manière synchronisée, ce qui est idéal pour l'impression sur des objets cylindriques. Cette méthode est couramment utilisée pour les stylos, les bouteilles et autres objets ronds. Le mouvement continu améliore la vitesse et l'efficacité de l'impression.

Les imprimantes à tampon à godet fermé utilisent un godet d'encre scellé qui glisse sur le cliché (plaque d'impression), minimisant ainsi l'évaporation et la contamination de l'encre. Cette technologie offre un fonctionnement plus propre et est préférée pour les applications de haute précision où la cohérence de l'encre est cruciale.

Contrairement aux systèmes à coupelle fermée, les systèmes à encrier ouvert disposent d'un réservoir d'encre exposé. Ces systèmes sont plus faciles à installer et à entretenir, ce qui les rend adaptés aux travaux à tirage court et aux applications nécessitant des changements de couleur fréquents.

Caractéristiques de performances

Les spécifications de performances sont essentielles pour déterminer l'efficacité et la qualité de l'imprimante à tampons. Les indicateurs de performances clés comprennent la vitesse d'impression, la résolution, la compatibilité des encres, ainsi que la taille et la zone d'impression.

La vitesse d'impression, mesurée en cycles par heure, indique la rapidité avec laquelle la machine peut terminer un cycle d'impression. Les imprimantes à tampon à grande vitesse sont avantageuses pour la production à grande échelle, mais peuvent nécessiter des systèmes de manutention plus sophistiqués pour suivre le rythme de production.

La résolution d'une imprimante à tampon est déterminée par la finesse de la plaque gravée et la précision du processus de transfert d'encre. Les imprimantes haute résolution peuvent produire des images détaillées et nettes, ce qui est essentiel pour les applications nécessitant des graphiques complexes ou du texte de petite taille.

Différentes encres sont utilisées pour différents supports et applications. La compatibilité de l'imprimante à tampon avec différents types d'encre, tels que les encres à base de solvant, à séchage UV ou à base d'eau, est essentielle pour obtenir la qualité d'impression et la durabilité souhaitées.

La taille et la surface d'impression maximales que l'imprimante à tampons peut traiter doivent correspondre aux dimensions de votre produit. Des zones d'impression plus grandes offrent plus de flexibilité, mais peuvent nécessiter des machines plus importantes et des coûts plus élevés.

Construire la qualité et la durabilité

La qualité de fabrication d'une imprimante à tampons a un impact sur sa longévité et sa fiabilité. Tenez compte des matériaux et de la construction, de la qualité des composants et de la réputation du fabricant.

Les imprimantes à tampon de haute qualité sont généralement fabriquées à partir de matériaux robustes tels que l'acier inoxydable ou l'aluminium, qui résistent à l'usure et à la corrosion. Le châssis de la machine doit être robuste pour maintenir l'alignement et la précision au fil du temps.

La qualité des composants tels que les tampons en silicone, les clichés et les godets d'encre affecte les performances de la machine. Des composants de haute qualité garantissent des résultats d'impression cohérents et réduisent les temps d'arrêt dus à la maintenance ou aux remplacements.

Acheter auprès de fabricants réputés ayant fait leurs preuves dans la production d'imprimantes à tampon fiables peut vous garantir la qualité et le service après-vente. Recherchez les certifications du secteur et les avis des clients qui reflètent l'engagement du fabricant envers l'excellence.

Facilité d'utilisation et de configuration

Les imprimantes à tampons conviviales peuvent réduire considérablement le temps de configuration et les besoins de formation des opérateurs. Tenez compte de l'interface de commande, de la complexité de la configuration et des exigences de maintenance.

Les imprimantes à tampon modernes sont souvent équipées de panneaux de commande numériques qui permettent de régler et de surveiller facilement les paramètres d'impression. Des interfaces intuitives peuvent réduire la courbe d'apprentissage et améliorer l'efficacité opérationnelle.

Les machines équipées de systèmes de changement rapide de tampons et de clichés simplifient le processus de configuration et réduisent les temps d'arrêt lors des changements de couleur ou de la maintenance. Les fonctions d'étalonnage automatisées peuvent également améliorer la facilité d'utilisation.

Les imprimantes à tampon dotées de composants accessibles et de procédures de maintenance simples peuvent minimiser les temps d'arrêt et les coûts d'exploitation. Un entretien régulier est essentiel pour garantir une qualité d'impression constante et prolonger la durée de vie de la machine.

Considérations de coûts

Le coût d'une imprimante à tampons est un facteur important, mais il doit être mis en balance avec d'autres considérations telles que les performances, la durabilité et la facilité d'utilisation. Les principaux aspects liés aux coûts comprennent l'investissement initial, les coûts d'exploitation et le retour sur investissement (ROI).

Le coût initial de l'imprimante à tampons comprend le prix de la machine et tous les accessoires supplémentaires ou coûts d'installation. Les modèles haut de gamme dotés de fonctionnalités avancées peuvent avoir des coûts initiaux plus élevés, mais peuvent offrir une meilleure valeur à long terme grâce à des performances améliorées et une maintenance réduite.

Les coûts récurrents tels que l'encre, les tampons, les clichés et la maintenance doivent être pris en compte dans le coût total de possession. Les modèles à faible consommation d'encre et à faible consommation d'énergie peuvent réduire les dépenses d'exploitation.

Évaluez le retour sur investissement potentiel en fonction de la productivité, de la qualité et de la polyvalence de l'imprimante. Un investissement initial plus élevé peut être justifié si la machine peut gérer une gamme plus large d'applications et fournir des résultats cohérents et de haute qualité.

Fonctionnalités avancées des imprimantes à tampon modernes

Les imprimantes à tampon modernes sont équipées de fonctionnalités avancées qui améliorent leur fonctionnalité et leur efficacité. Ces fonctionnalités comprennent l'intégration numérique, les capacités d'automatisation et les options respectueuses de l'environnement.

L'intégration des technologies numériques dans les imprimantes à tampon a révolutionné le processus d'impression. Les interfaces numériques et les systèmes de contrôle permettent des réglages précis et une surveillance en temps réel des paramètres d'impression. Les options de connectivité telles que USB ou Ethernet permettent un transfert de données transparent et une intégration avec d'autres systèmes de production. Ces avancées améliorent la précision, réduisent les temps de configuration et facilitent l'automatisation des processus.

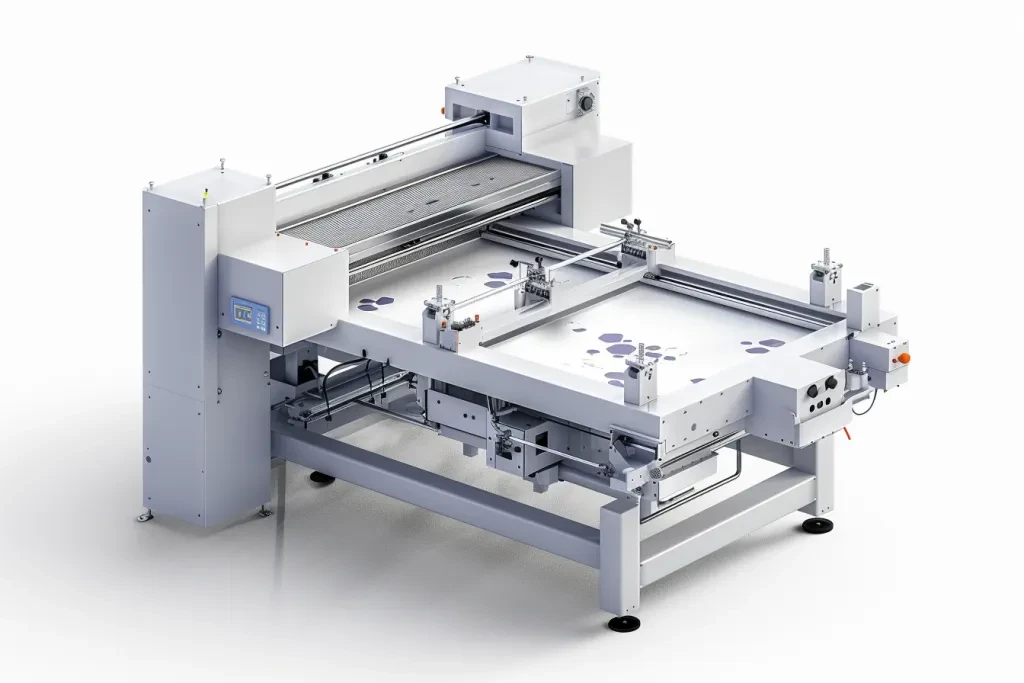

L'automatisation de la tampographie peut améliorer considérablement la productivité et la cohérence. Les imprimantes à tampon automatisées peuvent gérer des tâches telles que l'alimentation du substrat, l'application de l'encre et l'éjection des pièces sans intervention manuelle. Cela réduit le risque d'erreurs et garantit une qualité d'impression uniforme. L'automatisation est particulièrement avantageuse pour les environnements de production à volume élevé où la vitesse et la cohérence sont essentielles.

Les préoccupations environnementales devenant de plus en plus importantes, de nombreux fabricants proposent des solutions de tampographie respectueuses de l'environnement. Il s'agit notamment de machines conçues pour être utilisées avec des encres et des solvants respectueux de l'environnement, ainsi que de modèles économes en énergie qui réduisent la consommation d'énergie. Les imprimantes à tampon respectueuses de l'environnement aident les entreprises à respecter les exigences réglementaires et à réduire leur empreinte environnementale.

Applications des imprimantes à tampon dans diverses industries

Les imprimantes à tampon sont polyvalentes et peuvent être utilisées dans de nombreux secteurs industriels. Parmi les applications courantes, on trouve l'industrie automobile, les appareils médicaux et l'électronique grand public.

Dans l'industrie automobile, les imprimantes à tampon sont utilisées pour imprimer sur divers composants tels que les boutons du tableau de bord, les pommeaux de levier de vitesse et les panneaux indicateurs. La possibilité d'imprimer sur des surfaces profilées rend les imprimantes à tampon idéales pour ces applications, garantissant des marquages durables et de haute qualité qui résistent aux rigueurs de l'utilisation automobile.

La tampographie est largement utilisée dans l'industrie des dispositifs médicaux pour imprimer sur des articles tels que des seringues, des cathéters et des instruments chirurgicaux. La précision et la propreté de la tampographie la rendent adaptée aux applications médicales, où la précision et la stérilité sont primordiales. Des encres de qualité médicale conformes aux normes réglementaires sont utilisées pour garantir la sécurité et la durabilité.

Les appareils électroniques grand public nécessitent souvent des marquages et des logos détaillés sur des composants petits et complexes. Les imprimantes à tampons excellent dans ce domaine, en fournissant des impressions haute résolution sur des articles tels que des coques de téléphone portable, des télécommandes et des circuits imprimés. La possibilité d'imprimer sur divers matériaux, notamment les plastiques et les métaux, ajoute à la polyvalence des imprimantes à tampons dans ce secteur.

Tendances futures de la technologie de tampographie

L'industrie de la tampographie continue d'évoluer et plusieurs tendances émergentes façonnent son avenir. Ces tendances comprennent une automatisation accrue, des avancées dans la technologie de l'encre et des solutions d'impression intelligentes.

La tendance à l'automatisation croissante devrait se poursuivre, avec de plus en plus d'imprimeurs tampographes intégrant des systèmes robotisés et des technologies de contrôle avancées. Cela améliorera l'efficacité, réduira les coûts de main-d'œuvre et améliorera la cohérence de l'impression. L'automatisation permet également l'intégration de la tampographie à d'autres processus de fabrication, créant ainsi des lignes de production rationalisées et hautement efficaces.

Les progrès de la technologie des encres améliorent les capacités des imprimantes à tampon. De nouvelles formulations d'encres offrent une adhérence, une durabilité et des performances environnementales améliorées. Les encres à séchage UV, par exemple, offrent des temps de séchage rapides et une qualité d'impression supérieure, ce qui les rend idéales pour les environnements de production à grande vitesse.

L'adoption de solutions d'impression intelligentes est en hausse, les imprimantes à tampons devenant de plus en plus connectées et axées sur les données. Les imprimantes compatibles IoT peuvent fournir des données en temps réel sur les performances des machines, les niveaux d'encre et les besoins de maintenance. Ces données peuvent être utilisées pour optimiser les processus de production, prévoir les besoins de maintenance et réduire les temps d'arrêt.

Réflexions finales

Le choix de la bonne tampographie nécessite une prise en compte minutieuse de divers facteurs, notamment la technologie d'impression, les spécifications de performances, la qualité de fabrication, la facilité d'utilisation et le coût. Les tampographies modernes offrent des fonctionnalités avancées qui améliorent leur fonctionnalité et leur efficacité, ce qui les rend adaptées à une large gamme d'applications. À mesure que la technologie continue d'évoluer, le secteur de la tampographie connaîtra une automatisation accrue, des progrès dans la technologie de l'encre et l'adoption de solutions d'impression intelligentes, ce qui entraînera de nouvelles améliorations de la qualité d'impression et de l'efficacité de la production.