Pada tahun 2025, permintaan akan peralatan jahit dengan efisiensi tinggi terus meningkat, didorong oleh industri tekstil yang sedang berkembang pesat. Artikel ini memberikan analisis mendalam tentang pasar mesin jahit jahitan, termasuk tolok ukur kinerja, kualitas pembuatan, dan teknologi yang sedang berkembang. Pembeli profesional akan menemukan wawasan berharga untuk membantu membuat keputusan pembelian yang tepat.

Daftar Isi:

– Tinjauan Pasar Komprehensif Mesin Jahit Penutup

– Analisis Rinci Pasar Mesin Jahitan Penutup

– Faktor Penting yang Perlu Dipertimbangkan Saat Memilih Mesin Jahit Penutup

– Teknologi Baru pada Mesin Jahit Penutup

- Kesimpulan

Tinjauan Pasar Komprehensif Mesin Jahit Penutup

Pasar mesin jahit jahitan global mengalami pertumbuhan signifikan, didorong oleh industri tekstil dan pakaian jadi yang terus berkembang. Pada tahun 2024, pasar mesin jahit global, yang mencakup mesin jahit jahitan, mencapai valuasi sebesar USD 5.34 miliar. Pasar ini diproyeksikan tumbuh pada CAGR sebesar 5.75%, mencapai USD 7.51 miliar pada tahun 2030. Pertumbuhan ini didorong oleh meningkatnya permintaan akan peralatan jahit efisiensi tinggi baik dalam aplikasi domestik maupun industri. Pasar mesin jahit jahitan diuntungkan oleh meningkatnya tren mode dan dekorasi rumah DIY serta meningkatnya kebutuhan akan jahitan yang presisi dan tahan lama dalam produksi pakaian profesional.

Amerika Utara, khususnya Amerika Serikat dan Kanada, merupakan pasar yang signifikan untuk mesin jahit penutup, dengan konsumen yang mengutamakan kualitas dan fitur-fitur canggih. Pasar Eropa juga menunjukkan permintaan yang kuat, didorong oleh penjahit profesional, perancang busana, dan penghobi. Di kawasan Asia-Pasifik, Tiongkok memimpin dalam produksi dan konsumsi, didukung oleh kemampuan manufaktur yang substansial dan kemajuan teknologi di negara-negara seperti Jepang dan India.

Analisis Terperinci Pasar Mesin Jahitan Penutup

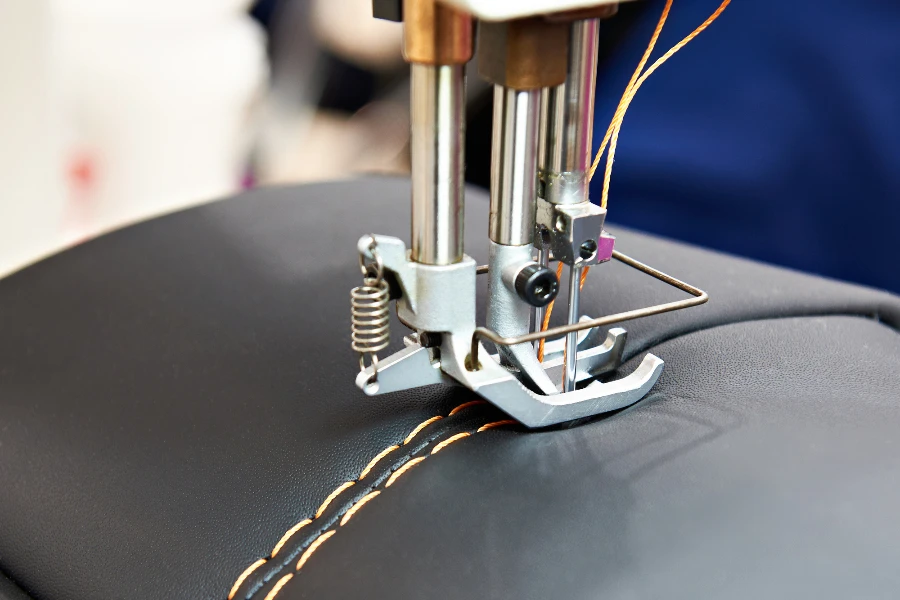

Mesin jahit tutup sangat penting untuk menghasilkan keliman dan hasil akhir yang tampak profesional pada pakaian rajut. Mesin ini menangani sifat kain rajut yang elastis dan halus, sehingga menghasilkan hasil akhir yang bersih dan tahan lama. Tolok ukur kinerja utama untuk mesin jahit tutup meliputi kecepatan jahitan, variasi lebar dan panjang jahitan, serta jumlah jarum, yang memengaruhi keserbagunaan dan jangkauan aplikasi mesin.

Dinamika pasar dipengaruhi oleh kebutuhan akan mesin dengan efisiensi tinggi yang melayani industri mode yang bergerak cepat. Inovasi seperti mesin jahit penutup terkomputerisasi menawarkan presisi dan otomatisasi yang lebih baik, yang penting untuk produksi skala besar. Namun, kompleksitas pengoperasian mesin jahit penutup yang canggih dapat menjadi kendala bagi sebagian pengguna, yang memerlukan pelatihan dan dukungan teknis.

Saluran distribusi untuk mesin jahit penutup beragam, dengan kehadiran signifikan di pasar daring dan luring. Segmen daring tumbuh pesat, didorong oleh kemudahan dan pilihan yang lebih luas yang tersedia bagi konsumen. Merek-merek besar memanfaatkan platform digital untuk menjangkau khalayak yang lebih luas dan menyediakan informasi produk terperinci serta ulasan pelanggan.

Inovasi terkini di pasar mesin jahit penutup meliputi integrasi teknologi IoT dan AI, yang meningkatkan efisiensi mesin dan pengalaman pengguna. Kemajuan ini membantu dalam pemeliharaan prediktif, mengurangi waktu henti, dan meningkatkan produktivitas secara keseluruhan. Selain itu, fokus pada efisiensi energi dan keberlanjutan membentuk pengembangan mesin jahit penutup baru, yang mengatasi masalah lingkungan dalam industri tekstil.

Siklus hidup produk mesin jahit penutup biasanya berlangsung selama beberapa tahun, dengan pembaruan rutin dan model baru yang diperkenalkan untuk mengikuti kemajuan teknologi dan kebutuhan konsumen yang terus berkembang. Merek-merek terkemuka memposisikan diri dengan menawarkan berbagai mesin yang melayani pengguna pemula dan tingkat lanjut, memberikan diferensiasi melalui fitur, kualitas pembuatan, dan dukungan purnajual.

Faktor Penting yang Perlu Dipertimbangkan Saat Memilih Mesin Jahit Penutup

Kinerja dan Fungsionalitas

Saat memilih mesin jahit penutup, kinerja dan fungsionalitas sangatlah penting. Mesin tersebut harus memenuhi kebutuhan menjahit spesifik Anda, baik untuk penggunaan profesional di lingkungan pabrik atau proyek rumahan. Fungsi utama mesin jahit penutup adalah untuk membuat keliman, jahitan, dan jahitan dekoratif yang tampak profesional. Oleh karena itu, kualitas jahitan, kecepatan, dan keserbagunaan mesin merupakan aspek penting yang harus dinilai.

Mesin jahit tutup menawarkan berbagai pilihan jahitan, termasuk jahit tutup sempit, jahit tutup lebar, dan jahit tutup rangkap tiga. Pilihan ini memberikan fleksibilitas dalam menciptakan hasil jahitan dan efek dekoratif yang berbeda. Mesin berperforma tinggi dapat mencapai hingga 1,500 jahitan per menit, yang secara signifikan meningkatkan produktivitas dalam lingkungan profesional.

Kemudahan dalam memasang benang dan menyetel tegangan sangat penting untuk menjaga kualitas jahitan yang konsisten. Model-model yang canggih sering kali dilengkapi dengan penyetelan tegangan otomatis dan sistem pemasangan benang yang mudah sehingga menghemat waktu dan mengurangi kesulitan belajar bagi pengguna baru. Sangat penting untuk memilih mesin yang menyeimbangkan kecepatan, kualitas jahitan, dan kemudahan penggunaan untuk memastikan kinerja yang optimal.

Membangun Kualitas dan Daya Tahan

Kualitas pembuatan dan ketahanan mesin jahit penutup merupakan faktor penting yang memengaruhi keawetan dan keandalannya. Mesin yang dibuat dengan bahan berkualitas tinggi, seperti rangka dan komponen logam, cenderung menawarkan stabilitas dan ketahanan yang lebih baik dibandingkan dengan mesin yang dibuat dengan komponen plastik. Mesin yang kokoh dapat bertahan terhadap penggunaan terus-menerus dan tugas menjahit berat tanpa mengurangi kinerjanya.

Mesin jahit penutup berkelas industri dirancang untuk lingkungan produksi bervolume tinggi dan dibuat untuk bertahan dalam kondisi penggunaan sehari-hari yang keras. Mesin ini sering kali dilengkapi motor tugas berat dan rangka yang diperkuat untuk menangani kain tebal dan beberapa lapisan dengan mudah. Bagi pengguna rumahan, mesin yang kokoh dengan rangka logam dan komponen internal berkualitas tinggi memastikan keandalan jangka panjang dan kinerja yang konsisten.

Garansi mesin dan ketersediaan suku cadang pengganti merupakan indikator ketahanannya. Produsen yang menawarkan garansi lebih lama dan suku cadang yang mudah didapat menunjukkan kepercayaan diri terhadap keawetan produk mereka. Berinvestasi pada mesin jahit penutup yang dibuat dengan baik memastikan pengalaman menjahit yang andal dan mengurangi kebutuhan untuk perbaikan atau penggantian yang sering.

Spesifikasi dan Fitur Teknis

Saat mengevaluasi mesin jahit penutup, spesifikasi dan fitur teknis memegang peranan penting dalam menentukan kemampuan dan kesesuaian mesin untuk tugas tertentu. Spesifikasi utama yang perlu dipertimbangkan meliputi lebar dan panjang jahitan, penyesuaian tekanan sepatu penekan, serta jumlah jarum dan benang yang dapat ditampung mesin.

Mesin jahit penutup biasanya menawarkan lebar dan panjang jahitan yang dapat disesuaikan, yang memungkinkan pengguna untuk menyesuaikan ukuran jahitan untuk berbagai kain dan teknik menjahit. Kemampuan untuk menyesuaikan tekanan sepatu penekan memastikan pemasukan kain yang optimal dan mencegah kerutan atau peregangan bahan yang halus. Mesin dengan berbagai pilihan jarum dan benang memberikan fleksibilitas yang lebih besar dalam pola jahitan dan aplikasi.

Fitur-fitur canggih seperti pengumpanan diferensial, pemotongan benang otomatis, dan pengaturan jahitan yang dapat diprogram meningkatkan fungsionalitas dan kemudahan penggunaan mesin. Pengumpanan diferensial memungkinkan kontrol yang tepat atas peregangan dan pengumpulan kain, sehingga ideal untuk menjahit rajutan dan kain yang elastis. Pemotongan benang otomatis menghemat waktu dan memastikan hasil akhir yang bersih, sementara pengaturan jahitan yang dapat diprogram memungkinkan pengguna untuk menyimpan dan mengingat konfigurasi jahitan yang mereka sukai.

Kisaran Harga dan Pertimbangan Anggaran

Kisaran harga mesin jahit penutup sangat bervariasi berdasarkan fitur, kualitas pembuatan, dan reputasi mereknya. Mesin tingkat pemula yang cocok untuk penghobi dan penggunaan di rumah dapat berkisar antara $300 hingga $600, menawarkan opsi jahitan dasar dan kinerja yang memadai untuk proyek jahit sesekali. Mesin kelas menengah, dengan harga antara $600 dan $1,200, biasanya menyediakan fitur yang lebih canggih, kualitas pembuatan yang lebih baik, dan kecepatan jahitan yang lebih tinggi, sehingga cocok untuk penghobi serius dan usaha kecil.

Mesin jahit penutup berkualitas tinggi, dengan harga $1,200 ke atas, dirancang untuk penggunaan profesional dan aplikasi tugas berat. Mesin ini menawarkan kinerja yang unggul, fitur canggih, dan kualitas pembuatan yang luar biasa, sehingga menjadikannya investasi yang berharga untuk lingkungan produksi berskala besar.

Saat menentukan anggaran, pertimbangkan tujuan penggunaan mesin, frekuensi penggunaan, dan jenis proyek yang akan Anda lakukan. Berinvestasi pada mesin berkualitas tinggi dengan fitur-fitur canggih dapat menghasilkan kualitas jahitan yang lebih baik, peningkatan produktivitas, dan penghematan biaya jangka panjang karena berkurangnya perawatan dan perbaikan.

Kompatibilitas dengan Perangkat dan Sistem Lain

Kompatibilitas dengan mesin jahit dan sistem lain merupakan faktor penting yang perlu dipertimbangkan, terutama bagi pengguna yang sudah memiliki beberapa mesin atau berencana untuk memperluas pengaturan jahit mereka. Mesin jahit penutup harus terintegrasi dengan lancar dengan perangkat jahit yang ada, seperti serger dan mesin bordir, untuk menciptakan lingkungan jahit yang kohesif dan efisien.

Beberapa mesin jahit penutup menawarkan kompatibilitas dengan berbagai kaki penekan dan alat tambahan, yang memungkinkan pengguna untuk melakukan berbagai teknik menjahit. Kaki penekan dan alat tambahan universal dapat digunakan di berbagai mesin, sehingga memberikan fleksibilitas dan penghematan biaya. Selain itu, mesin dengan sistem jarum dan jenis benang yang terstandarisasi memastikan kemudahan pengadaan bahan habis pakai dan aksesori.

Bagi pengguna yang mengandalkan perangkat lunak desain digital dan sistem jahit terkomputerisasi, kompatibilitas dengan perangkat lunak dan pilihan konektivitas, seperti port USB dan Wi-Fi, dapat meningkatkan pengalaman menjahit. Fitur-fitur ini memungkinkan pengguna untuk mengimpor dan menyesuaikan pola jahitan, memperbarui firmware mesin, dan mengakses tutorial dan sumber daya daring.

Teknologi Baru pada Mesin Jahit Tutup

Pengaturan Benang dan Ketegangan Otomatis

Salah satu kemajuan terbaru dalam mesin jahit penutup adalah pengaturan benang dan tegangan otomatis. Fitur-fitur ini menyederhanakan proses pengaturan, mengurangi kemungkinan kesalahan pemasangan benang, dan memastikan kualitas jahitan yang konsisten. Sistem pemasangan benang otomatis memandu benang melalui mesin, sehingga memudahkan pengguna untuk beralih di antara berbagai warna dan jenis benang.

Penyesuaian ketegangan otomatis mendeteksi jenis dan ketebalan kain, lalu menyesuaikan ketegangan benang untuk menghasilkan jahitan yang seimbang. Teknologi ini menghilangkan kebutuhan penyesuaian ketegangan manual, yang dapat memakan waktu dan memerlukan uji coba. Pemasangan benang dan penyesuaian ketegangan otomatis meningkatkan kenyamanan pengguna dan meningkatkan efisiensi menjahit, terutama bagi pemula dan mereka yang bekerja dengan berbagai jenis kain.

Integrasi Teknologi Cerdas

Integrasi teknologi pintar dalam mesin jahit penutup tengah merevolusi industri jahit. Mesin jahit penutup pintar dilengkapi layar sentuh, antarmuka digital, dan opsi konektivitas yang memungkinkan pengguna mengakses berbagai fungsi dan pengaturan. Antarmuka layar sentuh menyediakan navigasi intuitif dan akses mudah ke pola jahitan, pengaturan, dan tutorial.

Pilihan konektivitas, seperti Wi-Fi dan Bluetooth, memungkinkan pengguna untuk menghubungkan mesin mereka ke ponsel pintar, tablet, dan komputer. Konektivitas ini memungkinkan pemantauan jarak jauh, pembaruan perangkat lunak, dan akses ke pustaka desain berbasis cloud. Pengguna dapat mengunduh pola jahitan baru, berbagi kreasi mereka di media sosial, dan menerima pemberitahuan waktu nyata serta kiat pemecahan masalah.

Mesin jahit penutup pintar juga menawarkan pengalaman menjahit yang dipersonalisasi melalui profil pengguna dan pengaturan khusus. Pengguna dapat menyimpan konfigurasi jahitan yang disukai, pengaturan ketegangan, dan tekanan sepatu penekan, memastikan hasil yang konsisten di berbagai proyek. Integrasi teknologi pintar meningkatkan fungsionalitas, fleksibilitas, dan pengalaman pengguna mesin jahit penutup.

Efisiensi Energi dan Keberlanjutan

Karena keberlanjutan menjadi perhatian yang semakin meningkat dalam industri manufaktur, mesin jahit penutup dirancang dengan fitur hemat energi dan ramah lingkungan. Motor dan komponen hemat energi mengurangi konsumsi daya, menurunkan biaya operasional, dan meminimalkan dampak lingkungan. Beberapa mesin juga dilengkapi mode tidur dan fungsi mati otomatis untuk menghemat energi saat tidak digunakan.

Produsen semakin banyak menggunakan bahan yang dapat didaur ulang dan proses produksi yang ramah lingkungan untuk membuat mesin jahit penutup. Praktik ini mengurangi limbah, menurunkan emisi karbon, dan mendorong produksi berkelanjutan. Mesin ramah lingkungan menarik bagi konsumen dan bisnis yang peduli lingkungan yang ingin mengurangi jejak ekologis mereka.

Selain itu, beberapa mesin jahit penutup dirancang agar mudah dirawat dan diperbaiki, sehingga memperpanjang masa pakainya dan mengurangi kebutuhan penggantian. Komponen modular dan suku cadang yang dapat diganti pengguna memudahkan perawatan dan peningkatan mesin, sehingga mendorong ekonomi sirkular dan mengurangi limbah elektronik.

Kesimpulan

Memilih mesin jahit penutup yang tepat melibatkan pertimbangan cermat terhadap berbagai faktor, termasuk kinerja, kualitas pembuatan, spesifikasi teknis, kisaran harga, dan kompatibilitas dengan perangkat lain. Teknologi yang baru muncul, seperti pemasangan benang otomatis, fitur cerdas, dan efisiensi energi, meningkatkan fungsionalitas dan keberlanjutan mesin jahit penutup. Dengan memahami faktor-faktor penting ini dan tetap mendapatkan informasi tentang kemajuan terbaru, pembeli dapat membuat keputusan yang tepat dan berinvestasi pada mesin yang memenuhi kebutuhan dan preferensi menjahit spesifik mereka.