With the increasing demand for high-efficiency ice makers in 2025, selecting the right pellet ice maker is essential for businesses. This article provides an in-depth analysis of performance, energy efficiency, build quality, and advanced features. Professional buyers will find valuable insights to make informed decisions, ensuring optimal performance and cost-efficiency in their operations.

Table of Contents:

– Market Overview: Pellet Ice Maker Industry

– Detailed Market Analysis: Pellet Ice Makers

– Key Considerations When Selecting a Pellet Ice Maker

– Advanced Features and Technology in Pellet Ice Makers

– Price Range and Budget Considerations

– Compliance with Safety Standards and Certifications

– Installation and Initial Setup

– Conclusion

Market Overview: Pellet Ice Maker Industry

The global market for pellet ice makers has shown substantial growth and is expected to continue this trend. In 2024, the ice makers market, including pellet ice makers, was valued at around USD 2.91 billion. By 2030, it is projected to reach USD 3.95 billion, growing at a compound annual growth rate (CAGR) of 5.1%. This growth is driven by the rising demand for efficient and high-capacity ice makers across various sectors, such as hospitality, healthcare, and residential applications. The market is diversifying, with pellet ice makers gaining popularity due to their unique ice texture and cooling efficiency.

The Americas, especially the United States, remain the largest market for pellet ice makers, driven by high demand in the foodservice and healthcare sectors. The Asia-Pacific region is emerging as a significant market due to rapid urbanization and increasing disposable incomes. In Europe, the market is supported by the expanding hospitality industry and stringent food safety regulations that require reliable ice-making equipment. The Middle East and Africa, though smaller in market size, are growing steadily due to the increasing number of hotels and restaurants catering to tourism and business travel.

Detailed Market Analysis: Pellet Ice Makers

Pellet ice makers, known for producing chewable and soft ice, are becoming more popular in both commercial and residential settings. Key performance benchmarks for these machines include ice production capacity, energy efficiency, and ease of maintenance. Leading brands are focusing on innovations like smart technology integration, allowing remote monitoring and control to enhance operational efficiency. For example, IoT-enabled pellet ice makers provide real-time updates on ice production and machine status, which is particularly useful for large-scale operations in the foodservice industry.

Market share dynamics show that established players like Hoshizaki Corporation and Scotsman Industries, Inc. dominate the market, leveraging their extensive distribution networks and brand recognition. However, new entrants are gaining traction by offering advanced features and competitive pricing. Economic factors, such as fluctuating raw material prices and energy costs, affect production costs and pricing strategies. Consumer behavior is shifting towards eco-friendly and energy-efficient appliances, prompting manufacturers to invest in sustainable technology.

Distribution channel preferences are evolving, with a notable increase in online sales. The COVID-19 pandemic accelerated this trend as consumers and businesses turned to e-commerce for their purchasing needs. Recent innovations in the pellet ice maker market include touchless dispensing mechanisms and antimicrobial surfaces, addressing heightened concerns about hygiene and sanitation. The product lifecycle stages for pellet ice makers are extending thanks to advancements in durability and maintenance features. Digitalization and social trends, such as the rise of smart kitchens and the demand for premium beverage experiences, are further driving market growth.

Customer pain points mainly involve high initial investment costs and the complexity of maintenance. To address these issues, manufacturers are offering financing options and developing user-friendly maintenance solutions. Brand positioning strategies focus on quality assurance and after-sales service, with differentiation strategies emphasizing unique features like customizable ice shapes and sizes. Niche markets, including healthcare and specialty food and beverage sectors, offer significant growth opportunities for pellet ice makers.

Key Considerations When Selecting a Pellet Ice Maker

Choosing the right pellet ice maker is crucial for ensuring optimal performance, efficiency, and longevity in your establishment. Here are some key factors to consider:

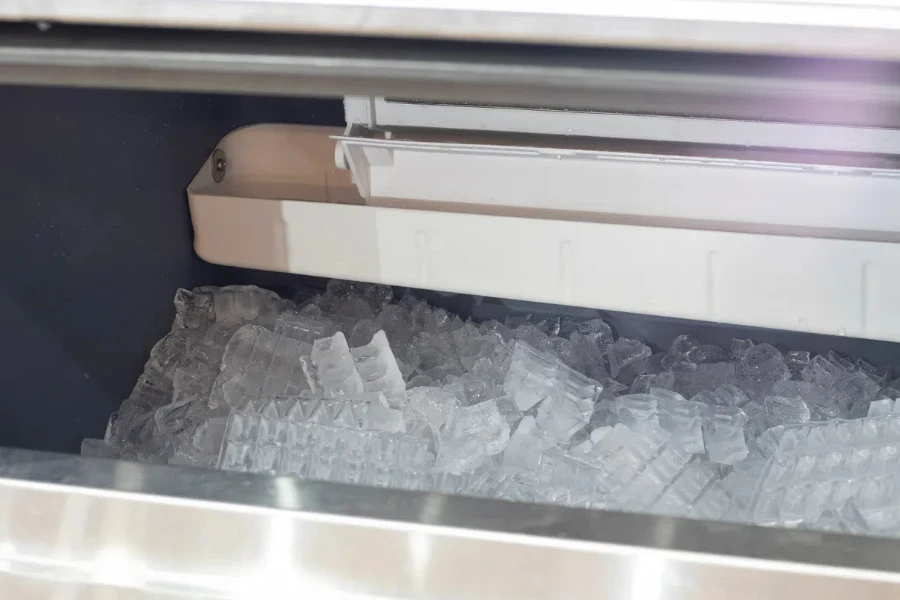

Performance and Ice Production Capacity

The performance of a pellet ice maker is a critical factor. Assess the ice production capacity, typically measured in pounds of ice produced per 24 hours. Commercial-grade machines can produce anywhere from 50 lbs to over 1000 lbs of ice per day. This capacity should align with your business needs, considering peak times and potential growth.

Machines like the Manitowoc IYT1500A Indigo NXT can produce up to 1660 lbs of half-size ice cubes per day, suitable for high-demand environments. Smaller units like the Follett 7CI100A-NW-NF-ST-00 can produce up to 125 lbs of ice per day, ideal for lower volume needs.

Energy Efficiency

Energy efficiency is another crucial consideration due to rising utility costs and the push for sustainable practices. Look for pellet ice makers that are Energy Star certified, as they consume less energy and water compared to non-certified models. For example, the Manitowoc IYT0500A Indigo NXT uses 12% less energy and 23% less condenser water compared to previous models.

Features such as programmable on/off timers and sleep modes can further enhance energy efficiency by allowing the machine to operate only when needed.

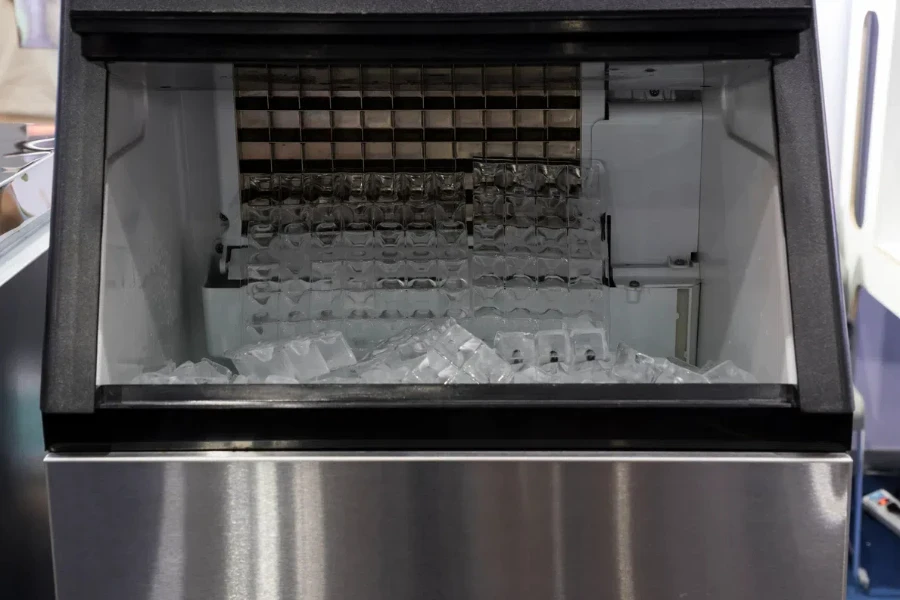

Build Quality and Materials

The build quality and materials used in the construction of the pellet ice maker significantly impact its durability and longevity. Stainless steel is a popular choice due to its corrosion resistance and ease of cleaning. Models like the Manitowoc IYT1500A feature a DuraTech stainless steel finish that provides superior corrosion resistance and resists fingerprints and dirt.

Components made with antimicrobial materials, such as AlphaSan, can enhance sanitation and reduce the risk of contamination, ensuring the ice produced is safe for consumption.

Ease of Maintenance and Cleaning

Regular maintenance and cleaning are essential for ensuring the longevity and optimal performance of your pellet ice maker. Machines with removable water troughs, distribution tubes, and curtains make cleaning more straightforward and efficient. The Manitowoc IYT0500A Indigo NXT includes these removable components, simplifying the cleaning process.

Some models come with built-in diagnostic systems that provide real-time maintenance updates and cleaning reminders. These systems help identify potential issues before they become significant problems, reducing downtime and repair costs.

Size and Installation Requirements

The size and installation requirements of the pellet ice maker are important factors to consider. Ensure that the chosen machine fits within the available space in your establishment and meets all necessary installation requirements, such as water supply, drainage, and electrical connections.

For instance, the Follett 7CI100A-NW-NF-ST-00 is designed to fit on countertops and under standard cabinets, making it a great option for establishments with limited space. Larger units, such as the Manitowoc IYT1500A, require more space and may need professional installation to ensure proper ventilation and operation.

Advanced Features and Technology in Pellet Ice Makers

Intelligent Diagnostics

Modern pellet ice makers often come equipped with advanced diagnostic systems that monitor the machine’s performance and provide real-time feedback. These systems can detect issues such as ice thickness, water levels, and temperature fluctuations, ensuring consistent ice production and reducing the likelihood of breakdowns. The Manitowoc IYT0500A Indigo NXT features state-of-the-art diagnostics that offer 24-hour preventative maintenance and feedback.

EasyTouch Display

An intuitive and user-friendly interface can significantly enhance the ease of use of a pellet ice maker. The easyTouch display, found in models like the Manitowoc IYT1500A, simplifies operation by providing clear, icon-based controls. This display allows users to monitor the machine’s status, set programmable on/off timers, and receive maintenance alerts, making it easier to manage the ice production process.

Acoustical Ice Sensing Probe

Ensuring uniform ice production is critical for maintaining the quality of the ice. The acoustical ice sensing probe, integrated into machines like the Manitowoc IYT1500A, detects the thickness of the ice to ensure uniformity. This feature helps in producing consistently sized ice pellets, ideal for various applications, from beverages to healthcare.

Antimicrobial Protection

Maintaining hygiene is paramount in any food service establishment. Some pellet ice makers are equipped with antimicrobial protection for key components, such as the water trough and distribution tube, to prevent the growth of bacteria and mold. The Follett 7CI100A-NW-NF-ST-00, for example, features Agion antimicrobial treatment, enhancing sanitation and safety during use.

Price Range and Budget Considerations

Initial Investment

The initial cost of a pellet ice maker can vary significantly based on its production capacity, features, and brand. High-capacity commercial units, such as the Manitowoc IYT1500A, can cost upwards of $7,500, while smaller, countertop models like the Follett 7CI100A-NW-NF-ST-00 may be priced around $5,200. Balance your budget with the machine’s capabilities and your business needs.

Operational Costs

Beyond the initial investment, consider the operational costs associated with running the pellet ice maker. Energy-efficient models can lead to significant savings on utility bills. Machines with built-in diagnostic systems and easy-to-clean components can reduce maintenance and repair costs over time. The Manitowoc IYT0500A saves on energy and water consumption and features a removable water trough and antimicrobial components that simplify maintenance.

Long-term Value

Investing in a high-quality pellet ice maker can provide long-term value through enhanced durability and reliability. Machines constructed with robust materials like stainless steel and equipped with advanced features such as intelligent diagnostics and antimicrobial protection tend to have longer lifespans and higher resale values. Ensuring that the chosen machine meets industry standards and certifications can also enhance its long-term value and performance.

Compliance with Safety Standards and Certifications

Industry Standards

When selecting a pellet ice maker, ensure that the machine complies with relevant industry standards and certifications. Look for certifications such as NSF (National Sanitation Foundation) and UL (Underwriters Laboratories), indicating that the machine meets stringent safety and sanitation requirements. Compliance with these standards ensures that the ice produced is safe for consumption and that the machine operates reliably.

Regulatory Compliance

Consider any local or regional regulatory requirements that may apply to your establishment. This may include health and safety regulations, water usage restrictions, and environmental guidelines. Ensuring that your pellet ice maker complies with these regulations can help you avoid potential fines and ensure smooth operation.

Manufacturer’s Warranty

A comprehensive manufacturer’s warranty can provide peace of mind and protect your investment. Look for pellet ice makers that come with a robust warranty covering parts and labor for an extended period. This can help mitigate the costs of unexpected repairs and ensure that your machine remains in optimal working condition.

Installation and Initial Setup

Professional Installation

Proper installation is critical for ensuring the optimal performance of your pellet ice maker. Have the machine installed by a professional to ensure that all connections, such as water supply, drainage, and electrical, are correctly set up. Professional installation can also help in verifying that the machine is level and has adequate ventilation, essential for efficient operation.

Initial Setup and Calibration

Once installed, the pellet ice maker may require initial setup and calibration to ensure it operates correctly. This may include setting the ice production schedule, adjusting the ice thickness, and configuring any programmable features. Refer to the manufacturer’s manual for detailed instructions on the initial setup, or consult with the installation technician for assistance.

Training and Operation

Proper training for staff on the operation and maintenance of the pellet ice maker is essential for ensuring its longevity and optimal performance. This includes understanding how to use the easyTouch display, perform routine cleaning, and troubleshoot common issues. Providing comprehensive training can help prevent user errors and ensure that the machine operates efficiently.

Conclusion

In summary, selecting the right pellet ice maker involves considering various factors, including performance, energy efficiency, build quality, ease of maintenance, size, and installation requirements. Advanced features such as intelligent diagnostics, easyTouch displays, and antimicrobial protection can enhance the machine’s functionality and reliability. Balancing the initial investment with long-term operational costs and ensuring compliance with safety standards and certifications can provide significant value for your business. Proper installation, initial setup, and staff training are also crucial for maximizing the performance and lifespan of your pellet ice maker.