Choosing the right wood laser cutter can significantly impact business efficiency and product quality. In 2025, the market continues to grow with advancements in precision technology and smart features. This article provides an in-depth analysis of key considerations, market dynamics, and the latest innovations. It offers invaluable guidance for professional buyers seeking to optimize their investment in wood laser cutting technology. Transitioning to the main content, let’s explore the critical factors and trends shaping the wood laser cutter market today.

Table of Contents:

– Market Overview of Wood Laser Cutters

– Detailed Analysis of the Wood Laser Cutter Market

– Key Factors When Selecting a Wood Laser Cutter

– Latest Technology Features in Wood Laser Cutters

– Maintenance and Durability Considerations

– Ensuring Regulatory Compliance and Safety Standards

– Summarizing Key Points

Market Overview of Wood Laser Cutters

The global laser cutting machine market, including wood laser cutters, was worth approximately USD 7.29 billion in 2023. It’s projected to reach USD 10.22 billion by 2030, growing at a CAGR of 4.94%. The wood laser cutting segment has seen significant growth due to the increasing demand for precision and efficiency in woodworking. Market segmentation by laser source includes CO2 lasers, diode/excimer lasers, and fiber lasers, with CO2 lasers being the most common in wood cutting. The key regions driving this growth are the Americas, Asia-Pacific, and Europe, with the U.S. and China being significant contributors due to their substantial manufacturing bases.

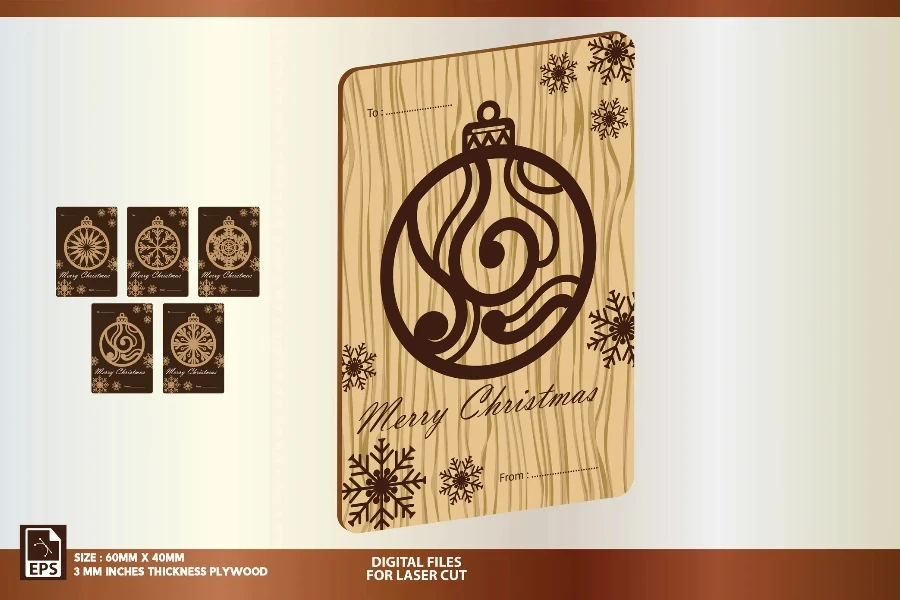

In terms of technology, the market is segmented into gas lasers, semiconductor lasers, and solid-state lasers, with gas lasers (specifically CO2 lasers) dominating the wood cutting segment. Wood laser cutters are used in various industries, including furniture manufacturing, interior decoration, and the arts and crafts sector. The trend of customized wood products, which requires high precision and intricate designs, also fuels market expansion.

Detailed Analysis of the Wood Laser Cutter Market

Key Performance Benchmarks

Wood laser cutters are benchmarked by their precision, speed, and cut quality. High-performance CO2 laser cutters can achieve cutting speeds of up to 150 mm/s with a precision of ±0.1 mm, making them ideal for intricate designs. These machines have power outputs ranging from 40W to 150W, with higher wattage machines capable of cutting through thicker wood. Their operational efficiency and low maintenance costs make them a preferred choice for both small and medium-sized enterprises (SMEs) and large-scale manufacturers.

Market Share Dynamics and Economic Influences

The wood laser cutter market is highly competitive, with key players like Epilog Laser, Trotec Laser GmbH, and Universal Laser Systems, Inc. These companies invest heavily in research and development to introduce innovative features such as automated material handling, advanced software integration, and enhanced safety mechanisms. Economic factors like the rising cost of raw materials and global economic fluctuations have influenced the market, prompting manufacturers to optimize production processes and reduce operational costs.

Consumer Behavior Shifts and Distribution Channel Preferences

Consumers now demand high-quality, customized wooden products, driving the adoption of wood laser cutters in small workshops and artisanal businesses. The growth of e-commerce platforms has also influenced distribution channel preferences. Manufacturers and distributors increasingly use online platforms to reach a broader audience, providing detailed product information, customer reviews, and after-sales support. This shift helps consumers compare products and make informed purchasing decisions.

Recent Innovations and Product Lifecycle Stages

Recent innovations in wood laser cutting technology include IoT and AI integration for predictive maintenance, real-time monitoring, and advanced design capabilities. These advancements have extended the product lifecycle of laser cutters by reducing downtime and enhancing performance. The product lifecycle stages of wood laser cutters involve introduction, growth, maturity, and decline. However, continuous technological advancements and the rising demand for customized products have prolonged the maturity stage, ensuring sustained market growth.

Digitalization and Social Trends

The digitalization of manufacturing processes has significantly impacted the wood laser cutter market. The adoption of CAD/CAM software allows for precise design and easy customization, aligning with the social trend of personalized products. Growing awareness of sustainability has led to the development of eco-friendly laser cutters that minimize waste and energy consumption.

Customer Pain Points and Brand Positioning Strategies

Key customer pain points include the initial high cost of investment, the need for skilled operators, and machine maintenance. To address these issues, manufacturers offer financing options, comprehensive training programs, and robust customer support services. Brand positioning strategies highlight the precision, efficiency, and versatility of their laser cutters, catering to both professional and hobbyist markets.

Differentiation Strategies and Niche Markets

Differentiation strategies involve offering specialized features like multi-functional capabilities (engraving and cutting), user-friendly interfaces, and compact designs for small workshops. Niche markets such as custom furniture making, artistic wood carving, and educational institutions are increasingly adopting laser cutting technology for its precision and versatility. Companies are also partnering with software developers to provide integrated solutions that enhance the overall user experience.

Key Factors When Selecting a Wood Laser Cutter

Choosing the right wood laser cutter involves several critical considerations. These factors ensure that the equipment meets the specific needs and requirements of your business operations. Below are the key aspects to evaluate when selecting a wood laser cutter.

Types of Lasers

Understanding the types of lasers available is crucial. The most common types are CO2 lasers and fiber lasers.

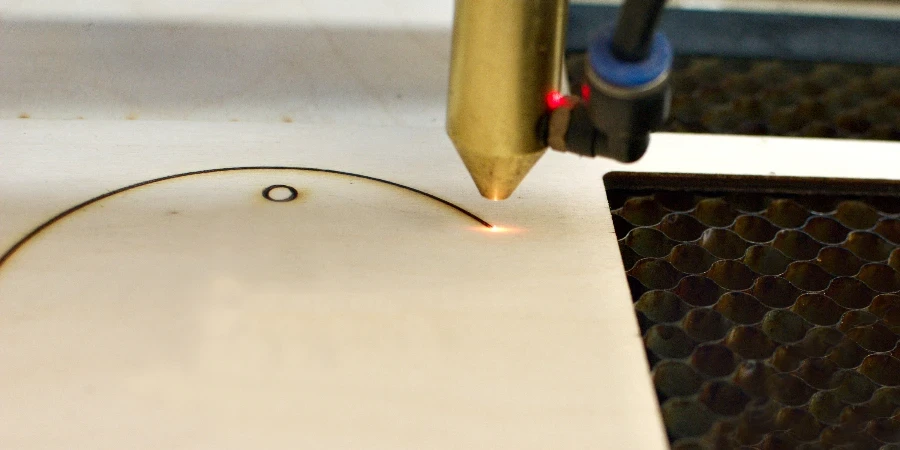

CO2 lasers use carbon dioxide gas as the lasing medium and emit infrared light at a wavelength of 10.6 micrometers. They are highly efficient for cutting wood due to their ability to produce a continuous wave output, ideal for creating smooth cuts. CO2 lasers are known for their high power and versatility, making them suitable for various wood types and thicknesses.

Fiber lasers use optical fibers doped with rare-earth elements as the lasing medium. They emit light at a wavelength of 1064 nanometers and are generally more efficient in terms of energy consumption. However, fiber lasers are less commonly used for wood cutting compared to CO2 lasers, as they are better suited for cutting metals and other hard materials.

Power and Speed

The power of a wood laser cutter determines its cutting capabilities. Power is usually measured in watts (W), and higher wattage means the laser can cut through thicker materials more efficiently. For wood cutting, laser cutters typically range from 40W to 150W. A 40W laser is sufficient for cutting thin wood sheets, while a 150W laser can handle thicker and denser wood materials.

Speed is another important consideration. The cutting speed of a laser cutter is measured in millimeters per second (mm/s). Higher cutting speeds result in faster processing times, which is essential for high-volume production. However, the speed must be balanced with precision and the quality of the cut. High-speed cutting can sometimes lead to rough edges or incomplete cuts if not properly calibrated.

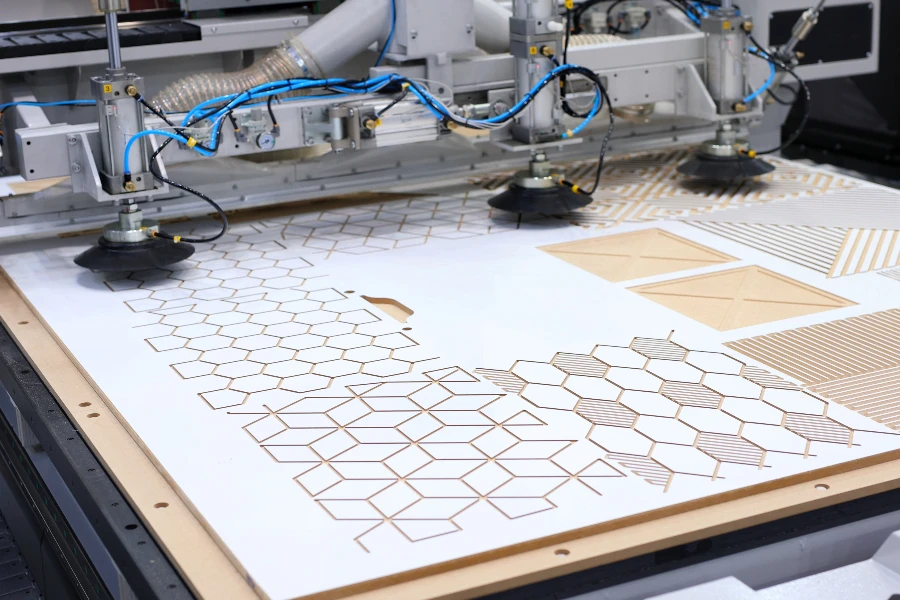

Cutting Area

The size of the cutting area is significant, especially for businesses that handle large wood panels or require intricate designs on large surfaces. The cutting area is defined by the dimensions of the X and Y axes. Common cutting area sizes range from 300mm x 200mm for small desktop models to 1300mm x 900mm for industrial-grade machines.

A larger cutting area allows for greater flexibility in handling various project sizes and reduces the need for repositioning the material. This is particularly beneficial for improving efficiency and reducing labor costs in high-volume production environments.

Software and Compatibility

The software used to control the wood laser cutter plays a vital role in its overall functionality and ease of use. Most laser cutters come with proprietary software that offers various features such as design import capabilities, vector editing, and parameter adjustments. Compatibility with popular design software like AutoCAD, CorelDRAW, and Adobe Illustrator is essential for seamless workflow integration.

Advanced software features, such as nesting (optimizing the placement of parts to minimize material waste), layer management, and real-time monitoring, can significantly enhance productivity and precision. User-friendly interfaces and comprehensive support resources can reduce the learning curve for operators and ensure efficient operation.

Safety Features

Safety is paramount when operating a wood laser cutter, especially in industrial settings. Key safety features to look for include fully enclosed machines with safety interlocks to prevent the laser from operating when the enclosure is open, protecting operators from accidental exposure to harmful laser radiation. Proper ventilation systems and air filtration units are essential for removing fumes, smoke, and particulate matter generated during the cutting process. This ensures a safe working environment and prevents respiratory hazards. An easily accessible emergency stop button allows operators to quickly halt the machine in case of any malfunction or unsafe conditions.

Performance and Functionality

The performance and functionality of a wood laser cutter are determined by several technical specifications. These include the precision and accuracy of the cuts, influenced by factors such as the quality of the laser beam, the stability of the machine, and the resolution of the control system. High-performance laser cutters offer features like autofocus, which automatically adjusts the focal length based on the material thickness, ensuring consistent cutting quality. Additionally, features like dual-head cutting and rotary attachments can enhance functionality by allowing simultaneous cuts or enabling cylindrical object processing.

Latest Technology Features in Wood Laser Cutters

The wood laser cutter industry has seen significant advancements in technology, enhancing both performance and user experience. These innovations cater to the evolving needs of businesses, ensuring higher efficiency, precision, and versatility.

Automation and Smart Features

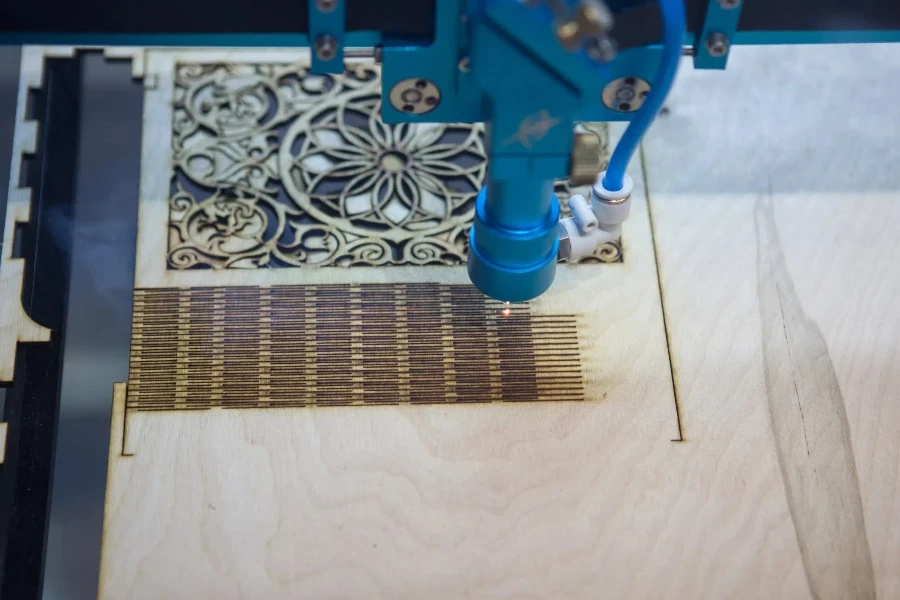

Modern wood laser cutters are increasingly incorporating automation and smart features to streamline operations. Automated material handling systems, such as conveyor belts and robotic arms, can significantly reduce manual labor and improve processing speed. These systems are particularly advantageous for high-volume production environments where efficiency is crucial.

Smart features, such as real-time monitoring and diagnostics, allow operators to track the machine’s performance and identify potential issues before they become critical. Integration with IoT (Internet of Things) platforms enables remote monitoring and control, providing greater flexibility and operational oversight. Predictive maintenance algorithms can analyze machine data to forecast maintenance needs, minimizing downtime and extending the equipment’s lifespan.

Enhanced Laser Sources

Advancements in laser source technology have led to the development of more powerful and efficient lasers. High-power CO2 lasers with output exceeding 150W are now available, capable of cutting through thicker wood materials with ease. These lasers also offer improved beam quality, resulting in cleaner cuts and reduced material waste.

Hybrid laser systems that combine CO2 and fiber lasers in a single machine are also gaining popularity. These systems provide the versatility to cut a wide range of materials, including wood, metals, plastics, and composites. The ability to switch between laser sources seamlessly enhances operational flexibility and expands the range of applications.

Improved Software Capabilities

The software that controls wood laser cutters has seen significant enhancements, offering more intuitive interfaces and advanced features. Modern software solutions provide comprehensive design and editing tools, allowing operators to create intricate patterns and complex designs with ease. Features like automatic nesting optimize material usage by arranging parts efficiently on the cutting bed, reducing waste and lowering production costs.

Integration with CAD/CAM (Computer-Aided Design and Manufacturing) software enables seamless transition from design to production. Advanced simulation tools allow operators to visualize the cutting process and make necessary adjustments before actual cutting, ensuring precision and minimizing errors. Cloud-based software solutions facilitate collaborative design and remote access, improving workflow efficiency.

Energy Efficiency and Sustainability

Energy efficiency is a growing concern in the machinery industry, and wood laser cutters are no exception. Manufacturers are focusing on developing energy-efficient lasers that consume less power without compromising performance. Innovations like high-efficiency power supplies and optimized cooling systems contribute to reducing the overall energy footprint of the equipment.

Sustainability is also being addressed through the use of eco-friendly materials and manufacturing processes. Laser cutters with low-emission designs and advanced filtration systems minimize the release of harmful pollutants, ensuring compliance with environmental regulations. Additionally, the ability to recycle and repurpose waste materials generated during the cutting process aligns with sustainable manufacturing practices.

Maintenance and Durability Considerations

Ensuring the longevity and reliability of wood laser cutters requires regular maintenance and attention to durability. Understanding the maintenance requirements and factors affecting durability can help businesses maximize their investment and minimize downtime.

Regular Maintenance Practices

Regular maintenance is essential to keep wood laser cutters operating at peak performance. Key maintenance practices include regular cleaning of the laser optics, lenses, and mirrors to maintain optimal beam quality. Lubricating moving parts, such as rails and bearings, reduces friction and wear, ensuring smooth operation. Periodic calibration and alignment of the laser head and mirrors ensure accurate and precise cuts. Proper functioning of the cooling system is vital to prevent overheating and ensure consistent laser performance. Regularly checking and replacing coolant, cleaning filters, and inspecting pumps are essential maintenance tasks.

Durability Factors

The durability of wood laser cutters depends on several factors, including build quality, material selection, and design. Machines constructed with high-quality materials, such as stainless steel and aluminum, offer greater resistance to wear and tear. Robust frame construction and precision-engineered components contribute to the machine’s overall stability and longevity.

Environmental factors, such as temperature and humidity, can also impact the durability of laser cutters. Ensuring the machine is operated in a controlled environment and protected from dust and moisture helps extend its lifespan. Additionally, investing in machines with advanced protective features, such as dustproof enclosures and anti-corrosion coatings, can enhance durability.

Warranty and Support

When selecting a wood laser cutter, evaluating the warranty and support offered by the manufacturer is crucial. A comprehensive warranty provides assurance against manufacturing defects and covers essential components like the laser source, control system, and mechanical parts. Understanding the warranty terms and conditions, including coverage period and exclusions, helps businesses make informed decisions.

Access to reliable technical support and customer service is equally important. Manufacturers that offer prompt and knowledgeable support can assist with troubleshooting, repairs, and maintenance, minimizing downtime and ensuring smooth operations. Availability of spare parts and service centers also plays a significant role in maintaining the machine’s performance and durability.

Ensuring Regulatory Compliance and Safety Standards

Compliance with regulatory standards and safety guidelines is essential for operating wood laser cutters. Adhering to these standards ensures the safety of operators and the surrounding environment while maintaining legal and industry compliance.

Regulatory Standards

Wood laser cutters must comply with various regulatory standards, including those related to laser safety, electrical safety, and environmental regulations. Key standards to consider include ANSI Z136.1, which outlines the safe use of lasers, including classification, control measures, and safety procedures. Compliance with ANSI Z136.1 ensures that laser cutters are operated safely and that operators are protected from potential hazards. ISO 11553 specifies safety requirements for laser processing machines, including protective measures, risk assessment, and safety controls. Compliance with ISO 11553 ensures that machines meet global safety standards and are designed to minimize risks. For machines sold in the European Union, CE marking indicates compliance with relevant EU directives, including those related to safety, health, and environmental protection. CE marking ensures that machines meet stringent safety and quality requirements.

Safety Features

Modern wood laser cutters are equipped with various safety features to protect operators and ensure safe operation. Key safety features include fully enclosed laser cutters with safety interlocks to prevent accidental exposure to laser radiation. Interlocks ensure that the laser cannot operate when the enclosure is open, protecting operators from potential harm. Effective ventilation systems and air filtration units remove fumes, smoke, and particulate matter generated during the cutting process. This ensures a safe working environment and prevents respiratory hazards. An easily accessible emergency stop button allows operators to quickly halt the machine in case of any malfunction or unsafe conditions. This feature provides an immediate response to potential safety issues.

Training and Certification

Proper training and certification of operators are essential for safe and effective operation of wood laser cutters. Training programs should cover machine operation, maintenance, safety procedures, and emergency response. Operators should be familiar with the machine’s features, controls, and safety measures to minimize risks and ensure optimal performance.

Certification programs, such as those offered by industry associations or manufacturers, provide formal recognition of an operator’s competence and knowledge. Certified operators are better equipped to handle the machine safely and efficiently, reducing the likelihood of accidents and ensuring compliance with regulatory standards.

Summarizing Key Points

Selecting the right wood laser cutter involves evaluating various factors, including laser type, power and speed, cutting area, software compatibility, safety features, and maintenance requirements. Advancements in technology, such as automation, enhanced laser sources, and improved software capabilities, have significantly enhanced the performance and functionality of wood laser cutters.

Ensuring regulatory compliance and adherence to safety standards is crucial for safe operation and legal compliance. Regular maintenance and attention to durability factors contribute to the longevity and reliability of the equipment. By carefully considering these aspects, businesses can make informed decisions and maximize the benefits of their investment in wood laser cutters.