Nel 2025, le tendenze di automazione e sostenibilità stanno rimodellando il mercato delle macchine etichettatrici. Questo articolo approfondisce la scelta della macchina giusta, coprendo tipologie, prestazioni e conformità. Gli acquirenti professionisti troveranno spunti preziosi per prendere decisioni informate, migliorando l'efficienza e garantendo l'aderenza alle normative.

Sommario:

– Mercato delle macchine etichettatrici: una panoramica completa

– Fattori chiave nella scelta di una macchina etichettatrice

– Caratteristiche tecnologiche più recenti nelle macchine etichettatrici

– Applicazioni industriali delle macchine etichettatrici

– Considerazioni sui costi per le macchine etichettatrici

- Pensieri finali

Mercato delle macchine etichettatrici: una panoramica completa

Panoramica del mercato: panorama attuale e proiezioni future

Il mercato globale delle macchine etichettatrici ha registrato una crescita significativa negli ultimi anni ed è destinato a un'ulteriore espansione. Il mercato valeva circa 7.6 miliardi di USD nel 2023 e si prevede che raggiungerà i 10.5 miliardi di USD entro il 2030, con un tasso di crescita annuale composto (CAGR) del 4.8%. Questa crescita è guidata dalla crescente domanda di prodotti confezionati, dalla conformità normativa e dai progressi nelle tecnologie di etichettatura.

Il segmento delle macchine etichettatrici automatiche è particolarmente robusto. Nel 2023, questo segmento valeva 3.36 miliardi di USD e si prevede che raggiungerà i 5.71 miliardi di USD entro il 2030, con un CAGR del 7.83%. La crescente necessità di soluzioni di etichettatura ad alta velocità e accurate in settori come quello alimentare e delle bevande, farmaceutico e dei beni di consumo alimenta questa crescita.

A livello regionale, gli Stati Uniti e la Cina sono mercati chiave. Il mercato statunitense è stato valutato a 2.0 miliardi di USD nel 2023, mentre si prevede che il mercato cinese crescerà a un CAGR dell'8.5%, raggiungendo i 2.4 miliardi di USD entro il 2030. Altri mercati significativi includono Giappone, Canada, Germania e la regione Asia-Pacifico, tutti contribuendo all'espansione del mercato globale.

Analisi approfondita: fattori chiave e dinamiche di mercato

Diversi fattori influenzano il mercato delle macchine etichettatrici, tra cui progressi tecnologici, requisiti normativi e cambiamenti nel comportamento dei consumatori. L'automazione e la digitalizzazione stanno trasformando il settore. Le moderne macchine etichettatrici incorporano sensori avanzati, robotica e intelligenza artificiale (IA) per garantire un posizionamento preciso delle etichette e ridurre l'intervento manuale. I sistemi di etichettatura digitale consentono ai produttori di adattarsi rapidamente alle richieste del mercato e ai cambiamenti normativi.

Anche i fattori economici svolgono un ruolo significativo. L'espansione dell'industria alimentare e delle bevande, guidata dalla crescita della popolazione globale, ha portato a una maggiore domanda di prodotti confezionati e di macchine etichettatrici. La conformità normativa in settori come quello farmaceutico e dei beni di consumo richiede soluzioni di etichettatura accurate ed efficienti per la sicurezza e la tracciabilità dei prodotti.

I cambiamenti nel comportamento dei consumatori verso trasparenza e sostenibilità hanno un impatto anche sul mercato. I consumatori richiedono sempre più informazioni dettagliate sui prodotti, tra cui ingredienti, date di scadenza e avvertenze di sicurezza. Questa tendenza ha portato a soluzioni di etichettatura sofisticate che gestiscono vari tipi e dimensioni di imballaggio, garantendo un'etichettatura ad alta velocità e ad alta precisione.

Le innovazioni recenti includono materiali di etichettatura eco-compatibili e tecnologie di stampa sostenibili. Le aziende stanno investendo in ricerca e sviluppo per creare soluzioni di etichettatura che riducano al minimo gli sprechi e utilizzino materiali eco-compatibili. L'uso di materiali di etichettatura biodegradabili e riciclabili sta guadagnando terreno, allineandosi alle aspettative dei consumatori per pratiche sostenibili.

Segmentazione del mercato e panorama competitivo

Il mercato delle macchine etichettatrici è segmentato in base a tipo, classificazione dell'imballaggio, metodo di posizionamento dell'etichetta, prodotto e applicazione. Le macchine di fascia alta e standard sono i tipi principali, con le macchine di fascia alta che dovrebbero vedere una crescita significativa grazie alle loro funzionalità e capacità avanzate.

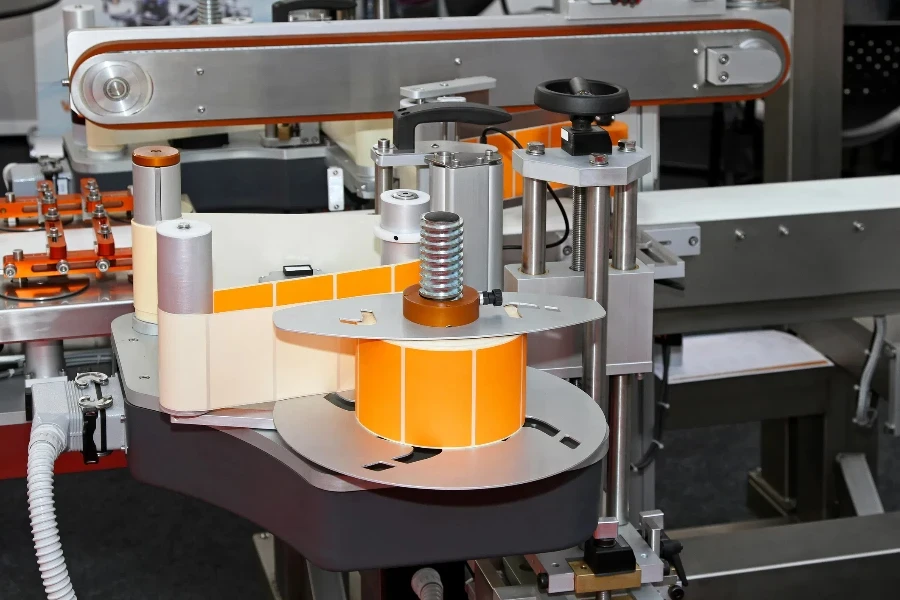

In termini di classificazione degli imballaggi, il mercato è diviso in vetro, metallo, carta o cartone e plastica. I metodi di posizionamento delle etichette includono fronte e retro o bifacciale, laterale, superiore e inferiore e avvolgente. I tipi di prodotto includono etichettatrici a base di colla, etichettatrici autoadesive/sensibili alla pressione, solo applicazione, stampa e applicazione ed etichettatrici shrink-sleeve/stretch-sleeve.

Le applicazioni delle macchine etichettatrici abbracciano vari settori, tra cui prodotti di consumo, cosmetici, cura della persona, alimenti e bevande e prodotti farmaceutici. L'industria alimentare e delle bevande detiene una quota di mercato significativa a causa della crescente domanda di alimenti confezionati e lavorati.

Il panorama competitivo vede la presenza di attori importanti quali Accutek Packaging Equipment Companies, Inc., Avery Dennison Corporation, Barry-Wehmiller Companies, Inc. e Fuji Seal International, Inc. Queste aziende si concentrano sull'innovazione di prodotto, sulle partnership strategiche e sulle fusioni e acquisizioni per rafforzare la propria posizione di mercato ed espandere la propria offerta.

Ad esempio, a gennaio 2024, Domino Printing Sciences PLC ha lanciato le sue nuove macchine etichettatrici Mx-Series print and apply con codifica di prodotti e pallet completamente integrata, automatizzata e conforme a GS1. Questa innovazione soddisfa la crescente domanda di tracciabilità nelle catene di fornitura globali, offrendo qualità costruttiva e affidabilità leader di mercato.

Fattori chiave nella scelta di una macchina etichettatrice

Scegliere la macchina etichettatrice giusta è fondamentale per garantire efficienza, qualità e conformità agli standard del settore. Ecco alcuni fattori chiave da considerare quando si seleziona una macchina etichettatrice.

Tipi di macchine etichettatrici

Le macchine etichettatrici sono disponibili in vari tipi, ciascuna adatta a diverse applicazioni e scale di produzione. Le macchine etichettatrici manuali sono adatte per operazioni su piccola scala in cui la precisione è meno critica. Le macchine semiautomatiche aumentano l'efficienza consentendo agli operatori di gestire più attività contemporaneamente. Le macchine completamente automatiche sono le migliori per la produzione ad alto volume, garantendo un'applicazione uniforme delle etichette con un intervento umano minimo. La scelta dipende dalle tue esigenze di produzione e dal tuo budget.

Ad esempio, un piccolo birrificio artigianale potrebbe optare per una macchina semiautomatica per bilanciare costi ed efficienza, mentre una grande azienda farmaceutica potrebbe investire in macchine completamente automatiche per garantire precisione e velocità.

Prestazioni e funzionalità

Quando si valutano le macchine etichettatrici, considerare parametri di prestazione quali velocità, accuratezza e versatilità. La velocità è in genere misurata in etichette al minuto (LPM) e può variare da 20 LPM per le macchine manuali a oltre 1000 LPM per le macchine automatiche di fascia alta. L'accuratezza garantisce che le etichette siano applicate correttamente senza disallineamenti, mantenendo l'immagine del marchio e la conformità normativa.

La versatilità si riferisce alla capacità della macchina di gestire varie dimensioni, forme e materiali di etichette. Le macchine con impostazioni regolabili e parti intercambiabili possono adattarsi a diverse attività di etichettatura, offrendo flessibilità alle aziende che gestiscono più prodotti.

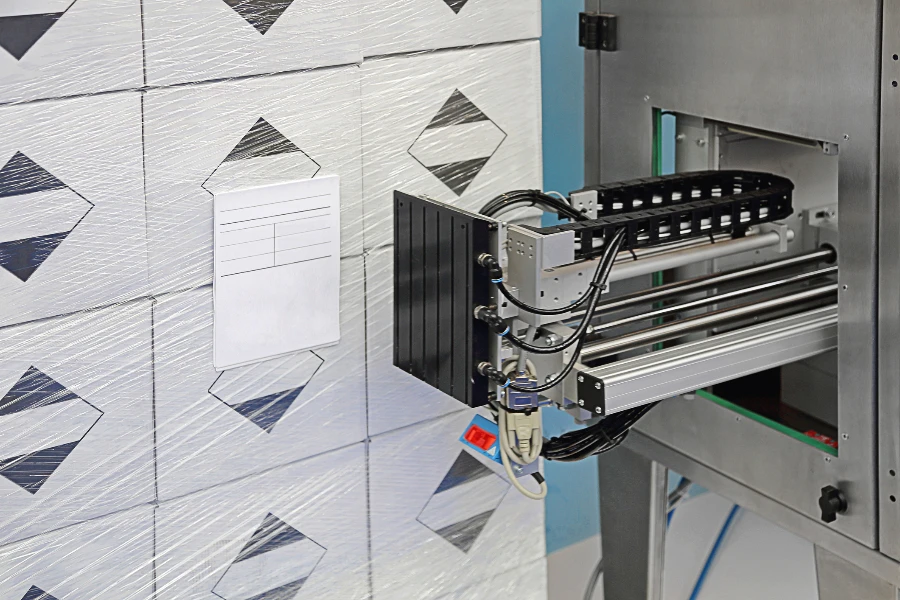

Design e specifiche tecniche

Il design di una macchina etichettatrice influisce sulla sua facilità d'uso, manutenzione e integrazione nelle linee di produzione esistenti. Le macchine compatte sono ideali per ambienti con spazi limitati, mentre le macchine più grandi possono offrire più funzionalità e una maggiore produttività. Considerare specifiche tecniche come consumo energetico, livelli di rumore e compatibilità con altre apparecchiature.

Ad esempio, una macchina con un'interfaccia user-friendly e capacità di cambio rapido può ridurre i tempi di fermo e aumentare la produttività. Inoltre, le macchine con basso consumo energetico e requisiti di manutenzione minimi possono ridurre i costi operativi nel tempo.

Qualità costruttiva e durata

La qualità costruttiva di una macchina etichettatrice influisce sulla sua longevità e affidabilità. Le macchine costruite con materiali robusti come l'acciaio inossidabile sono più durevoli e resistenti all'usura e alla corrosione, rendendole adatte ad ambienti di produzione difficili. La durata è particolarmente importante per settori come quello alimentare e delle bevande, in cui le apparecchiature sono esposte a umidità e sostanze chimiche.

Una macchina etichettatrice di alta qualità non solo ha una durata maggiore, ma richiede anche meno riparazioni, riducendo i tempi di fermo e i costi di manutenzione. Investire in una macchina durevole può fornire significativi risparmi a lungo termine e garantire una qualità di produzione costante.

Conformità e certificazioni

Le macchine etichettatrici devono essere conformi agli standard e alle normative del settore per garantire sicurezza e qualità. Certificazioni come CE (Conformité Européenne) e UL (Underwriters Laboratories) indicano che la macchina soddisfa specifici criteri di sicurezza e prestazioni. Anche la conformità a standard come ISO 9001 per i sistemi di gestione della qualità è importante per garantire una qualità costante del prodotto.

Ad esempio, nel settore farmaceutico, le macchine etichettatrici devono rispettare linee guida rigorose per garantire che le etichette siano precise e a prova di manomissione, tutelando la sicurezza dei consumatori e soddisfacendo i requisiti normativi.

Le ultime caratteristiche tecnologiche nelle macchine etichettatrici

Le moderne macchine etichettatrici incorporano tecnologie avanzate per migliorare le prestazioni, l'efficienza e la facilità d'uso. Queste caratteristiche possono avere un impatto significativo sulla produttività complessiva del processo di etichettatura.

Integrazione con sistemi di automazione

Molte macchine etichettatrici offrono ora un'integrazione perfetta con sistemi di automazione come PLC (Programmable Logic Controller) e sistemi SCADA (Supervisory Control and Data Acquisition). Questa integrazione consente monitoraggio, controllo e raccolta dati in tempo reale, migliorando l'efficienza operativa e riducendo gli errori.

Ad esempio, un'etichettatrice integrata con un PLC può regolare automaticamente le proprie impostazioni in base al prodotto da etichettare, riducendo la necessità di interventi manuali e aumentando la velocità di produzione.

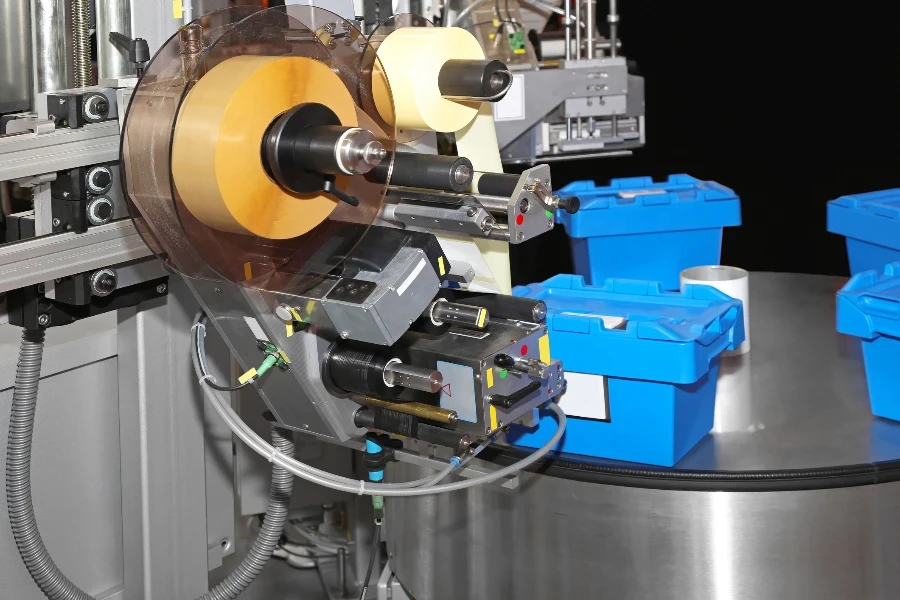

Sistemi avanzati di rilevamento e visione

Sistemi di rilevamento e visione avanzati migliorano l'accuratezza e l'affidabilità delle macchine etichettatrici. Questi sistemi possono rilevare le posizioni dei prodotti, la presenza e l'allineamento delle etichette, garantendo un'applicazione precisa delle etichette. I sistemi di visione possono anche ispezionare le etichette per rilevare eventuali difetti, come errori di stampa o danni, prima dell'applicazione.

Nel settore alimentare, dove la precisione dell'etichettatura è fondamentale per la conformità alle normative, i sistemi di visione possono contribuire a garantire che le etichette siano applicate correttamente e che tutte le informazioni necessarie siano presenti e leggibili.

Connettività IoT e monitoraggio remoto

La connettività Internet of Things (IoT) consente di monitorare e controllare da remoto le macchine etichettatrici. Questa funzionalità è particolarmente utile per le operazioni su larga scala con più linee di produzione, in quanto consente la gestione centralizzata e la risoluzione dei problemi.

Il monitoraggio remoto fornisce informazioni in tempo reale sulle prestazioni della macchina, avvisando gli operatori di potenziali problemi prima che causino tempi di inattività. Questo approccio proattivo alla manutenzione può migliorare l'efficacia complessiva delle apparecchiature (OEE) e ridurre i costi operativi.

Energy Efficiency

Le macchine etichettatrici a risparmio energetico sono progettate per ridurre al minimo il consumo di energia senza compromettere le prestazioni. Caratteristiche come le modalità di risparmio energetico e i motori efficienti aiutano a ridurre l'impatto ambientale e i costi operativi delle macchine etichettatrici.

Ad esempio, un'etichettatrice dotata di modalità di risparmio energetico può ridurre automaticamente il consumo di energia durante i periodi di inattività, riducendo i costi energetici e contribuendo al raggiungimento degli obiettivi di sostenibilità.

Interfacce user-friendly

Le moderne macchine etichettatrici spesso presentano interfacce intuitive e user-friendly che semplificano il funzionamento e riducono la curva di apprendimento per gli operatori. I comandi touchscreen, le interfacce utente grafiche (GUI) e le impostazioni personalizzabili semplificano la configurazione e la regolazione della macchina da parte degli operatori.

Un'interfaccia user-friendly può ridurre significativamente i tempi di configurazione e migliorare la produttività, specialmente in ambienti in cui sono richiesti rapidi cambi. Riduce inoltre la probabilità di errori dell'operatore, garantendo un'applicazione uniforme delle etichette.

Applicazioni industriali delle macchine etichettatrici

Le macchine etichettatrici sono utilizzate in vari settori, ognuno con requisiti e sfide unici. Comprendere queste applicazioni può aiutare le aziende a scegliere la macchina giusta per le loro esigenze.

Industria alimentare e delle bevande

Nel settore alimentare e delle bevande, le macchine etichettatrici devono gestire un'ampia gamma di tipi e dimensioni di imballaggi, da bottiglie e barattoli a lattine e buste. La precisione dell'etichettatura è fondamentale per la conformità alle normative sulla sicurezza alimentare e per fornire ai consumatori informazioni essenziali, come ingredienti e date di scadenza.

Ad esempio, un birrificio può utilizzare un'etichettatrice per applicare le etichette alle bottiglie di birra, assicurandosi che ogni etichetta sia allineata correttamente e contenga tutte le informazioni necessarie, come il contenuto alcolico e il numero di lotto.

Industria farmaceutica

L'industria farmaceutica richiede macchine etichettatrici in grado di gestire grandi volumi con precisione e affidabilità. Le etichette devono essere applicate con precisione per garantire che tutte le informazioni necessarie, come le istruzioni di dosaggio e le date di scadenza, siano leggibili e a prova di manomissione.

Un'azienda farmaceutica può utilizzare un'etichettatrice ad alta velocità con sistemi di visione avanzati per applicare etichette ai flaconi dei medicinali, garantendo la conformità ai requisiti normativi e tutelando la sicurezza dei consumatori.

Industria dei cosmetici e della cura della persona

Nel settore dei cosmetici e della cura della persona, le macchine etichettatrici devono adattarsi a varie forme e materiali di imballaggio, dai tubetti e flaconi ai barattoli e alle confezioni compatte. L'estetica è importante, poiché le etichette devono essere applicate in modo ordinato e coerente per mantenere l'immagine del marchio.

Ad esempio, un produttore di cosmetici può utilizzare un'etichettatrice con impostazioni regolabili per applicare etichette a prodotti di diverse dimensioni, assicurando che ogni etichetta sia allineata correttamente e migliori l'aspetto del prodotto.

Considerazioni sui costi per le macchine etichettatrici

Il costo delle macchine etichettatrici può variare notevolmente a seconda di fattori quali tipo, prestazioni e caratteristiche. Comprendere queste considerazioni sui costi può aiutare le aziende a prendere decisioni di acquisto consapevoli.

Prezzo di acquisto iniziale

Il prezzo di acquisto iniziale di una macchina etichettatrice è un investimento significativo, soprattutto per le macchine di fascia alta completamente automatiche. Tuttavia, questo costo deve essere soppesato rispetto ai potenziali benefici, come maggiore efficienza, costi di manodopera ridotti e migliore qualità del prodotto.

Ad esempio, una piccola azienda potrebbe optare per una macchina semi-automatica per mantenere bassi i costi iniziali, beneficiando comunque di una maggiore produttività. Al contrario, un grande produttore potrebbe investire in una macchina automatica ad alta velocità per massimizzare la produzione e ridurre i costi operativi a lungo termine.

Costi operativi e di manutenzione

I costi operativi e di manutenzione sono spese continue che devono essere considerate quando si sceglie una macchina etichettatrice. Le macchine a risparmio energetico possono aiutare a ridurre il consumo di energia e i costi operativi. Inoltre, le macchine con una costruzione robusta e componenti affidabili in genere richiedono meno manutenzione e hanno una durata maggiore.

Una manutenzione regolare è essenziale per garantire che la macchina funzioni al massimo delle prestazioni e per prevenire costosi tempi di fermo. Alcune macchine etichettatrici sono dotate di contratti di manutenzione o accordi di servizio, che possono offrire tranquillità e ridurre i costi di riparazione imprevisti.

Ritorno sull'investimento (ROI)

Il calcolo del ritorno sull'investimento (ROI) per una macchina etichettatrice implica il confronto dei costi iniziali e continuativi con i potenziali benefici, come maggiore produttività, costi di manodopera ridotti e migliore qualità del prodotto. Una macchina con un costo iniziale più elevato può offrire un ROI migliore se migliora significativamente l'efficienza e riduce le spese a lungo termine.

Ad esempio, una macchina etichettatrice ad alta velocità può avere un costo iniziale più elevato, ma può etichettare più prodotti al minuto, riducendo i costi di manodopera e aumentando la capacità produttiva complessiva. Questa maggiore efficienza può comportare un ROI più rapido rispetto a una macchina a basso costo e velocità inferiore.

Considerazioni finali

La scelta della macchina etichettatrice giusta per la tua attività implica la considerazione di vari fattori, tra cui tipologie, prestazioni, design, qualità costruttiva, conformità e costi. Valutando attentamente questi fattori e comprendendo le esigenze specifiche del tuo settore, puoi scegliere una macchina etichettatrice che migliori l'efficienza, garantisca la qualità e fornisca un solido ritorno sull'investimento.