Il mercato delle macchine per il taglio laser è in forte crescita, con proiezioni globali che mostrano un aumento da 7.60 miliardi di USD nel 2024 a 10.22 miliardi di USD entro il 2030, alimentato da una solida adozione in settori come l'automotive e l'elettronica. Questo articolo esplora le attuali tendenze di mercato, i principali produttori, i progressi tecnologici e i fattori decisionali critici, fornendo agli acquirenti professionisti le informazioni necessarie per prendere decisioni di acquisto strategiche.

Sommario:

Comprendere il mercato delle macchine per il taglio laser

Fattori critici da considerare quando si sceglie una macchina per il taglio laser

Tipi di macchine da taglio laser

Valutazione del costo delle macchine per il taglio laser

Tendenze emergenti nella tecnologia del taglio laser

Considerazioni finali sulla scelta della giusta macchina per il taglio laser

Comprendere il mercato delle macchine per il taglio laser

Introduzione

A partire dalla fine del 2024, il mercato globale delle macchine per il taglio laser sta vivendo una crescita significativa, con una dimensione di mercato stimata in 7.60 miliardi di USD. Si prevede che questa crescita continuerà, raggiungendo i 10.22 miliardi di USD entro il 2030, guidata da un tasso di crescita annuale composto (CAGR) del 4.94%. Questo articolo approfondisce l'attuale domanda di mercato, i principali attori, i progressi tecnologici e i fattori critici da considerare quando si sceglie una macchina per il taglio laser.

Domanda attuale del mercato

La domanda di macchine per il taglio laser è solida, guidata dalla loro precisione, efficienza e versatilità nel taglio di vari materiali. Nel 2023, il mercato è stato valutato a 7.29 miliardi di USD e si prevede che crescerà fino a 7.60 miliardi di USD nel 2024. Questa crescita è attribuita alla crescente adozione della tecnologia di taglio laser in settori come l'automotive, l'aerospaziale e l'elettronica. Il settore automobilistico, in particolare, è un motore significativo, che utilizza il taglio laser per la produzione di componenti leggeri e ad alta resistenza.

La segmentazione del mercato rivela che i laser a fibra sono i più ricercati, grazie alla loro elevata efficienza e alla capacità di tagliare materiali riflettenti come alluminio e rame. Si prevede che il segmento dei laser a fibra crescerà a un CAGR del 5.0% dal 2023 al 2030. Inoltre, la regione Asia-Pacifico è leader del mercato, con la Cina che dovrebbe crescere a un CAGR del 4.6%, raggiungendo 7.8 miliardi di USD entro il 2030. Questa crescita è alimentata dalla rapida industrializzazione e dall'espansione delle attività manifatturiere nella regione.

Attori chiave e produttori

Il mercato delle macchine per il taglio laser è altamente competitivo, con attori chiave come Alpha Laser GmbH, AMADA WELD TECH Inc., Bystronic Group e Coherent Corp. che dominano il panorama. Queste aziende sono all'avanguardia nell'innovazione, sviluppando continuamente soluzioni di taglio laser avanzate per soddisfare le esigenze in continua evoluzione di vari settori. Ad esempio, Bystronic Group si è concentrata sull'integrazione di automazione e digitalizzazione nei propri sistemi di taglio laser, migliorando la produttività e riducendo i costi operativi.

Nel 2023, l'analisi della quota di mercato ha evidenziato che TRUMPF SE + Co. KG e IPG Photonics Corporation sono leader del mercato con contributi significativi in termini di fatturato e base clienti. Queste aziende hanno investito molto in ricerca e sviluppo per introdurre tecnologie all'avanguardia come laser a fibra ad alta potenza e sistemi di taglio laser automatizzati. Il panorama competitivo è caratterizzato da collaborazioni strategiche, fusioni e acquisizioni volte ad ampliare i portafogli di prodotti e la portata geografica.

Progressi tecnologici

I progressi tecnologici sono fondamentali per guidare la crescita del mercato delle macchine per il taglio laser. Lo sviluppo dei laser a fibra ha rivoluzionato il settore, offrendo velocità di taglio più elevate, consumi energetici inferiori e la capacità di tagliare un'ampia gamma di materiali. L'integrazione di software di progettazione assistita da computer (CAD) e produzione assistita da computer (CAM) con macchine per il taglio laser ha consentito tagli più complessi e precisi, supportando la tendenza verso l'Industria 4.0.

Le innovazioni recenti includono l'introduzione di sistemi di taglio laser ibridi che combinano i vantaggi dei laser a fibra e CO2, offrendo versatilità ed efficienza. Inoltre, i progressi nell'automazione e nella robotica hanno portato allo sviluppo di sistemi di taglio laser completamente automatizzati, che migliorano la produttività e riducono i costi di manodopera. Si prevede che l'adozione di queste tecnologie avanzate accelererà, con un mercato che dovrebbe raggiungere i 10.22 miliardi di USD entro il 2030.

Fattori critici da considerare quando si sceglie una macchina per il taglio laser

Compatibilità dei materiali

La compatibilità dei materiali è un fattore cruciale quando si seleziona una macchina per il taglio laser. Diverse sorgenti laser, come laser a CO2, a fibra e a diodi, offrono diverse capacità nel taglio di materiali come metalli, plastica, ceramica e compositi. Ad esempio, i laser a fibra sono altamente efficienti nel taglio di materiali riflettenti come alluminio e rame, rendendoli ideali per l'industria automobilistica ed elettronica. D'altro canto, i laser a CO2 sono preferiti per il taglio di materiali non metallici come legno e acrilico.

La scelta della sorgente laser dovrebbe allinearsi ai requisiti specifici dei materiali dell'applicazione. Ad esempio, si prevede che il segmento laser a semiconduttore raggiungerà i 25.8 miliardi di USD entro il 2030, crescendo a un CAGR del 4.4%, guidato dalla sua applicazione nel taglio di progetti complessi nel settore dell'elettronica. Comprendere la compatibilità dei materiali di diverse sorgenti laser è essenziale per ottimizzare le prestazioni di taglio e ottenere risultati di alta qualità.

Velocità e precisione di taglio

La velocità di taglio e la precisione sono parametri di prestazione critici per le macchine di taglio laser. Le elevate velocità di taglio migliorano la produttività, mentre la precisione garantisce la qualità del taglio. I laser a fibra sono noti per le loro elevate velocità di taglio e precisione, rendendoli adatti per applicazioni che richiedono tagli intricati e dettagliati. La capacità di ottenere un'elevata precisione con il minimo spreco di materiale è un vantaggio significativo della tecnologia di taglio laser.

L'analisi di mercato indica che la domanda di macchine per il taglio laser ad alta velocità e precisione è in aumento, in particolare nei settori automobilistico e aerospaziale. Questi settori richiedono componenti con tolleranze strette e finiture di alta qualità. Lo sviluppo di sistemi di taglio laser avanzati con qualità e stabilità del raggio migliorate ha ulteriormente migliorato velocità e precisione di taglio, guidando l'adozione di macchine per il taglio laser in vari settori.

Consumo energetico ed efficienza

Il consumo energetico e l'efficienza sono considerazioni importanti per le aziende che cercano di ottimizzare i costi operativi e ridurre il loro impatto ambientale. Le macchine per il taglio laser con un consumo energetico inferiore e un'efficienza più elevata offrono notevoli risparmi sui costi in termini di utilizzo di energia. I laser a fibra sono noti per la loro elevata efficienza energetica, consumando meno energia rispetto ai tradizionali laser CO2.

La tendenza del mercato verso soluzioni di taglio laser a risparmio energetico è evidente, con il segmento laser a fibra che dovrebbe crescere a un CAGR del 5.0% dal 2023 al 2030. L'adozione di macchine per il taglio laser a risparmio energetico è guidata dalla necessità di rispettare severe normative ambientali e ridurre i costi operativi. Le aziende stanno investendo sempre di più in sistemi di taglio laser che offrono elevata efficienza e basso consumo energetico per ottenere pratiche di produzione sostenibili.

Manutenzione e durata

Manutenzione e durata sono fattori chiave che incidono sul costo totale di proprietà e sull'efficienza operativa delle macchine per il taglio laser. Le macchine con minori requisiti di manutenzione e maggiore durata offrono risparmi sui costi a lungo termine e riducono al minimo i tempi di fermo. Lo sviluppo di sistemi di taglio laser robusti e affidabili è stato un obiettivo per i produttori, con progressi nelle sorgenti laser e nei componenti che migliorano la durata e la durata delle macchine.

L'analisi di mercato evidenzia che le aziende stanno dando priorità alle macchine per il taglio laser con bassi requisiti di manutenzione e alta durabilità. Questa tendenza è guidata dalla necessità di garantire una produzione continua e ridurre i tempi di fermo correlati alla manutenzione. L'introduzione di sistemi avanzati di diagnostica e monitoraggio nelle macchine per il taglio laser ha ulteriormente migliorato la loro affidabilità e facilità di manutenzione, rendendole una scelta preferita per vari settori.

Tipi di macchine da taglio laser

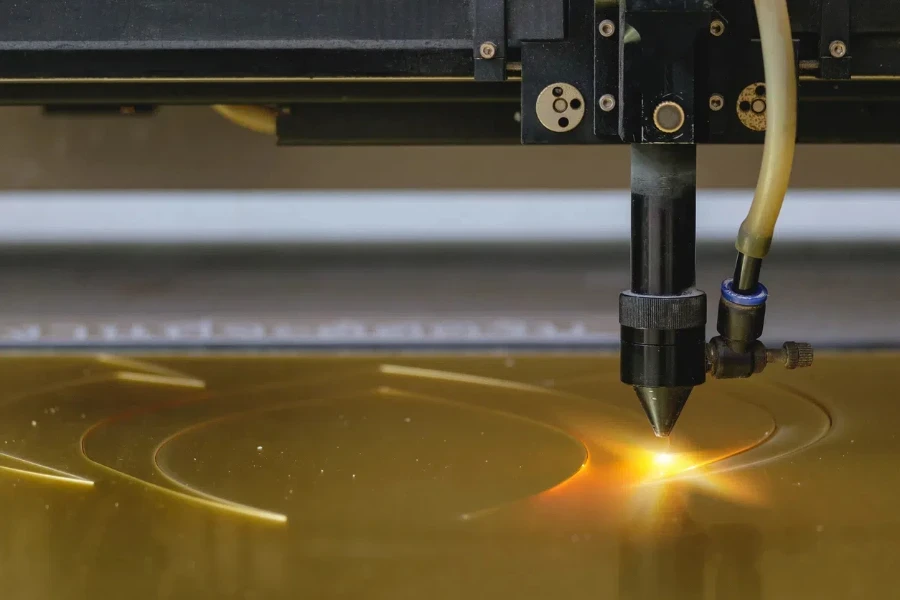

Macchine da taglio laser CO2

Le macchine per il taglio laser a CO2 utilizzano il gas di anidride carbonica come mezzo laser. Queste macchine sono note per la loro capacità di tagliare un'ampia gamma di materiali, tra cui metalli, plastica e legno. La lunghezza d'onda dei laser a CO2 è in genere di circa 10.6 micrometri, il che li rende altamente efficaci per i materiali non metallici.

La potenza in uscita dei laser a CO2 può variare da pochi watt a diversi kilowatt. Questa versatilità consente loro di essere utilizzati sia in applicazioni su piccola scala, come l'incisione, sia nel taglio industriale su larga scala. I laser a CO2 sono inoltre favoriti per il loro funzionamento a onda continua, che fornisce tagli fluidi e precisi.

Uno dei principali vantaggi delle macchine per il taglio laser a CO2 è il loro costo relativamente basso rispetto ad altri tipi di laser. Hanno anche una vita operativa più lunga e richiedono meno manutenzione. Tuttavia, sono meno efficaci su materiali altamente riflettenti come rame e alluminio.

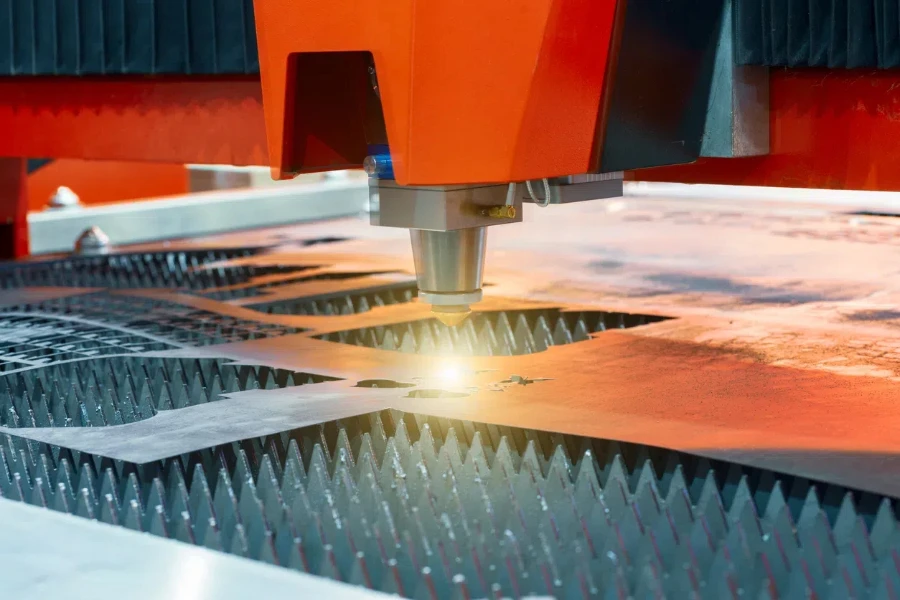

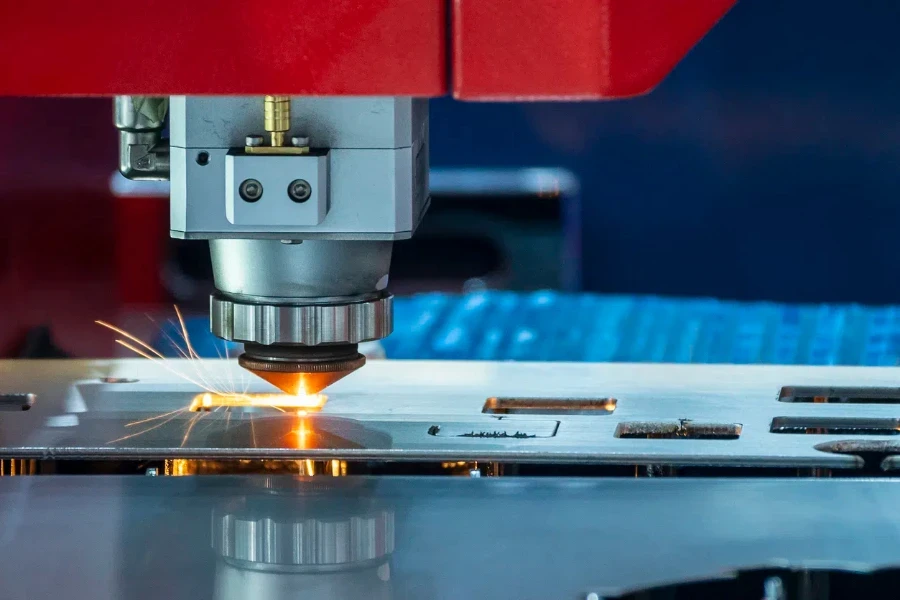

Macchine da taglio laser in fibra

Le macchine per il taglio laser a fibra utilizzano una fibra ottica drogata con elementi di terre rare come mezzo laser. Queste macchine sono altamente efficienti e possono tagliare una varietà di metalli, tra cui acciaio, alluminio e ottone. La lunghezza d'onda dei laser a fibra è di circa 1.06 micrometri, ideale per il taglio dei metalli.

I laser a fibra sono noti per la loro elevata densità di potenza e l'eccellente qualità del fascio. Ciò si traduce in velocità di taglio più elevate e maggiore precisione rispetto ai laser a CO2. Hanno anche un ingombro ridotto e costi operativi inferiori grazie alla loro elevata efficienza elettrica.

Un altro vantaggio significativo delle macchine per il taglio laser a fibra è la loro capacità di tagliare materiali riflettenti senza il rischio che i riflessi posteriori danneggino il laser. Ciò le rende adatte al taglio di rame, ottone e alluminio. Tuttavia, sono generalmente più costose dei laser a CO2 e potrebbero richiedere una manutenzione più specializzata.

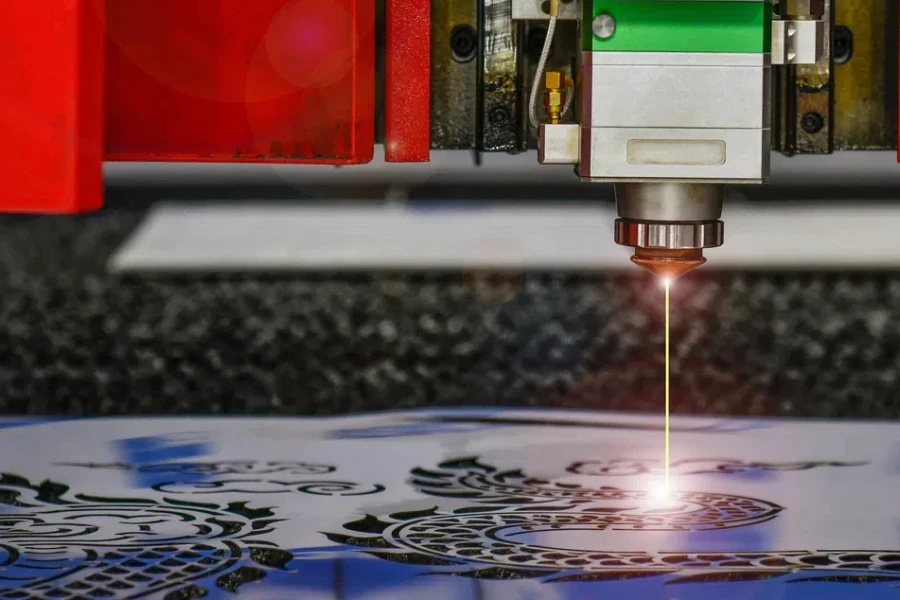

Macchine per il taglio laser di cristallo

Le macchine per il taglio laser dei cristalli utilizzano cristalli allo stato solido, come Nd:YAG (granato di ittrio e alluminio drogato al neodimio) o Nd:YVO4 (ortovanadato di ittrio drogato al neodimio), come mezzo laser. Questi laser sono in grado di produrre un'elevata potenza di picco e sono adatti per tagliare sia metalli che non metalli.

La lunghezza d'onda dei laser a cristallo è in genere di circa 1.064 micrometri, simile ai laser a fibra. Ciò li rende efficaci per tagliare i metalli con elevata precisione. I laser a cristallo possono funzionare sia in modalità a onda continua che pulsata, offrendo flessibilità per diverse applicazioni di taglio.

Uno dei principali vantaggi delle macchine per il taglio laser dei cristalli è la loro capacità di produrre tagli molto fini e dettagliati. Sono spesso utilizzate in applicazioni che richiedono elevata precisione, come la produzione di dispositivi medici e la microelettronica. Tuttavia, i laser dei cristalli hanno una vita operativa più breve e costi di manutenzione più elevati rispetto ai laser a CO2 e a fibra.

Valutazione del costo delle macchine per il taglio laser

Investimento iniziale

L'investimento iniziale per una macchina per il taglio laser può variare notevolmente in base al tipo e alle specifiche della macchina. Le macchine per il taglio laser CO2 sono generalmente le più convenienti, con prezzi che vanno da $ 10,000 a $ 100,000. Le macchine per il taglio laser a fibra sono più costose, in genere costano tra $ 50,000 e $ 500,000.

Le macchine per il taglio laser dei cristalli si collocano da qualche parte nel mezzo, con prezzi che vanno da $ 30,000 a $ 200,000. Il costo della macchina dipende anche da fattori quali potenza in uscita, velocità di taglio e funzionalità aggiuntive come automazione e integrazione software. È importante considerare questi fattori quando si valuta l'investimento iniziale.

Oltre al costo della macchina, gli acquirenti devono anche tenere conto delle spese di installazione e configurazione. Ciò può includere i costi per il lavoro elettrico, i sistemi di ventilazione e la formazione degli operatori. Un'installazione e una configurazione corrette sono essenziali per garantire che la macchina funzioni in modo efficiente e sicuro.

Costi operativi

I costi operativi per le macchine da taglio laser includono elettricità, materiali di consumo e manutenzione. I laser a fibra sono i più efficienti dal punto di vista energetico, consumando circa il 50% di energia in meno rispetto ai laser a CO2. Ciò si traduce in costi di elettricità inferiori, che possono essere un fattore significativo nei risparmi a lungo termine.

Anche i materiali di consumo come gas laser, lenti e ugelli contribuiscono ai costi operativi. I laser a CO2 richiedono una fornitura continua di gas CO2, mentre i laser a fibra e a cristallo no. Tuttavia, tutti i tipi di laser richiedono la sostituzione regolare di lenti e ugelli, che può accumularsi nel tempo.

I costi di manutenzione variano a seconda del tipo di laser. I laser a CO2 generalmente richiedono una manutenzione più frequente a causa dei loro complessi sistemi ottici. I laser a fibra hanno meno parti mobili e sono più robusti, con conseguenti costi di manutenzione inferiori. I laser a cristallo, sebbene precisi, hanno costi di manutenzione più elevati a causa della durata di vita più breve dei cristalli.

Ritorno sull'investimento (ROI)

Il calcolo del ritorno sull'investimento (ROI) per una macchina per il taglio laser comporta la considerazione sia dell'investimento iniziale che dei costi operativi correnti. Un investimento iniziale più elevato in un laser a fibra può essere giustificato da costi operativi inferiori e velocità di taglio più elevate, con conseguente aumento della produttività.

Il ROI può anche essere influenzato dalla versatilità della macchina e dalla gamma di materiali che può tagliare. Le macchine che possono gestire una varietà di materiali e spessori hanno maggiori probabilità di essere utilizzate frequentemente, massimizzando il loro valore. Inoltre, funzionalità come l'automazione e l'integrazione software possono migliorare l'efficienza e ridurre i costi di manodopera.

È importante condurre un'analisi costi-benefici approfondita per determinare il potenziale ROI. Ciò dovrebbe includere i risparmi previsti derivanti dalla riduzione dei costi operativi, dall'aumento della produttività e dai potenziali ricavi derivanti da nuove opportunità di business. Una macchina per il taglio laser ben scelta può fornire un ritorno sull'investimento significativo durante la sua vita operativa.

Tendenze emergenti nella tecnologia del taglio laser

Il settore del taglio laser è in continua evoluzione, con nuove tecnologie e tendenze emergenti per migliorare l'efficienza e la precisione. Una delle tendenze più significative è l'integrazione dell'intelligenza artificiale (IA) e dell'apprendimento automatico. Queste tecnologie consentono alle macchine per il taglio laser di ottimizzare i percorsi di taglio, regolare i parametri in tempo reale e prevedere le esigenze di manutenzione.

Un'altra tendenza emergente è lo sviluppo di macchine da taglio laser ibride. Queste macchine combinano i punti di forza di diversi tipi di laser, come i laser a CO2 e a fibra, per offrire maggiore versatilità ed efficienza. Le macchine ibride possono passare da una sorgente laser all'altra a seconda del materiale e dei requisiti di taglio, offrendo una soluzione più flessibile per i produttori.

Anche la sostenibilità sta diventando un obiettivo chiave nel settore del taglio laser. I produttori stanno sviluppando macchine più efficienti dal punto di vista energetico ed esplorando modi per ridurre sprechi ed emissioni. Ciò include l'uso di materiali e processi eco-compatibili, nonché l'implementazione di sistemi di riciclaggio e gestione dei rifiuti. Man mano che le normative ambientali diventano più severe, le pratiche sostenibili saranno essenziali per rimanere competitivi sul mercato.

Considerazioni finali sulla scelta della giusta macchina per il taglio laser

La scelta della macchina per il taglio laser giusta comporta la considerazione di vari fattori, tra cui il tipo di laser, l'investimento iniziale, i costi operativi e il potenziale ROI. È essenziale valutare le esigenze specifiche della tua attività e scegliere una macchina che offra il miglior equilibrio tra prestazioni, costi e versatilità.