2025'te elektrikli patates ve elma soyma makineleri pazarı, mutfak otomasyonundaki gelişmelerin etkisiyle hızla büyüyor. Bu makale, profesyonel alıcıların dikkate alması gereken performans, işlevsellik, tasarım, teknik özellikler ve güvenlik standartları gibi kritik faktörleri ele alıyor. Sağlanan içgörüler, bilinçli satın alma kararları alınmasına yardımcı olacaktır.

İçindekiler:

-Elektrikli Patates ve Elma Soyucularının Patlayan Pazarı

- Elektrikli Patates ve Elma Soyucu Seçerken Dikkat Edilmesi Gereken Temel Faktörler

-Malzemeler ve Yapı Kalitesi

-Çözüm

Elektrikli Patates ve Elma Soyucularının Patlayan Pazarı

Piyasa bakış

Elektrikli patates ve elma soyma makineleri pazarı önemli bir büyüme gördü ve küresel pazar 1.81'te yaklaşık 2024 milyar ABD doları değerinde olacak. Tahminler, %2.53'lık bir bileşik yıllık büyüme oranını (CAGR) yansıtarak 2030'a kadar 5.6 milyar ABD dolarına ulaşacağını öngörüyor. Bu büyüme, mutfak aletlerinde otomasyona olan artan talep ve gıda hizmeti ve gıda işleme endüstrilerinin genişlemesiyle yönlendiriliyor.

Elektrikli soyma makinesi pazarı, otomatik ve yarı otomatik soyma makineleri olarak türlere göre segmentlere ayrılmıştır. Verimliliği ve kullanım kolaylığı nedeniyle otomatik segmentin baskın olması bekleniyor. Uygulamalar açısından, tutarlılık ve hız ihtiyacından kaynaklanan restoranlarda ve gıda işleme tesislerinde ticari kullanım önemli bir paya sahiptir. Tüketiciler mutfaklarında kolaylık aradıkça ev kullanımı da artmaktadır.

Kuzey Amerika ve Avrupa, yüksek harcanabilir gelirler ve yenilikçi mutfak aletlerine yönelik güçlü bir tercih ile lider pazarlardır. Asya-Pasifik bölgesinin, kentleşme ve artan harcanabilir gelirler nedeniyle en hızlı büyümeyi göstermesi bekleniyor. Bu pazardaki kilit oyuncular arasında Astra Co., Ltd., DANA-Technology ApS ve Dash yer almaktadır.

Derinlemesine Piyasa Analizi

Elektrikli patates ve elma soyma makinesi pazarı, soyma hassasiyeti, hız ve dayanıklılık gibi birkaç önemli performans ölçütüyle karakterize edilir. Akıllı mutfak aletleri için IoT'nin entegrasyonu gibi soyma teknolojisindeki yenilikler, pazar farklılaşmasını yönlendiriyor. Şirketler, rekabette bir adım öne geçmek için çok işlevliliğe ve enerji verimliliğine odaklanıyor.

Artan harcanabilir gelirler ve kentleşme gibi ekonomik faktörler, pazar büyümesinin önemli itici güçleridir. İşlevselliği gelişmiş teknolojiyle birleştiren akıllı mutfak aletlerine olan artan talep, dikkate değer bir eğilimdir. Ancak, yüksek başlangıç maliyetleri ve daha ucuz manuel alternatiflerin mevcudiyeti, yaygın benimsenmeye karşı zorluklar oluşturmaktadır.

Tüketici davranışı, çevrimiçi dağıtım kanallarına yönelik artan bir tercihle birlikte kolaylığa doğru kayıyor. Bu, mutfak aletleri satışında e-ticaret platformlarının artan nüfuzundan da anlaşılıyor. Özel mağazalar ve süpermarketler gibi çevrimdışı kanallar da daha geniş bir kitleye ulaşmak için önemli olmaya devam ediyor.

Son yenilikler arasında kompakt, pille çalışan ve taşınabilir modeller yer alıyor ve mobil ve kompakt mutfak aletleri trendine hitap ediyor. Elektrikli soyucuların ürün yaşam döngüsü büyüme aşamasındadır ve teknolojideki sürekli gelişmeler çekiciliğini artırmaktadır.

Elektrikli Patates ve Elma Soyucu Seçerken Dikkat Edilmesi Gereken Temel Faktörler

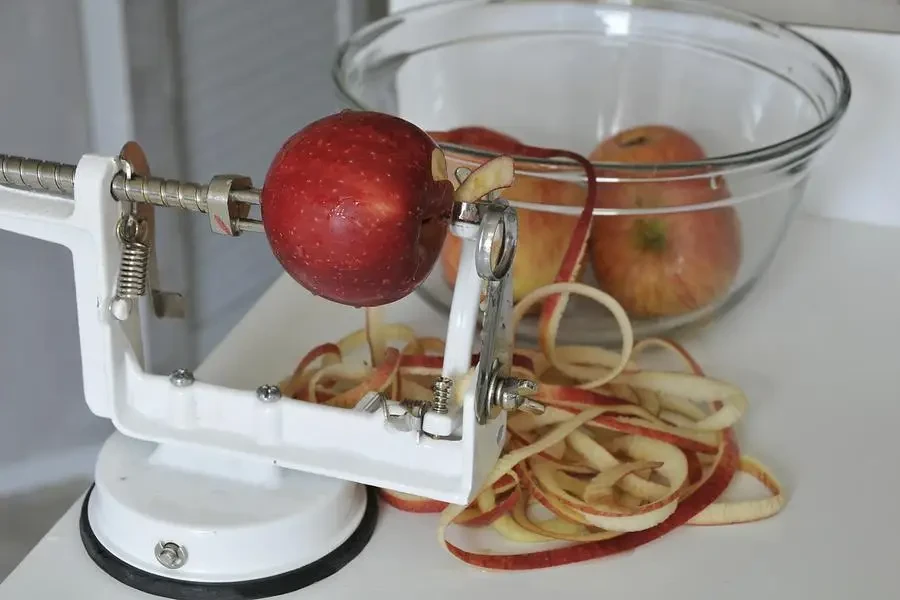

Ticari veya büyük ölçekli operasyonlar için bir elektrikli patates ve elma soyma makinesi seçerken, ürünün iş ihtiyaçlarınızı karşıladığından emin olmak için performansı, işlevselliği, tasarımı, teknik özellikleri ve güvenlik standartlarını göz önünde bulundurun.

Performans ve Verimlilik

Elektrikli patates ve elma soyucu seçerken performans çok önemlidir. Makinenin büyük miktarlarda ürünü soymadaki verimliliği, mutfak üretkenliğini önemli ölçüde etkileyebilir. Yüksek hacimli işlemler için yüksek soyma hızı esastır; bazı modeller dakikada 30 patatese kadar soyma kapasitesine sahiptir. Tutarlı soyma, minimum atık ve tekdüze ürün kalitesi sağlar; gelişmiş modeller tutarlı kalınlık için sensörler ve ayarlanabilir ayarlar sunar. Saat başına pound olarak ölçülen soyucunun kapasitesi, endüstriyel sınıf soyucuların saatte 300 poundun üzerinde işlem yapabilmesiyle mutfağın ihtiyaçlarına uymalıdır.

İşlevsellik ve Çok Yönlülük

Elektrikli bir soyucunun işlevselliği, birincil amacının ötesine uzanır. Bazı soyucular havuç ve salatalık gibi çeşitli ürün türlerini işleyebilir ve bu da birden fazla makineye olan ihtiyacı azaltır. Soyma kalınlığı ve hızı için ayarlanabilir ayarlar, son ürün üzerinde daha fazla kontrol sağlar ve yiyecek israfını azaltır. Kullanıcı dostu kontroller ve sezgisel arayüzler verimliliği artırır ve yeni personel için eğitim süresini azaltır.

Tasarım ve Estetik

Performans en önemli unsur olsa da, tasarım ve estetik de önemlidir, özellikle açık mutfaklarda. Sınırlı tezgah alanına sahip mutfaklar için yerden tasarruf sağlayan tasarımlar çok önemlidir ve kompakt soyucular oldukça tercih edilir. Yapı kalitesi ve kullanılan malzemeler, soyucunun uzun ömürlülüğünü ve aşınma ve yıpranmaya karşı direncini etkiler; paslanmaz çelik ve yüksek kaliteli alüminyum yaygın dayanıklı malzemelerdir. Açık mutfaklarda, diğer cihazlarla uyumlu şık, modern tasarımlar genel ambiyansa katkıda bulunur.

Teknik özellikler

Elektrikli bir soyucunun teknik özelliklerini anlamak doğru modeli seçmeye yardımcı olur. Enerji tasarruflu modeller, enerji tasarrufu modları ve daha düşük güç tüketimi oranları gibi özelliklerle zamanla işletme maliyetlerini azaltır. Güçlü bir motor, özellikle daha sert ürünlerde pürüzsüz ve verimli bir çalışma sağlarken, düşük gürültülü modeller rahat bir çalışma ortamı sağlar.

Güvenlik Standartları ve Sertifikalar

Güvenlik standartlarına ve sertifikalarına uyum pazarlığa tabi değildir. Soyucular, kazaları önlemek için otomatik kapanma, acil durdurma düğmeleri ve koruyucu korumalar gibi güvenlik özelliklerine sahip olmalıdır. Güvenlik ve hijyeni sağlamak için NSF (National Sanitation Foundation) veya UL (Underwriters Laboratories) gibi tanınmış kuruluşlardan sertifikalı ürünler arayın. Düzenli bakım çok önemlidir, sökülmesi ve temizlenmesi kolay modeller yiyecek artıklarının birikmesini ve kirlenmesini önler.

Malzemeler ve Yapı Kalitesi

Elektrikli patates ve elma soyucusunun malzemeleri ve yapı kalitesi, dayanıklılığı ve performansı için temeldir. Yüksek kaliteli malzemeler, yoğun bir ticari mutfakta kritik öneme sahip olan uzun ömürlülüğü ve aşınma ve yıpranmaya karşı direnci garanti eder.

Paslanmaz Çelik Konstrüksiyon

Paslanmaz çelik, dayanıklılığı ve korozyona karşı direnci nedeniyle ticari mutfak ekipmanları için tercih edilir. Paslanmaz çelik soyucular sağlamdır, paslanma olasılığı daha düşüktür ve temizlenmesi kolaydır, sağlık standartlarına uyumu garanti eder. Şık, modern görünümleri diğer mutfak aletlerini tamamlar ve profesyonel bir ortama katkıda bulunur.

Yüksek Dereceli Alüminyum

Yüksek kaliteli alüminyum, hafif ve dayanıklı özellikleriyle bilinir. Alüminyum soyucular, motorun aşırı ısınmasını önleyen mükemmel ısı dağıtma özellikleriyle kullanımı ve taşınması daha kolaydır. Genellikle paslanmaz çelikten daha uygun maliyetlidirler, fiyat ve performansı dengelerler.

Plastik Bileşenler

Ağır hizmet tipi ticari soyucularda daha az yaygın olsa da, plastik bileşenler daha küçük veya daha ucuz modellerde kullanılır. Plastik parçalar genel ağırlığı ve üretim maliyetini azaltarak soyucuyu daha uygun fiyatlı hale getirir. Ancak, sağlık tehlikelerini önlemek için plastiğin yüksek kalitede ve gıda sınıfında olduğundan emin olmak önemlidir. Plastik bileşenler metal olanlar kadar dayanıklı olmayabilir ve yoğun kullanımda çatlamaya meyilli olabilir.

Sonuç

Doğru elektrikli patates ve elma soyucuyu seçmek, performansını, işlevselliğini, tasarımını, malzemelerini ve güvenlik standartlarına uygunluğunu değerlendirmeyi içerir. Bu faktörleri göz önünde bulundurarak, işletmeler operasyonel ihtiyaçlarını karşılayan ve güvenli ve üretken bir mutfak ortamına katkıda bulunan güvenilir ve verimli bir soyucuya yatırım yapabilirler.