В 2025 году мировой рынок 3-точечных разбрасывателей процветает благодаря достижениям в области точного земледелия. В этой статье представлен углубленный анализ рынка, ключевые критерии выбора и новейшие технологические характеристики. Она направлена на то, чтобы помочь профессиональным покупателям принимать обоснованные решения о покупке.

Содержание:

-Обзор рынка: 3-точечный разбрасыватель

-Подробное введение и анализ рынка 3-точечных разбрасывателей

-Основные факторы, которые следует учитывать при выборе 3-точечного разбрасывателя

-Обеспечение совместимости с другими системами

-Важность соблюдения нормативных требований и стандартов безопасности

-Заключительные мысли по выбору 3-точечного разбрасывателя

Обзор рынка: 3-точечный разбрасыватель

Мировой рынок 3-точечных разбрасывателей удобрений пережил заметный рост, обусловленный растущим спросом на эффективную сельскохозяйственную технику. По состоянию на 2025 год объем рынка разбрасывателей удобрений, включая 3-точечные разбрасыватели, оценивался в 728.12 млн долларов США в 2024 году и, по прогнозам, достигнет 1.07 млрд долларов США к 2030 году, увеличившись с годовым темпом прироста (CAGR) в 6.63%. Этот рост в значительной степени обусловлен достижениями в области точного земледелия и переходом к устойчивым методам ведения сельского хозяйства.

В Америке, особенно в США и Канаде, спрос на 3-точечные разбрасыватели обусловлен крупномасштабным коммерческим фермерством и потребностью в высокоэффективном оборудовании. Эти регионы предпочитают машины, которые интегрируются с интеллектуальными решениями для фермерства, чтобы оптимизировать использование удобрений и снизить воздействие на окружающую среду. Аналогичным образом, на европейский рынок влияют жесткие государственные политики, поощряющие устойчивое сельское хозяйство, что приводит к предпочтению разбрасывателей с уменьшенным углеродным следом и повышенной точностью.

Азиатско-Тихоокеанский регион, особенно такие страны, как Китай, Япония и Индия, демонстрирует значительное разнообразие в потребностях потребителей и покупательском поведении. Правительственные инициативы, направленные на устойчивое сельское хозяйство и увеличение инвестиций в НИОКР, существенно влияют на рынок. Эти инициативы направлены на содействие внедрению передовой сельскохозяйственной техники, включая 3-точечные разбрасыватели, для повышения производительности и устойчивости.

Подробное введение и анализ рынка 3-точечных разбрасывателей

Рынок 3-точечных разбрасывателей имеет решающее значение для повышения эффективности и производительности сельского хозяйства. Эти разбрасыватели, оснащенные такими функциями, как динамическое взвешивание и точное внесение, необходимы для современного сельского хозяйства. Основные показатели производительности 3-точечных разбрасывателей включают точность внесения, долговечность и простоту обслуживания. Интеграция GPS и сенсорных систем еще больше улучшила их функциональность, что позволяет точно вносить удобрения и снижать воздействие на окружающую среду.

Ведущие производители, такие как Kverneland, Oxbo International Corp. и Bredal, доминируют на рынке с инновационными продуктами. Например, разбрасыватель Kverneland среднего класса с характеристиками Pro и возможностями динамического взвешивания установил новый стандарт рынка. Экономические факторы, такие как растущий спрос на продукты питания и государственные субсидии на сельскохозяйственную технику, также стимулируют рост рынка.

Потребительское поведение смещается в сторону устойчивых методов ведения сельского хозяйства, отдавая предпочтение оборудованию, которое минимизирует отходы удобрений и воздействие на окружающую среду. Каналы дистрибуции демонстрируют сильное предпочтение производителям оригинального оборудования (OEM) для обеспечения совместимости и надежности. Недавние инновации, такие как настраиваемые решения для разбрасывателей, адаптированные к конкретным типам почв, культурам и удобрениям, открыли новые сегменты рынка и возможности для роста.

Обзор рынка и тенденции

Технологические достижения в области точного земледелия и эффективных методов разбрасывания способствуют росту рынка. Внедрение интеллектуальных методов ведения сельского хозяйства, включая GPS и сенсорные системы, произвело революцию в области 3-точечных разбрасывателей, что привело к повышению точности и снижению воздействия на окружающую среду. Растущее предпочтение устойчивым методам ведения сельского хозяйства еще больше стимулирует рынок, поскольку эти разбрасыватели обеспечивают эффективное использование удобрений и минимальные отходы.

Болевые точки клиентов в первую очередь связаны с высокими первоначальными инвестициями и сложным обслуживанием современных разбрасывателей. Решение этих проблем путем разработки экономически эффективных, долговечных и простых в использовании разбрасывателей может повысить проникновение на рынок. Стратегии позиционирования бренда, ориентированные на превосходную точность внесения, возможности настройки и интеграцию с интеллектуальными решениями для сельского хозяйства, могут дифференцировать продукты в конкурентной среде.

Ключевые факторы, которые следует учитывать при выборе 3-точечного разбрасывателя

При выборе 3-точечного разбрасывателя для сельскохозяйственного или промышленного использования необходимо учитывать несколько ключевых факторов, чтобы гарантировать, что он соответствует вашим конкретным потребностям и обеспечивает оптимальную производительность. Ниже мы рассмотрим наиболее важные соображения по выбору 3-точечного разбрасывателя.

Типы и стили 3-точечных разбрасывателей

Типы и стили 3-точечных разбрасывателей, доступных на рынке, могут существенно влиять на их производительность и пригодность для конкретных задач. В основном существуют два типа: разбрасыватели и капельные разбрасыватели.

Широкополосные разбрасыватели быстро распределяют материал по большой площади с помощью вращающегося дискового механизма. Этот тип идеально подходит для эффективного покрытия больших полей или газонов. С другой стороны, капельные разбрасыватели обеспечивают более точное внесение, сбрасывая материал непосредственно под разбрасыватель. Такая точность делает их подходящими для задач, требующих точного распределения, например, внесения удобрений на грядки или небольшие участки.

Выбор между этими типами зависит от конкретного применения и требуемого уровня точности. Например, фермер с обширными полями может предпочесть разбрасыватель из-за его эффективности, в то время как ландшафтный дизайнер, работающий на меньших, более детализированных участках, может выбрать капельный разбрасыватель.

Производительность и функциональность

Производительность и функциональность являются критическими факторами при выборе 3-точечного разбрасывателя. Ключевые показатели включают в себя емкость, ширину разбрасывания и равномерность распределения.

Емкость относится к объему материала, который может вместить разбрасыватель. Большая емкость выгодна для обширных операций, сокращая частоту повторного внесения. Однако разбрасыватели с большей емкостью могут быть тяжелее и требовать более мощных тракторов. Ширина разбрасывания — еще один важный фактор; более широкое разбрасывание означает меньше проходов по полю, что экономит время и топливо. Важно обеспечить равномерное распределение по всей ширине, чтобы избежать избыточного или недостаточного внесения материалов.

Продвинутые модели могут иметь такие функции, как регулируемые схемы разбрасывания, управление переменной скоростью и интеграция GPS для точного земледелия. Эти функции повышают производительность, позволяя более эффективно и точно вносить материалы.

Качество сборки и материалы

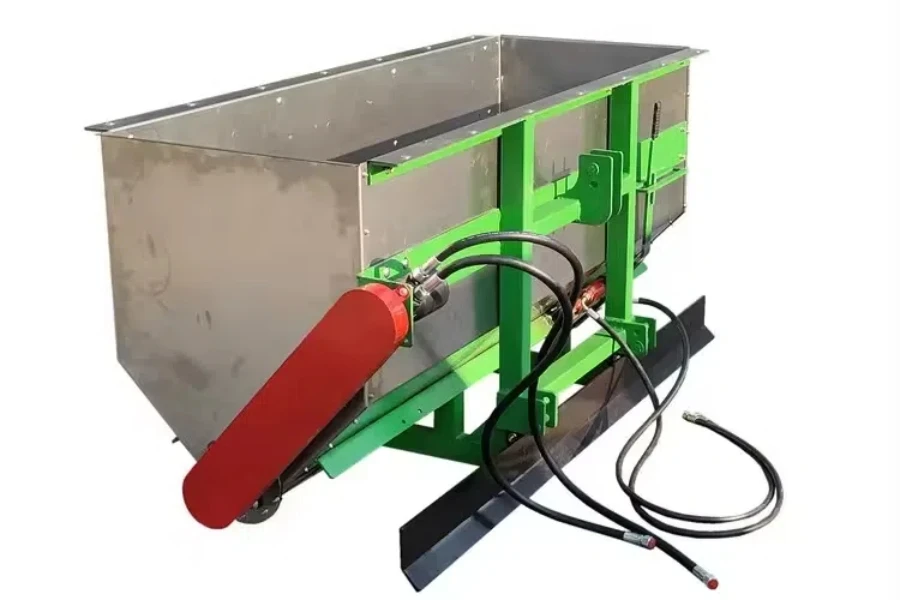

Качество сборки и материалы, используемые в конструкции 3-точечного разбрасывателя, напрямую влияют на его прочность и долговечность. Высококачественные материалы, такие как нержавеющая сталь и прочный пластик, предпочтительны из-за их устойчивости к коррозии и износу.

Компоненты из нержавеющей стали, особенно в бункере и разбрасывающем механизме, обеспечивают превосходную прочность и меньше подвержены ржавчине, что важно при работе с едкими материалами, такими как удобрения. Для некоторых деталей также можно использовать прочный пластик, что обеспечивает баланс между прочностью и снижением веса. Общая конструкция должна быть достаточно прочной, чтобы выдерживать полевые работы, включая воздействие суровых погодных условий и пересеченной местности.

Регулярное обслуживание и правильный уход необходимы для обеспечения долговечности распределителя. Ищите модели, которые обеспечивают легкий доступ к критически важным компонентам для очистки и обслуживания. Некоторые распределители поставляются с дополнительными защитными покрытиями или обработками для повышения их устойчивости к коррозии и износу.

Новейшие технологические возможности

Внедрение новейших технологических функций в 3-точечные разбрасыватели может значительно повысить их эффективность и простоту использования. Современные разбрасыватели могут включать в себя системы с GPS-навигацией для точного внесения, снижения отходов материала и обеспечения равномерного покрытия.

Технология переменной скорости (VRT) позволяет распределителю регулировать скорость внесения на основе данных в реальном времени. Это гарантирует, что нужное количество материала будет внесено на различные участки, оптимизируя использование ресурсов и повышая урожайность. Кроме того, некоторые распределители оснащены электронными системами управления, которые позволяют операторам регулировать настройки из кабины трактора, что повышает удобство и снижает утомляемость оператора.

Интеграция с программным обеспечением для управления фермой может предоставить ценные идеи и данные для принятия лучших решений. Эти функции, хотя и потенциально увеличивают первоначальную стоимость, могут предложить значительные долгосрочные преимущества с точки зрения эффективности, производительности и экономии средств.

Ценовой диапазон и бюджет

Диапазон цен на 3-точечные разбрасыватели может значительно варьироваться в зависимости от их типа, мощности, качества сборки и дополнительных функций. Базовые модели могут стоить от нескольких сотен долларов, в то время как продвинутые модели с высокой мощностью и новейшими технологическими функциями могут стоить несколько тысяч долларов.

При рассмотрении цены оцените общую стоимость владения, включая первоначальную цену покупки, техническое обслуживание, эксплуатационные расходы и потенциальную экономию за счет повышения эффективности. Инвестирование в более дорогую модель с расширенными функциями может обеспечить лучшую долгосрочную ценность за счет сокращения отходов материала, повышения точности нанесения и повышения общей производительности.

Установите бюджет на основе ваших конкретных потребностей и масштаба ваших операций. Сравнение различных моделей и их характеристик может помочь вам принять обоснованное решение, которое сбалансирует стоимость и производительность.

Обеспечение совместимости с другими системами

Совместимость с существующими системами и оборудованием является еще одним критическим фактором при выборе 3-точечного разбрасывателя. Разбрасыватель должен быть совместим с трактором или оборудованием, на которое он будет установлен, включая правильную категорию сцепки и достаточную гидравлическую или валовую мощность.

Современные фермы часто используют интегрированные системы для управления различными задачами. Обеспечение связи разбрасывателя с другим оборудованием и программными системами может повысить общую эффективность. Например, разбрасыватели с возможностями GPS и VRT должны быть совместимы с существующими на ферме системами точного земледелия.

Рассмотрение потенциала будущих обновлений также может быть полезным. По мере развития технологий наличие разбрасывателя, который можно легко модернизировать или интегрировать с новыми системами, гарантирует, что ваши инвестиции останутся актуальными и ценными с течением времени.

Важность соблюдения нормативных требований и стандартов безопасности

Соблюдение нормативных требований и стандартов безопасности имеют первостепенное значение при выборе 3-точечного разбрасывателя. Обеспечение соответствия разбрасывателя местным и международным стандартам безопасности помогает предотвратить несчастные случаи и обеспечивает безопасную эксплуатацию.

Производители часто предоставляют данные о сертификации, которые указывают на соответствие соответствующим стандартам. Ищите такие сертификаты, как ISO, CE или ANSI, которые гарантируют, что продукт был протестирован и соответствует требуемым стандартам безопасности и качества.

Помимо соответствия, необходимы такие функции безопасности пользователя, как ограждения, щитки и четкие инструкции по эксплуатации. Эти функции помогают предотвратить несчастные случаи и травмы во время работы. Также рекомендуется регулярное обучение операторов безопасному использованию распределителя, чтобы гарантировать соблюдение протоколов безопасности.

Заключительные мысли по выбору 3-точечного разбрасывателя

Выбор правильного 3-точечного разбрасывателя включает в себя рассмотрение различных факторов, включая типы и стили, производительность, качество сборки, технологические особенности, ценовой диапазон, совместимость и соответствие нормативным требованиям. Тщательно оценив эти факторы, вы можете выбрать разбрасыватель, который соответствует вашим конкретным потребностям и обеспечивает оптимальную производительность.

Инвестирование в высококачественный, прочный разбрасыватель с расширенными функциями может повысить эффективность, сократить расходы и улучшить общую производительность. Обеспечение совместимости с существующими системами и соблюдение стандартов безопасности еще больше гарантирует, что ваши инвестиции будут безопасными и перспективными.