Table of Contents

MOPA & Q-switched fiber lasers

Internal structure comparison

Optical parameters comparison

Application Comparison

Technical parameters comparison

Examples of different fiber laser marking machines

MOPA & Q-switched fiber lasers

MOPA is an abbreviation for Master Oscillator Power Amplifier. A MOPA laser refers to a laser structure in which a laser oscillator and amplifier are cascaded. In the industrial world, a MOPA laser refers to a unique, more “intelligent” nanosecond pulsed fiber laser composed of a semiconductor laser seed source and a fiber amplifier, driven by electrical pulses.

Its “intelligence” is mainly reflected in its ability to independently adjust the output pulse width (ranging from 2 to 500 ns), with a repetition frequency as high as 1MHz. The seed source structure of the Q-switched fiber laser inserts a loss modulator into the fiber oscillating cavity, which generates a nanosecond pulse light output with a determined pulse width by periodically modulating the optical loss in the cavity.

Nanosecond pulsed lasers are well established in industrial applications such as metal marking, welding, cleaning, and cutting. As the two main types of nanosecond pulsed lasers, what are the differences, advantages, and disadvantages of a MOPA structure vs a Q-switch structure? To make this easier to understand we discuss the differences through a simple analysis of the internal structure of the lasers, output optical parameters, and application scenarios.

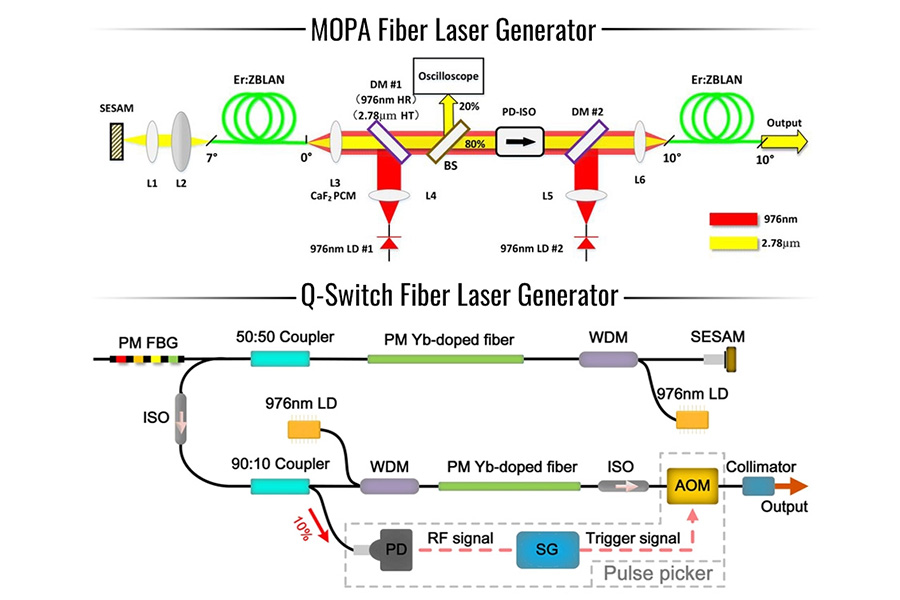

Internal structure comparison

Comparison between the internal structure and principles of a MOPA fiber laser generator and a Q-switched fiber laser generator.

The main difference in internal structure between MOPA fiber lasers and Q-switched fiber lasers is the way the pulse seed optical signal is generated.

The MOPA fiber laser pulse seed optical signal is generated by an electric pulse driving the semiconductor laser chip. In other words, the output optical signal is modulated by driving the electric signal, enabling it to generate variable pulse parameters (pulse width, repetition frequency, pulse shape, and power). This is extremely useful when marking sensitive materials such as plastics.

The pulsed seed optical signal of the Q-switched fiber laser generates a pulsed light output by periodically increasing or decreasing the resonator optical loss. It has a simple structure and therefore also a price advantage. However, due to the influence of Q-switched devices, the pulse parameters are limited.

Optical parameters comparison

The MOPA fiber laser output pulse width is independently adjustable and arbitrarily tunable (ranging from 2 ns to 500 ns). The narrower the pulse width, the smaller the heat-affected area and the higher the machining accuracy. The Q-switched fiber laser is not adjustable and is generally unchanged at around a fixed value of 80 to 140 ns.

MOPA fiber lasers have a wider repetition frequency range and can reach a high frequency output of 1MHz. High repetition frequency means high processing efficiency, and MOPA can maintain high peak power characteristics under high repetition frequency conditions. Due to the limitations of the Q-switch working conditions, Q-switched fiber lasers have a narrow output frequency range, only reaching a frequency of ~100 kHz.

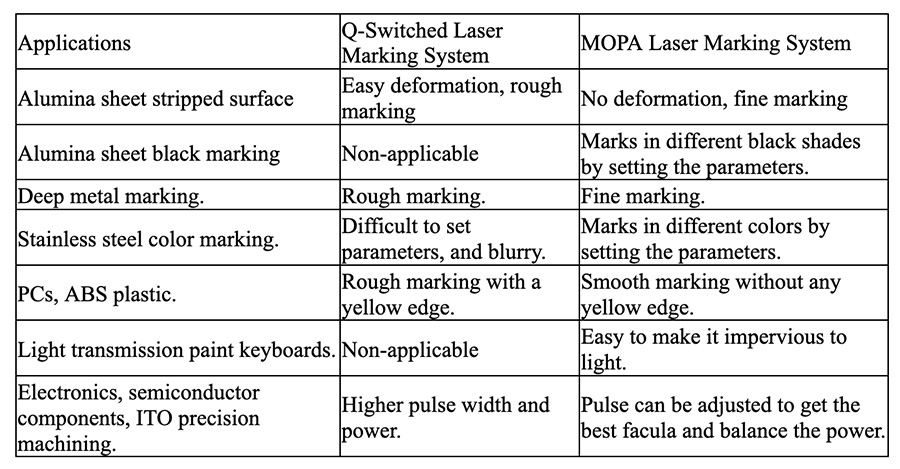

Application Comparison

The difference in possible applications of MOPA laser marking machines and Q-Switch laser marking machines is significant.

Alumina Sheet Stripped Surface Applications

Currently, an increasing number of slim electronic products like mobile phones, tablets, and computers are using thin aluminum oxide as the main frame, or shell, constituent. Using Q-switch lasers on thin aluminum plate can easily lead to deformation of the material or produce a “convex hull” which directly affects its appearance. The smaller pulse width of MOPA laser markers allow easy and accurate changes to the material, the shading is more delicate, and any white is brighter. This is due to the MOPA laser machine being faster due to the smaller pulse width needing less time in contact with the material. In addition, the high-energy laser removes the anode layer, and therefore the MOPA laser is a better choice for stripping or altering thin aluminum plate surfaces.

Black Marking on Anodic Alumina

The use of lasers on anodic alumina surfaces can create black marks, graphics, or text. Apple, Huawei, Lenovo, and Samsung have extensively used black marking to create trademarks, logos, and text on their electronic product shells for the last couple of years. Only MOPA lasers can be employed for this type of application. Their extensive pulse width and adjustable pulse frequency ranges which allow narrow pulse width and high frequency parameters, can effectively black mark the material surface. Different parameter combinations can also enable different shades of grays.

Electronic, Semiconductor, and ITO Precision Machining Applications

In the electronics industry, semiconductors, ITO, and other precision machining applications need to use fine line marking. Fine lines are difficult to achieve with Q-switch laser structures, due to their inability to adjust the pulse width parameters. MOPA laser machines can be flexible and adjust the pulse width and frequency parameters, which can not only create very fine lines, but also smooth edges.

In addition to the applications stated above, MOPA laser and Q-switch laser machines can be used in multiple applications. The table below gives some typical application examples:

after comparing the two types it is clear that MOPA fiber laser marking machines can replace Q-switched fiber laser engravers in many applications. In many of the more high-end applications, a MOPA fiber laser engraver is a much better option than a Q-switched fiber laser marking system.

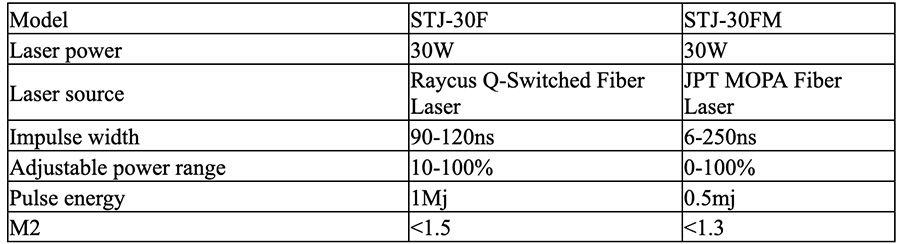

Technical parameters comparison

MOPA and Q-Switch Laser Marking Machine Technical Parameter Similarities & Differences

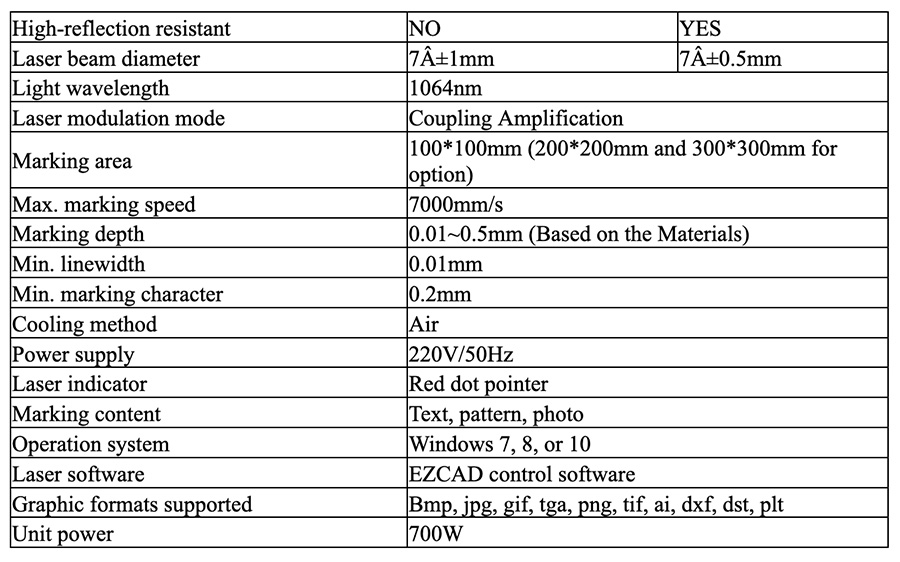

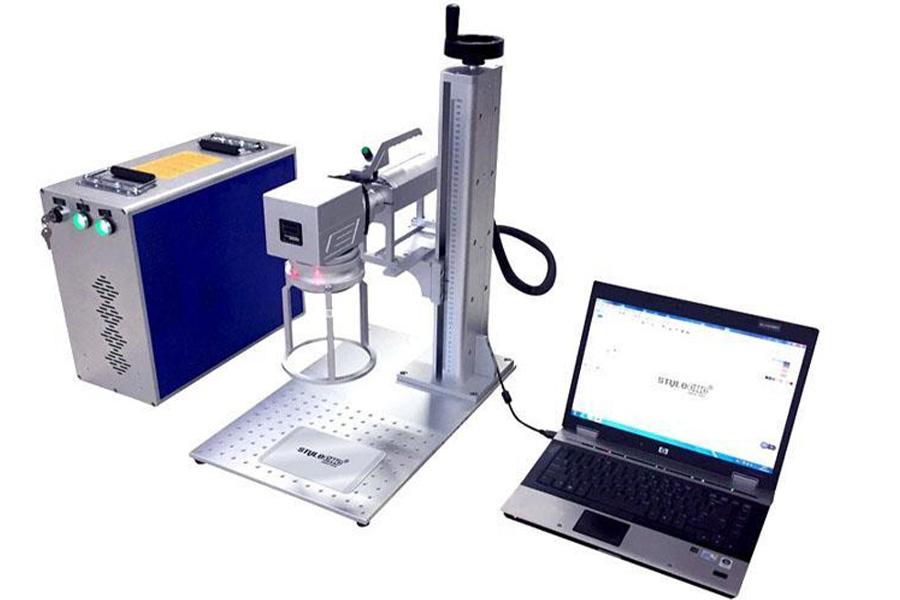

Examples of different fiber laser marking machines

|

|

| MOPA Fiber Laser Marking Machine | Q-Switch Fiber Laser Marking Machine |

Summary

To summarize, MOPA fiber lasers have a wider laser parameter coverage, more flexible adjustment, and a more comprehensive application range than Q-switched fiber lasers. In terms of machines with the same power, Q-switched fiber lasers are cheaper in several aspects. Therefore, these two types of nanosecond pulsed laser machines have different selling points, depending on where they are to be used, on what scale, and how intricate the machining detail needs to be.

Source from Stylecnc

Disclaimer: The information set forth above is provided by Stylecnc independently of Chovm.com. Chovm.com makes no representation and warranties as to the quality and reliability of the seller and products.

বাংলা

বাংলা Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português Русский

Русский Español

Español Kiswahili

Kiswahili ไทย

ไทย Türkçe

Türkçe اردو

اردو Tiếng Việt

Tiếng Việt isiXhosa

isiXhosa Zulu

Zulu