Amid the rapid advancements in automation technology in 2025, the demand for precision equipment like linear slide rails has surged. This article delves into the key factors for selecting these essential components, offering professional buyers a comprehensive guide to making informed decisions. Leveraging recent innovations and market dynamics, this piece provides valuable insights to optimize your purchasing strategy and ensure the highest quality and performance in your inventory.

Table of Contents:

-Market Overview of Linear Slide Rails

-Detailed Analysis of the Linear Slide Rail Market

-Key Factors When Selecting Linear Slide Rails

-Advanced Features and Innovations in Linear Slide Rails

-Industry Applications of Linear Slide Rails

-Summary

Market Overview of Linear Slide Rails

The global linear slide rail market has seen robust growth, expanding from USD 391.13 million in 2023 to USD 419.14 million in 2024. This growth is expected to continue, with a projected compound annual growth rate (CAGR) of 7.67%, reaching USD 656.24 million by 2030. The increasing demand for precision equipment in manufacturing and assembly processes, along with the rising adoption of automation across various industries, drives this upward trend.

Regionally, the Asia-Pacific market, particularly China, is leading due to rapid industrialization and significant investments in precision engineering and electronics manufacturing. The Americas, driven by the United States, also show strong growth owing to the surge in manufacturing automation and the rebound of the automotive sector. Europe, with its advanced automotive and aerospace sectors, remains a significant market, while the Middle East and Africa are gradually catching up with increased investments in infrastructure and industrial manufacturing.

The market dynamics are influenced by the need for low-friction guidance and high stiffness for heavy loads, and the increasing deployment of linear slide rails in construction and aerospace industries. However, high initial costs and maintenance requirements pose challenges. Despite these challenges, opportunities abound with the introduction of high-performance and low-cost linear slide rails and their growing application in optical and medical equipment.

Detailed Analysis of the Linear Slide Rail Market

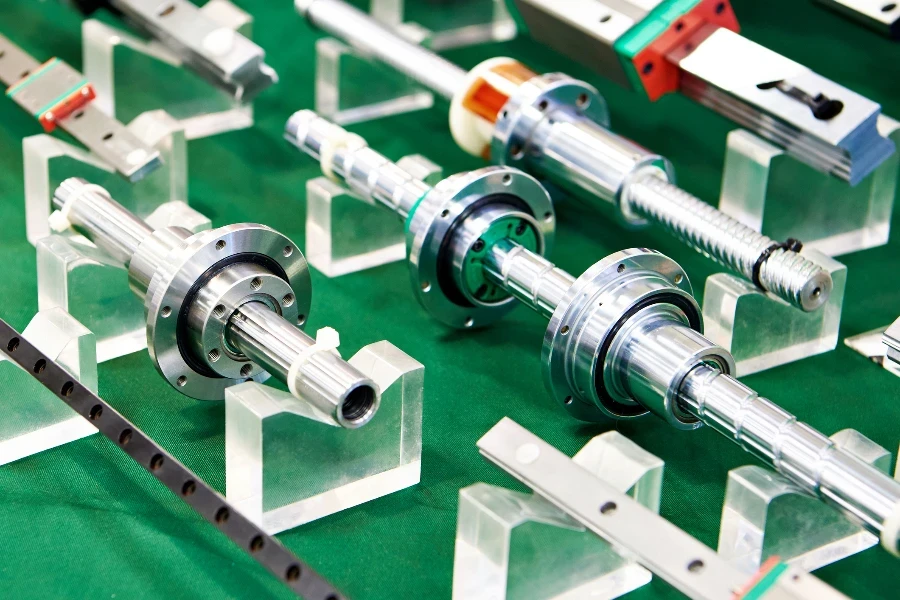

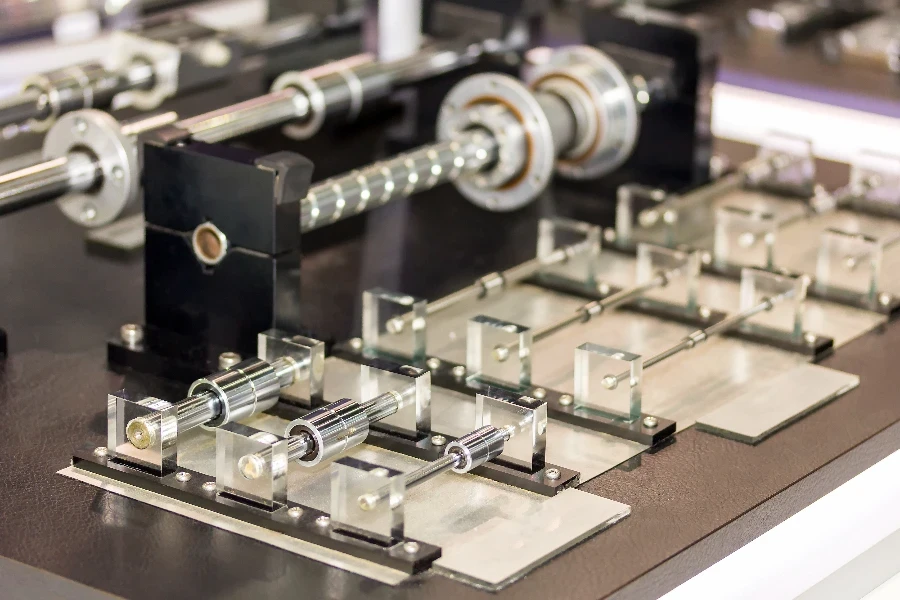

Linear slide rails are essential in high-precision applications such as CNC machining, robotics, and complex assembly lines. They consist of a rail that serves as a track and a bearing or block that moves along this track, reducing friction and maintaining stability. Key performance benchmarks include precision, load capacity, and durability. Innovations like corrosion-resistant and self-lubricating features have significantly enhanced the performance and lifespan of these components.

The market features a diverse range of materials used in manufacturing linear slide rails, including aluminum, bronze, and copper. Aluminum is lightweight and corrosion-resistant, while bronze and copper offer excellent durability and load-bearing capabilities. The development of miniature linear slide rails for small devices has also opened new niche markets, particularly in medical and optical equipment.

Consumer behavior is shifting towards advanced automation systems, driving the demand for reliable and efficient motion control systems. Distribution channels have evolved, with a preference for direct sales and long-term partnerships with OEMs to ensure the supply of high-quality components. The product lifecycle of linear slide rails is significantly influenced by technological advancements and the need for regular maintenance to ensure optimal performance.

Recent innovations in the market include NSK’s development of ultra-smooth motion technology for linear guides, enhancing dynamic friction consistency and ideal for high-precision inspection and measurement equipment. Similarly, Igus has introduced a hygienic design linear guide that is self-lubricating and suitable for use in food and beverage processing and medical technology, addressing concerns over machine cleanliness and safety.

Economic influences such as the need to reduce production time and labor costs are driving investments in automation technologies, where linear slide rails play a pivotal role. Social trends towards increased automation and precision in manufacturing processes are further propelling market growth. However, customer pain points such as high initial costs and maintenance requirements need to be addressed through innovations and cost-effective solutions.

Key Factors When Selecting Linear Slide Rails

Load Capacity

When selecting a linear slide rail, load capacity is a critical factor. Load capacity refers to the maximum weight the rail can support without permanent deformation or failure, typically measured in pounds (lbs) or kilograms (kg). For example, a rail with a load capacity of 200 kg is suitable for heavy-duty industrial applications, while a lower capacity rail is better for lighter tasks like laboratory equipment. Ensuring the load capacity matches the application requirements is essential for maintaining machinery integrity and performance.

Load capacity is influenced by factors such as the rail material and the type of bearings used. Rails made from high-grade steel or aluminum alloys generally offer higher load capacities due to their strength and durability. Additionally, ball bearings or needle roller bearings can enhance load-carrying capabilities by distributing the load more evenly across the rail.

It’s also important to consider dynamic load capacity, which refers to the load the rail can handle while in motion. This is particularly relevant for applications involving continuous or repetitive movement, as dynamic load capacities are often lower than static load capacities due to additional stresses from movement.

Precision and Accuracy

Precision and accuracy are paramount in applications requiring exact positioning and repeatability. Linear slide rails with high precision and accuracy ensure that moving components maintain their intended path with minimal deviation. This is crucial in applications like CNC machinery, medical devices, and semiconductor manufacturing, where even slight errors can cause significant issues.

Precision is often determined by the manufacturing process and component quality. Rails ground to high tolerances typically offer better precision than those that are simply machined. The type of bearings used also plays a crucial role; ball bearings and crossed roller bearings provide high precision by reducing friction and maintaining consistent contact with the rail.

Accuracy is influenced by the drive mechanism. Linear motors and ball screws are common choices for high-accuracy applications. Ball screws, in particular, offer excellent repeatability and minimal backlash, making them ideal for precision tasks. Rail accuracy is quantified by parameters such as linear travel deviation and positioning accuracy, usually specified by the manufacturer.

Environmental Suitability

The operating environment significantly impacts the selection of linear slide rails. Environments like cleanrooms or vacuum chambers require rails designed to meet stringent cleanliness and contamination control standards. Cleanroom-rated rails are manufactured to ensure minimal particle generation and are often made from materials that do not outgas or shed particles.

In harsh environments, such as those with dust, dirt, or corrosive substances, rails need protective features. Way covers or bellows shield the rails from contaminants, while materials like stainless steel or specially coated surfaces provide resistance to corrosion and wear. Rails with integrated wipers or scrapers help maintain cleanliness by removing debris during operation.

Temperature extremes also affect linear slide rail performance. Rails used in high-temperature environments must maintain structural integrity and performance without significant expansion or contraction. Conversely, applications in cryogenic conditions require materials and lubricants effective at extremely low temperatures.

Installation and Maintenance

Ease of installation and maintenance is another critical consideration when selecting linear slide rails. Rails that are easy to install can significantly reduce downtime and labor costs. Features like pre-drilled mounting holes, alignment dowels, and modular designs facilitate quick and accurate installation. Some rails are available with integrated drive mechanisms, further simplifying the installation process.

Maintenance requirements vary depending on the rail design and components. Rails with self-lubricating bearings or maintenance-free designs minimize the need for regular lubrication and adjustments. This is advantageous in applications where access to the rail is limited or maintenance intervals need to be extended. Rails with easily replaceable components, like bearings or wipers, ensure quick and efficient maintenance, reducing overall downtime.

Proper maintenance is essential to prolong the lifespan and performance of linear slide rails. Regular inspection for wear and damage, lubrication according to the manufacturer’s recommendations, and keeping the rails clean and free from contaminants are key practices. Some advanced rails come equipped with sensors and monitoring systems that provide real-time feedback on the rail’s condition, allowing for predictive maintenance and reducing the risk of unexpected failures.

Cost and Value

Cost is always a significant factor in selecting linear slide rails, but it should be considered in the context of overall value. High-end rails with advanced features and superior materials may have a higher initial cost but often offer better performance, longer lifespan, and lower maintenance requirements, leading to lower total cost of ownership.

When evaluating cost, consider the specific application requirements. For instance, a high-precision rail with a high load capacity may be necessary for a CNC machine but overkill for a simple conveyor system. Balancing cost with necessary specifications ensures the selected rail provides the best value for the application.

Additionally, the availability of replacement parts and manufacturer support services can impact overall value. Rails from reputable manufacturers often come with comprehensive warranties, technical support, and readily available spare parts, ensuring quick resolution of issues, minimizing downtime and additional costs.

Advanced Features and Innovations in Linear Slide Rails

Integration with Smart Technologies

The integration of smart technologies into linear slide rails has revolutionized the machinery industry. Modern rails are increasingly equipped with sensors and IoT capabilities, providing real-time data on performance metrics like load, speed, temperature, and vibration. This data can be used for predictive maintenance, allowing operators to address potential issues before they lead to downtime.

For example, sensors embedded in the rail can monitor bearing wear and provide alerts when maintenance is required. This proactive approach extends the rail’s lifespan and enhances overall efficiency. Additionally, IoT-enabled rails can integrate into larger automation systems, enabling seamless communication and coordination with other components.

Customization and Modularity

Customization and modularity are increasingly important in the selection of linear slide rails. Manufacturers now offer options tailored to specific application needs, including varying lengths, load capacities, materials, and drive mechanisms. This flexibility ensures the rail is optimized for specific requirements, enhancing performance and efficiency.

Modular designs allow for easy assembly and reconfiguration of the rail system. This is beneficial in applications where requirements may change over time, such as in research and development environments. Modular rails can be easily extended, shortened, or reconfigured to accommodate new specifications, providing a cost-effective and adaptable solution.

Energy Efficiency

Energy efficiency is a growing concern in the machinery industry, and linear slide rails are no exception. Advances in materials and design have led to the development of rails requiring less energy to operate. For example, rails with low-friction bearings and optimized drive mechanisms reduce the force needed to move the carriage, resulting in lower energy consumption.

Additionally, using lightweight materials like aluminum or composites reduces the rail system’s overall mass, further enhancing energy efficiency. Energy-efficient rails lower operational costs and contribute to sustainability efforts by reducing the machinery’s carbon footprint.

Industry Applications of Linear Slide Rails

Manufacturing and Automation

Linear slide rails play a crucial role in manufacturing and automation, providing precise and reliable linear motion for various processes. In CNC machining, linear slide rails ensure accurate positioning of the cutting tool, enabling the production of high-precision components. Similarly, in robotic assembly lines, linear slide rails facilitate the smooth and accurate movement of robotic arms, enhancing assembly process efficiency and accuracy.

Packaging equipment also relies heavily on linear slide rails for tasks like filling, sealing, and labeling. The high precision and repeatability of linear slide rails ensure consistent packaging processes that meet required specifications. Additionally, the durability and load capacity of linear slide rails make them suitable for handling heavy packages and materials.

Medical Devices

In the medical field, linear slide rails are used in various devices and equipment requiring precise and reliable motion control. For example, in imaging equipment like MRI and CT scanners, linear slide rails ensure the smooth and accurate movement of imaging components, providing high-quality images for diagnosis. Similarly, in surgical robots, linear slide rails enable precise control of robotic arms, enhancing the accuracy and safety of surgical procedures.

Cleanroom-rated and vacuum-rated versions of linear slide rails are particularly important in medical applications, where contamination control is critical. These specialized rails are designed to operate in environments with stringent cleanliness requirements, ensuring medical devices and equipment meet necessary standards for patient safety.

Aerospace and Defense

The aerospace and defense industries demand high-performance linear slide rails that can withstand extreme conditions and provide reliable operation. In aerospace applications, linear slide rails are used in aircraft manufacturing and maintenance, ensuring precise alignment and movement of components. The high load capacity and durability of linear slide rails make them suitable for handling the heavy and complex parts used in aircraft.

In defense applications, linear slide rails are used in various equipment and systems, such as missile guidance systems, radar equipment, and military vehicles. The ability to operate in harsh environments, including exposure to extreme temperatures and corrosive substances, is essential for these applications. Additionally, the high precision and reliability of linear slide rails ensure defense equipment operates effectively and meets stringent industry requirements.

Summary

Linear slide rails are essential components in various industries, providing precise and reliable linear motion for a wide range of applications. When selecting linear slide rails, it is important to consider factors such as load capacity, precision and accuracy, environmental suitability, installation and maintenance, and cost and value. Advances in technology have led to the development of smart, customizable, and energy-efficient linear slide rails that enhance machinery performance and efficiency. With their wide range of applications, from manufacturing and automation to medical devices and aerospace, linear slide rails continue to be a critical element in the machinery industry.