The woodworking machinery market is constantly evolving, with new innovations and reliable products dominating the sales charts each month. This list showcases the hot-selling “Chovm Guaranteed” products for December 2024, selected based on the highest sales volume from top international vendors on Chovm.com. These products are sourced directly from vendors who provide a streamlined purchasing experience, offering guaranteed fixed prices, on-time delivery, and a money-back guarantee for any issues related to the order or shipment. Whether you’re a seasoned retailer or new to the woodworking industry, this list will guide you toward popular machinery that meets high demand this season. Each product featured has been carefully selected to ensure it not only meets quality standards but also offers practical value for online retailers.

At Chovm, we understand the importance of a hassle-free purchasing process. The “Chovm Guaranteed” program offers you fixed prices that include shipping costs, guaranteed delivery by scheduled dates, and a full money-back guarantee for any order discrepancies. This makes it easier for retailers to stock their inventory with confidence, knowing that there will be no hidden costs or unexpected delays.

Product 1: Portable Edge Banding Machine – Efficient MDF Production

Edge banding is a crucial process in woodworking, especially for those working with MDF (Medium Density Fiberboard). The Portable Edge Banding Machine is a compact, fully automatic solution for businesses that need an efficient, high-quality machine for edge finishing. Designed for ease of use, this model is ideal for both small and large-scale woodworking operations, offering a balance of precision and portability. With its simple operation, this machine allows users to achieve smooth, professional-quality edges on MDF and similar materials.

This automatic mini edge banding machine is engineered for high productivity, providing quick and consistent results. Weighing just 50 kg and with a compact size (63x50x62 cm), it’s highly suitable for workshops with limited space. Powered by a 0.8 kW motor and operating at 220V, it ensures effective edge banding on a variety of materials without requiring complex setup or technical knowledge. Whether you’re in a building materials shop, a machinery repair shop, or even working from home, this machine is versatile enough for various applications.

Key features include its portability, making it a perfect solution for retailers and small businesses. The machine comes with a 1-year warranty, and the manufacturer offers video outgoing inspection to ensure quality control before shipping. Backed by a reputable brand like Boling, this edge banding machine provides a solid option for those looking to streamline their woodworking processes.

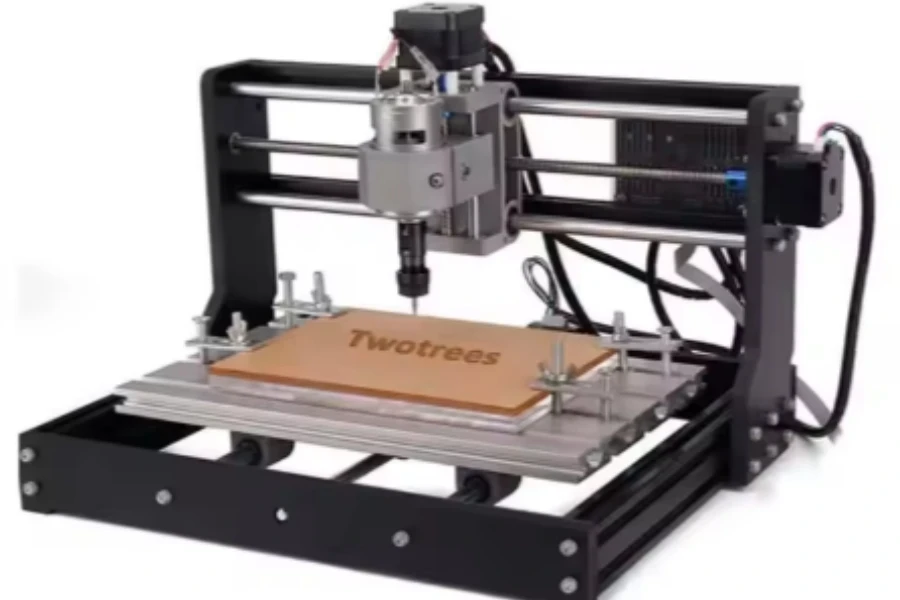

Product 2: TWOTREES DIY Small 3018 Pro Engraver Mini CNC Wood Router

The TWOTREES 3018 Pro Engraver Mini CNC Wood Router offers a versatile and compact solution for DIY enthusiasts and small businesses looking to create intricate designs on a variety of materials. This multi-functional CNC router comes equipped with advanced features that allow users to engrave wood, plastic, acrylic, and even metal. It is ideal for applications in advertising companies, garment shops, construction works, and even home use, providing the flexibility to work with different materials and offer a broad range of custom designs.

Designed with a 3-axis system, this machine boasts a work table size of 300x180x40mm and a positioning accuracy of 0.1 mm, ensuring precision in every engraving project. The 775 spindle motor can reach speeds ranging from 1 to 8000 rpm, giving users complete control over the cutting and engraving process. This allows for high-quality results on materials such as wood, plastic, aluminum, and brass. The automatic operation and compatibility with GRBL control software make it easy for users to operate, even with minimal technical experience.

Weighing just 7.5 kg and with a compact size of 420x355x280 mm, the TWOTREES 3018 Pro is highly portable, making it an excellent choice for businesses with limited space. The machine also features replaceable drill bits (3.175mm diameter, 30mm length), and users can easily switch out the laser head for laser engraving applications. The 1-year warranty and video inspection before shipment ensure quality assurance, while the multi-spindle system enhances the machine’s flexibility for different engraving and milling tasks. Supporting a variety of operating systems, including Windows XP, 7, 8, 10, and Linux, the router is adaptable to various setups. Whether engraving metal, plastic, or wood, this machine offers precision and efficiency for all types of crafting and production tasks.

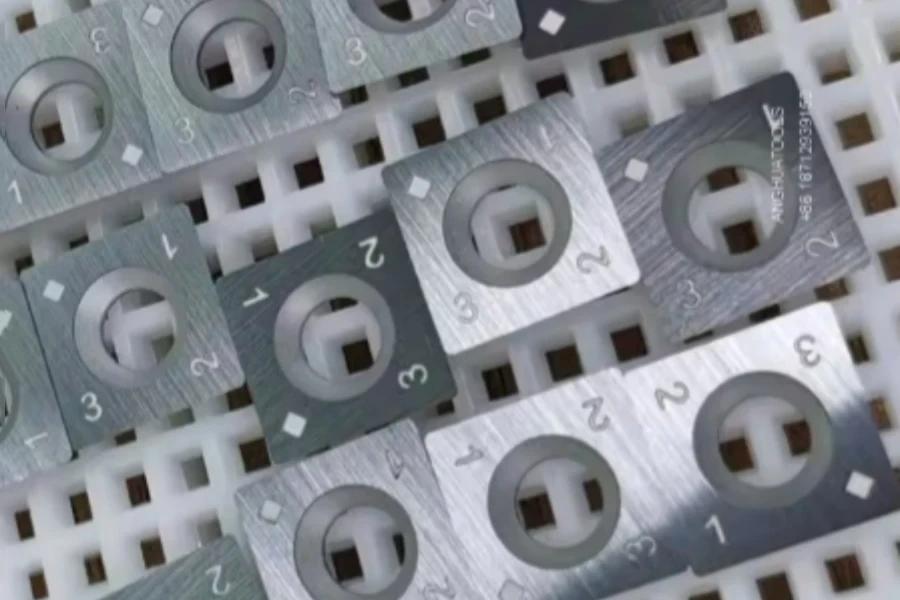

Product 3: Carbide Knife Inserts for Woodworking Planer Cutter Heads

The Carbide Knife Inserts 15x15x2.5 are designed for precision in planing and finishing applications, specifically crafted for woodworking planer cutter heads. Made from high-quality tungsten carbide, these inserts are highly durable and maintain their sharpness for extended periods, making them essential for achieving smooth and accurate finishes in woodworking operations. With a size of 15x15x2.5 mm, they are compatible with 4-sides planers and 2-sides planers, offering flexibility for various machinery setups.

These inserts are a vital component in manufacturing plants that require high-accuracy cutting and finishing for wood. Whether used in mass production or small-scale operations, they ensure consistent and precise results. The carbide material provides resistance to wear and tear, even during heavy-duty operations, making these inserts suitable for long-term use. The inserts come in a silver color and are packaged in a PC box for secure storage and easy handling. While the product doesn’t include a warranty, the manufacturer provides online support for any inquiries or troubleshooting, ensuring peace of mind for buyers.

With a delivery time of 3-7 days and the option for customized sizes, these carbide knife inserts cater to the specific needs of your woodworking projects. The MOQ of 100 pieces makes them accessible for both small and large businesses. Whether you’re outfitting a new machine or replacing worn-out components, these carbide inserts provide a reliable solution for efficient, high-accuracy woodworking operations.

Product 4: Carbide Knife Inserts for Thicknesser Machine Helical Cutterheads

The Planer Knife Cutterhead Carbide Inserts 15x15x2.5 are designed specifically for use with woodworking thicknesser machines featuring helical cutterheads. These inserts are crafted from high-performance tungsten carbide, known for its exceptional durability and wear resistance. With sizes available in R50, R100, and R150, these inserts cater to various machine configurations, ensuring compatibility with both 4-sides planers and 2-sides planers. The 15x15x2.5 mm size provides optimal performance for planing and finishing tasks, delivering precise cuts with minimal wear.

These inserts are perfect for manufacturing plants and woodworking operations that require high-accuracy cutting for smoother, finer finishes. Whether you are replacing worn components or upgrading your machines, these carbide inserts will significantly extend the life of your cutterhead while improving the quality of your work. The R50, R100, and R150 options allow users to choose the radius that best suits their specific machinery and project needs. The inserts come in a silver color and are packaged securely in a PC box for easy handling and storage.

With a delivery time of 3-7 days and the ability to accept customized sizes, these carbide inserts are designed to meet the needs of both small and large businesses. The MOQ of 100 pieces makes it a cost-effective solution for businesses looking to stock up. While no warranty is included, online support is available for any post-purchase inquiries, ensuring reliable service after the sale. These inserts are an essential tool for those seeking precision and longevity in their woodworking machinery operations.

Product 5: Suction Cup Cover for CNC Machines – Durable Rubber Pad

The High-Quality Suction Cup Cover is an essential accessory for CNC machines, providing reliable functionality for a variety of industries including machinery repair shops, manufacturing plants, and furniture factories. Made from durable rubber, this suction cup cover helps secure materials during the CNC machining process, ensuring stability and precision. Designed to fit most CNC machines, it offers a reliable solution for improving the efficiency and safety of machining operations.

With a size of 140x115x17 mm, the cover is compact yet robust enough to withstand the demands of frequent use. The long service life of this rubber pad makes it a cost-effective solution for businesses looking to reduce downtime and extend the lifespan of their CNC machines. While it is ideal for securing materials during cutting, milling, and engraving processes, the suction cup cover’s versatile design makes it suitable for a wide range of CNC machine applications. Its non-slip grip helps prevent material slippage, leading to smoother, more accurate machining results.

The product is available in 140mm length, 115mm width, and 17mm thickness, and is manufactured by the reliable YD brand. The suction cup cover is delivered with video technical support and online support for any post-purchase queries. Though it does not come with a warranty, the product’s quality is assured through video outgoing-inspection before shipping. This cover is designed for CNC machines and can handle a range of materials and workloads, offering a practical solution for shops seeking improved machining accuracy and efficiency.

Product 6: MF280 Automatic Edge Bander for MDF Production

The MF280 Edge Bander is an automatic edge banding machine designed for high-volume MDF production and woodworking applications. Manufactured by YOWING, this machine is well-suited for businesses in the manufacturing plant, food & beverage factory, and decoration shop sectors. With its robust design and advanced automation features, the MF280 offers an efficient solution for achieving professional-quality edge banding on a variety of materials. It is particularly effective for producing smooth, durable edges on MDF panels, which are widely used in furniture and cabinetry.

This automatic edge banding machine features an impressive feeding speed of 18-22 m/min, making it a high-performance solution for continuous production. The working piece length can be as short as 120mm, while the working piece width accommodates up to 60mm. The machine can handle panel thicknesses ranging from 10mm to 60mm and is compatible with band tape widths from 13mm to 63mm, allowing it to cover a wide range of applications. The 0.3-3mm band tape thickness range ensures versatility, making it suitable for both thin and thick edge bands.

With a 14.5 kW power rating and 220V/380V voltage, the MF280 is built for heavy-duty operation, capable of handling demanding tasks in high-output environments. The machine dimensions of 5480 x 750 x 1522mm and its weight of 1200kg highlight its industrial build, designed to withstand continuous usage. The machine also includes essential components such as bearings, motors, PLC, gearbox, and engine, all of which come with a 1-year warranty. While the product does not come with a warranty on the machine itself, video outgoing-inspection ensures quality control before shipping, and online support is available for post-purchase service.

The MF280 Edge Bander is an efficient and cost-effective choice for businesses that require an automated, reliable solution for edge banding MDF panels, helping to boost productivity while maintaining high-quality standards in their operations.

Product 7: Chuck Tool Holder Fork for CNC Woodworking Machines – Homag Machine 3011019270

The 3-011-01-9270 Chuck Tool Holder Fork is designed specifically for use with CNC machining centers, particularly those utilizing Homag machines. This essential component ensures smooth and efficient tool changes during CNC operations, making it a critical piece for machinery repair shops and other industrial applications that involve precise machining. Made from durable plastic, this tool holder fork is engineered for long service life, reducing the need for frequent replacements and downtime in production.

With a weight of just 0.1 kg, the chuck tool holder fork is lightweight, yet strong enough to withstand the demands of continuous CNC operations. While the size is customizable to fit different machine setups, it is specifically compatible with Homag CNC woodworking machines, making it a perfect replacement or spare part for businesses utilizing this brand. The long service life of the fork, combined with video technical support and online support after purchase, ensures that users can maintain optimal performance throughout the lifespan of their equipment.

This product is available for purchase with a minimum order quantity of 1 piece, providing flexibility for both small-scale and large-scale businesses. Although it does not come with a warranty, it undergoes video outgoing-inspection to ensure quality before shipment. This fork is an ideal solution for businesses looking to maintain the reliability and efficiency of their CNC machining centers.

Product 8: Fully Automatic Compact Economic Edge Bander for MDF Production

The Fully Automatic Compact Economic Edge Bander is an advanced solution designed for high-efficiency MDF production and woodworking applications. Manufactured by YOWING, this edge banding machine offers automated operation for industries such as manufacturing plants, food & beverage factories, and decoration shops. Its robust design and automated features make it ideal for producing high-quality edge banding on MDF panels, a staple in furniture and cabinetry production.

This edge bander is equipped with powerful specifications, including a 14.5 kW power rating and 220V/380V voltage, capable of handling demanding tasks efficiently. The feeding speed ranges from 18 to 22 m/min, ensuring fast and consistent banding for high-output production lines. It accommodates working piece lengths as short as 120mm, with working piece widths up to 60mm, making it versatile for various panel sizes. The machine can handle panel thicknesses between 10mm and 60mm, and is compatible with band tape widths from 13mm to 63mm, providing flexibility in edge banding applications.

The machine dimensions of 5480 x 750 x 1650mm and a weight of 1200kg highlight the industrial-grade build of the edge bander. Its core components, including bearings, motors, PLC, gearbox, and engine, come with a 1-year warranty. While it does not offer warranty coverage for the machine itself, video outgoing-inspection ensures quality control prior to shipment. The edge bander is designed for ease of use and efficiency, providing automatic operation for businesses seeking to enhance productivity while maintaining precision in edge banding tasks.

Product 9: Yowing Panel Processing Machine – Automatic Furniture Edge Bander

The Yowing Panel Processing Machine is a high-performance automatic edge bander, specially designed for MDF production and woodworking applications. Manufactured by YOWING, this edge banding machine is ideal for industries such as manufacturing plants, food & beverage factories, and decoration shops. With its automated operation, this machine streamlines the process of edge banding for MDF panels, which are commonly used in the production of furniture, cabinets, and other wood-based products.

The edge bander features a powerful 14.5 kW motor and is compatible with 220V/380V voltage, enabling it to handle demanding tasks in high-output environments. Its feeding speed of 18-22 m/min ensures fast and consistent edge banding, while the machine accommodates working piece lengths starting from 120mm and working piece widths up to 60mm. The machine can handle panel thicknesses from 10mm to 60mm and band tape widths ranging from 13mm to 63mm, making it highly adaptable to a variety of edge banding needs. The band tape thickness can vary from 0.3mm to 3mm, providing further flexibility for different edge banding requirements.

With machine dimensions of 5480 x 750 x 1650mm and a weight of 1200kg, this edge bander is built for heavy-duty industrial use. The core components — including the bearing, motor, gear, PLC, gearbox, and engine — are covered by a 1-year warranty, ensuring peace of mind for users. While the machine does not come with a warranty for the entire unit, it undergoes a thorough video outgoing-inspection to ensure high-quality standards before shipment. The automatic operation of the Yowing edge bander helps reduce manual labor and increases production efficiency, making it an essential tool for businesses looking to improve their panel processing capabilities.

Product 10: XPtools 13 Inch DW735 Spiral Helical Cutter Head for Wood Planers

The XPtools Replacement Planer Spare Parts 13 Inch DW735 Spiral Helical Cutter Head is an essential upgrade for enhancing the performance of DW735 wood planers. Crafted from high-quality alloy steel, this spiral helical cutter head is designed to provide perfect high cutting efficiency, ensuring smooth, clean cuts in wood planing applications. It is ideal for industries such as building material shops, machinery repair shops, manufacturing plants, and construction works that require precision in their woodworking operations.

This cutter head is designed to fit DW735 wood planers, providing a reliable and durable replacement part for improved productivity. The 13-inch size ensures compatibility with standard planing widths, and the spiral helical design reduces noise while delivering superior cutting results. Weighing 7 kg, this component is built for long-lasting use, with a 6-month warranty that ensures quality for the first months of operation. While the cutter head does not come with after-sales service, it offers great value for businesses seeking to replace worn-out parts and maintain their planer’s efficiency.

The minimum order quantity (MOQ) is 1 piece, allowing for flexibility in purchasing based on the needs of the business. The cutter head comes securely packaged in a plastic box for safe delivery and storage. Additionally, OEM support is available for businesses that require customization to fit specific needs or machine configurations.

Conclusion

This list of hot-selling woodworking machinery features high-quality products designed to boost productivity and precision. From edge banders to CNC engravers and planer cutterheads, these Chovm Guaranteed tools cater to various industries, ensuring fixed prices, on-time delivery, and reliable support. Incorporating these machines into your operations will enhance efficiency and help your business stay competitive in the woodworking market.

Please note that, as of now, the ‘Chovm Guaranteed’ products featured in this list are only available for shipping to addresses within the United States, Canada, Mexico, United Kingdom, France, and Germany. If you are accessing this article from outside these countries, you may not be able to view or purchase the linked products.