O mercado global de máquinas de boxe está se expandindo rapidamente, com automação e eficiência liderando a carga. Inovações recentes em tecnologias inteligentes e embalagens sustentáveis estão transformando esta indústria. Este artigo fornece uma análise aprofundada do mercado de máquinas de boxe, oferecendo insights valiosos e orientação para compradores profissionais na seleção das melhores máquinas para suas necessidades. Descubra como aumentar a produtividade e permanecer à frente no cenário competitivo.

Sumário:

– Visão geral do mercado: Indústria de máquinas de boxe

– Introdução e análise detalhada do mercado de máquinas de boxe

– Fatores-chave ao selecionar uma máquina de boxe

– Integração com sistemas existentes

– Manutenção e Suporte

– Tendências e inovações em máquinas de boxe

- Pensamentos finais

Visão geral do mercado: Indústria de máquinas de boxe

O mercado global de máquinas de boxe está experimentando um crescimento constante devido ao aumento da automação em embalagens e ao foco em eficiência e precisão na produção. Em 2024, o tamanho do mercado valia US$ 1.2 bilhão, com projeções de atingir US$ 1.6 bilhão até 2030, crescendo a uma taxa de crescimento anual composta (CAGR) de 5.1%. Esse crescimento é impulsionado pela demanda por soluções de embalagem automatizadas em vários setores, incluindo alimentos e bebidas, produtos farmacêuticos e bens de consumo.

A Ásia-Pacífico é o maior mercado para máquinas de boxe, detendo cerca de 35% da participação de mercado global em 2024. Isso se deve à rápida industrialização e aos principais centros de fabricação em países como China, Índia e Japão. A América do Norte e a Europa também têm participações de mercado significativas, apoiadas por avanços na tecnologia de embalagem e na adoção de práticas de fabricação inteligentes.

Os principais participantes do mercado de máquinas de boxe incluem Bosch Packaging Technology, IMA Group e ProMach. Essas empresas se concentram em inovação e expansão de seus portfólios de produtos para atender às necessidades em evolução dos usuários finais. O mercado é altamente competitivo, com fabricantes investindo em pesquisa e desenvolvimento para melhorar a eficiência e versatilidade de suas máquinas.

Introdução e análise detalhadas do mercado de máquinas de boxe

As máquinas de encaixotamento, ou máquinas de encaixotamento, são cruciais para o processo de embalagem, automatizando a embalagem de produtos em caixas ou caixas de papelão. Essas máquinas são categorizadas como automáticas, semiautomáticas e manuais. As máquinas de encaixotamento automáticas dominam o mercado com mais de 60% de participação em 2024 devido à sua alta eficiência e capacidade de lidar com grandes volumes.

Os benchmarks de desempenho para máquinas de boxe incluem velocidade, precisão e adaptabilidade. Máquinas de alta velocidade, capazes de embalar até 300 caixas por minuto, são procuradas, especialmente na indústria de alimentos e bebidas. A precisão garante a integridade do produto e minimiza o desperdício, enquanto a adaptabilidade permite que as máquinas manipulem vários tamanhos de caixa e tipos de produto, aumentando sua utilidade em diferentes setores.

Fatores econômicos como aumento dos custos de mão de obra e a necessidade de eficiência operacional estão impulsionando a adoção de máquinas de boxe. As empresas visam reduzir a dependência de mão de obra e aumentar a produtividade por meio da automação. O comportamento do consumidor também está mudando para produtos embalados devido à conveniência e higiene, impulsionando ainda mais o mercado de máquinas de boxe.

Inovações recentes incluem a integração de digitalização e tecnologias inteligentes. Máquinas de boxe inteligentes com recursos de IoT oferecem monitoramento em tempo real e manutenção preditiva, reduzindo o tempo de inatividade e melhorando a eficiência operacional. O uso de materiais ecológicos na construção e embalagem de máquinas também está ganhando popularidade, atraindo consumidores ambientalmente conscientes e se alinhando com as metas globais de sustentabilidade.

Os canais de distribuição para máquinas de boxe incluem vendas diretas, distribuidores e plataformas online. As vendas diretas são as mais comuns, respondendo por cerca de 50% do mercado em 2024, pois permitem que os fabricantes ofereçam soluções personalizadas e suporte pós-venda abrangente. No entanto, espera-se que a crescente popularidade do comércio eletrônico influencie a dinâmica de distribuição, tornando mais fácil para pequenas e médias empresas acessar soluções avançadas de embalagem.

Em resumo, o mercado de máquinas de boxe está definido para crescimento contínuo, impulsionado por avanços tecnológicos, fatores econômicos e mudanças nas preferências do consumidor. Os fabricantes se concentram em inovação e sustentabilidade para permanecerem competitivos, enquanto a adoção de tecnologias inteligentes está pronta para transformar a indústria de embalagens. À medida que as empresas se esforçam para obter eficiência e precisão, a demanda por máquinas de boxe avançadas deve aumentar, moldando o futuro da embalagem automatizada.

Fatores-chave ao selecionar uma máquina de boxe

Tipos e Estilos

Ao selecionar uma máquina de boxe, considere o tipo e o estilo. As opções incluem modelos manuais, semiautomáticos e totalmente automáticos. Máquinas manuais exigem intervenção significativa do operador, tornando-as adequadas para operações de baixo volume onde a precisão é fundamental. Máquinas semiautomáticas oferecem um equilíbrio entre operações manuais e automáticas, proporcionando maior eficiência e facilidade de uso. Máquinas totalmente automáticas são projetadas para linhas de produção de alto volume, exigindo intervenção humana mínima e oferecendo as maiores taxas de rendimento.

Os estilos de máquinas de encaixotamento variam com base nos requisitos de embalagem. As máquinas de encaixotamento verticais são ideais para produtos que precisam ser embalados na vertical, como garrafas e potes. As máquinas de encaixotamento horizontais são adequadas para itens planos ou de formato irregular, como bandejas e embalagens blister. A escolha do tipo e estilo corretos garante a compatibilidade com o produto e maximiza a eficiência operacional.

Desempenho e Funcionalidade

Métricas de desempenho como velocidade, precisão e confiabilidade são cruciais ao selecionar uma máquina de boxe. A velocidade, medida em caixas por minuto (BPM), varia de alguns BPM para máquinas manuais a várias centenas de BPM para modelos totalmente automáticos. A precisão no ajuste do tamanho da caixa e no posicionamento do produto minimiza o desperdício e garante a integridade do produto.

Recursos de funcionalidade como configurações ajustáveis, controladores lógicos programáveis (PLC) e integração com linhas de produção existentes são importantes. Máquinas de encaixotamento modernas geralmente vêm com interfaces de tela sensível ao toque para fácil operação e monitoramento em tempo real. A troca rápida entre diferentes tamanhos e tipos de caixa sem tempo de inatividade significativo é um recurso desejável, especialmente em operações que lidam com vários produtos.

Especificações técnicas

Entender as especificações técnicas de uma máquina de boxe é essencial. As principais especificações incluem dimensões máximas da caixa, capacidade de peso e requisitos de potência. As dimensões máximas da caixa determinam a faixa de tamanhos de caixa que a máquina pode manipular, crucial para operações que lidam com tamanhos variados de produtos.

A capacidade de peso é vital, especialmente para indústrias que manuseiam produtos pesados. Exceder a capacidade de peso pode levar a quebras de máquinas e aumento nos custos de manutenção. Os requisitos de energia, incluindo voltagem e consumo de energia, devem corresponder à infraestrutura elétrica da instalação para garantir uma operação perfeita.

Qualidade de construção e materiais

A qualidade de construção e os materiais usados na construção de uma máquina de boxe impactam significativamente sua durabilidade e longevidade. Máquinas feitas de aço inoxidável de alta qualidade oferecem resistência superior à corrosão e ao desgaste, tornando-as ideais para indústrias como a alimentícia e farmacêutica, onde a higiene é primordial. Componentes de alumínio também são populares devido às suas propriedades leves e de resistência.

A qualidade de componentes como motores, correias e sensores desempenha um papel crucial no desempenho geral da máquina. Investir em uma máquina com componentes de alta qualidade pode reduzir os custos de manutenção e o tempo de inatividade, levando a maior produtividade e economia de custos ao longo da vida útil da máquina.

Normas de segurança e certificações

A conformidade com os padrões e certificações de segurança não é negociável ao selecionar uma máquina de boxe. As máquinas devem aderir aos padrões internacionais de segurança, como as certificações CE (Conformité Européene) e UL (Underwriters Laboratories). Essas certificações garantem que a máquina atenda aos rigorosos requisitos de segurança, reduzindo o risco de acidentes no local de trabalho e garantindo um ambiente de trabalho seguro.

Recursos de segurança adicionais, como botões de parada de emergência, proteções de segurança e sistemas de desligamento automatizados, aumentam a segurança do operador. Máquinas projetadas com considerações ergonômicas também podem reduzir o risco de lesões por esforço repetitivo, contribuindo para um ambiente de trabalho mais seguro e confortável.

Integração com sistemas existentes

Compatibilidade com outros dispositivos e sistemas

Ao integrar uma nova máquina de boxe em uma linha de produção existente, a compatibilidade com outros dispositivos e sistemas é crucial. A máquina deve se integrar perfeitamente com equipamentos upstream e downstream, como transportadores, máquinas de envase e sistemas de etiquetagem. Isso garante um fluxo de produção suave e contínuo, minimizando gargalos e tempo de inatividade.

As máquinas de boxe modernas geralmente vêm com protocolos de comunicação avançados, como Ethernet/IP, Modbus e OPC UA, facilitando a integração com sistemas de controle existentes e software de planejamento de recursos empresariais (ERP). Isso permite troca de dados em tempo real e monitoramento centralizado, aprimorando a eficiência geral da produção e a tomada de decisões.

Potencial de atualização

Preparar seu investimento para o futuro selecionando uma máquina de boxe com potencial de atualização é uma estratégia inteligente. Máquinas com designs modulares permitem atualizações e expansões fáceis, como adicionar novas funcionalidades ou aumentar a capacidade. Essa flexibilidade pode acomodar futuras necessidades de produção e avanços tecnológicos sem precisar de uma substituição completa da máquina.

Atualizações de software também são importantes. Máquinas com firmware e software atualizáveis podem se beneficiar dos últimos recursos e melhorias, estendendo a vida útil da máquina e mantendo sua competitividade no mercado.

Eficiência energética

A eficiência energética é cada vez mais importante devido aos crescentes custos de energia e preocupações ambientais. Selecionar uma máquina de boxe com eficiência energética pode levar a economias de custo significativas e reduzir a pegada ambiental de suas operações. Procure máquinas com recursos de economia de energia, como acionamentos de frequência variável (VFDs), que otimizam a velocidade do motor e reduzem o consumo de energia.

Máquinas com componentes de eficiência energética, como iluminação LED e sensores de baixa potência, também contribuem para a economia geral de energia. Além disso, algumas máquinas oferecem recursos de monitoramento de energia, permitindo que você rastreie e otimize o uso de energia em tempo real.

Manutenção e Suporte

Complexidade da configuração inicial

A complexidade da configuração inicial é uma consideração importante ao selecionar uma máquina de boxe. Máquinas com interfaces amigáveis e instruções de configuração claras podem reduzir o tempo de instalação e minimizar a necessidade de suporte técnico especializado. Alguns fabricantes oferecem serviços de instalação e treinamento para garantir um processo de configuração suave e eficiente.

Máquinas com capacidades plug-and-play são particularmente vantajosas, pois podem ser rapidamente integradas em linhas de produção existentes com interrupção mínima. Além disso, máquinas com recursos de autodiagnóstico podem simplificar a solução de problemas e a manutenção, reduzindo o tempo de inatividade e garantindo operação contínua.

Requisitos de manutenção regular

Entender os requisitos de manutenção regular de uma máquina de boxe é essencial para manter o desempenho ideal e minimizar o tempo de inatividade. Máquinas com designs de baixa manutenção, como componentes autolubrificantes e rolamentos selados, podem reduzir a frequência e a complexidade das tarefas de manutenção.

Algumas máquinas vêm com recursos de manutenção preditiva, que usam sensores e análise de dados para monitorar a condição da máquina e prever problemas potenciais antes que eles levem a quebras. Essa abordagem proativa à manutenção pode estender a vida útil da máquina e reduzir os custos gerais de manutenção.

Suporte e garantia do fabricante

O nível de suporte fornecido pelo fabricante é um fator crítico ao selecionar uma máquina de boxe. Procure fabricantes com uma forte reputação de atendimento ao cliente e suporte técnico. O acesso a uma equipe de suporte experiente, recursos online e tempos de resposta rápidos podem fazer uma diferença significativa na resolução de problemas e na manutenção da produtividade.

Além disso, considere a garantia oferecida pelo fabricante. Uma garantia abrangente que cobre peças e mão de obra por um período estendido pode fornecer tranquilidade e proteger seu investimento. Alguns fabricantes também oferecem opções de garantia estendida e contratos de serviço, aumentando ainda mais a confiabilidade e a longevidade da máquina.

Tendências e inovações em máquinas de boxe

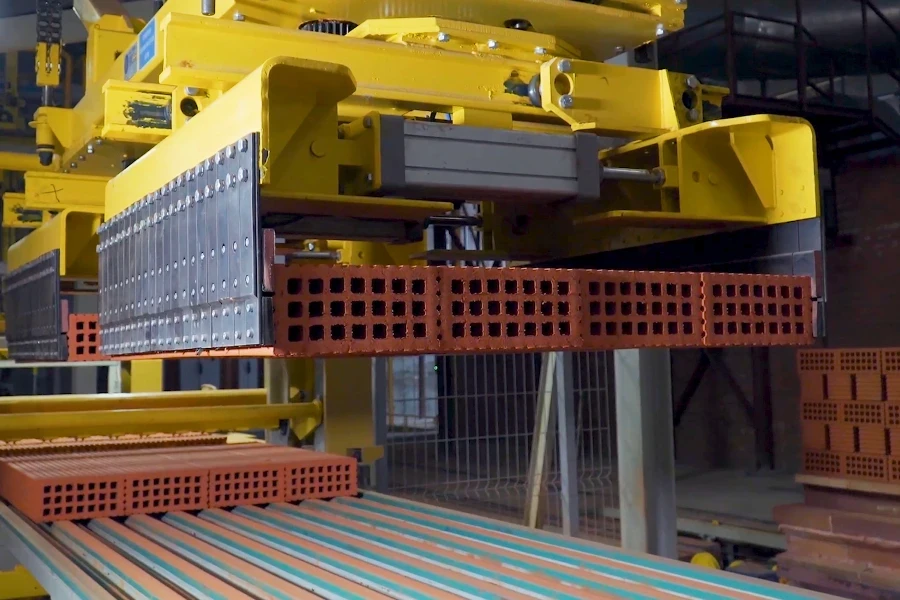

Automação e Robótica

A tendência para automação e robótica na indústria de máquinas está transformando máquinas de boxe. Sistemas robóticos avançados podem lidar com tarefas complexas de embalagem com alta precisão e velocidade, reduzindo a necessidade de trabalho manual e aumentando a eficiência da produção. Robôs colaborativos, ou cobots, também estão ganhando popularidade, pois podem trabalhar junto com operadores humanos, aumentando a flexibilidade e a produtividade.

Integração de Tecnologia Inteligente

A integração da tecnologia inteligente e da Internet das Coisas (IoT) está revolucionando as máquinas de boxe. Máquinas habilitadas para IoT podem coletar e analisar dados em tempo real, fornecendo insights valiosos sobre o desempenho da máquina, eficiência de produção e necessidades de manutenção. Essa abordagem orientada por dados permite manutenção preditiva, otimização de processos e tomada de decisão informada.

Soluções de embalagem sustentável

A sustentabilidade é uma preocupação crescente na indústria de embalagens, e as máquinas de encaixotamento estão evoluindo para atender a essas demandas. Máquinas projetadas para soluções de embalagens sustentáveis, como materiais recicláveis e biodegradáveis, estão se tornando mais prevalentes. Além disso, designs com eficiência energética e desperdício reduzido de material contribuem para processos de embalagem mais ecológicos.

Considerações Finais

Em resumo, selecionar a máquina de boxe certa envolve consideração cuidadosa de vários fatores, incluindo tipos e estilos, desempenho e funcionalidade, especificações técnicas, qualidade de construção, padrões de segurança, integração com sistemas existentes, manutenção e suporte, e tendências emergentes. Ao avaliar completamente esses fatores e se manter informado sobre as últimas inovações, você pode tomar uma decisão informada que atenda às suas necessidades de produção e posicione seu negócio para o sucesso futuro.

বাংলা

বাংলা Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português Русский

Русский Español

Español Kiswahili

Kiswahili ไทย

ไทย Türkçe

Türkçe اردو

اردو Tiếng Việt

Tiếng Việt isiXhosa

isiXhosa Zulu

Zulu