Avanços recentes na tecnologia de embalagem tornaram os seladores térmicos de impulso indispensáveis para várias indústrias. Este artigo fornece uma análise aprofundada do mercado de seladores térmicos de impulso, destacando critérios de seleção cruciais e os benefícios de recursos avançados. Ele auxilia compradores profissionais a tomar decisões informadas para melhorar a eficiência operacional e a qualidade do produto.

Sumário:

- Visão geral do mercado da indústria de seladores térmicos por impulso

-Introdução e análise detalhadas do mercado de seladores térmicos por impulso

- Fatores-chave ao selecionar um selador térmico por impulso

-Últimos recursos de tecnologia em seladoras térmicas por impulso

-Faixa de preço e considerações orçamentárias

-Manutenção e Longevidade

-Análise do impacto dos seladores térmicos de impulso na eficiência da embalagem

-Melhorando a qualidade da embalagem com seladoras térmicas de impulso

- Seladoras Térmicas de Impulso e Sustentabilidade

-Considerações finais

Visão geral do mercado da indústria de seladores térmicos por impulso

O mercado global de seladores térmicos de impulso tem experimentado um crescimento constante, impulsionado pelo aumento da demanda em vários setores, como embalagens de alimentos, produtos farmacêuticos e bens de consumo. Em 2024, o mercado foi avaliado em aproximadamente US$ 1.5 bilhão e está projetado para atingir US$ 2.3 bilhões até 2030, crescendo a uma taxa de crescimento anual composta (CAGR) de 6.5%. A região da Ásia-Pacífico detém a maior fatia de mercado, respondendo por quase 40% do mercado global, seguida pela América do Norte e Europa.

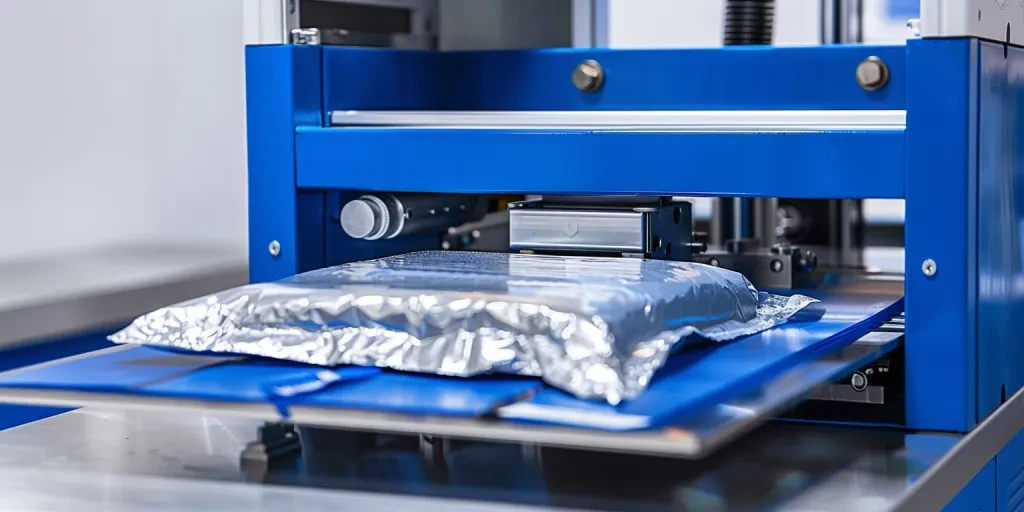

O mercado é segmentado com base no tipo de selagem, com a selagem a quente dominando devido à sua ampla aplicação em embalagens de alimentos e dispositivos médicos. A indústria de alimentos e bebidas é o maior usuário final, contribuindo com mais de 50% da receita do mercado. Os seladores a quente por impulso são preferidos por sua eficiência, custo-benefício e capacidade de criar selos herméticos, cruciais para preservar a qualidade e a segurança dos produtos embalados.

Os avanços tecnológicos nos processos de fabricação e materiais melhoraram significativamente o desempenho e a durabilidade dos seladores térmicos de impulso. A integração de controles digitais e automação melhorou ainda mais a eficiência operacional, reduzindo o tempo de inatividade e aumentando o rendimento da produção. O mercado também está testemunhando uma mudança em direção a soluções de embalagem sustentáveis e ecologicamente corretas, impulsionando a demanda por seladores térmicos de impulso compatíveis com materiais biodegradáveis e recicláveis.

Introdução e análise detalhadas do mercado de seladores térmicos por impulso

Os seladores térmicos de impulso são essenciais em vários setores devido à sua capacidade de criar selos fortes e herméticos de forma eficiente. Os principais benchmarks de desempenho para essas máquinas incluem velocidade de selagem, precisão do controle de temperatura e eficiência energética. Os modelos avançados agora oferecem configurações programáveis para controle preciso sobre os parâmetros de selagem, essenciais para manter a integridade do produto.

Os principais players, como Sealed Air Corporation e US Packaging & Wrapping LLC, dominam o mercado com extensos portfólios de produtos e redes de distribuição globais. Influências econômicas, como aumento dos custos de matéria-prima e preços flutuantes de energia, impactam o mercado, pressionando os fabricantes a inovar e adotar tecnologias de eficiência energética.

O comportamento do consumidor está mudando para conveniência e sustentabilidade, com uma preferência crescente por alimentos embalados e produtos ecológicos. Essa tendência impulsiona a demanda por seladoras térmicas de impulso que podem lidar com vários materiais de embalagem, incluindo filmes biodegradáveis. Os canais de distribuição estão evoluindo, com o comércio eletrônico ganhando destaque, permitindo que os fabricantes alcancem uma base de clientes mais ampla.

Inovações recentes no mercado incluem o desenvolvimento de seladores térmicos de impulso com sistemas de controle de qualidade integrados, garantindo desempenho de selagem consistente e reduzindo o risco de defeitos. Os estágios do ciclo de vida do produto dos seladores térmicos de impulso geralmente envolvem design e desenvolvimento, fabricação, distribuição e suporte pós-venda, com foco na extensão da vida útil operacional por meio de manutenção e atualizações regulares.

A digitalização está transformando a indústria, com recursos inteligentes como monitoramento habilitado para IoT e manutenção preditiva se tornando padrão. Tendências sociais, como a crescente conscientização sobre segurança alimentar e higiene, estão impulsionando ainda mais o crescimento do mercado. Os pontos problemáticos do cliente geralmente giram em torno do tempo de inatividade da máquina e dos custos de manutenção, que os fabricantes abordam por meio de design robusto e serviços de pós-venda responsivos.

As estratégias de posicionamento de marca enfatizam confiabilidade, eficiência e sustentabilidade, com diferenciação alcançada por meio de recursos avançados e opções de personalização. Mercados de nicho, como produtores de alimentos em pequena escala e aplicações de embalagens especiais, oferecem oportunidades de crescimento significativas para fabricantes que podem fornecer soluções personalizadas.

Fatores-chave ao selecionar um selador térmico de impulso

Tipos e Estilos

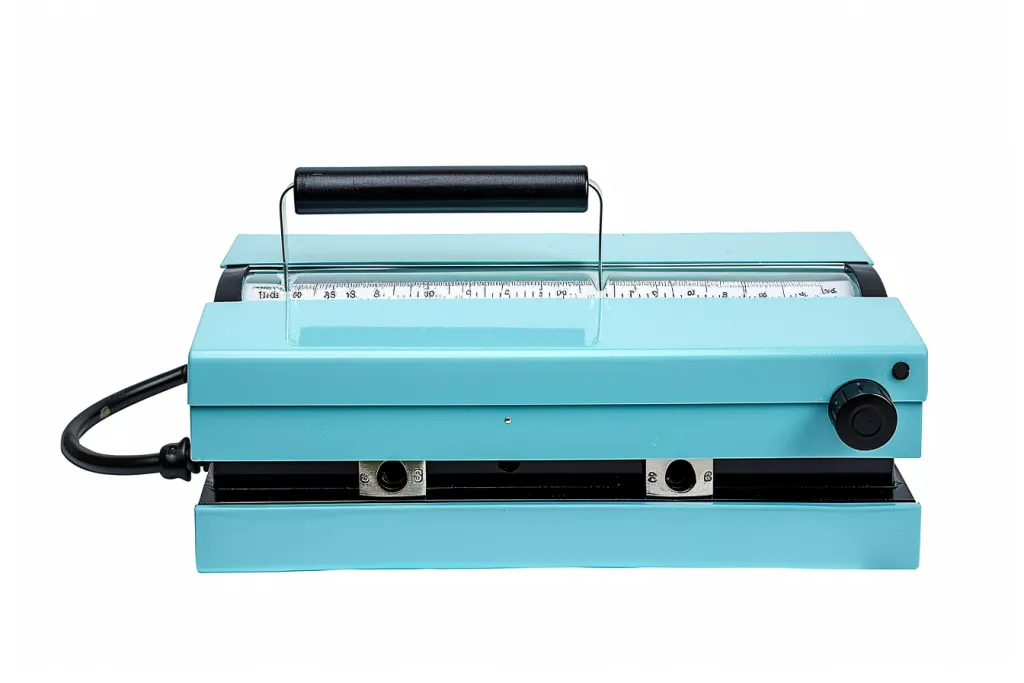

Os seladores térmicos de impulso vêm em vários tipos e estilos, cada um adequado para aplicações específicas. Os tipos mais comuns incluem seladores manuais, seladores de mesa e seladores operados por pedal. Os seladores manuais são portáteis e ideais para operações de pequena escala ou selagem de itens de formato irregular. Eles são normalmente usados em indústrias como varejo e produção de alimentos em pequena escala. Os seladores de mesa oferecem mais estabilidade e são adequados para operações de média escala, frequentemente encontrados em departamentos de embalagem de empresas de médio porte. Os seladores operados por pedal fornecem operação sem as mãos e são projetados para tarefas de selagem de alto volume, tornando-os ideais para grandes unidades de fabricação.

A escolha entre esses tipos depende do volume de selagem necessário e da natureza dos produtos que estão sendo selados. Por exemplo, uma pequena padaria pode achar um selador portátil suficiente, enquanto uma grande fábrica de processamento de alimentos se beneficiaria de um modelo operado por pedal para manter a eficiência e a produtividade. Alguns modelos vêm com barras de selagem duplas, permitindo a selagem simultânea de dois sacos, aumentando ainda mais a eficiência operacional.

Desempenho e Funcionalidade

O desempenho de um selador térmico de impulso é crucial para garantir a integridade de embalagens seladas. Os principais indicadores de desempenho incluem o tempo de selagem, o comprimento máximo de selagem e a espessura dos materiais que podem ser selados. O tempo de selagem pode variar de uma fração de segundo a vários segundos, dependendo do material e da potência do selador. Seladores de alto desempenho podem selar materiais mais espessos rapidamente, essencial para manter a velocidade de produção em um ambiente de alto volume.

Recursos de funcionalidade, como controles de temperatura ajustáveis e temporizadores, aumentam a versatilidade do selador. Esses recursos permitem que os operadores ajustem o processo de selagem com base nos requisitos específicos de diferentes materiais de embalagem. Por exemplo, sacos de polietileno podem exigir uma configuração de temperatura diferente em comparação com sacos de polipropileno. Modelos avançados também podem incluir displays digitais para controle e monitoramento precisos dos parâmetros de selagem.

Especificações técnicas

As especificações técnicas fornecem insights detalhados sobre as capacidades de um selador térmico de impulso. Especificações importantes a serem consideradas incluem a classificação de potência, a largura da selagem e o tipo de elemento de aquecimento usado. As classificações de potência geralmente variam de 300 watts a mais de 1000 watts, influenciando a capacidade do selador de lidar com vários materiais e velocidades de selagem. Uma classificação de potência mais alta geralmente se traduz em um desempenho de selagem mais robusto, especialmente para materiais mais espessos ou multicamadas.

A largura da vedação é outra especificação crítica, com opções comuns variando de 2 mm a 10 mm. Vedações mais largas fornecem maior resistência e durabilidade, cruciais para aplicações pesadas. O tipo de elemento de aquecimento, como fio de nicromo, também afeta o desempenho e a longevidade do selador. Fios de nicromo são conhecidos por sua durabilidade e propriedades de aquecimento eficientes, tornando-os uma escolha preferida para seladores de nível industrial.

Qualidade de construção e materiais

A qualidade de construção e os materiais usados na construção de um selador térmico de impulso impactam significativamente sua durabilidade e confiabilidade. Seladores de alta qualidade são normalmente feitos de materiais robustos, como aço inoxidável ou alumínio reforçado. Esses materiais oferecem resistência à corrosão e ao desgaste, garantindo que o selador possa suportar os rigores do uso diário em ambientes exigentes.

O design do mecanismo de vedação também desempenha um papel na qualidade geral da construção. Por exemplo, um selador com uma dobradiça reforçada e base resistente fornece melhor estabilidade e longevidade. Além disso, a qualidade do elemento de aquecimento e o isolamento ao redor dele afetam a segurança e a eficiência do selador. O isolamento adequado evita a perda de calor e garante um desempenho de vedação consistente.

Normas de segurança e certificações

A adesão aos padrões e certificações de segurança é essencial para garantir a operação segura de seladores térmicos de impulso. Procure seladores que estejam em conformidade com os padrões internacionais de segurança, como as certificações CE, UL e ISO. Essas certificações indicam que o selador passou por testes rigorosos e atende aos critérios de segurança e desempenho exigidos.

Recursos de segurança como desligamento automático, proteção contra superaquecimento e alças isoladas aumentam a segurança do operador. O desligamento automático evita o superaquecimento desligando o elemento de aquecimento assim que o ciclo de selagem estiver concluído. A proteção contra superaquecimento garante que o selador não exceda as temperaturas operacionais seguras, reduzindo o risco de incêndio ou danos à unidade. As alças isoladas fornecem uma pegada confortável e protegem o operador de queimaduras acidentais.

Últimos recursos de tecnologia em seladoras térmicas por impulso

Controles Digitais e Automação

Os seladores de calor por impulso modernos estão cada vez mais incorporando controles digitais e recursos de automação. Os painéis de controle digitais permitem o ajuste preciso dos parâmetros de selagem, como temperatura e tempo de selagem. Essa precisão é particularmente benéfica para aplicações que exigem qualidade de selagem consistente em grandes lotes. Recursos de automação, como configurações programáveis e ciclos de selagem automáticos, aumentam a eficiência ao reduzir a intervenção manual.

Por exemplo, modelos avançados podem incluir telas sensíveis ao toque com programas predefinidos para diferentes materiais, permitindo que os operadores alternem rapidamente entre as configurações com tempo de inatividade mínimo. A automação também se estende a recursos como detecção automática de saco, que inicia o processo de selagem assim que um saco é colocado no selador, simplificando ainda mais o fluxo de trabalho de embalagem.

Eficiência energética

A eficiência energética é uma consideração essencial para empresas que buscam reduzir custos operacionais e impacto ambiental. Os seladores térmicos de impulso são inerentemente eficientes em termos de energia em comparação aos seladores térmicos contínuos, pois eles só usam energia durante o ciclo de selagem. No entanto, modelos mais novos estão incorporando recursos adicionais de economia de energia, como modos de espera e elementos de aquecimento com eficiência energética.

Os modos de espera reduzem o consumo de energia quando o selador não está em uso, enquanto os elementos de aquecimento com eficiência energética fornecem tempos de aquecimento e resfriamento mais rápidos, reduzindo a energia geral necessária para cada selagem. Esses recursos não apenas reduzem as contas de eletricidade, mas também contribuem para uma operação mais sustentável.

Compatibilidade com atualizações futuras

À medida que a tecnologia evolui, a capacidade de atualizar e expandir a funcionalidade dos seladores de calor por impulso se torna cada vez mais importante. Alguns fabricantes oferecem designs modulares que permitem atualizações e personalização fáceis. Por exemplo, os usuários podem adicionar barras de selagem adicionais, atualizar para painéis de controle mais avançados ou integrar o selador com outros equipamentos de embalagem.

A compatibilidade com atualizações futuras garante que o selador possa se adaptar às necessidades de mudança e aos avanços tecnológicos, proporcionando uma vida útil mais longa do produto e melhor retorno sobre o investimento. Essa flexibilidade é particularmente valiosa para empresas em crescimento que podem precisar dimensionar suas operações ou se adaptar a novos requisitos de embalagem.

Faixa de preço e considerações de orçamento

Modelos básicos

Os seladores de calor por impulso de nível básico geralmente custam entre US$ 50 e US$ 200. Esses modelos são ideais para pequenas empresas ou aplicações de baixo volume. Eles oferecem funcionalidade básica e geralmente são limitados a selar materiais mais finos. Embora possam não ter recursos avançados, eles fornecem uma solução econômica para empresas com orçamentos limitados. Os modelos de nível básico são adequados para aplicações como selar pequenos sacos de salgadinhos, produtos de varejo ou tarefas leves de embalagem.

Modelos Médios

Seladoras térmicas de impulso de médio porte, com preços entre US$ 200 e US$ 500, oferecem um equilíbrio entre desempenho e custo. Esses modelos geralmente incluem recursos adicionais, como controles de temperatura ajustáveis, visores digitais e construção mais robusta. Eles são capazes de lidar com uma gama mais ampla de materiais e são adequados para aplicações de médio volume. Seladoras térmicas de médio porte são comumente usadas em indústrias como embalagens de alimentos, produtos farmacêuticos e eletrônicos.

Modelos de última geração

Seladoras térmicas de impulso de ponta, com preços acima de US$ 500, são projetadas para aplicações industriais e de alto volume. Esses modelos vêm com recursos avançados, como automação, configurações programáveis e construção resistente. Eles são capazes de selar materiais espessos e multicamadas de forma rápida e eficiente. Seladoras de ponta são ideais para grandes fábricas, unidades de processamento de alimentos e outros ambientes exigentes onde confiabilidade e desempenho são essenciais.

Manutenção e Longevidade

Manutenção de rotina

A manutenção regular é essencial para garantir a longevidade e o desempenho ideal dos seladores térmicos de impulso. As tarefas de manutenção de rotina incluem a limpeza das barras de vedação, a inspeção dos elementos de aquecimento e a verificação de desgaste nas peças móveis. Manter as barras de vedação limpas garante uma qualidade de vedação consistente e evita o acúmulo de resíduos que podem afetar o processo de vedação. Inspecionar os elementos de aquecimento quanto a sinais de danos ou desgaste ajuda a evitar quebras inesperadas e garante um desempenho de aquecimento eficiente.

Peças de reposição

A disponibilidade de peças de reposição é uma consideração essencial para manter a longevidade de um selador térmico de impulso. Peças de reposição comuns incluem elementos de aquecimento, fios de vedação e tampas de Teflon. Os fabricantes geralmente fornecem kits de manutenção que incluem esses componentes essenciais, facilitando para os usuários realizar reparos e substituições conforme necessário. Ter acesso a peças de reposição garante que pequenos problemas possam ser resolvidos prontamente, minimizando o tempo de inatividade e estendendo a vida útil do selador.

Atendimento Profissional

Para modelos industriais e de ponta, pode ser necessária manutenção profissional para manter o desempenho ideal. A manutenção regular por técnicos qualificados garante que o selador esteja operando com eficiência máxima e que quaisquer problemas potenciais sejam identificados e resolvidos com antecedência. A manutenção profissional pode incluir calibração de controles digitais, inspeção completa de componentes mecânicos e substituição de peças desgastadas. Investir em manutenção profissional ajuda a manter a confiabilidade e a durabilidade do selador, garantindo que ele continue atendendo às demandas de operações de alto volume.

Analisando o impacto dos seladores térmicos de impulso na eficiência da embalagem

Os seladores térmicos de impulso desempenham um papel crucial no aprimoramento da eficiência da embalagem em vários setores. Sua capacidade de criar selos fortes e herméticos de forma rápida e eficiente ajuda a agilizar os processos de embalagem e melhorar a produtividade geral. Ao reduzir o tempo e o esforço necessários para a selagem, os seladores térmicos de impulso contribuem para tempos de resposta mais rápidos e maior produção.

Por exemplo, na indústria de embalagens de alimentos, os seladores de calor por impulso ajudam a manter o frescor do produto e a estender a vida útil ao criar selos herméticos que evitam contaminação e deterioração. Na indústria eletrônica, eles fornecem proteção confiável para componentes sensíveis, garantindo que permaneçam livres de umidade e poeira durante o armazenamento e o transporte.

A versatilidade dos seladores de calor por impulso também permite que as empresas manipulem uma ampla gama de materiais de embalagem, de filmes plásticos finos a sacos multicamadas grossos. Essa adaptabilidade os torna um ativo valioso para empresas com diversas necessidades de embalagem, permitindo que elas alcancem selos consistentes e de alta qualidade, independentemente do material usado.

Melhorando a qualidade da embalagem com seladoras térmicas de impulso

Os seladores térmicos de impulso são fundamentais para melhorar a qualidade da embalagem em várias aplicações. A capacidade de criar selos consistentes e uniformes garante que os produtos embalados permaneçam seguros e protegidos durante toda a sua vida útil. Essa consistência é particularmente importante para produtos que exigem um alto nível de proteção, como produtos farmacêuticos, eletrônicos e alimentos perecíveis.

Por exemplo, na indústria farmacêutica, seladores de calor por impulso são usados para embalar medicamentos em bolsas invioláveis, garantindo a integridade e a segurança do produto. Na indústria alimentícia, eles ajudam a evitar queimaduras de congelamento e estendem a vida útil de produtos congelados, criando selos herméticos que mantêm o frescor e o sabor.

A precisão e o controle oferecidos pelos modernos seladores de calor por impulso também contribuem para a qualidade da embalagem. Configurações de temperatura ajustáveis e controles digitais permitem que os operadores ajustem o processo de selagem para diferentes materiais, garantindo a resistência e a aparência ideais da vedação. Esse nível de controle ajuda a manter um alto padrão de qualidade da embalagem, reduzindo o risco de defeitos e retrabalho.

Seladoras Térmicas de Impulso e Sustentabilidade

Os seladores térmicos de impulso contribuem para os esforços de sustentabilidade ao reduzir o desperdício de embalagens e aumentar a eficiência energética. A capacidade de criar selos fortes e confiáveis com uso mínimo de material ajuda a minimizar o desperdício e reduzir o impacto ambiental dos processos de embalagem. Além disso, a operação com eficiência energética dos seladores térmicos de impulso, que consomem energia apenas durante o ciclo de selagem, apoia ainda mais as práticas sustentáveis.

Por exemplo, as empresas podem usar seladoras de calor por impulso para embalar produtos em sacos menores e mais eficientes, reduzindo a quantidade de plástico usado e diminuindo os custos de transporte. O consumo reduzido de energia das seladoras de calor por impulso também ajuda a diminuir o uso geral de energia, contribuindo para uma pegada de carbono menor.

Além disso, alguns fabricantes estão desenvolvendo seladores de calor por impulso com recursos ecológicos, como materiais recicláveis e modos de economia de energia. Esses avanços se alinham com a crescente demanda por soluções de embalagem sustentáveis e ajudam as empresas a atingir suas metas ambientais.

Considerações Finais

Em resumo, os seladores de calor por impulso são ferramentas versáteis, eficientes e essenciais para uma ampla gama de aplicações de embalagem. Sua capacidade de criar selos fortes e herméticos de forma rápida e eficiente melhora a qualidade da embalagem, melhora a produtividade e apoia os esforços de sustentabilidade. Ao considerar cuidadosamente fatores como tipos, desempenho, especificações técnicas, qualidade de construção e padrões de segurança, as empresas podem selecionar o selador de calor por impulso certo para atender às suas necessidades específicas e atingir resultados ideais.