When temperatures drop, machinery equipment is usually at risk of experiencing freezing-related issues. Nonetheless, following a routine maintenance schedule can help to avoid predictable failure and save money—because fixing this heavy-duty machinery is cost-effective.

Keep reading to find out more about planned maintenance for machinery in the winter to avoid the trap of high repair costs.

Table of Contents

How to Maintain Construction Machinery in Winter

Conclusion

9 ways to keep construction machiney working in Winter

Ensure the batteries are in good condition.

Cold weather reduces the lifespan of a machine’s batteries. Hence, running engines in the winter is hectic as machines discharge their batteries quickly. Thus, it’s advisable to check for electrolyte levels and ensure they are full during the cold period.

Clean any dirt or rust in the terminals and connectors, which could potentially drain the batteries. Operators can use a brush or battery cleaner to clean the debris from the terminal and connecting points.

Another rule of thumb is disconnecting the batteries when they aren’t in use, and storing them in a temperature-controlled facility. Also, keeping them charged all the time ensures prolonged good health.

Spray a protective coating over exposed cylinders

Most construction equipment’s material comprises 90% metal and is susceptible to rust. When essential parts of the machinery, like cylinders rust, the engine may not function properly or breakdown, thus, requiring an expensive repair or replacement.

If the cylinders are exposed to the cold, seal rubbers, and rings break, leading to engine oil leaks. Users can apply the coating to stored construction equipment during the colder months to prevent unnecessary and premature wear and tear.

Keep machine running overnight

It’s advisable to leave the engine running at night in a construction site—during winter.

The exhaust heat assists in keeping the engine warm to operate in the cold the next day. Idling the equipment at RPMs between 700 and 800 may damage the engine. Therefore, leaving the engine idle at 1200 RPMs is advisable. Install an auto start-stop system in the machine to set times for idling with better fuel economy.

Use seasonally appropriate oils, greases, and fluids

The construction machines require lubrication in their moving parts. However, during the colder months, many lubricants freeze and function abnormally..

Hence, it’s wise to only use the respective oils, greases, and fluids suitable for winter. For instance, switch to a low-temp grade grease for machines using standard grade grease for its hydraulic systems, which freeze in extremely cold climates. The same applies to fluids running in the brake lines and other truck parts. Switch them to low-temp grade to help the machine work better.

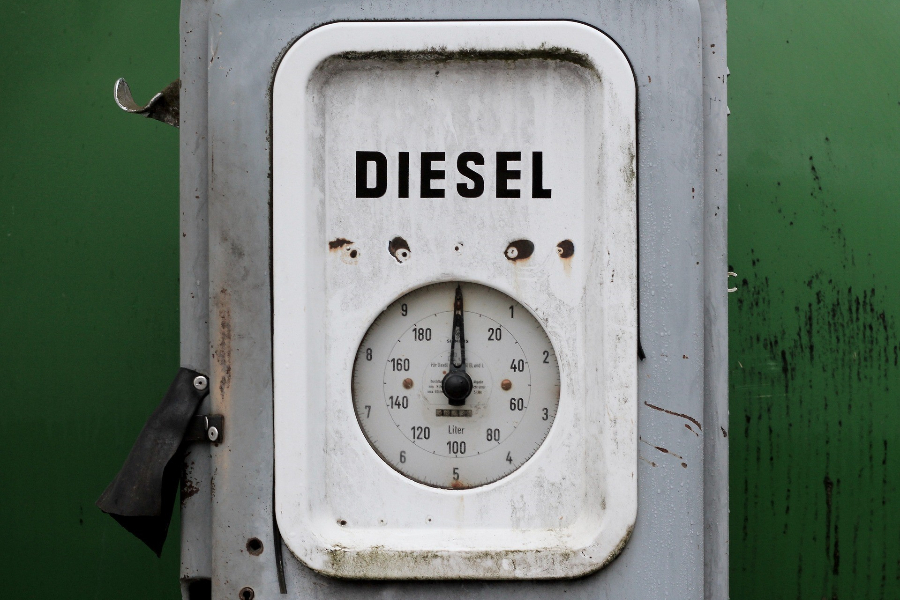

Use seasonally correct fuel in colder months.

The type of fuel used in construction machines is a key point to consider when dealing with maintenance in winter months. Fault codes may pop on the dash because of the fuel used. The regular fuel isn’t appropriate to for colder seasons.

Normally, construction machines use diesel number 2 in other warmer seasons because it’s affordable. During winter, diesel number 2 is swapped for number 1 diesel. Even though number 2 diesel boasts of additives, there aren’t suitable for colder months. Also, number 1 diesel flows better during cold weather than number 2 because it’s less dense.

Load up the engine to create enough heat for regens

The machine requires enough heat to run appropriately during winter. For this reason, it’s wise to engage the machine with heavy-duty work to perform a regen.

A regen is crucial because the engine produces usable heat as the machine performs its tasks. Heat is later converted to energy that gets stored in the battery. In short, if the engine is not producing the right amount of heat, it may not perform properly.

Keep the fuel tank full

In the summer, the storage conditions of diesel equipment do not require extra attention as the conditions in the cold season. Take a close look at the fuel levels in the construction machines, especially if you are storing them for winter. Low fuel levels do not favor the tanks of the machinery.

When machines aren’t in use, keep the tanks filled up. The reason for keeping the tanks full is to prevent condensation. Also, remember to use the correct fuel for winter when filling up.

Run a routine check for the tires

Inspecting tires before and after shifts is a crucial safety measure for construction machinery. For instance, the tire pressure drops by 0.2% for every 10 degrees Fahrenheit (100F) temperature. Low-pressure tires are detrimental to fuel economy. Thus, check the pressure regularly and gauge when it necessary.

Additionally, monitor the physical status of the tires for wear and tear on the treads. Cut out any loose rubber on the tires. Release unnecessary stress on the tires, like an unnecessary weight on the machinery when it’s not in use.

Keep equipment clean

Commonly used construction equipment like bulldozers, excavators, backhoes, graders, trenchers, loaders, cranes, pavers, and compactors collect lots of dirt at the end of the day. During winter, mud freezes on parts like tracks, driveshafts, joints, and steering cylinders, which are usually hard to remove when they solidify.

So, it’s best to clean any stains that settle on the equipment that may potentially break expensive moving parts.

Conclusion

All construction equipment needs care and maintenance, like cars and homes. The winter is a period when they get vulnerable to environmental elements. Following the above tips, construction machines can enjoy extended use and a longer lifespan.

বাংলা

বাংলা Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português Русский

Русский Español

Español Kiswahili

Kiswahili ไทย

ไทย Türkçe

Türkçe اردو

اردو Tiếng Việt

Tiếng Việt isiXhosa

isiXhosa Zulu

Zulu