The year 2025 has seen a surge in demand for efficient cooling systems, driven by sectors like automotive and consumer goods. This article provides an in-depth analysis of performance benchmarks, technical specifications, and recent innovations in evaporator cooling fans. Professional buyers will find valuable insights to assist in making informed purchasing decisions.

Table of Contents:

– Market Overview: Evaporator Cooling Fan Industry

– Detailed Introduction and Analysis of the Evaporator Cooling Fan Market

– Key Factors to Consider When Selecting Evaporator Cooling Fans

– Latest Technological Advancements in Evaporator Cooling Fans

– Regulatory Compliance and Certifications

– Packaging Quality and Initial Setup Complexity

– Future Trends and Upgrade Potential

– Wrapping Up: Key Takeaways

Market Overview: Evaporator Cooling Fan Industry

The global evaporator cooling fan market is set to grow significantly over the next decade. In 2024, the market value reached USD 64.46 billion, with projections to reach USD 99.15 billion by 2030, growing at a compound annual growth rate (CAGR) of 7.4%. This growth is fueled by the rising demand for efficient cooling systems in various industries, including automotive, industrial, and consumer goods. The increasing adoption of electric and hybrid vehicles, which require advanced thermal management systems, is a major contributor to this market expansion.

In the automotive sector, the evaporator cooling fan market includes several types, such as condenser fans, electrical fans, heat or ventilation fans, mechanical fans, and radiator fans. The market is further categorized by distribution channels, such as aftermarket and original equipment manufacturers (OEMs), and by vehicle types, including commercial and passenger vehicles. The demand for these cooling fans is particularly high in regions with extreme climatic conditions, where efficient cooling is essential for optimal vehicle performance and longevity.

The Asia-Pacific region holds the largest market share, accounting for 38% of the total market value in 2023. North America and Western Europe follow closely, driven by the high production and sales of automobiles and the presence of major automotive manufacturers. The market in these regions is also influenced by stringent emission norms and the need for more efficient cooling solutions to comply with regulatory standards.

Detailed Introduction and Analysis of the Evaporator Cooling Fan Market

The evaporator cooling fan market is characterized by key performance benchmarks that manufacturers must meet to stay competitive. These include energy efficiency, noise reduction, durability, and cost-effectiveness. Energy-efficient cooling fans are in high demand due to their ability to reduce overall energy consumption and operating costs. Innovations like brushless motor cooling-fan assemblies, which offer higher efficiency and lower noise levels, are gaining traction in the market.

The competition is intense, with key players like Ametek, Inc., Delta Performance Automotive Group, Denso Corporation, ebm-papst Mulfingen GmbH & Co. KG, and Valeo leading the market. These companies invest heavily in research and development to introduce innovative products that meet the evolving demands of consumers. The market is also witnessing consolidation, with larger companies acquiring smaller firms to expand their product portfolios and enhance their market presence.

Economic factors, such as fluctuations in raw material prices and global economic conditions, impact the production and pricing of evaporator cooling fans. High costs of advanced cooling solutions can be a barrier for some manufacturers, particularly in regions with lower economic stability. Additionally, consumer shifts towards eco-friendly and energy-efficient products are driving demand for innovative cooling technologies that align with environmental sustainability goals.

Recent innovations in the market include smart and IoT-enabled cooling solutions that offer real-time performance monitoring and predictive maintenance. These advanced systems can adjust cooling based on the engine’s needs, improving efficiency and reducing wear and tear. The integration of advanced materials like composites also enhances the durability and performance of cooling fans, making them suitable for a wider range of applications.

The product lifecycle stages of evaporator cooling fans vary, with some products in the maturity stage while others are in the growth or introduction stages. Digitalization and advanced manufacturing techniques are shortening product development cycles and enabling faster time-to-market for new innovations. Social trends, such as the increasing focus on sustainability and energy conservation, are also influencing the market, with consumers and businesses prioritizing products that offer long-term environmental benefits.

OEMs dominate the market, accounting for approximately 75% of the total market share in 2023. However, the aftermarket segment is also growing, driven by the need for replacement parts and the increasing lifespan of vehicles. Customer pain points, such as the high cost of maintenance and the need for reliable and efficient cooling solutions, are being addressed by manufacturers through continuous product improvements and customer support services.

Brand positioning and differentiation are crucial for companies to stand out in the competitive evaporator cooling fan market. Leading brands focus on offering high-quality, innovative products that meet stringent performance standards. They also invest in marketing and customer education to highlight the benefits of their products, such as energy savings and environmental sustainability.

Niche markets, including electric and hybrid vehicles, present significant growth opportunities. These vehicles require advanced thermal management systems to ensure optimal performance and safety. By developing specialized cooling solutions for these applications, companies can tap into a growing market segment and enhance their competitive edge.

The evaporator cooling fan market is poised for substantial growth, driven by technological advancements, increasing demand for energy-efficient solutions, and the expanding adoption of electric and hybrid vehicles. Manufacturers that can innovate and adapt to changing market dynamics will be well-positioned to capitalize on the emerging opportunities in this evolving industry.

Key Factors to Consider When Selecting Evaporator Cooling Fans

Performance and Functionality

Performance and functionality are crucial when choosing an evaporator cooling fan. These fans ensure efficient heat transfer and maintain optimal temperatures in cooling systems. Key aspects to evaluate include:

Airflow Rate: Measured in cubic feet per minute (CFM), this determines the volume of air the fan can move. Higher airflow rates are essential for larger systems or environments needing substantial cooling. Choose an airflow rate that aligns with your cooling demands.

Static Pressure: Measured in inches of water gauge (in. wg), this indicates the resistance the fan must overcome to move air through the system. High static pressure fans are necessary for systems with significant airflow restrictions, such as long ductwork or dense filters.

Motor Specifications: The motor’s power, efficiency, and type (AC or DC) significantly impact the fan’s performance. Brushless DC motors are preferred for their higher efficiency and longer lifespan, while AC motors are typically more robust and cost-effective for larger industrial applications.

Technical Specifications

Understanding the technical specifications of evaporator cooling fans ensures compatibility and optimal performance. Key specifications include:

Fan Blade Design: The design and material of fan blades affect airflow efficiency and noise levels. Modern fans often use aerodynamically optimized blade shapes, such as backward-curved or airfoil blades, to enhance performance while minimizing noise.

Fan Diameter and Dimensions: The fan’s physical size, including its diameter and overall dimensions, must fit within the spatial constraints of the cooling system. Larger diameters generally provide higher airflow rates but require more space.

Operating Temperature Range: The fan’s ability to operate within specific temperature ranges is crucial, especially in extreme environments. Ensure the selected fan can withstand the operational conditions without compromising performance.

Energy Efficiency

Energy efficiency is critical for reducing operational costs and environmental impact. Consider the following when evaluating energy efficiency:

Energy Consumption: Assess the fan’s power consumption, typically measured in watts (W). High-efficiency fans consume less energy while delivering the required performance, contributing to lower energy bills.

Variable Speed Control: Fans with variable speed control can adjust their output based on real-time cooling demands, enhancing efficiency. This feature is particularly beneficial in systems with fluctuating cooling loads.

Compliance with Efficiency Standards: Look for fans that meet or exceed industry efficiency standards, such as those set by the Air Movement and Control Association (AMCA) or the International Electrotechnical Commission (IEC). Compliance ensures the fan operates efficiently and reliably.

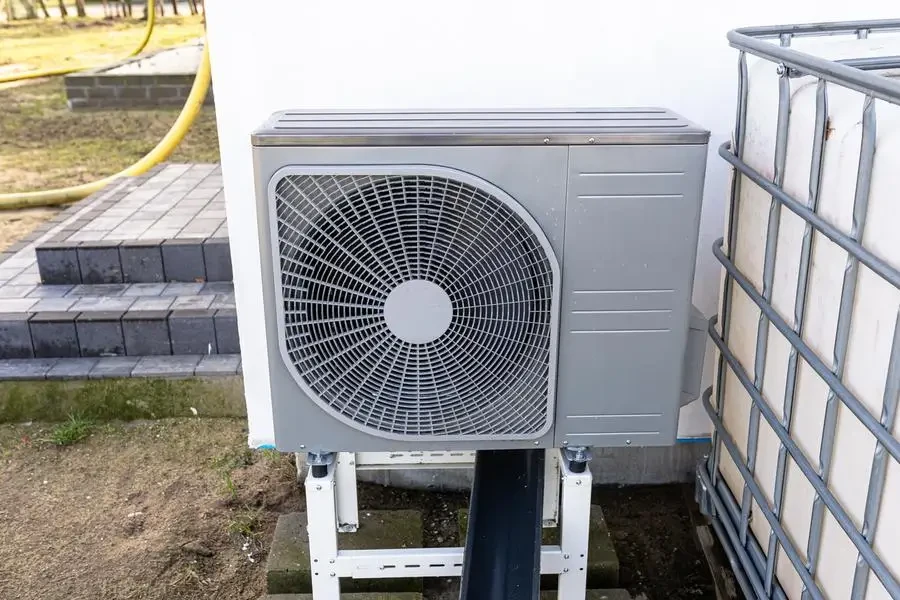

Build Quality and Durability

Build quality and durability directly impact the lifespan and maintenance requirements of evaporator cooling fans. Consider these factors:

Materials of Construction: High-quality materials, such as corrosion-resistant metals or high-strength plastics, enhance the fan’s longevity and resistance to harsh environments. Stainless steel and aluminum are commonly used for their durability and corrosion resistance.

Bearing Types: The type of bearings in the fan’s motor affects its operational smoothness and lifespan. Ball bearings are preferred for their low friction and long service life, while sleeve bearings are more cost-effective but may require more frequent maintenance.

Protective Features: Fans with protective features, such as thermal overload protection and dust-resistant housings, are more robust and reliable in demanding conditions. These features help prevent damage and extend the fan’s operational life.

Noise Levels

Noise levels are significant, especially in environments where low noise is critical. Factors influencing noise levels include:

Fan Blade Design: Aerodynamically optimized blades can reduce noise while maintaining performance. Look for fans with noise-reducing blade designs.

Motor Type and Mounting: Brushless DC motors are generally quieter than AC motors. Vibration-isolating mounts can help minimize noise transmitted to the surrounding structure.

Operating Speed: Fans operating at lower speeds produce less noise. Variable speed fans can adjust their output to balance performance and noise levels.

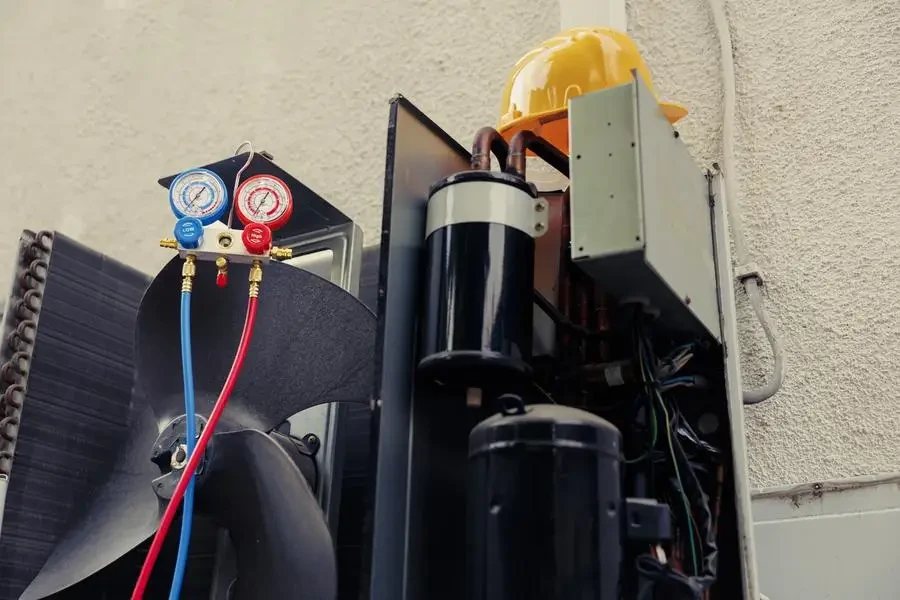

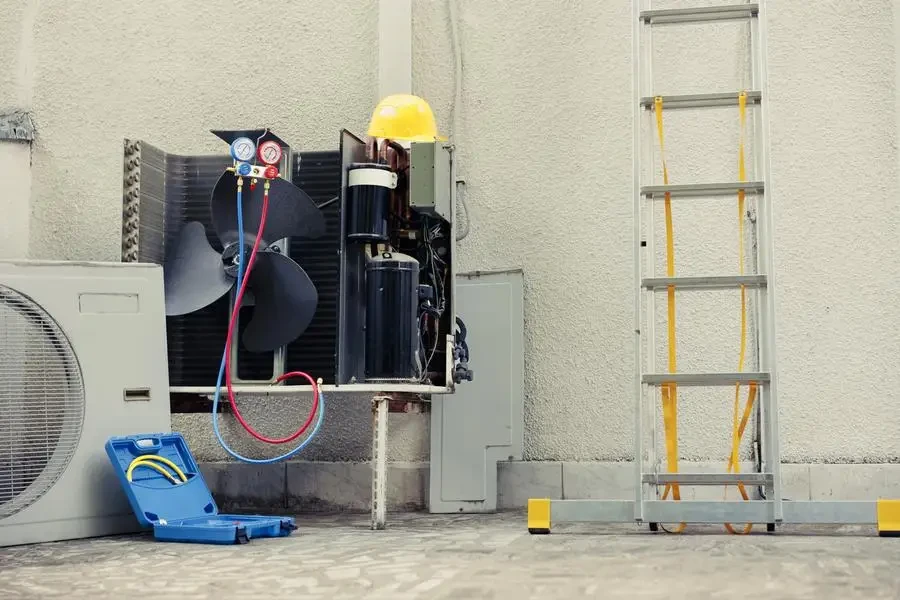

Latest Technological Advancements in Evaporator Cooling Fans

Recent technological advancements have significantly enhanced evaporator cooling fans’ performance and efficiency. Innovations include:

Smart Control Systems

Smart control systems integrate sensors and microprocessors to optimize fan operation. These systems monitor parameters like temperature, humidity, and airflow, adjusting the fan speed and performance in real-time to maintain optimal cooling conditions. Smart controls can also provide predictive maintenance alerts, reducing downtime and maintenance costs.

High-Efficiency Motors

High-efficiency motors, particularly brushless DC motors, have revolutionized evaporator cooling fan technology. These motors offer improved efficiency, longer lifespan, and lower maintenance requirements compared to traditional AC motors. They also provide precise speed control, enhancing overall system efficiency.

Advanced Blade Designs

Innovative blade designs, such as biomimetic and airfoil blades, have been developed to improve airflow efficiency and reduce noise. Inspired by natural phenomena like bird wings or marine animal fins, these designs achieve optimal aerodynamic performance.

Integration with IoT

Integrating evaporator cooling fans with the Internet of Things (IoT) allows for remote monitoring and control. IoT-enabled fans can communicate with other system components, providing valuable data and enabling centralized control. This connectivity enhances system efficiency, reliability, and ease of maintenance.

Regulatory Compliance and Certifications

Ensuring evaporator cooling fans comply with relevant regulatory standards and certifications is essential for safety, performance, and market acceptance. Considerations include:

Safety Standards

Fans must comply with safety standards set by organizations like the Occupational Safety and Health Administration (OSHA) and Underwriters Laboratories (UL). These standards ensure the fans operate safely and do not pose hazards to users or the environment.

Energy Efficiency Certifications

Energy efficiency certifications, such as Energy Star and AMCA Certified Ratings Program, indicate that the fan meets stringent efficiency criteria. These certifications are crucial for reducing energy consumption and qualifying for energy rebates or incentives.

Environmental Regulations

Compliance with environmental regulations, such as the Restriction of Hazardous Substances (RoHS) and Waste Electrical and Electronic Equipment (WEEE) directives, ensures the fan’s materials and disposal methods are environmentally responsible. This compliance is increasingly important in global markets.

Packaging Quality and Initial Setup Complexity

Packaging quality and the complexity of the initial setup impact the ease of installation and user experience. Key aspects include:

Robust Packaging

High-quality packaging protects the fan during transportation and storage, reducing the risk of damage. Look for packaging that includes protective materials, such as foam inserts or double-walled boxes, to ensure the fan arrives in optimal condition.

Clear Installation Instructions

Clear and detailed installation instructions are essential for a smooth setup process. Instructions should include diagrams, step-by-step guidelines, and safety precautions. Some manufacturers also provide video tutorials or online support to assist with installation.

Pre-Configured Settings

Fans with pre-configured settings for common applications simplify the setup process. These settings can be easily adjusted if needed, but they provide a convenient starting point for most users.

Future Trends and Upgrade Potential

Several trends and upgrade potentials are poised to shape the future of evaporator cooling fans. These include:

Increased Focus on Sustainability

As environmental concerns grow, there will be an increased focus on sustainable materials and energy-efficient designs. Future fans may incorporate biodegradable materials and advanced energy-saving technologies to reduce their environmental impact.

Enhanced Connectivity and Automation

The trend towards smart and connected devices is likely to continue, with future fans offering even greater integration with IoT and building management systems. Enhanced connectivity will enable more sophisticated automation and remote control capabilities.

Modular Designs

Modular designs will allow for easier upgrades and customization. Users will be able to add or replace components, such as motors or blades, to adapt the fan to changing requirements or to take advantage of new technologies.

Advanced Diagnostics and Predictive Maintenance

Future fans will feature advanced diagnostic capabilities, providing real-time data on performance and potential issues. Predictive maintenance algorithms will analyze this data to anticipate and prevent failures, further reducing downtime and maintenance costs.

Wrapping Up: Key Takeaways

Selecting the right evaporator cooling fan involves evaluating performance, technical specifications, energy efficiency, build quality, and regulatory compliance. Staying updated with the latest technological advancements and future trends ensures your cooling system remains efficient, reliable, and adaptable to evolving needs. By considering these factors, you can make an informed decision that optimizes your evaporator cooling system’s performance and longevity.