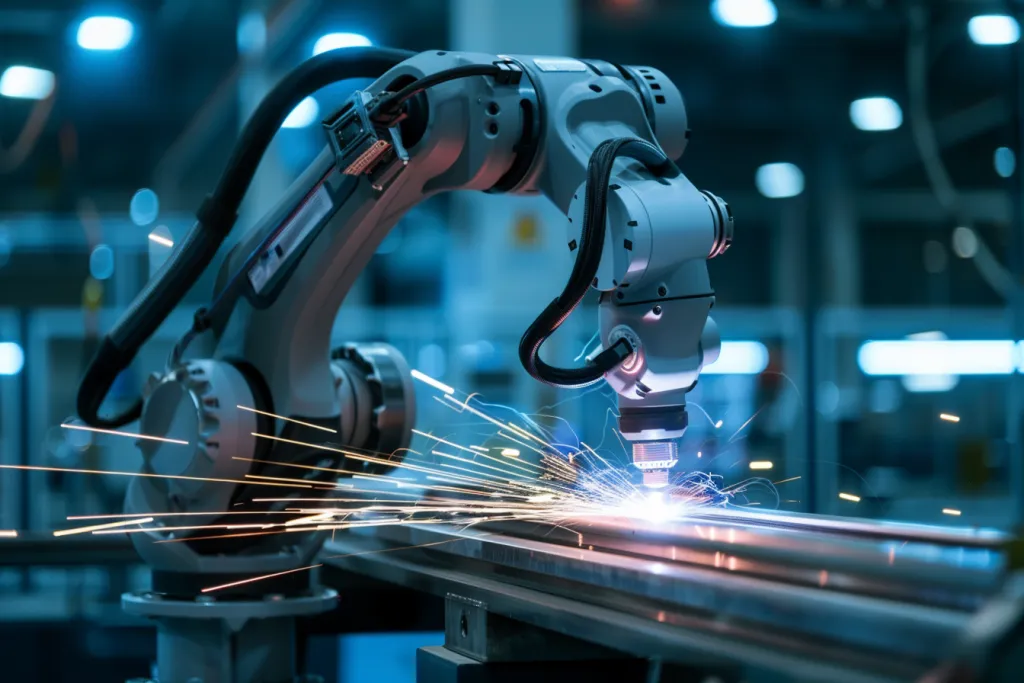

Laser beam welding is a cutting-edge technology that has revolutionized the manufacturing and fabrication industries. By focusing a high-powered laser beam to melt and fuse materials, it offers unparalleled precision, speed, and efficiency. This blog post delves into the intricacies of laser beam welding, exploring how it works, its applications, costs, and the top machines on the market today.

Table of Contents:

– What is laser beam welding?

– How does laser beam welding work?

– How to use laser beam welding

– How much does laser beam welding cost?

– Top laser beam welding machines

What is laser beam welding?

Laser beam welding (LBW) is a modern welding technique that employs a laser to join pieces of metal or thermoplastics through heating. The method is known for its high welding speeds, deep penetration, and minimal heat distortion, making it ideal for delicate or complex welding tasks. Unlike traditional welding methods, LBW allows for the precise control of the weld area, resulting in strong, high-quality joints with minimal finishing required.

How does laser beam welding work?

The core of laser beam welding’s functionality lies in its use of a concentrated laser beam as the heat source. This laser beam is focused to a fine point, allowing for precise application of heat to the materials being joined. As the laser interacts with the material, it rapidly heats and melts the metal or thermoplastic, allowing the two pieces to fuse as they cool. This process can be performed in open air or under a vacuum in a specialized chamber, depending on the materials and desired outcome. The key to LBW’s effectiveness is the control it offers over the welding process, enabling the creation of high-quality welds with minimal thermal distortion.

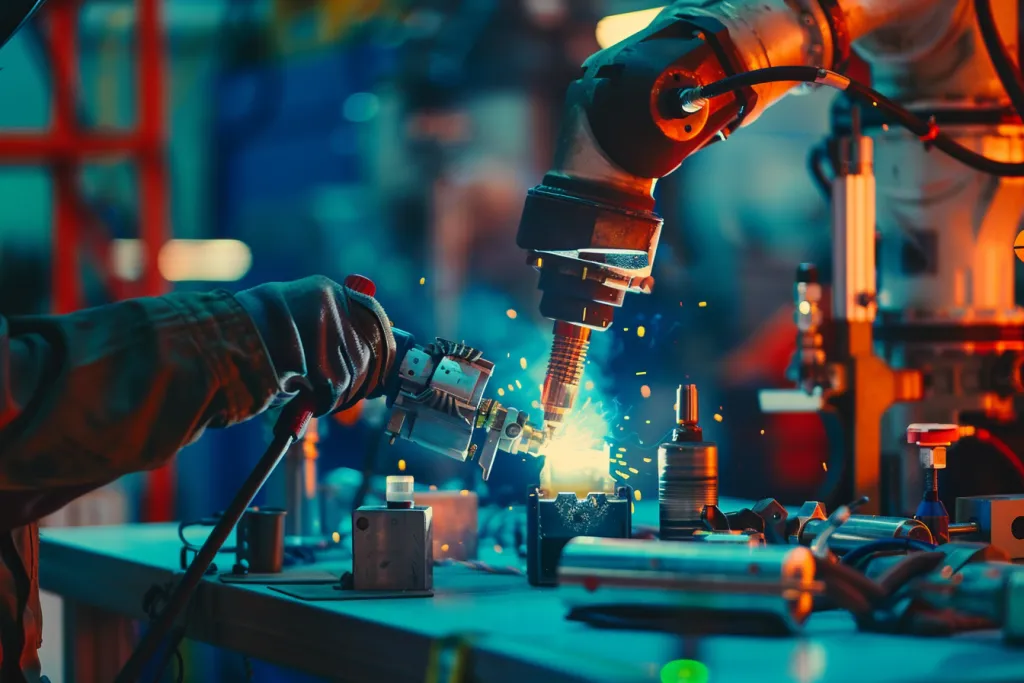

How to use laser beam welding

Using laser beam welding effectively requires a thorough understanding of the process and the specific equipment being used. The first step is to prepare the materials for welding, ensuring they are clean and properly aligned. Once the materials are ready, the laser welding machine must be set up according to the material type, thickness, and desired weld properties. This involves adjusting the laser’s power, speed, and focus to achieve the optimal welding conditions. During the welding process, it’s crucial to monitor the weld quality and make any necessary adjustments to the machine settings. With practice and experience, operators can achieve consistent, high-quality welds using laser beam welding technology.

How much does laser beam welding cost?

The cost of laser beam welding can vary widely depending on several factors, including the type and power of the laser, the complexity of the welding application, and the required equipment. Entry-level laser welding machines can start at several thousand dollars, while high-end systems equipped with the latest technology can cost hundreds of thousands of dollars. Additionally, operating costs such as power consumption, maintenance, and consumables must be considered. Despite the initial investment, the efficiency, speed, and quality of laser beam welding can lead to significant cost savings in the long run, making it a worthwhile investment for many businesses.

Top laser beam welding machines

The market for laser beam welding machines is diverse, with several leading manufacturers offering a range of models designed for various applications. Some of the top machines include:

- Trumpf TruLaser Weld Series: Known for its versatility and precision, the TruLaser Weld series from Trumpf is suitable for a wide range of materials and thicknesses.

- IPG Photonics YLS Series: IPG Photonics offers high-power fiber lasers that are ideal for deep penetration welding and high-speed applications.

- Coherent HighLight FL Series: Coherent’s HighLight FL series features fiber lasers designed for reliability and high performance in demanding industrial environments.

- Amada Miyachi LW Series: The LW series from Amada Miyachi is renowned for its precision and control, making it ideal for delicate welding tasks.

Each of these machines offers unique features and capabilities, allowing businesses to choose the best solution for their specific welding needs.

Conclusion:

Laser beam welding represents a significant advancement in joining technology, offering unparalleled precision, efficiency, and versatility. By understanding how it works, how to use it effectively, and the costs involved, businesses can leverage this powerful technology to enhance their manufacturing and fabrication processes. With the right equipment and expertise, laser beam welding can be a game-changer in the production of high-quality, durable products.