Table of Contents

1. Introduction

2. Understanding the types and usage of transmission jacks

3. The transmission jack market: A brief overview

4. Key considerations for selecting the right transmission jack

5. Leading transmission jack models and their features in 2025

6. Conclusion

Introduction

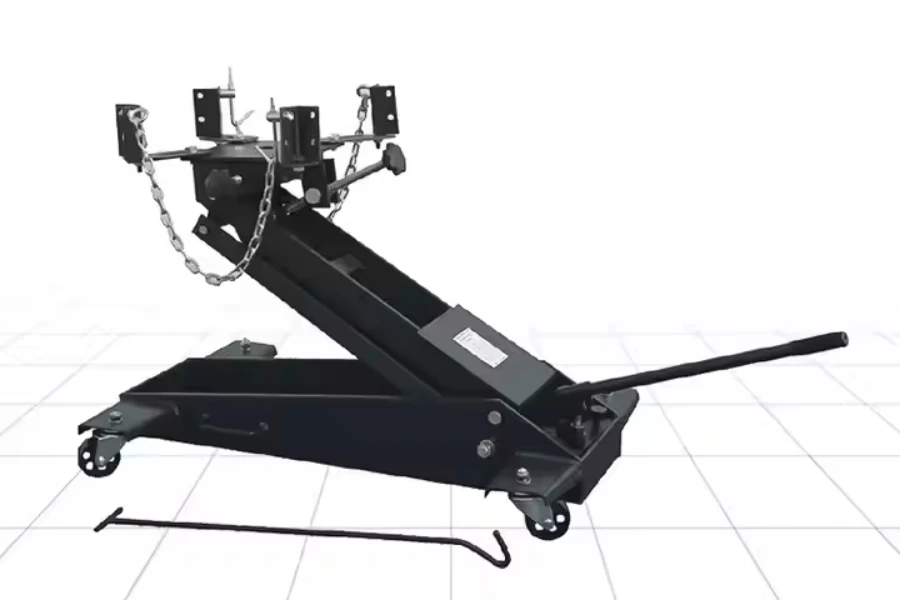

A transmission jack is one of the most important equipment in automotive repair. This device is designed to safely lift and hold transmissions during removal, installation, or servicing. These jacks are key for handling the weight of a transmission, which mostly varies depending on the vehicle type. Selecting the right transmission jack in 2025 ensures efficiency, safety, and precision in workshop operations, particularly for those handling different vehicle types. With the right tool, maintenance tasks become smoother and reduce the risk of damage to the vehicle and the technician.

Understanding the types and usage of transmission jacks

Hydraulic transmission jacks

Hydraulic transmission jacks are very important in professional settings because of their superior lifting capacity and their versatility across different vehicle types. The jacks make use of hydraulic pressure to uplift heavy transmissions, ensuring a smooth as well as a controlled lift. They normally have load capacities typically ranging from 1,000 to 1,500 pounds and are designed for precision and stability. Their adjustable saddles and high-lift capabilities are particularly effective in handling larger commercial vehicles. They also have steel construction, which adds to their durability, making them perfect for long-term, rigorous use in many professional garages.

Pneumatic transmission jacks

Pneumatic transmission jacks are ideal for commercial environments that require high-efficiency operations. Powered by compressed air, these jacks are designed for speed and ease, reducing operator fatigue in high-volume repair shops. Their primary strength is handling heavy-duty tasks with minimal manual effort, making them perfect for large trucks or buses. Pneumatic jacks provide precise control over the lifting process, which is essential in tasks that require delicate maneuvering of large, cumbersome transmissions. However, they require an air compressor to function, making them more suited for advanced, high-capacity workshops.

Manual transmission jacks

Manual transmission jacks, while lacking the automatic functionality of their hydraulic and pneumatic counterparts, offer simplicity and cost-efficiency for lighter tasks. These jacks are well-suited for smaller vehicles or garages where budget constraints are a concern. Operated through a basic mechanical or screw mechanism, manual jacks provide sufficient lifting power for lighter transmissions, making them a practical choice in smaller automotive repair settings. Their straightforward design minimizes the need for complex systems, offering reliability and ease of use, particularly in environments where heavy-duty equipment is not essential.

The transmission jack market: A brief overview

Global growth and trends

Industry Growth Insight reports indicate that the global transmission jack market was estimated to be worth $1.3 billion in 2023 and is expected to reach around $1.9 billion by the conclusion of 2028, with a compound growth rate of 5.5% from 2023 to 2028.

Market growth is influenced by technological progress in the automotive industry, requiring specific tools like transmission jacks for better maintenance efficiency and effectiveness. Also, the trend toward electric and hybrid vehicles is expected to drive further demand. This is because specialized jacks will be needed to handle their unique designs. The worldwide focus on efficiency and safety in workshops is again pushing manufacturers to develop durable easy-to-use transmission jacks.

Key market segments

The primary market segments driving transmission jack demand are automotive repair shops and commercial vehicle maintenance services. The automotive repair industry is thriving due to the rise in vehicle ownership and longer car lifespans. As vehicles age, the demand for maintenance services like transmission repairs and specialized jacks is increasing, which are capable of handling various vehicle sizes and models. Moreover, commercial vehicle maintenance is crucial in industries like logistics and public transportation, where vehicles such as buses and trucks necessitate heavy-duty transmission jacks with the capacity to ensure the safe handling of their substantial transmissions.

Another notable segment is DIY mechanics, though their contribution remains smaller than that of professional shops. While they primarily seek cost-effective manual jacks, the growing trend of home automotive repairs, driven by cost-saving measures, adds a layer of diversity to the market.

Key considerations for selecting the right transmission jack

Weight capacity and lift range

When picking a transmission jack, paying attention to its weight capacity is crucial. How high can it lift the load for effective use with the vehicle’s transmission system in mind? Transmission jacks come with weight capacities ranging from 500 pounds to over 2,000 pounds to cater to different job requirements accurately. For vehicles such as trucks and commercial fleets, it becomes necessary to opt for high-capacity jacks to handle the substantial weight of their transmissions. A higher lift range is also necessary for vehicles with elevated transmission positions, such as SUVs and heavy-duty trucks, ensuring that the jack can reach the required height for transmission removal and installation.

Durability and construction quality

A transmission lift’s long-term effectiveness and reliability are significantly influenced by its stability and build quality. Many top-notch lifts are crafted using high-grade steel to ensure durability and resistance to wear and tear. Steel frames are favored for their capacity to support weights without buckling or distorting with use. Furthermore, additional features like corrosion-resistant coatings or powder-coated finishes can help extend the lifespan of the jack by protecting it from rust and environmental damage. Opting for a well-constructed jack ensures durability and contributes to operational safety by maintaining stability under load.

Safety features and compliance standards

Safety is paramount when working with heavy machinery, and transmission jacks are no exception. Key safety features, such as overload protection systems and locking mechanisms, are critical to preventing accidents and ensuring smooth operation. The overload protection feature ensures that the jack does not surpass its specified capacity to lower the chances of breakdowns. Moreover, adhering to industry safety regulations like those set by ANSI or OSHA is essential for settings where safety is a top priority. Jacks with safety certifications have been tested to meet the performance and safety standards, giving operators more confidence in using them.

Portability and maneuverability

In professional settings, portability and maneuverability are essential for selecting the right transmission jack. Features like swivel casters and adjustable saddles can simplify the process of positioning and moving the jack within the workspace effectively and efficiently. Swivel casters enable movement in confined or crowded spaces while locking wheels offer stability during usage. For establishments dealing with multiple vehicle types regularly, having a lightweight jack that is easy to maneuver with a small footprint design can enhance workflow efficiency significantly. Additionally, jacks with foot-operated pumps enable hands-free control, allowing technicians to focus on safely positioning the transmission.

Leading transmission jack models and their features in 2025

For business professionals purchasing transmission jacks for their operations, certain product types stand out in the market due to their high demand and best-selling status. These items are designed to meet a range of car repair requirements spanning from heavy-duty commercial usage to mid-range and cost-effective choices available to consumers. The top-selling models typically have characteristics that guarantee effectiveness in getting the job done efficiently while lasting long and being user-friendly – qualities that are vital for use in professional settings.

Best high-capacity jacks for heavy-duty applications

High-capacity transmission jacks are top choices in industries that work with big vehicles like trucks and buses. These jacks usually have a weight capacity of 2,000 to 3,000 pounds and are made to handle heavy transmissions in commercial vehicle fleets. Their key feature is stability, thanks to a reinforced base to reduce any shifting during use. Advanced tilt controls are another feature in these devices that enable technicians to adjust the position of the transmission for accurate alignment purposes. Features like easy-to-operate hydraulic systems and durable steel construction ensure that these jacks withstand high pressure and last for extended periods, reducing maintenance downtime.

Recommended mid-range models for general use

Transmission jacks that fall within the mid-range category are quite favored by small workshops and mixed-use facilities that cater to various needs because of their adaptability and affordability. These particular models usually come with lifting capacities ranging from 1,000 to approximately 1,500 pounds—a perfect fit for tasks involving personal automobiles and smaller commercial trucks. One key feature found across the top-selling mid-range of transmission jacks is their adjustable lifting ranges that offer versatile options for handling various vehicle sizes and shapes. These jacks have swivel caster wheels and foot-operated hydraulic pumps to ensure maneuverability and control in confined work areas. They cater to both the professional workshop setting and DIY mechanics, blending functionality with affordability, which drives their high sales volume.

Budget-friendly options without compromising quality

In the budget segment, transmission jacks that offer solid performance at a lower price point tend to dominate the market. These products are particularly attractive to small businesses or shops with limited budgets, yet they still deliver reliable functionality. Many budget-friendly models, for instance, use adapters for floor jacks, providing a flexible solution without purchasing a dedicated transmission jack. Despite their lower cost, these models often incorporate essential safety features such as locking mechanisms and adjustable saddles. Their compact design and ease of assembly make them practical choices for shops that need effective equipment but have less frequent demand for heavy-duty tasks. These products offer good value, striking a balance between quality and affordability, ensuring their popularity in the market.

Conclusion

Selecting the right transmission jack ensures efficiency and safety in any professional automotive setting. Whether focusing on heavy-duty models for large trucks or mid-range options for everyday vehicle maintenance, the key factors remain consistent—weight capacity, durability, maneuverability, and safety features. Understanding the market’s leading products and their common features helps buyers make informed decisions. Different varieties of jacks are available to meet specific requirements, from heavy-duty tasks to affordable choices. Each is designed to deliver dependable performance tailored to specific needs. By selecting the right features for their operations, companies can make smart investments in equipment that boost efficiency while managing expenses effectively.