In the high-tech world of pulse laser cleaning, it’s imperative that buyers and sellers understand the different types of working mechanisms and applications involved. Choosing one variety over the other will depend on the type of surface that requires cleaning and the industry in which it will be used.

Here, we’ll explain the differences between pulse and continuous laser cleaning and what to consider when choosing the right laser for your business.

Laser cleaning industry outlook

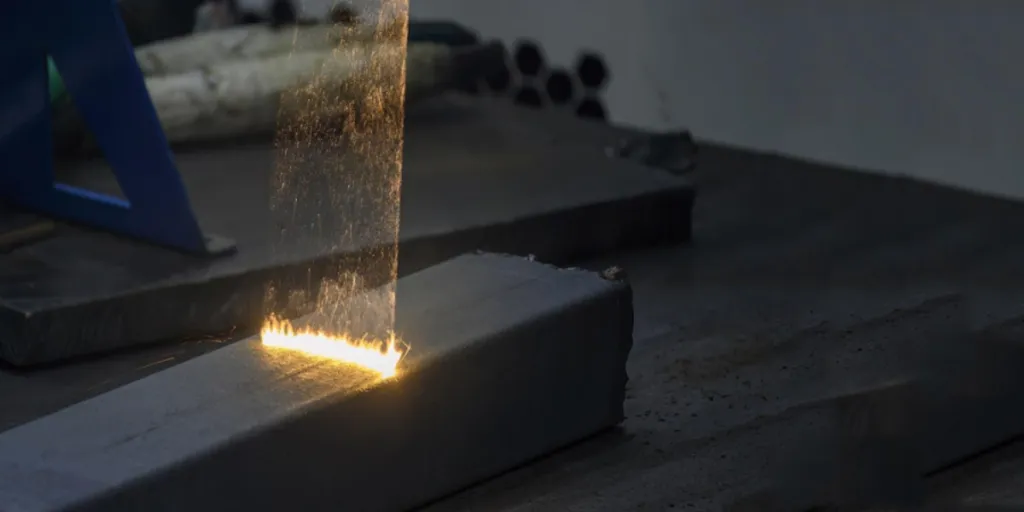

Laser cleaning uses a high-density and focused laser beam to remove rust, paint, or oxide from surfaces like walls and metal. It does not involve chemicals, making it an excellent substitute for other environmentally unfriendly cleaning methods.

According to verified market research, the laser cleaning market was valued at USD 659.92 million in 2023 and is forecast to grow at a CAGR of 4.10% to USD 883.65 million by 2031.

With more people embracing environmentally conscious cleaning processes, laser cleaning may be preferable for small or medium-sized businesses.

Depending on the industry, laser cleaning can be used for large-scale, small-scale, and more precise cleaning. By stocking a variety of laser cleaners, your clients will be able to choose the model that best fits their needs.

What is pulse laser cleaning?

As the name suggests, pulse laser cleaning works by producing short bursts of laser beams – regulated by a pulsed laser generator – during the cleaning process.

Pulse laser cleaners tend to operate within a power range of 100 to 500 watts. This lower energy level means that they do not emit a lot of heat, so there is a reduced chance of burning the surface being cleaned.

What is continuous laser cleaning?

Continuous laser cleaning involves the emission of an uninterrupted laser energy beam over a long time. The machine has a continuous laser generator that regulates the production of the beams.

A continuous laser cleaner uses high power, ranging from 1,000 to 3,000 watts, so there’s a high chance that it may burn or damage the surface being cleaned. As such, correct precautions should be taken prior to use.

Differences between pulse and continuous laser cleaning

Due to their working principles, pulse and continuous laser cleaning differ in various ways. Although the technology is similar, each has different applications.

The main differences include:

EfficiencyPulse laser cleaning is more controlled and, hence, more efficient than continuous laser cleaning.

Pulse laser cleaning involves using short bursts of high-density energy beams, which cause rapid abrasion and vaporization of contaminants. Since the beams are more targeted, cleaning some surfaces, such as those that are curved, can be easier. On the other hand, continuous laser cleaning is less efficient since it’s not targeted. Therefore, it’s much more effort to clean smaller or curved surfaces using continuous laser cleaning, and the results may not be as good.

Speed

Continuous lasers are faster than pulse lasers when it comes to speed. Their continuous-wave laser beam ensures consistent and uniform cleaning over large surfaces, making them more suitable for large-scale cleaning.

Although continuous beams are less precise, they’re better at the steady removal of dirt or contaminants, thus perfect for high-throughput processes. On the other hand, pulse laser cleaning is slower due to its targeted energy waves.

Heat

Pulse laser cleaners use power between 100 and 300 watts, producing low heat during the cleaning process. Pulse laser cleaning is therefore more gentle on surfaces and can be used to clean fragile objects and materials.

Continuous laser cleaning uses high amounts of energy, ranging between 1,000 and 3,000 watts. Therefore, the temperatures can be quite high during cleaning and lead to surface damage if not managed appropriately.

Applications

Due to its targeted cleaning technology, pulse laser cleaning is more efficient and less likely to damage surfaces. It’s better suited for cleaning detailed or fragile surfaces prone to damage or deformation. It’s mainly used in manufacturing industries, including automotive and aerospace, to clean surfaces before coating and welding, as well as in the electronics industry to remove contaminants from delicate surfaces.

On the other hand, continuous laser cleaning is fast and may be too intense for fragile surfaces and materials. Thus, it’s more suitable for large-scale cleaning, where speed is paramount, such as in heavy-duty industries like metal fabrication and shipbuilding.

Price

Pulse laser cleaners are significantly more expensive than continuous laser cleaners, so getting a return on investment (ROI) will take longer. Continuous laser cleaners are cheaper, and you can expect a return on investment after the first year. It’s recommended to stock both types of laser cleaner to cater to different client budgets.

Considerations when choosing the right laser cleaning method

Although the two types have similar cleaning technology, they work differently, choosing the laser cleaning method most appropriate for your customer base is essential.

These are the main points to consider when choosing laser cleaners to stock for your business:

Nature of the surface

Pulse laser cleaning is more efficient and precise, causing little or no damage to surfaces, making it the best choice for cleaning delicate materials such as wood and glass. It’s also great for surface cleaning molds and the inside of pipes.

On the other hand, continuous laser cleaning is better for harder materials that don’t require precise cleaning.

Cleaning time

If your customers want fast cleaning, a continuous laser is likely the best choice, cleaning large surfaces in the shortest time. Although they may not be as effective as pulse laser cleaners, they save time, making them suitable for jobs where speed is a priority.

Conclusion

Laser cleaning is a worthwhile investment for your business. By stocking both types of laser cleaners, you can provide a choice to your clients depending on their needs and preferences.

Pulse laser cleaning is more effective and precise and is best for fragile surfaces. However, it is slower and not suitable for cleaning larger surfaces. Meanwhile, continuous laser cleaning is faster and more suitable for surfaces that don’t require careful cleaning. Therefore, it’s important to understand your buyers’ needs and the surfaces they’re likely wanting to clean before making a sale.

No matter what type of laser cleaner you’re after, you’ll find it among the thousands of options on Chovm.com.