The grain mill grinder market has seen rapid advancements in 2025, fueled by the growing popularity of processed foods and home baking. This article provides a comprehensive analysis, covering types, performance, design, and the latest technology features of grain mill grinders. Professional buyers will find valuable insights to make informed purchasing decisions and enhance their business operations. Transitioning to the main text, let’s delve into the critical factors for selecting the right grain mill grinder.

Sommaire :

Grain Mill Grinder Market: A Comprehensive Overview

In-Depth Analysis of the Grain Mill Grinder Market

Key Trends Shaping the Grain Mill Grinder Market

Key Factors When Selecting a Grain Mill Grinder

Latest Technology Features in Grain Mill Grinders

Normes de sécurité et certifications

Qualité des emballages et conformité réglementaire

Réflexions finales

Grain Mill Grinder Market: A Comprehensive Overview

The global grain mill grinder market has experienced significant growth in recent years. This is due to the increasing demand for processed food and the rising popularity of home baking. By 2025, the market is valued at approximately USD 1.8 billion, with a projected compound annual growth rate (CAGR) of 4.2% through 2030. The expanding middle class in emerging economies such as China and India, where disposable incomes and urbanization rates are increasing, largely drives this growth.

North America and Europe remain the largest markets for grain mill grinders, accounting for over 50% of global sales. The United States alone represents a market share of 25%, influenced by a strong consumer preference for home-cooked meals and a growing trend towards healthy eating. In Europe, Germany and the United Kingdom lead the market with substantial investments in advanced grain milling technologies.

Asia-Pacific is the fastest-growing region, with a CAGR of 5.6%. This growth is fueled by increasing agricultural activities, a surge in small-scale milling operations, and growing awareness of the benefits of freshly milled grains. Additionally, government initiatives to support local food processing industries are providing further momentum to the market.

In-Depth Analysis of the Grain Mill Grinder Market

The grain mill grinder market offers a diverse range of products, including manual, electric, and commercial-grade grinders. Key performance benchmarks for these products include grinding efficiency, durability, and ease of use. Electric grinders, which account for 60% of the market, are preferred for their high efficiency and convenience, especially in urban areas where time-saving appliances are highly sought after.

Leading players such as Kitchenaid, NutriMill, and WonderMill dominate the market with a combined share of 40%. These companies leverage advanced technologies and strong distribution networks to maintain their competitive edge. Economic influences, such as fluctuating raw material prices and trade tariffs, have also impacted market dynamics, prompting manufacturers to optimize their supply chains and explore alternative materials.

Consumer behavior has shifted significantly towards online shopping, with e-commerce channels accounting for 35% of grain mill grinder sales. This trend is expected to continue, driven by the convenience and variety offered by online platforms. Additionally, innovations such as smart grinders equipped with IoT capabilities are gaining traction, allowing users to monitor and control the grinding process remotely.

Key Trends Shaping the Grain Mill Grinder Market

A notable trend in the grain mill grinder market is the increasing demand for organic and gluten-free flours. Consumers are becoming more health-conscious and seek products that cater to specific dietary needs. This has led to the development of specialized grinders designed to process a variety of grains, including quinoa, millet, and amaranth.

Digitalization is another significant trend, with manufacturers incorporating advanced technologies such as AI and machine learning to enhance product performance and user experience. For example, some modern grain mill grinders feature sensors that adjust grinding speed and pressure based on the type of grain being processed, ensuring optimal results.

The market is also witnessing a rise in niche markets, particularly in regions with strong culinary traditions. In countries like Italy and France, there is a growing demand for traditional stone grinders that produce flour with a unique texture and flavor. These niche products command a premium price and cater to consumers who value authenticity and artisanal quality.

Key Factors When Selecting a Grain Mill Grinder

Types of Grain Mill Grinders

Grain mill grinders come in manual, electric, and combination types. Manual grinders are ideal for small-scale operations without electricity. They require physical effort but offer precise control. Electric grinders suit larger-scale operations, powered by motors to handle significant quantities with minimal effort. Combination grinders provide the flexibility of both manual and electric operation.

Consider the volume of grain you plan to process and power availability when selecting a type. Manual grinders are affordable and portable but not ideal for high-volume needs. Electric grinders offer efficiency and speed but come at a higher cost and need a stable power supply. Combination grinders, though more expensive, offer operational flexibility.

Performances et fonctionnalités

A grain mill grinder’s performance is determined by its grinding capacity, speed, and consistency. High-performance grinders process large quantities quickly, ideal for commercial use. Grinding capacity is measured in pounds per hour, with industrial models handling hundreds of pounds. Speed is crucial, with some grinders offering adjustable settings for grind fineness.

Consistency is essential for uniform flour quality. Grinders with adjustable settings achieve various textures, from coarse to fine. This flexibility is vital for businesses producing different types of flour. High-end models may feature advanced technologies like burr or stone grinding mechanisms, enhancing output quality.

Design & Esthétique

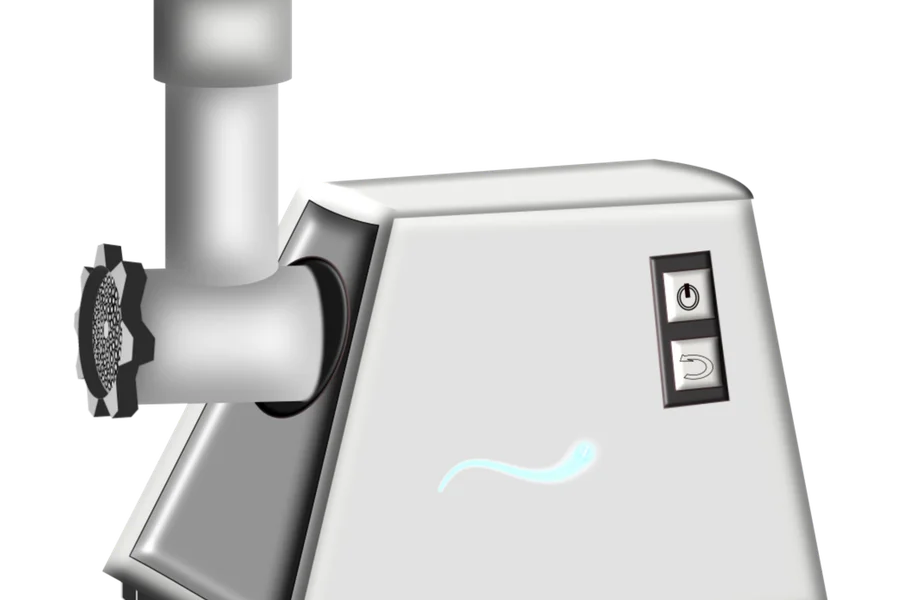

The design and aesthetics of a grain mill grinder impact its usability and workspace integration. A well-designed grinder should be easy to operate, clean, and maintain. Ergonomic features like comfortable handles and intuitive controls make it user-friendly. Compact designs benefit small spaces, while larger models suit industrial settings.

Aesthetics, though secondary, can influence your decision. A visually appealing grinder enhances your workspace, especially in customer-facing environments. Stainless steel models are popular for their sleek appearance and durability. Ensure the build quality is robust to withstand frequent use.

Spécifications techniques

Understanding a grain mill grinder’s technical specifications is crucial. Key specs include motor power, voltage, and grinding capacity. Motor power, measured in horsepower (HP), indicates the grinder’s ability to handle tough grains consistently. Higher HP motors are typically in industrial-grade grinders for large-scale operations.

Ensure voltage requirements match your power supply. Most commercial grinders operate on standard voltages, but verify compatibility to avoid issues. Grinding capacity indicates how much grain the grinder can process in a specific time frame, meeting production needs without compromising performance.

Gamme de prix et budget

Grain mill grinders’ prices vary based on type, performance, and features. Manual grinders are the most affordable, ranging from $50 to $200. Electric grinders cost between $200 and $1,000, depending on capacity and features. Combination grinders can exceed $1,000 due to their dual functionality.

When setting a budget, consider the long-term benefits of a high-quality grinder. While initial costs may be higher, durable models can save money by reducing maintenance and replacement expenses. Higher-end grinders often come with warranties and customer support, providing added value.

Latest Technology Features in Grain Mill Grinders

Modern grain mill grinders incorporate digital controls, automated settings, and advanced mechanisms. Digital controls allow precise adjustments for grind size and consistency. Automated settings simplify operation, reducing manual intervention.

Advanced mechanisms, like burr and stone grinders, offer superior performance. Burr grinders use two abrasive surfaces for a uniform texture. Stone grinders use natural or synthetic stones, preserving nutritional value and flavor. These technologies enhance flour quality, suitable for both commercial and artisanal purposes.

Normes de sécurité et certifications

Safety is crucial when selecting a grain mill grinder. Ensure the model meets industry safety standards and certifications. Look for features like overload protection and safety interlocks. Certifications from recognized bodies like the National Sanitation Foundation (NSF) or Underwriters Laboratories (UL) indicate compliance with safety and hygiene standards.

Proper maintenance and regular inspections are essential for safe operation. Follow the manufacturer’s guidelines for cleaning and servicing to prevent hazards and prolong lifespan. A certified grinder ensures safety, enhancing efficiency and reliability.

Qualité des emballages et conformité réglementaire

Packaging quality affects a grain mill grinder’s durability during transit and storage. Ensure secure packaging to prevent damage. High-quality materials like foam inserts and sturdy boxes provide protection.

Regulatory compliance ensures the grinder meets legal and industry standards. Verify compliance with food safety standards and electrical safety codes. Look for certifications from recognized authorities, indicating adherence to regulations.

Réflexions finales

Selecting the right grain mill grinder requires considering type, performance, design, technical specifications, and price. Modern grinders offer advanced features that enhance efficiency and quality. Prioritize safety standards, certifications, and regulatory compliance for reliable operation. Investing in a high-quality grinder can significantly impact production capabilities and business success.