Pada tahun 2025, pasar mesin pengiris daging diproyeksikan mencapai USD 1.2 miliar, menunjukkan pertumbuhan kuat yang didorong oleh kemajuan teknologi. Artikel ini membahas analisis mendalam tentang pasar, memberikan wawasan berharga bagi pembeli profesional tentang kinerja, kualitas pembuatan, fitur keselamatan, dan pertimbangan biaya.

Daftar Isi:

-Tinjauan Pasar Mesin Pengiris Daging

-Analisis Rinci Pasar Mesin Pengiris Daging

-Inovasi dan Posisi Merek di Pasar Mesin Pengiris Daging

-Faktor Kunci Saat Memilih Mesin Pengiris Daging

-Memastikan Efisiensi Energi dan Kepatuhan Lingkungan

-Mengevaluasi Biaya dan Pengembalian Investasi

-Pikiran Akhir

Tinjauan Pasar Mesin Pengiris Daging

Pasar global untuk mesin pengiris daging mengalami pertumbuhan yang signifikan, didorong oleh meningkatnya permintaan akan produk daging olahan dan kemajuan dalam teknologi pemrosesan makanan. Pada tahun 2025, ukuran pasar diperkirakan mencapai USD 1.2 miliar, dengan proyeksi tingkat pertumbuhan tahunan gabungan (CAGR) sebesar 6.3% selama lima tahun ke depan. Pertumbuhan ini didorong oleh meningkatnya preferensi konsumen terhadap makanan siap saji dan makanan instan, bersama dengan modernisasi fasilitas pemrosesan daging.

Amerika Utara dan Eropa mendominasi pasar, menguasai sekitar 60% pangsa pasar global. Dominasi ini disebabkan oleh tingginya konsumsi daging dan ketatnya regulasi keamanan pangan di kawasan ini. Asia-Pasifik muncul sebagai kawasan dengan pertumbuhan tinggi, dengan CAGR yang diharapkan sebesar 8.1%, didorong oleh meningkatnya urbanisasi, meningkatnya pendapatan yang dapat dibelanjakan, dan perluasan kapasitas produksi daging.

Pelaku pasar utama seperti Hobart Corporation, Bizerba SE & Co. KG, dan Sirman SpA memimpin lanskap persaingan. Mereka berfokus pada inovasi produk dan kolaborasi strategis untuk meningkatkan kehadiran pasar mereka. Meningkatnya adopsi mesin pengiris daging otomatis dan semi-otomatis di pabrik pengolahan daging juga berkontribusi pada perluasan pasar, memberikan peluang bagi pendatang baru dan produsen yang sudah ada untuk memanfaatkan permintaan yang terus meningkat.

Analisis Rinci Pasar Mesin Pengiris Daging

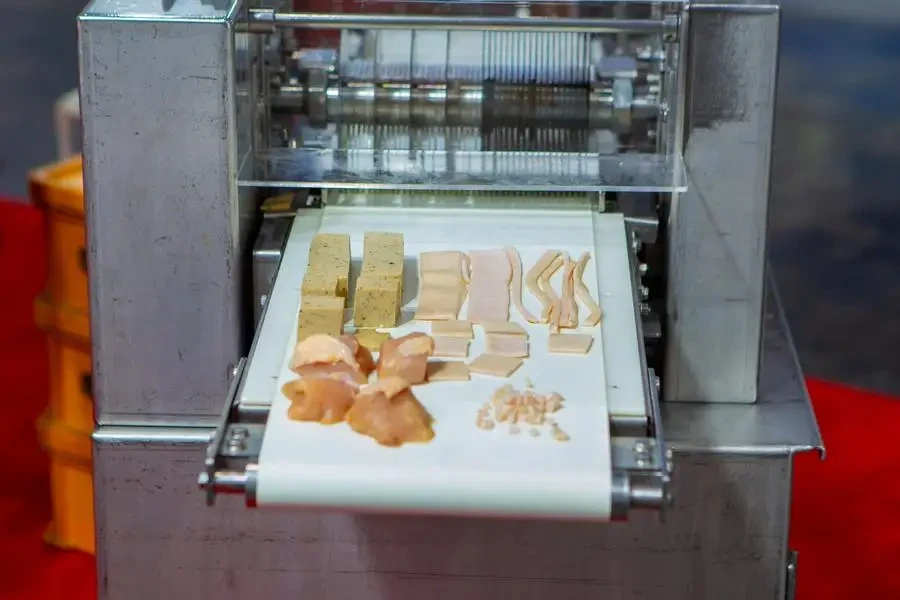

Pasar mesin pengiris daging dicirikan oleh tolok ukur kinerja utama seperti presisi, efisiensi, dan kemudahan perawatan. Faktor-faktor seperti akurasi ketebalan irisan, kecepatan, dan daya tahan mesin secara signifikan memengaruhi keputusan pembelian di antara fasilitas pemrosesan daging. Pasar disegmentasikan berdasarkan jenis produk, termasuk pengiris daging manual, semi-otomatis, dan otomatis penuh. Model semi-otomatis lebih populer karena keseimbangan antara efisiensi dan efektivitas biaya.

Segmen yang sepenuhnya otomatis akan tumbuh pada CAGR sebesar 7.4%, yang mencerminkan meningkatnya permintaan akan solusi pemrosesan daging dengan hasil tinggi. Meningkatnya biaya tenaga kerja dan kebutuhan akan efisiensi operasional mendorong peralihan ke arah otomatisasi. Selain itu, preferensi konsumen terhadap produk daging premium dan khusus mendorong pengolah daging untuk berinvestasi dalam teknologi pengirisan canggih yang memastikan kualitas dan presisi yang konsisten.

Preferensi saluran distribusi terus berkembang, dengan kecenderungan yang semakin meningkat terhadap saluran penjualan langsung dan daring. Pergeseran ini didukung oleh digitalisasi proses pengadaan dan kebutuhan akan sumber peralatan yang tepat waktu dan hemat biaya. Inovasi terkini dalam mesin pengiris daging mencakup integrasi teknologi IoT dan AI untuk pemantauan waktu nyata dan pemeliharaan prediktif, meningkatkan efisiensi operasional dan mengurangi waktu henti.

Inovasi dan Posisi Merek di Pasar Mesin Pengiris Daging

Inovasi memainkan peran penting dalam pasar mesin pengiris daging. Produsen berfokus pada pengembangan mesin dengan fitur keselamatan yang ditingkatkan, antarmuka yang mudah digunakan, dan efisiensi energi. Pengiris daging pintar yang dilengkapi dengan sensor dan kemampuan analisis data memungkinkan kontrol yang tepat atas operasi pengirisan, meminimalkan pemborosan, dan memastikan keseragaman produk. Misalnya, pengiris yang mendukung IoT memberikan umpan balik waktu nyata tentang kinerja mesin, memungkinkan pemeliharaan proaktif, dan mengurangi risiko kerusakan yang tidak terduga.

Strategi penempatan merek di antara produsen terkemuka menekankan kualitas, keandalan, dan kemajuan teknologi. Strategi diferensiasi mencakup penawaran solusi yang dapat disesuaikan dengan kebutuhan pemrosesan tertentu, seperti ketebalan irisan yang dapat disesuaikan, pengaturan kecepatan variabel, dan bilah khusus untuk berbagai jenis daging. Merek seperti Bizerba dan Hobart memanfaatkan pengalaman industri mereka yang luas dan kemampuan R&D yang kuat untuk mempertahankan keunggulan kompetitif di pasar.

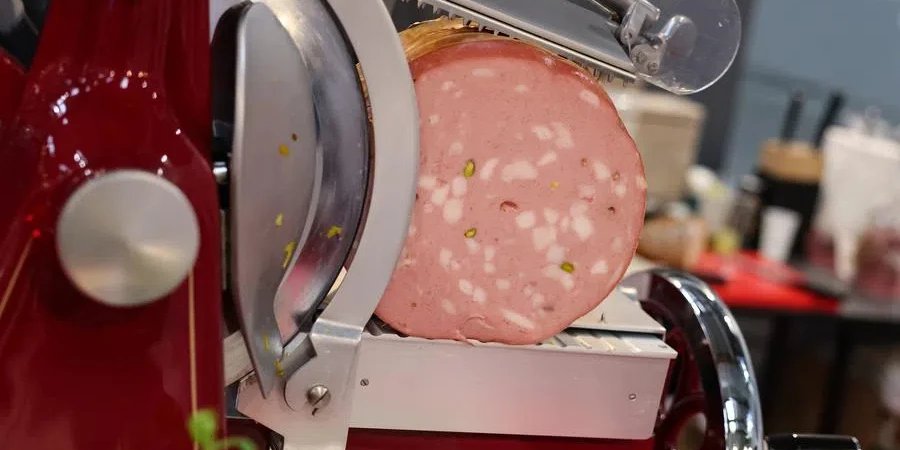

Pasar khusus, seperti pengolahan daging artisanal dan gourmet, menghadirkan peluang menguntungkan bagi mesin pengiris daging khusus yang dirancang untuk operasi skala kecil. Mesin-mesin ini memenuhi permintaan yang terus meningkat akan produk daging berkualitas tinggi yang dibuat dengan tangan, menyediakan kemampuan mengiris yang presisi dan menjaga integritas potongan premium. Masalah yang dihadapi pelanggan, seperti perlunya desain yang mudah dibersihkan dan kepatuhan terhadap standar kebersihan yang ketat, diatasi melalui desain mesin inovatif yang mengutamakan kenyamanan pengguna dan keamanan pangan.

Faktor Kunci Saat Memilih Mesin Pengiris Daging

Saat memilih mesin pengiris daging, pertimbangkan beberapa faktor untuk memastikannya memenuhi kebutuhan spesifik dan tuntutan operasional Anda. Faktor-faktor tersebut meliputi kinerja, desain, standar keselamatan, kualitas pembuatan, dan fitur tambahan mesin. Memahami aspek-aspek ini akan membantu Anda membuat keputusan yang tepat dan sesuai dengan kebutuhan bisnis Anda.

Performa dan Daya Motor

Performa mesin pengiris daging bergantung pada daya motornya. Mesin dengan daya kuda yang lebih tinggi dirancang untuk penggunaan yang sering dan terus-menerus. Misalnya, mesin pengiris tugas berat seperti Hobart HS9-1 dilengkapi motor 1/2 hp, sehingga cocok untuk operasi bervolume tinggi. Daya ini memungkinkan mesin pengiris untuk menangani daging, keju, dan produk lainnya dalam jumlah besar secara efisien. Mesin pengiris tugas ringan dengan daya kuda yang lebih rendah, seperti Globe Chefmate C10 dengan motor 1/4 hp, ideal untuk penggunaan sesekali, biasanya hingga 30 menit per hari.

Kecepatan mengiris dan kecepatan putaran bilah juga penting. Alat pengiris berkecepatan tinggi dapat menghasilkan lebih banyak irisan per menit, yang penting bagi toko daging dan deli yang sibuk. Mesin dengan berbagai pengaturan kecepatan, seperti Berkel X13A-PLUS, menawarkan fleksibilitas, yang memungkinkan Anda untuk menyesuaikan kecepatan mengiris berdasarkan produk.

Ukuran dan Bahan Bilah

Ukuran dan bahan bilah pisau sangat memengaruhi efisiensi dan kualitas potongan alat pengiris. Alat pengiris daging komersial biasanya memiliki bilah dengan diameter mulai dari 9 inci hingga 14 inci. Bilah yang lebih besar, seperti bilah 13 inci pada Hobart HS7-1, cocok untuk mengiris potongan daging dan keju yang lebih besar, sehingga menghasilkan irisan yang lebih seragam.

Bahan bilah juga berperan penting dalam kinerja dan perawatan. Bilah baja tahan karat umum digunakan karena daya tahan dan ketahanannya terhadap karat dan korosi. Beberapa model kelas atas, seperti Berkel X13A-PLUS, memiliki bilah baja tahan karat yang ditempa dan diperkeras yang mempertahankan ketajaman lebih lama dan tahan aus. Penajaman secara teratur sangat penting untuk menjaga efisiensi bilah, dan banyak alat pengiris dilengkapi dengan pengasah bawaan untuk menjaga bilah tetap tajam.

Membangun Kualitas dan Bahan

Kualitas pembuatan alat pengiris daging memengaruhi daya tahan dan kemudahan perawatannya. Alat pengiris berkualitas tinggi sering kali dibuat dengan aluminium anodized atau baja tahan karat, yang kuat dan mudah dibersihkan. Misalnya, Globe G10 memiliki konstruksi aluminium anodized, yang menyediakan permukaan yang tahan lama dan higienis yang tahan terhadap penggunaan yang sering.

Desainnya harus memudahkan pembongkaran untuk dibersihkan. Komponen yang dapat dilepas seperti saluran makanan, penutup bilah, dan deflektor irisan menyederhanakan proses pembersihan, mengurangi waktu henti, dan memastikan kepatuhan terhadap standar kebersihan. Avantco SL713MAN, misalnya, dilengkapi kereta yang dapat dilepas dan penutup bilah, sehingga lebih mudah dibersihkan dan dirawat.

Fitur Keselamatan

Keselamatan adalah hal terpenting saat mengoperasikan mesin pengiris daging. Fitur-fitur seperti pelindung bilah, sistem pelepasan tanpa tegangan, dan mekanisme interlock sangat penting untuk mencegah kecelakaan. Hobart HS9-1, misalnya, memiliki desain tanpa paparan pada bilahnya, yang meminimalkan risiko cedera selama pengoperasian.

Sistem pelepasan tanpa tegangan memastikan bahwa alat pengiris tidak akan menyala kembali secara otomatis setelah listrik padam, sehingga operator harus menyetel ulang mesin secara manual. Fitur ini penting untuk mencegah mesin menyala secara tidak sengaja yang dapat mengakibatkan cedera. Selain itu, beberapa model, seperti Globe G10, dilengkapi dengan kunci penutup pisau, yang mencegah mesin beroperasi tanpa penutup pisau terpasang.

Fitur dan Aksesori Tambahan

Alat pengiris daging modern sering kali dilengkapi dengan fitur dan aksesori tambahan yang meningkatkan fungsionalitas dan kenyamanan. Alat pengiris otomatis, seperti Vollrath 40954, dilengkapi kereta otomatis yang memungkinkan operator melakukan tugas lain saat mesin mengiris produk. Otomatisasi ini meningkatkan produktivitas dan efisiensi dalam pengaturan volume tinggi.

Fitur bermanfaat lainnya termasuk kenop ketebalan yang dapat disesuaikan, yang memungkinkan kontrol presisi atas ketebalan irisan, dan penajam bawaan yang menjaga ketajaman bilah. Aksesori seperti pendorong makanan, pemberat ujung, dan bilah khusus untuk berbagai jenis produk juga dapat menjadi tambahan yang berharga, yang memberikan fleksibilitas dan meningkatkan kinerja secara keseluruhan.

Memastikan Efisiensi Energi dan Kepatuhan Lingkungan

Efisiensi energi menjadi perhatian yang berkembang dalam industri permesinan, dan mesin pengiris daging tidak terkecuali. Mesin yang efisien tidak hanya mengurangi konsumsi energi tetapi juga menurunkan biaya pengoperasian. Saat memilih mesin pengiris daging, pertimbangkan model dengan fitur hemat energi, seperti mekanisme mati otomatis yang mematikan mesin saat tidak digunakan.

Kepatuhan terhadap peraturan lingkungan juga penting. Carilah mesin pemotong yang memenuhi standar industri untuk efisiensi energi dan memiliki sertifikasi dari badan yang diakui. Sertifikasi ini menunjukkan bahwa mesin tersebut telah diuji dan memenuhi kriteria kinerja lingkungan tertentu, yang berkontribusi pada praktik bisnis yang berkelanjutan.

Selain itu, pertimbangkan dampak lingkungan secara keseluruhan dari mesin tersebut, termasuk bahan yang digunakan dalam konstruksinya dan daur ulang komponen-komponennya. Memilih mesin yang terbuat dari bahan yang berkelanjutan dan yang meminimalkan limbah selama produksi dan operasi dapat secara signifikan mengurangi jejak lingkungan bisnis Anda.

Mengevaluasi Biaya dan Pengembalian Investasi

Biaya mesin pengiris daging merupakan faktor penting, tetapi harus dipertimbangkan terhadap potensi laba atas investasi (ROI). Sementara model kelas atas seperti Hobart HS9-1 dan Berkel X13A-PLUS hadir dengan banderol harga lebih tinggi, daya tahan, kinerja, dan fitur tambahannya sering kali sepadan dengan investasi untuk operasi bervolume tinggi.

Pertimbangkan masa pakai dan biaya perawatan mesin saat mengevaluasi nilai keseluruhannya. Mesin dengan konstruksi yang tahan lama dan komponen yang mudah diganti dapat mengurangi biaya perawatan jangka panjang dan waktu henti. Selain itu, fitur yang meningkatkan produktivitas, seperti pemotongan otomatis dan penajam bawaan, dapat meningkatkan efisiensi operasional, yang menghasilkan output dan profitabilitas yang lebih tinggi.

Untuk bisnis dengan kebutuhan pemotongan sedang, model kelas menengah seperti Avantco SL713MAN menawarkan keseimbangan antara biaya dan kinerja. Mesin ini menyediakan fitur penting dan kinerja yang andal tanpa harga yang lebih tinggi yang terkait dengan model premium.

Final Thoughts

Memilih mesin pengiris daging yang tepat melibatkan pertimbangan cermat terhadap berbagai faktor, termasuk kinerja, kualitas pembuatan, fitur keselamatan, efisiensi energi, dan biaya. Dengan memahami kebutuhan spesifik Anda dan mengevaluasi opsi yang tersedia, Anda dapat memilih mesin yang memenuhi persyaratan operasional Anda dan memberikan pengembalian investasi yang solid. Memprioritaskan kualitas dan fungsionalitas akan memastikan bahwa pengiris daging Anda tetap menjadi aset berharga dalam bisnis Anda selama bertahun-tahun yang akan datang.