O mercado de Tunnel Boring Machine (TBM) está crescendo em 2025, impulsionado por projetos de infraestrutura em todo o mundo. Este artigo fornece uma análise aprofundada da seleção da máquina TBM certa, com foco no tipo de máquina, desempenho e tendências futuras. Ele oferece insights e orientações valiosos para compradores profissionais tomarem decisões de compra informadas.

Sumário:

– Visão geral do mercado da indústria de máquinas TBM

– Introdução e análise detalhada do mercado de máquinas TBM

– Fatores-chave ao selecionar uma máquina TBM

– Tendências futuras em tecnologia TBM

– Garantindo compatibilidade com atualizações futuras

- Pensamentos finais

Visão geral do mercado da indústria de máquinas TBM

O mercado global de Tunnel Boring Machines (TBMs) deve crescer significativamente devido à crescente demanda por desenvolvimento de infraestrutura, urbanização e sistemas de transporte eficientes. Em 2024, o mercado de TBM foi avaliado em aproximadamente US$ 6.5 bilhões e deve crescer a um CAGR de 5.9% de 2024 a 2030, atingindo US$ 9.2 bilhões até 2030. Esse crescimento é impulsionado por projetos de construção de túneis em andamento e planejados em todo o mundo, especialmente nas regiões Ásia-Pacífico e Europa.

A Ásia-Pacífico é o maior mercado para TBMs, com mais de 45% da participação de mercado global em 2024. Esse domínio se deve a extensos projetos de infraestrutura na China, Índia e Japão. A Europa segue com investimentos significativos na construção de túneis para projetos de transporte e serviços públicos. O mercado norte-americano também está se expandindo, impulsionado por atualizações de infraestrutura urbana e novos projetos de transporte.

Avanços tecnológicos no design e funcionalidade de TBM estão impulsionando o crescimento do mercado. Inovações como TBMs híbridas que alternam entre diferentes modos com base nas condições do solo e a integração de IoT e IA para monitoramento em tempo real e manutenção preditiva estão aumentando a eficiência e a confiabilidade dessas máquinas. Esses avanços são cruciais para atender à crescente demanda por precisão e velocidade na construção de túneis.

Introdução e análise detalhadas do mercado de máquinas TBM

Máquinas de perfuração de túneis (TBMs) são essenciais para a construção de túneis em várias condições de solo, incluindo rocha, areia e argila. Os principais benchmarks de desempenho para TBMs incluem diâmetro de corte, taxa de penetração e capacidade de torque. TBMs modernas podem atingir diâmetros de corte de 3 a 17 metros, com taxas de penetração de até 20 metros por dia, dependendo das condições do solo.

O mercado é competitivo, com participantes importantes como Herrenknecht AG, Robbins Company e China Railway Construction Heavy Industry Corporation (CRCHI) liderando o setor. Essas empresas investem pesadamente em P&D para desenvolver TBMs avançados que oferecem maior eficiência e menores custos operacionais. Investimentos governamentais em projetos de desenvolvimento de infraestrutura e urbanização são impulsionadores econômicos críticos para o mercado.

O comportamento do consumidor está mudando para TBMs mais avançados e automatizados para reduzir riscos operacionais e aumentar a segurança. Os canais de distribuição para TBMs incluem vendas diretas para empresas de construção e aquisição por meio de licitações governamentais. Inovações recentes incluem TBMs de modo duplo, que operam em modos aberto e fechado, fornecendo maior flexibilidade e eficiência em condições geológicas variáveis.

O ciclo de vida do produto de TBMs é caracterizado por inovação e atualizações contínuas. Com a digitalização e práticas de fabricação inteligentes, os TBMs estão se tornando mais confiáveis e eficientes. Tendências sociais, como o foco em práticas de construção sustentáveis e ecologicamente corretas, também influenciam o mercado. Os pontos problemáticos do cliente incluem alto investimento inicial e a necessidade de operadores especializados. Para resolver esses problemas, os fabricantes de TBMs oferecem programas de treinamento e suporte pós-venda para aumentar a eficiência operacional e reduzir o tempo de inatividade.

As estratégias de posicionamento de marca no mercado de TBM enfatizam capacidades tecnológicas avançadas e confiabilidade. As estratégias de diferenciação focam em oferecer soluções personalizadas adaptadas a requisitos específicos do projeto e condições do solo. Os nichos de mercado dentro da indústria de TBM incluem micro-TBMs para túneis de pequeno diâmetro e TBMs especializados para construção de túneis subaquáticos.

Fatores-chave ao selecionar uma máquina TBM

Tipo de máquina e aplicação

Ao selecionar uma Tunnel Boring Machine (TBM), o tipo de máquina e sua aplicação são cruciais. As TBMs são geralmente categorizadas em Earth Pressure Balance Machines (EPB), Slurry Shield Machines e Hard Rock TBMs. Cada tipo é projetado para condições específicas do solo e requisitos do projeto. Por exemplo, as máquinas EPB são adequadas para solos macios e coesos e podem lidar com uma mistura de areia, silte e argila. Elas mantêm a pressão da face para evitar o colapso do solo e são comumente usadas em ambientes urbanos onde o controle de assentamento é crucial.

As máquinas Slurry Shield são ideais para solos macios com alto teor de água. Essas máquinas usam uma mistura de lama para dar suporte à face do túnel e transportar o material escavado. As Hard Rock TBMs são projetadas para condições de rocha estáveis e utilizam cortadores de disco para quebrar a rocha. A escolha entre esses tipos deve ser guiada por uma análise geotécnica completa do local do projeto.

Desempenho e Funcionalidade

Desempenho e funcionalidade são essenciais ao escolher um TBM. Métricas importantes incluem a taxa de avanço da máquina, influenciada pela potência, torque e impulso da cabeça de corte. A alta potência da cabeça de corte permite que o TBM rompa com eficiência formações geológicas difíceis, enquanto o torque adequado garante uma rotação suave mesmo sob alta resistência. A capacidade de impulso é essencial para manter o impulso para frente e lidar com a pressão exercida pelo solo ao redor.

Recursos de funcionalidade como sistemas de orientação automatizados, monitoramento em tempo real e recursos de registro de dados aumentam a eficiência operacional. Esses sistemas fornecem informações críticas sobre o desempenho da máquina, condições do solo e alinhamento, permitindo que os operadores tomem decisões informadas e ajustem os parâmetros conforme necessário.

Especificações técnicas

Especificações técnicas são considerações vitais. Elas incluem o diâmetro da máquina, que deve corresponder aos requisitos de tamanho do túnel do projeto. TBMs vêm em vários diâmetros, desde máquinas pequenas para túneis de utilidade até máquinas grandes para túneis de transporte. O peso e as dimensões da máquina também impactam a logística de transporte e montagem, que são críticas para o planejamento do projeto.

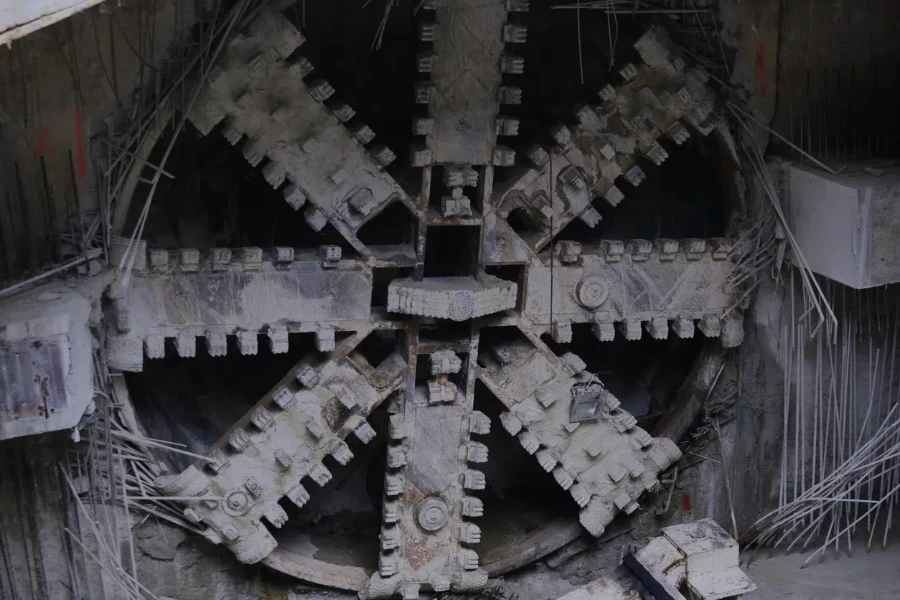

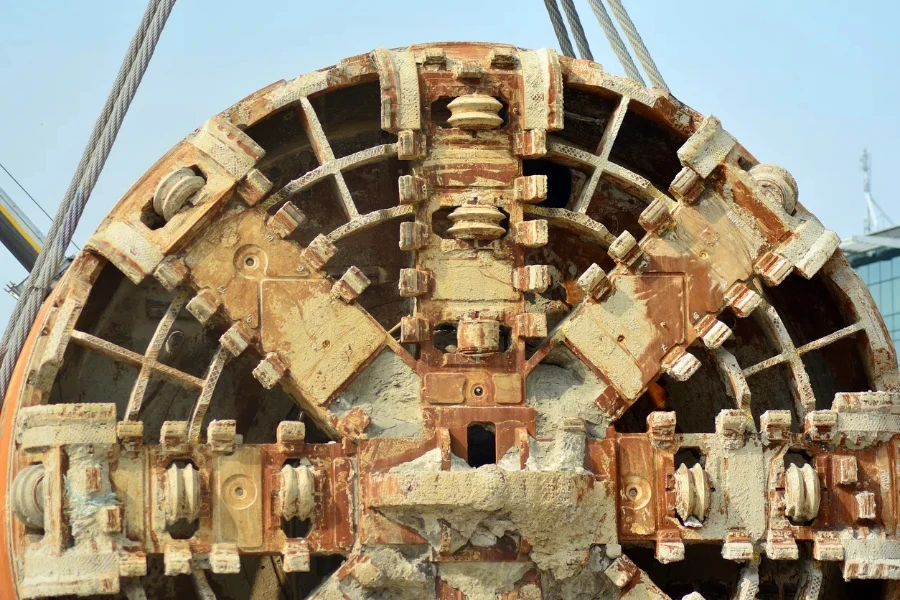

Outra especificação importante é o tipo de cabeça de corte e sua configuração. As cabeças de corte podem ser equipadas com diferentes tipos de ferramentas de corte, como cortadores de disco para rochas duras ou rippers para solos mais macios. A seleção das ferramentas de corte deve ser baseada nas condições do solo e no perfil de túnel desejado. Além disso, a fonte de alimentação e os sistemas hidráulicos da máquina devem ser robustos o suficiente para suportar operação contínua sob cargas variadas.

Qualidade e durabilidade de construção

A qualidade de construção e a durabilidade de uma TBM são cruciais para garantir desempenho confiável e minimizar o tempo de inatividade. Materiais de alta qualidade, como aço temperado para a cabeça de corte e ligas resistentes ao desgaste para as ferramentas de corte, estendem a vida útil da máquina e reduzem os custos de manutenção. A integridade estrutural da máquina deve suportar as tensões da escavação de túneis, incluindo alta pressão e condições de solo abrasivo.

A durabilidade também é influenciada pela qualidade dos componentes da máquina, como rolamentos, vedações e sistemas hidráulicos. Manutenção regular e substituição oportuna de peças desgastadas são essenciais para manter o desempenho da máquina. Os fabricantes geralmente fornecem garantias e acordos de serviço para dar suporte à operação de longo prazo e garantir que a máquina permaneça em condições ideais.

Normas de segurança e certificações

A segurança é uma preocupação primordial nas operações de TBM. A máquina deve estar em conformidade com os padrões e certificações de segurança relevantes, como aqueles definidos pela Organização Internacional para Padronização (ISO) e autoridades nacionais de segurança. Os principais recursos de segurança incluem sistemas de parada de emergência, válvulas de alívio de pressão e sistemas de supressão de incêndio. Esses recursos protegem os operadores e o equipamento em caso de eventos inesperados.

As certificações garantem que a máquina foi testada e atende a critérios específicos de segurança e desempenho. Por exemplo, a certificação ISO 9001 indica que o fabricante segue práticas rigorosas de gerenciamento de qualidade. Além disso, as máquinas devem ser equipadas com sistemas de monitoramento de segurança que forneçam dados em tempo real sobre parâmetros críticos, como pressão, temperatura e alinhamento da máquina, para evitar acidentes e garantir uma operação segura.

Tendências futuras na tecnologia TBM

Automação e Integração de IA

A integração de automação e inteligência artificial (IA) está revolucionando a indústria de TBM. TBMs automatizados equipados com sistemas de IA podem otimizar as operações de tunelamento analisando dados em tempo real e fazendo ajustes nos parâmetros da máquina. Algoritmos de IA podem prever problemas potenciais, como instabilidade do solo ou desgaste do equipamento, permitindo manutenção proativa e reduzindo o tempo de inatividade. Esses avanços aumentam a eficiência e a segurança dos projetos de tunelamento.

Designs sustentáveis e ecológicos

À medida que as preocupações ambientais se tornam mais proeminentes, os fabricantes de TBM estão se concentrando em projetos sustentáveis e ecologicamente corretos. As inovações incluem motores com eficiência energética, emissões reduzidas e o uso de materiais recicláveis. Além disso, alguns TBMs são projetados para minimizar o impacto no ambiente ao redor, reduzindo o ruído e a vibração. Esses recursos não apenas atendem às regulamentações ambientais, mas também melhoram a aceitação social de projetos de construção de túneis.

Tecnologias Avançadas de Corte

Avanços em tecnologias de corte estão melhorando o desempenho e a versatilidade dos TBMs. Novas ferramentas de corte feitas de materiais de alta resistência, como cortadores compactos de diamante policristalino (PDC), oferecem resistência ao desgaste e eficiência de corte superiores. Essas ferramentas podem lidar com uma gama mais ampla de condições geológicas, de solos moles a rochas duras, e reduzem a necessidade de trocas de ferramentas. Além disso, inovações no design do cabeçote de corte, como configurações de geometria variável, permitem que os TBMs se adaptem a diferentes condições de solo rapidamente.

Garantindo compatibilidade com atualizações futuras

Design modular

O design modular está se tornando cada vez mais importante na fabricação de TBM. Um TBM modular pode ser facilmente atualizado ou reconfigurado para atender aos requisitos de projeto em evolução. Por exemplo, cabeçotes de corte podem ser trocados por diferentes tipos de ferramentas de corte, e módulos adicionais podem ser adicionados para aprimorar as capacidades da máquina. Essa flexibilidade estende a vida útil da máquina e permite que ela seja usada em uma variedade de projetos de tunelamento.

Atualizações de Software

As atualizações de software desempenham um papel crítico na manutenção do desempenho dos TBMs modernos. Os fabricantes estão desenvolvendo plataformas de software avançadas que permitem monitoramento remoto, diagnósticos e atualizações. Essas plataformas permitem que os operadores recebam dados em tempo real, realizem solução de problemas e implementem melhorias de software sem a necessidade de intervenção física. Atualizações regulares de software garantem que a máquina permaneça na vanguarda da tecnologia e possa se beneficiar dos últimos avanços em automação e IA.

Integração com BIM e IoT

A integração do Building Information Modeling (BIM) e da Internet das Coisas (IoT) está transformando as operações de TBM. O BIM permite o planejamento detalhado e a visualização de projetos de tunelamento, enquanto os dispositivos de IoT fornecem dados em tempo real sobre o desempenho da máquina e as condições do solo. Essa integração permite melhor tomada de decisão, coordenação aprimorada entre as partes interessadas do projeto e eficiência aprimorada nas operações de tunelamento. À medida que essas tecnologias continuam a evoluir, os TBMs se tornarão ainda mais conectados e inteligentes, levando a projetos de tunelamento mais seguros e eficientes.

Considerações Finais

Selecionar a máquina TBM correta envolve consideração cuidadosa de vários fatores, incluindo tipo de máquina, desempenho, especificações técnicas, qualidade de construção, padrões de segurança e potencial de atualização futura. Ao avaliar completamente esses aspectos, os gerentes de projeto podem garantir que escolherão uma máquina que atenda às suas necessidades específicas e ofereça desempenho ideal durante todo o projeto de tunelamento. À medida que a tecnologia continua a avançar, os TBMs se tornarão ainda mais eficientes, sustentáveis e adaptáveis, abrindo caminho para projetos de tunelamento inovadores e bem-sucedidos.