O mercado global de lavadoras de peças está projetado para atingir US$ 1.92 bilhão até 2029, impulsionado por avanços na tecnologia e aumento da demanda em todos os setores. Este artigo fornece uma análise aprofundada dos fatores essenciais a serem considerados ao selecionar uma lavadora de peças, oferecendo insights valiosos para compradores profissionais que buscam otimizar seus processos de limpeza.

Sumário:

– Mercado global de máquinas de lavar peças: uma análise aprofundada

– Fatores-chave ao selecionar uma máquina de lavar peças

– A Importância da Manutenção Adequada

– O papel das máquinas de lavar peças em várias indústrias

– O Futuro das Máquinas de Lavar Peças

- Pensamentos finais

Mercado global de máquinas de lavar peças: uma análise aprofundada

Visão Geral do Mercado

O mercado global de máquinas de lavar peças valia cerca de US$ 1.40 bilhão em 2023 e está projetado para atingir US$ 1.92 bilhão até 2029, crescendo a uma taxa de crescimento anual composta (CAGR) de 5.51%. Esse crescimento é impulsionado pela crescente demanda por lavadoras de peças em vários setores, incluindo automotivo, aeroespacial e manufatura. A região da Ásia-Pacífico é a maior contribuinte de receita, respondendo por mais de 43% da participação de mercado em 2023, com contribuições significativas de países como China, Japão e Índia.

Em 2023, o segmento de lavadoras de peças à base de solvente detinha a maior fatia de mercado devido à sua alta eficiência na remoção de graxa, óleo e contaminantes teimosos. No entanto, a adoção de lavadoras de peças à base de água está aumentando devido aos seus benefícios ambientais e custo-benefício. Entre os tipos de lavadoras, as lavadoras de esteira dominaram o mercado, favorecidas por sua adequação em operações de limpeza de alto volume.

Introdução e análise detalhada do mercado

O mercado de lavadoras de peças é caracterizado por benchmarks de desempenho e dinâmicas de participação de mercado. Um dos principais impulsionadores é o uso crescente de lavadoras de peças na indústria automotiva, essencial para manter a limpeza e a funcionalidade dos componentes do motor, caixas de câmbio e outras peças críticas. Espera-se que o segmento automotivo contribua significativamente para o crescimento do mercado, impulsionado pela crescente produção de veículos globalmente.

A industrialização e a modernização dos processos de produção também estão impulsionando o mercado para frente. A crescente demanda por limpeza de precisão em indústrias como aeroespacial e eletrônica impulsiona a adoção de máquinas avançadas de lavagem de peças. Além disso, a mudança para práticas sustentáveis está influenciando o comportamento do consumidor, com um aumento notável na preferência por lavadoras de peças de base aquosa que usam menos água e energia em comparação com limpadores à base de solvente.

As preferências do canal de distribuição estão evoluindo, com uma mudança crescente em direção às plataformas de vendas online. Essa tendência é apoiada pela conveniência e acessibilidade do comércio eletrônico, permitindo que os consumidores comparem produtos facilmente e tomem decisões de compra informadas. Inovações recentes no mercado incluem lavadoras de peças automatizadas equipadas com recursos avançados como conectividade IoT e algoritmos de limpeza orientados por IA, aumentando a eficiência e reduzindo os custos operacionais.

Inovações e Tendências em Máquinas Lavadoras de Peças

O mercado de lavadoras de peças está testemunhando diversas inovações voltadas para melhorar o desempenho e a sustentabilidade. Uma tendência notável é a crescente adoção de lavadoras automáticas de peças à base de água. Essas máquinas são favorecidas por sua natureza ecologicamente correta, pois não requerem produtos químicos agressivos e reduzem significativamente a geração de águas residuais. Os fabricantes estão aprimorando essas lavadoras para atender às crescentes preocupações ambientais e aos padrões regulatórios.

Outra inovação significativa é a integração de tecnologias digitais em máquinas lavadoras de peças. O uso de tecnologias de IoT e IA está transformando o mercado, permitindo monitoramento em tempo real e manutenção preditiva. Esses avanços ajudam a otimizar o processo de limpeza, reduzir o tempo de inatividade e estender a vida útil das máquinas. Por exemplo, lavadoras de peças acionadas por IA podem ajustar automaticamente os parâmetros de limpeza com base no tipo e nível de contaminação, garantindo uma limpeza eficiente.

O mercado também está mudando para máquinas de lavar peças modulares e personalizáveis, impulsionado pela necessidade de flexibilidade em aplicações de limpeza industrial. Os designs modulares permitem que os usuários configurem as máquinas de acordo com seus requisitos específicos, aumentando a eficiência operacional e reduzindo custos. Além disso, o desenvolvimento de lavadoras de peças com eficiência energética está ganhando força, alinhando-se com o impulso global em direção à sustentabilidade e à conservação de energia.

Fatores-chave ao selecionar uma máquina de lavar peças

Escolher a máquina de lavar peças certa é crucial para a eficiência e eficácia dos seus processos de limpeza. Essa decisão envolve considerar fatores que influenciam o desempenho, o custo e a compatibilidade do sistema. Abaixo estão os principais fatores a serem considerados ao selecionar uma máquina de lavar peças.

Tipo de lavadora de peças

O tipo de lavadora de peças é fundamental. Diferentes tipos atendem a várias necessidades de limpeza e indústrias. Os sistemas de limpeza de tanque de imersão mergulham as peças em uma solução de limpeza agitada, ideal para remover contaminações pesadas como graxa, óleo e tinta. Eles são úteis nas indústrias automotiva e aeroespacial, onde a limpeza completa é essencial. As lavadoras de pulverização usam bicos de alta pressão, eficazes para limpar peças com geometrias complexas, comumente usadas em indústrias de manufatura que exigem limpeza de precisão. Os limpadores ultrassônicos usam ondas ultrassônicas para agitar a solução de limpeza, removendo contaminantes de peças complexas, adequados para a fabricação de eletrônicos e dispositivos médicos. Os sistemas de queima usam altas temperaturas para remover contaminantes orgânicos como graxa e óleo, frequentemente usados em aplicações industriais pesadas. Os desengordurantes usam solventes ou soluções à base de água para remover graxa e óleo, versáteis em várias indústrias.

Desempenho e Funcionalidade

Desempenho e funcionalidade são essenciais para determinar a adequação de uma lavadora de peças. A eficiência de limpeza mede a capacidade da máquina de remover contaminantes dentro de um tempo especificado, reduzindo o tempo de inatividade e aumentando a produtividade. O tempo de ciclo, ou a duração de um processo de limpeza completo, afeta o rendimento; máquinas com tempos de ciclo mais curtos são preferíveis para linhas de produção de alto volume. A capacidade de carga determina o peso e o tamanho máximos das peças que podem ser limpas. Certifique-se de que a máquina possa lidar com suas peças maiores e mais pesadas. Parâmetros ajustáveis, como temperatura, pressão e duração da limpeza, oferecem maior flexibilidade e controle sobre o processo de limpeza.

Materiais e qualidade de construção

Os materiais e a qualidade de construção de uma máquina de lavar peças determinam sua durabilidade e longevidade. O material de construção normalmente inclui aço inoxidável, aço carbono ou plástico. O aço inoxidável é preferido por sua resistência à corrosão e durabilidade. A qualidade de construção envolve componentes robustos, reduzindo o risco de quebras e estendendo a vida útil da máquina. Procure máquinas com juntas reforçadas e vedações de alta qualidade. A resistência à corrosão é essencial para máquinas expostas a produtos químicos agressivos e agentes de limpeza para manter o desempenho e evitar a degradação.

Normas de segurança e certificações

A conformidade com os padrões e certificações de segurança é essencial para uma operação segura e adesão regulatória. Recursos de segurança como botões de parada de emergência, intertravamentos de segurança e mecanismos de desligamento automático aumentam a segurança do operador. Certificações como CE, UL e ISO indicam que a máquina atende a rigorosos requisitos de segurança e qualidade. A conformidade regulatória garante que a máquina atenda aos regulamentos locais e internacionais relacionados à segurança ambiental e operacional.

Últimos recursos de tecnologia

Incorporar os recursos de tecnologia mais recentes pode melhorar o desempenho e a facilidade de uso de uma máquina de lavar peças. O controle CNC permite ajustes precisos dos parâmetros de limpeza, melhorando a consistência e a eficiência. Os sistemas automatizados reduzem o manuseio manual e aumentam a produtividade. Os recursos de monitoramento remoto permitem que os operadores acompanhem o desempenho e diagnostiquem problemas em tempo real. Os recursos de eficiência energética reduzem os custos operacionais e o impacto ambiental, com modos de economia de energia e sistemas de aquecimento eficientes.

A importância da manutenção adequada

A manutenção de uma máquina de lavar peças é crucial para garantir sua longevidade e desempenho consistente. A manutenção regular pode evitar quebras inesperadas e reparos caros. Isso inclui limpar o tanque de lavagem, inspecionar e substituir componentes desgastados e garantir que todos os recursos de segurança estejam funcionais. Siga as diretrizes do fabricante para cronogramas e procedimentos de manutenção.

O papel das máquinas de lavar peças em várias indústrias

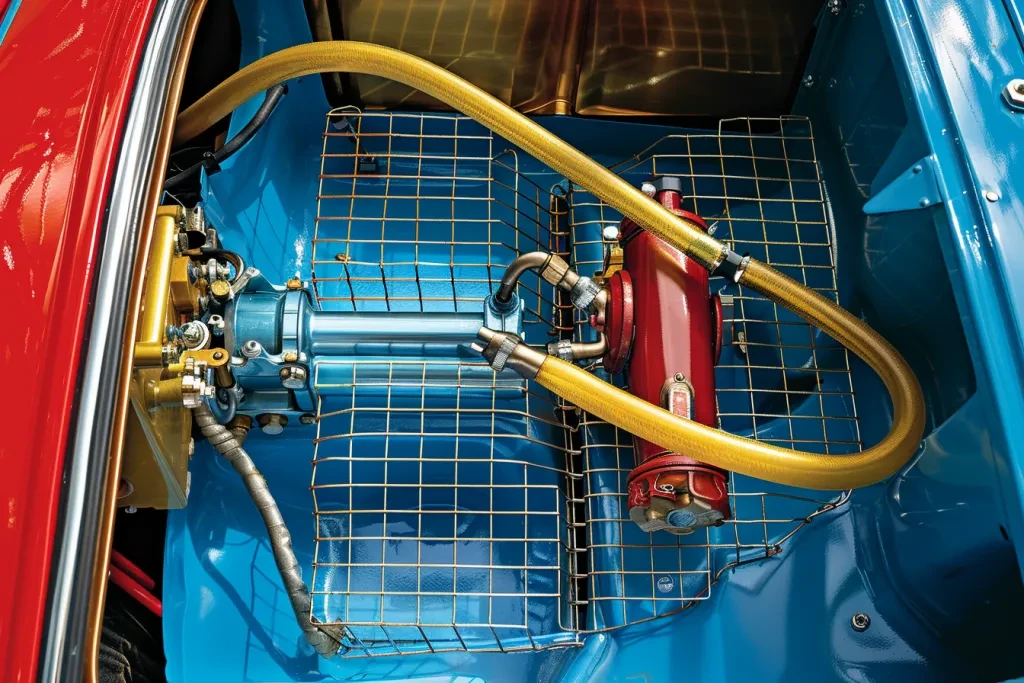

As lavadoras de peças desempenham um papel crítico em várias indústrias, garantindo que os componentes estejam livres de contaminantes que podem afetar seu desempenho ou levar a falhas prematuras. Na indústria automotiva, as lavadoras de peças limpam componentes do motor, transmissões e outras peças mecânicas. Na indústria aeroespacial, elas garantem que as peças de precisão estejam livres de detritos e contaminantes. Na eletrônica, as lavadoras de peças limpam placas de circuito e outros componentes sensíveis.

O futuro das máquinas de lavar peças

O futuro das lavadoras de peças está na integração de tecnologias avançadas e práticas sustentáveis. Inovações como máquinas habilitadas para IoT, permitindo monitoramento em tempo real e manutenção preditiva, estão prontas para revolucionar a indústria. A sustentabilidade também é um foco crescente, com fabricantes desenvolvendo máquinas que usam menos água e energia e são compatíveis com soluções de limpeza ecologicamente corretas.

Considerações Finais

Selecionar a máquina de lavar peças certa envolve avaliar vários fatores, incluindo o tipo de máquina, desempenho, qualidade de construção, padrões de segurança e os recursos de tecnologia mais recentes. A manutenção adequada e a compreensão do papel dessas máquinas em diferentes indústrias também são essenciais. Ao considerar esses fatores, as empresas podem garantir que escolherão uma máquina que atenda às suas necessidades e aprimore seus processos de limpeza.