In 2025, the laser cutter engraver market is booming, driven by advancements in precision manufacturing. This article delves into the critical aspects of choosing the right laser cutter engraver, including technology, power output, and additional functionalities. Professional buyers will find valuable insights to make informed purchasing decisions, ensuring optimal performance and cost-efficiency.

Sommario:

– Market Overview: Laser Cutter Engraver Industry

– Detailed Introduction and Analysis of the Laser Cutter Engraver Market

– Key Factors When Selecting a Laser Cutter Engraver

– Valutazione della qualità costruttiva e della durata

– Standard di sicurezza e certificazioni

– Cost Considerations and Budget

– Practical Examples of Laser Cutter Engraver Applications

– Conclusione

Market Overview: Laser Cutter Engraver Industry

The laser cutter engraver market is experiencing strong growth due to the rising demand for precision manufacturing and advanced technological solutions. In 2024, the global market for laser cutting machines was worth around USD 7.60 billion, with projections estimating an increase to USD 10.22 billion by 2030, at a Compound Annual Growth Rate (CAGR) of 4.94%. This growth is driven by expanding applications in industries such as automotive, aerospace, electronics, and metal fabrication.

Fiber lasers dominate a significant portion of the market, offering higher efficiency and lower operating costs compared to traditional CO2 lasers. The adoption of fiber lasers is expected to continue growing, thanks to their ability to handle reflective materials like aluminum and copper, which are commonly used in automotive and electronics manufacturing. The Asia-Pacific region, particularly China, Japan, and South Korea, leads the market with substantial contributions from the manufacturing and electronics sectors.

The laser cutter engraver market is segmented by technology (gas lasers, semiconductor lasers, solid-state lasers), laser source (CO2 laser, diode/excimer laser, fiber laser), and end-user industry (automotive, consumer electronics, defense & aerospace, industrial). The market’s growth is further supported by the integration of Industry 4.0 technologies, enhancing efficiency and automation in manufacturing processes.

Detailed Introduction and Analysis of the Laser Cutter Engraver Market

The laser cutter engraver market is defined by key performance benchmarks such as precision, speed, and versatility. These machines are vital in industries requiring high-quality, intricate cuts and engravings. Market dynamics are shaped by technological advancements, economic factors, and changing consumer preferences. Trends like digital manufacturing and the demand for customized, small-batch production are significantly impacting the market.

Economic factors, including increased industrialization and urbanization, drive demand for laser cutter engravers, especially in emerging markets. Consumers are increasingly adopting advanced manufacturing solutions that offer efficiency and precision. The rise in disposable income and the growing number of SMEs contribute to market expansion. Distribution channels are evolving towards direct sales and online platforms, making advanced laser cutting technologies more accessible.

Recent innovations include compact and energy-efficient laser cutter engravers. Companies are investing in R&D to create products for niche markets such as jewelry design, medical device manufacturing, and aerospace components. The product lifecycle of laser cutter engravers involves continuous upgrades to incorporate the latest technological advancements, meeting the evolving needs of various industries.

Digitalization plays a crucial role in the market, with CAD/CAM software integration enhancing the precision and capabilities of laser cutter engravers. Social trends indicate a growing emphasis on sustainability, prompting manufacturers to develop eco-friendly models that reduce energy consumption and material waste. Customer pain points like high initial costs and technical complexities are being addressed through innovative financing solutions and user-friendly designs.

Brand positioning strategies in the laser cutter engraver market emphasize reliability, precision, and technological superiority. Differentiation strategies include customizable solutions, after-sales services, and training programs to enhance customer satisfaction. Niche markets such as personalized engraving services and small-scale manufacturing are gaining traction, providing new growth opportunities for market players.

The laser cutter engraver market is set for significant growth, driven by technological advancements, economic development, and evolving consumer preferences. As companies continue to innovate and adapt to market demands, the future of the laser cutter engraver industry looks promising.

Key Factors When Selecting a Laser Cutter Engraver

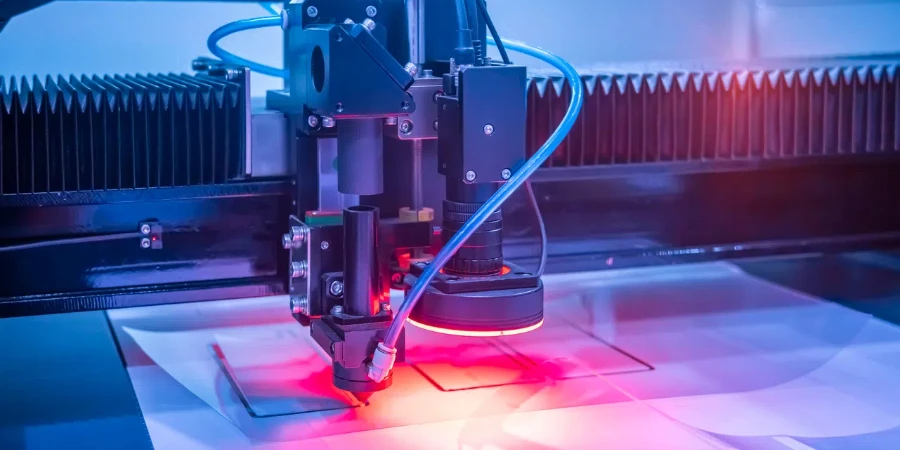

When purchasing a laser cutter engraver, several essential factors must be considered to ensure the equipment meets your operational needs. These factors include the type of laser, power output, cutting speed, precision, and additional functionalities. Each of these aspects plays a crucial role in determining the efficiency, quality, and overall performance of the laser cutter engraver.

Tipo laser

The type of laser used in a laser cutter engraver significantly impacts its performance and application range. The most common types are CO2 lasers, Nd:YAG lasers, and fiber lasers.

Laser CO2: These lasers are widely used for cutting and engraving non-metal materials such as wood, acrylic, and plastics. They operate at a wavelength of 10.6 µm and are known for their high power and continuous operation capabilities. CO2 lasers are ideal for applications requiring smooth and precise cuts.

Laser Nd:YAG: Neodymium-doped Yttrium Aluminum Garnet (Nd:YAG) lasers emit light at a wavelength of 1064 nm and can operate in both pulsed and continuous modes. They are suitable for cutting metals and other hard materials. Nd:YAG lasers are also used in medical applications, such as laser eye surgery, due to their ability to deliver high peak power.

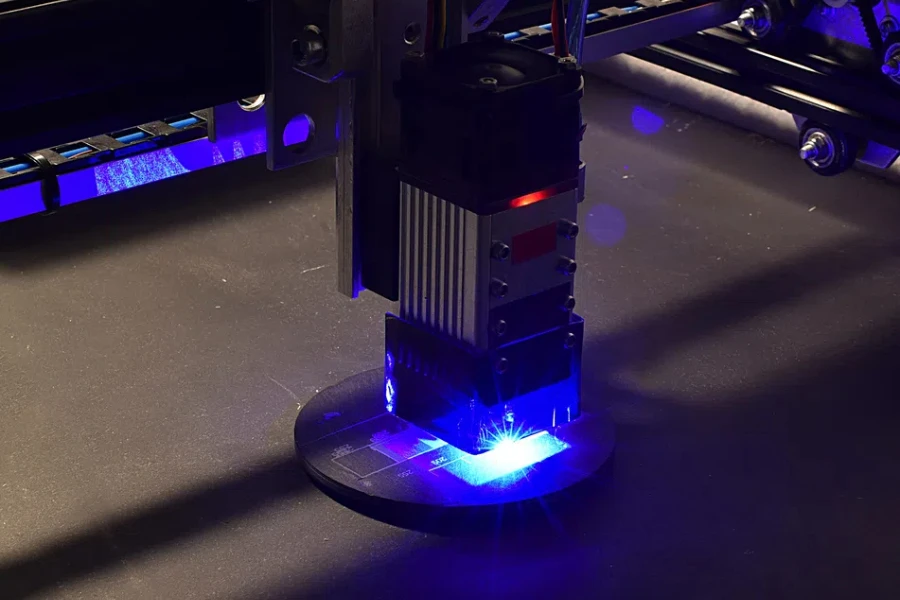

Laser a fibra: These lasers use optical fibers doped with rare-earth elements as the lasing medium. They are highly efficient and capable of cutting and engraving metals with high precision. Fiber lasers are known for their low maintenance and long lifespan, making them a popular choice for industrial applications.

Potenza di uscita

The power output of a laser cutter engraver determines its cutting and engraving capabilities. Power is measured in watts (W), and higher power levels enable the machine to cut through thicker materials and achieve faster cutting speeds.

Low-Power Lasers (20-60W): Suitable for engraving and cutting thin materials such as paper, fabric, and thin plastics. These lasers are typically used for detailed and intricate work.

Medium-Power Lasers (60-150W): Ideal for more demanding applications, including cutting thicker materials like wood, acrylic, and some metals. They offer a good balance between cutting speed and precision.

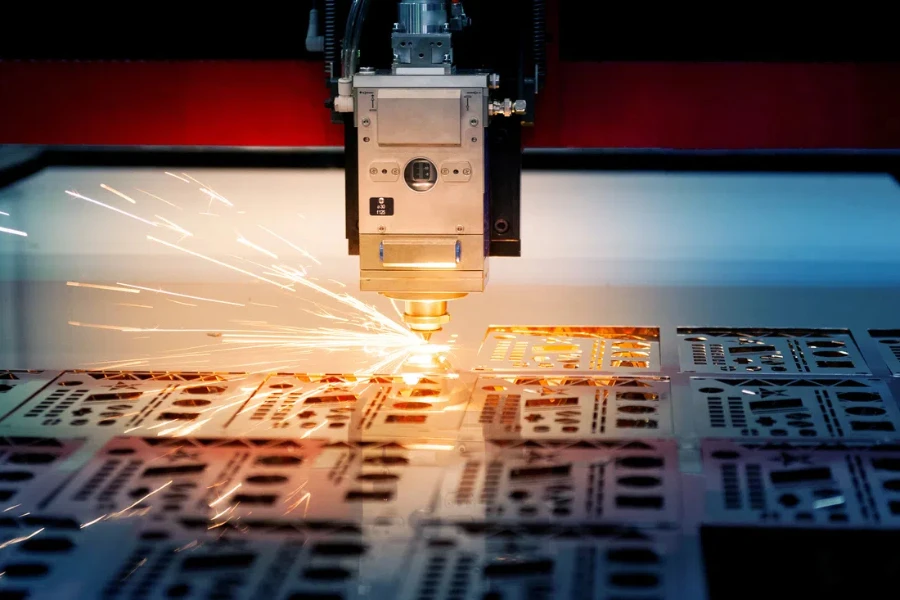

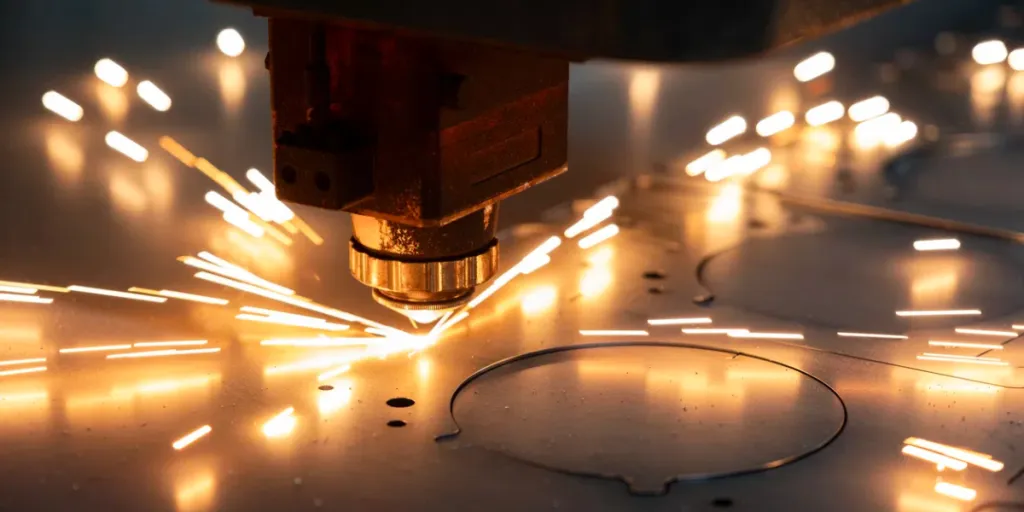

High-Power Lasers (150W and above): Designed for industrial applications, these lasers can cut through thick metals and other hard materials. They provide fast cutting speeds and high precision, making them suitable for large-scale production.

Velocità e precisione di taglio

Cutting speed and precision are critical factors that affect the efficiency and quality of the laser cutter engraver’s output. Cutting speed, measured in inches per minute (IPM) or millimeters per second (mm/s), varies depending on the material and the laser’s power output. Higher cutting speeds reduce production time but may compromise precision if not appropriately managed. Precision is determined by the laser’s ability to maintain accurate cuts and engravings. It is influenced by factors such as the laser beam diameter, the quality of the laser optics, and the machine’s mechanical stability. High-precision lasers are essential for applications requiring detailed and intricate designs.

Funzionalità aggiuntive

Additional functionalities can enhance the versatility and usability of a laser cutter engraver. Auto-focus automatically adjusts the laser’s focal length, ensuring optimal cutting and engraving quality across different material thicknesses. Rotary attachments allow the laser cutter engraver to work on cylindrical objects, expanding its application range to include items like bottles and tubes. Advanced laser cutter engravers come with integrated software that allows for easy design and control. This software can include features like batch processing, real-time monitoring, and compatibility with various design file formats.

Valutazione della qualità costruttiva e della durata

The build quality and durability of a laser cutter engraver are paramount to its long-term performance and reliability. High-quality construction materials and robust design ensure the machine can withstand the rigors of continuous use.

Materiali da costruzione

Laser cutter engravers are typically constructed from materials such as steel, aluminum, and high-quality plastics. Steel frames provide excellent stability and durability, reducing vibrations and ensuring precise cuts. Aluminum components offer a good balance between strength and weight, making the machine easier to handle and transport.

Componenti meccanici

The quality of mechanical components, such as linear guides, motors, and belts, directly impacts the machine’s performance. High-precision linear guides ensure smooth and accurate movement of the laser head, while powerful motors provide the necessary torque for fast and precise cutting. Durable belts and pulleys reduce wear and tear, extending the machine’s lifespan.

Caratteristiche protettive

Protective features, such as dust covers and cooling systems, help maintain the laser cutter engraver’s performance and longevity. Dust covers protect sensitive components from debris, while efficient cooling systems prevent overheating and ensure consistent laser output.

Standard di sicurezza e certificazioni

Ensuring that a laser cutter engraver meets safety standards and certifications is essential for protecting operators and complying with regulatory requirements.

Laser Safety Classifications

Laser cutter engravers are classified based on their potential hazards. These classifications range from Class 1 (safe under all conditions of normal use) to Class 4 (high-risk, requiring stringent safety measures). Most industrial laser cutter engravers fall under Class 3B or Class 4, necessitating appropriate safety precautions, such as protective eyewear and restricted access areas.

Conformità normativa

Compliance with international safety standards, such as ISO 11553 and IEC 60825, ensures that the laser cutter engraver meets stringent safety requirements. These standards cover aspects such as laser radiation, electrical safety, and mechanical hazards.

Caratteristiche di sicurezza

Modern laser cutter engravers are equipped with various safety features, including emergency stop buttons, interlock systems, and protective enclosures. These features help prevent accidents and ensure safe operation.

Cost Considerations and Budget

The cost of a laser cutter engraver can vary significantly based on its features, power output, and build quality. Establishing a budget and understanding the factors that influence pricing can help you make an informed purchasing decision.

Costo di acquisto iniziale

The initial purchase cost of a laser cutter engraver includes the price of the machine and any additional accessories or attachments. Entry-level machines suitable for hobbyists and small businesses can cost a few thousand dollars, while high-end industrial models can exceed $100,000.

Costi operativi

Operating costs include expenses such as electricity, maintenance, and consumables. High-power lasers consume more electricity, increasing operating costs. Regular maintenance, such as cleaning and replacing worn components, is essential to keep the machine running smoothly. Consumables, such as laser tubes and lenses, also contribute to ongoing expenses.

Return on Investment

Evaluating the potential return on investment (ROI) is crucial when purchasing a laser cutter engraver. Consider factors such as increased production capacity, reduced labor costs, and the ability to offer new services. A well-chosen laser cutter engraver can significantly enhance your business’s profitability and competitiveness.

Practical Examples of Laser Cutter Engraver Applications

Laser cutter engravers are versatile tools used in various industries for cutting, engraving, and marking different materials. Understanding practical examples of their applications can help you choose the right machine for your needs.

Produzione e fabbricazione

In manufacturing and fabrication, laser cutter engravers are used for cutting and engraving metals, plastics, and composites. They are essential for producing parts with high precision and repeatability, such as automotive components, electronic enclosures, and aerospace parts.

Segnaletica e pubblicità

Laser cutter engravers are widely used in the signage and advertising industry for creating intricate designs and lettering on materials like acrylic, wood, and metal. They enable the production of high-quality signs, plaques, and promotional items with detailed and accurate engravings.

Arti e Mestieri

In the arts and crafts sector, laser cutter engravers are popular for creating custom designs on various materials, including wood, leather, and glass. Artists and hobbyists use these machines to produce unique items such as jewelry, home decor, and personalized gifts.

Medicina e sanità

In the medical and healthcare industry, laser cutter engravers are used for precision cutting and engraving of medical devices, implants, and surgical instruments. They provide the accuracy and cleanliness required for producing high-quality medical products.

Educazione e la ricerca

Educational institutions and research facilities use laser cutter engravers for prototyping and experimental work. These machines enable students and researchers to create precise models and test new ideas, enhancing the learning and innovation process.

Avvolgere Up

Selecting the right laser cutter engraver involves careful consideration of various factors, including laser type, power output, cutting speed, precision, build quality, safety standards, and cost. By understanding these aspects and evaluating practical applications, you can make an informed decision that meets your operational needs and budget.