2025 yılında, metal kesme bant testere pazarı teknolojik gelişmeler ve artan endüstriyel talepler tarafından yönlendirilen önemli bir büyüme yaşıyor. Bu makale, metal kesme bant testere seçerken dikkate alınması gereken temel faktörlerin derinlemesine bir analizini sunarak profesyonel alıcılar için değerli içgörüler sunuyor. Performans, dayanıklılık ve güvenliğe odaklanan bu kılavuz, işletmelerin bilinçli satın alma kararları almasına yardımcı olacak.

İçindekiler:

-Metal Kesme Bant Testere Pazarına Genel Bakış

-Metal Kesme Bant Testere Pazarının Derinlemesine Analizi

-Metal Kesme Bant Testeresi Seçerken Önemli Faktörler

-Metal Kesme Bant Testerelerinde İleri Teknoloji

-Pazar Eğilimleri ve Gelecek Görünümü

-Son Düşünceler

Metal Kesme Bant Testere Pazarına Genel Bakış

Küresel Metal Kesme Bant Testereleri pazarı, çeşitli endüstriyel sektörlerdeki artan taleple desteklenen istikrarlı bir büyümeye tanıklık ediyor. 2023'teki pazar yaklaşık 1.6 milyar ABD doları değerindeydi ve 2.2'a kadar 2030 milyar ABD dolarına ulaşması ve tahmin döneminde %5'lik bir CAGR ile büyümesi öngörülüyor. Bu büyüme, öncelikle otomotiv, inşaat ve havacılık endüstrilerinde metal kesme bant testerelerinin artan kullanımından kaynaklanmaktadır.

Bölgesel olarak, ABD pazarı 412.9'te 2023 milyon ABD doları değerindeydi ve Çin'in 7.4'a kadar 472.9 milyon ABD dolarına ulaşarak %2030'lük güçlü bir CAGR sergilemesi bekleniyor. Diğer önemli pazarlar arasında, her biri genel pazar büyümesine önemli ölçüde katkıda bulunan Japonya, Kanada ve Almanya yer almaktadır. Asya-Pasifik bölgesinde, pazar hızlı sanayileşme ve altyapı geliştirme nedeniyle önemli bir genişlemeye hazırdır.

Pazardaki temel segmentler arasında Yüksek Hızlı Çelik (HSS) Bant Testere Bıçakları ve Karbür Uçlu Bant Testere Bıçakları yer almaktadır. HSS segmentinin 1.2 yılına kadar %2030'lük bir CAGR ile 5.3 milyar ABD dolarına ulaşması beklenirken, Karbür Uçlu segmentin %4.5 CAGR ile büyümesi bekleniyor. Bu segmentler, küresel olarak metal kesme bant testerelerine olan talebi yönlendiren çeşitli uygulamaları ve teknolojik gelişmeleri vurgulamaktadır.

Metal Kesme Bant Testere Pazarının Derinlemesine Analizi

Performans Ölçütleri ve Pazar Payı Dinamikleri

Metal kesme şerit testereleri için performans ölçütleri, pazar rekabet güçlerini belirlemede kritik öneme sahiptir. Temel performans göstergeleri arasında kesme hızı, hassasiyet, dayanıklılık ve bıçak ömrü yer alır. Yüksek Hızlı Çelik (HSS) şerit testere bıçakları, sertlik ve kesme verimliliği arasındaki denge nedeniyle tercih edilir ve bu da onları genel metal kesmeden daha uzmanlaşmış görevlere kadar çeşitli uygulamalar için ideal hale getirir. Karbür Uçlu şerit testere bıçakları, sert malzemeleri kesmede üstün performans sunar ve yüksek hassasiyet gerektiren endüstrilerde önemli bir paya sahiptir.

Pazar payı dinamikleri, AMADA, WIKUS ve LENOX gibi önde gelen oyuncuların pazara liderlik ettiği rekabetçi bir manzara ortaya koyuyor. Bu şirketler, gelişmiş Ar-Ge ve kapsamlı dağıtım ağlarından yararlanarak güçlü bölgesel ve küresel varlıklara sahip. Üretim süreçlerinde dijital çözümlerin ve otomasyonun artan benimsenmesi, bu önemli oyuncuların operasyonel verimliliğini ve pazar payını daha da artırıyor.

Ekonomik Etkiler ve Tüketici Davranışlarındaki Değişimler

Endüstriyel büyüme, altyapı yatırımları ve üretim teknolojilerindeki gelişmeler gibi ekonomik faktörler metal kesme bant testere pazarını önemli ölçüde etkiler. Pandemi sonrası ekonomik toparlanma, üretim faaliyetlerinin artmasına ve metal kesme aletlerine olan talebin artmasına yol açmıştır. Ayrıca, sürdürülebilir ve verimli üretim uygulamalarına doğru kayma, tüketicileri daha iyi enerji verimliliği ve daha az malzeme israfı sunan yüksek performanslı bant testerelere yatırım yapmaya teşvik etmektedir.

Tüketici davranışı da, çevrimiçi satın alma kanallarına yönelik artan bir tercihle birlikte evrim geçiriyor. Çevrimiçi platformların rahatlığı, ayrıntılı ürün özellikleri ve müşteri incelemelerinin kullanılabilirliğiyle birleşince, geleneksel çevrimdışı kanallardan geçişi yönlendiriyor. Bu eğilimin devam etmesi bekleniyor ve e-ticaret platformları, metal kesme bant testere üreticilerinin dağıtım stratejisinde önemli bir rol oynuyor.

Son Yenilikler ve Ürün Yaşam Döngüsü Aşamaları

Metal kesme bant testere pazarındaki son yenilikler, kesme hassasiyetini, bıçak dayanıklılığını ve operasyonel verimliliği artırmaya odaklanmaktadır. Gelişmiş diş geometrileri, değişken aralıklı tasarımlar ve iyileştirilmiş bıçak kaplamaları gibi yenilikler, gelişmiş performansa katkıda bulunmaktadır. Dahası, IoT ve AI teknolojilerinin bant testere makinelerine entegrasyonu, öngörücü bakım ve gerçek zamanlı performans izlemeyi mümkün kılarak pazarda devrim yaratmaktadır.

Metal kesme bant testere pazarındaki ürün yaşam döngüsü genellikle tanıtım, büyüme, olgunluk ve düşüş aşamalarını içerir. Şu anda pazar, artan ürün benimsemesi, teknolojik ilerlemeler ve çeşitli endüstrilerde genişleyen uygulamalarla karakterize edilen büyüme aşamasındadır. Sürekli Ar-Ge çalışmaları ve yeni, daha verimli ürünlerin tanıtımının önümüzdeki yıllarda bu büyüme ivmesini sürdürmesi bekleniyor.

Metal Kesme Bant Testeresi Seçerken Önemli Faktörler

Bıçak Boyutu ve Tipi

Bıçak boyutu ve türü, metal kesme şerit testeresinin performansını önemli ölçüde etkiler. İnç olarak ölçülen bıçak boyutu, testerenin kesebileceği malzemenin genişliğini ve kalınlığını belirler. Daha büyük bıçak boyutları, endüstriyel uygulamalar için gerekli olan daha kalın ve daha geniş malzemeleri kesmeye olanak tanır. Örneğin, 1/2 inç ila 1 inç genişliğindeki bıçaklar genellikle ağır işlerde kullanılır ve daha fazla stabilite ve hassasiyet sağlar.

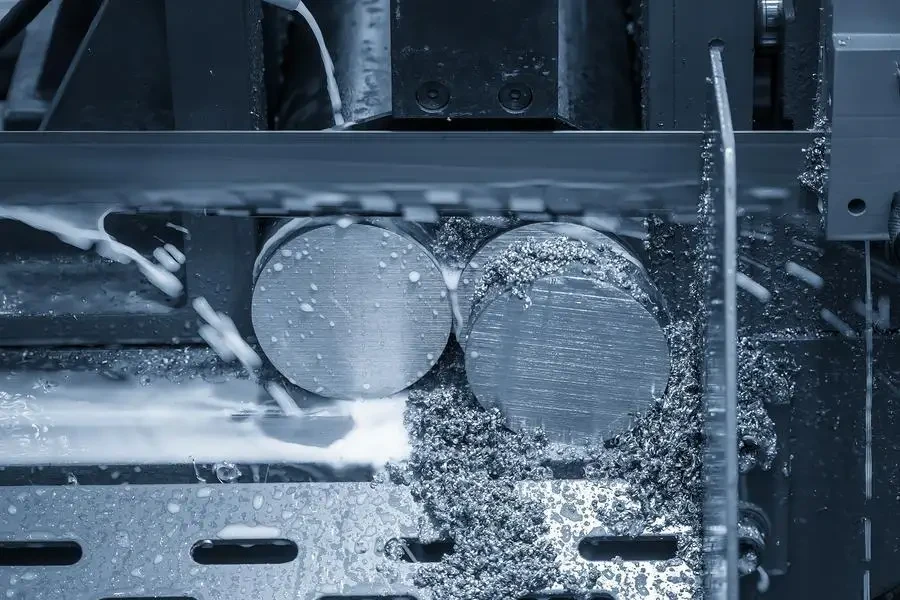

Bıçak dişinin türü de kritik bir rol oynar. İnç başına daha fazla diş sayısına (TPI) sahip bıçaklar, daha pürüzsüz kesimler sağladıkları ve malzeme israfını en aza indirdikleri için ince metal levhaları kesmek için idealdir. Tersine, daha az TPI'ye sahip bıçaklar daha kalın metal parçalar için daha uygundur, daha hızlı kesme hızları ve daha az bıçak aşınması sunar. Bimetal ve karbür uçlu bıçaklar gibi özel bıçaklar, paslanmaz çelik ve titanyum gibi belirli malzemeleri kesmek için tasarlanmıştır, dayanıklılığı ve kesme verimliliğini artırır.

Motor Gücü ve Hızı

Motor gücü ve hızı, bir metal kesme şerit testeresinin kesme yeteneklerini ve verimliliğini belirler. Beygir gücü (HP) olarak ölçülen motor gücü, testerenin çeşitli metal türlerini ve kalınlıklarını kesme yeteneğini doğrudan etkiler. Endüstriyel uygulamalar için, ağır kesme görevleri için gerekli torku sağlayan 1.5 HP ile 3 HP arasında değişen motor gücüne sahip şerit testereler tercih edilir.

Dakikada ayak (FPM) olarak ölçülen kesme hızı, bir diğer kritik faktördür. Değişken hızlı şerit testereler, kesilen malzemeye göre kesme hızını ayarlama esnekliği sunar. Örneğin, daha düşük hızlar (yaklaşık 100 FPM) paslanmaz çelik gibi sert metalleri kesmek için uygundur, daha yüksek hızlar (300 FPM'ye kadar) ise alüminyum gibi daha yumuşak metaller için idealdir. Gelişmiş modeller, hassas ayarlamalar ve kesme performansının optimize edilmesine olanak tanıyan dijital hız kontrollerine sahiptir.

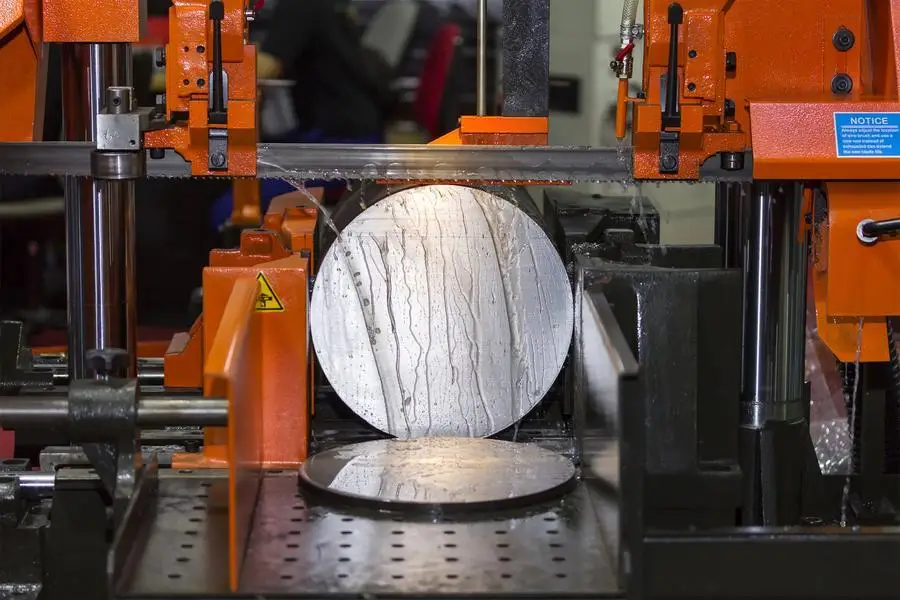

Kesme Kapasitesi ve Boğaz Derinliği

Kesme kapasitesi ve boğaz derinliği, kesilebilecek malzemenin maksimum boyutunu belirler. Kesme kapasitesi, testerenin işleyebileceği malzemenin maksimum genişliğini ve yüksekliğini ifade eder. Daha büyük kesme kapasitelerine sahip şerit testereler, büyük metal parçaları kesmenin yaygın bir gereklilik olduğu endüstriyel uygulamalar için uygundur. Örneğin, 12 inç x 18 inç kesme kapasitesine sahip bir şerit testere, büyük metal iş parçalarını verimli bir şekilde işleyebilir.

Bıçak ile testerenin dikey çerçevesi arasındaki mesafe olan boğaz derinliği, bir diğer kritik husustur. Daha büyük bir boğaz derinliği, yeniden konumlandırmadan daha geniş malzemeleri kesmeye olanak tanır, verimliliği ve doğruluğu artırır. 9 inç ila 14 inç arasında değişen boğaz derinliklerine sahip şerit testereler, metal işleme endüstrilerinde yaygın olarak kullanılır ve çeşitli kesme görevleri için geniş alan sağlar.

Kalite ve Dayanıklılık Oluşturun

Metal kesme bant testeresinin yapı kalitesi ve dayanıklılığı, uzun vadeli performans ve güvenilirlik sağlamak için çok önemlidir. Yüksek kaliteli bant testereler, yapısal bütünlük ve aşınma ve yıpranmaya karşı direnç sağlayan dökme demir ve çelik gibi sağlam malzemeler kullanılarak üretilir. Testerenin çerçevesi ve tablası sert ve sağlam olmalı, titreşimleri en aza indirmeli ve hassas kesimler sağlamalıdır.

Dayanıklılık ayrıca bıçak kılavuzları, yataklar ve kasnaklar gibi bileşenlerin kalitesinden de etkilenir. Birinci sınıf şerit testereler, daha iyi bıçak desteği ve uzun ömür sunan sertleştirilmiş çelik veya karbürden yapılmış ağır hizmet tipi bıçak kılavuzlarına sahiptir. Sızdırmaz yataklar ve hassas taşlanmış kasnaklar daha düzgün çalışmaya ve daha az bakım gereksinimine katkıda bulunur. Üstün yapı kalitesine ve dayanıklı bileşenlere sahip bir şerit testereye yatırım yapmak, tutarlı performans sağlar ve makinenin kullanım ömrünü uzatır.

Güvenlik Özellikleri ve Standartları

Özellikle endüstriyel ortamlarda metal kesme bant testeresi seçerken güvenlik kritik bir husustur. Modern bant testereler operatörleri korumak ve kazaları önlemek için çeşitli güvenlik özellikleriyle donatılmıştır. Bıçak koruyucuları bıçağın açık kısımlarını kaplayarak temas yaralanmaları riskini azaltır. Otomatik kapanma mekanizmaları bıçak kırıldığında veya sıkıştığında testereyi durdurarak daha fazla hasarı önler ve operatör güvenliğini sağlar.

Güvenlik standartlarına ve sertifikalarına uyum da önemlidir. OSHA (Mesleki Güvenlik ve Sağlık İdaresi) yönetmeliklerine uyan ve UL (Underwriters Laboratories) veya CE (Conformité Européene) gibi kuruluşlar tarafından onaylanan bant testereler güvenlik ve kalite güvencesi sunar. Ayrıca, acil durdurma düğmeleri, güvenlik kilitleri ve geri tepme önleyici cihazlar gibi özellikler operasyonel güvenliği artırır ve kaza riskini en aza indirir.

Metal Kesme Bant Testerelerinde İleri Teknoloji

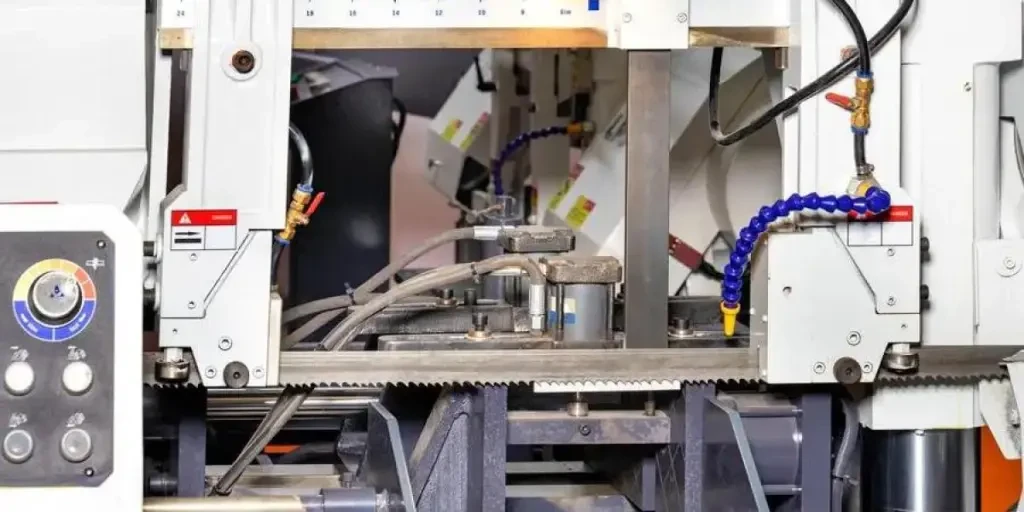

Metal kesme şerit testereleri, performanslarını, hassasiyetlerini ve kullanım kolaylığını artıran önemli teknolojik gelişmelere tanık oldu. Modern şerit testereler, hassas ayarlamalar ve tutarlı kesim sonuçları sağlayan dijital kontroller ve otomasyon özellikleriyle donatılmıştır. CNC (Bilgisayar Sayısal Kontrol) şerit testereler, otomatik kesme işlemlerini etkinleştirerek manuel müdahaleyi azaltır ve verimliliği artırır.

Bir diğer önemli gelişme ise akıllı sensörler ve izleme sistemlerinin entegrasyonudur. Bu sistemler, bıçak gerginliği, kesme hızı ve motor yükü gibi parametreler hakkında gerçek zamanlı geri bildirim sağlayarak operatörlerin bilinçli ayarlamalar yapmasına ve kesme performansını optimize etmesine olanak tanır. Bazı gelişmiş modeller ayrıca, kullanıcıları olası sorunlar hakkında, duruşa yol açmadan önce uyaran öngörücü bakım yeteneklerine sahiptir.

Enerji verimliliği, teknolojinin önemli bir etki yarattığı bir diğer alandır. Yüksek verimli motorlar ve değişken frekanslı sürücüler (VFD'ler) güç tüketimini azaltır ve genel enerji verimliliğini artırır. Ek olarak, gelişmiş soğutma sistemleri ve yağlama mekanizmaları bıçak ömrünü ve kesme performansını artırarak operasyonel maliyetleri ve çevresel etkiyi azaltır.

Pazar Eğilimleri ve Gelecek Görünümü

Metal kesme bant testere pazarı, otomotiv, havacılık ve inşaat gibi çeşitli endüstrilerden gelen artan taleple yönlendirilen istikrarlı bir büyümeye hazırdır. Endüstriyel otomasyondaki artış ve akıllı üretim uygulamalarının benimsenmesinin, dijital kontroller ve otomasyon özelliklerine sahip gelişmiş bant testerelere olan talebi daha da artırması bekleniyor.

Sürdürülebilirlik de üreticilerin çevre dostu teknolojilere ve malzemelere yatırım yapmasıyla önemli bir odak alanı haline geliyor. Enerji tasarruflu şerit testerelerin geliştirilmesi ve yapımında geri dönüştürülebilir malzemelerin kullanılması, küresel sürdürülebilirlik hedefleri ve düzenleyici gerekliliklerle uyumludur.

Gelecekte, AI (Yapay Zeka) ve IoT'nin (Nesnelerin İnterneti) önemli bir rol oynamasıyla otomasyon ve dijitalleşmede daha fazla ilerleme bekleyebiliriz. Uyarlanabilir kesme yetenekleri ve gerçek zamanlı optimizasyon özelliklerine sahip AI destekli şerit testereler üretkenliği ve hassasiyeti artıracaktır. Uzaktan izleme ve kontrol yeteneklerine sahip IoT özellikli şerit testereler daha fazla esneklik ve operasyonel verimlilik sağlayarak metal kesme şerit testere pazarında bir sonraki yenilik dalgasını yönlendirecektir.

Son Düşüncelerimiz

Doğru metal kesme şerit testeresini seçmek, bıçak boyutu ve türü, motor gücü ve hızı, kesme kapasitesi, yapı kalitesi ve güvenlik özellikleri gibi çeşitli faktörlerin dikkatli bir şekilde değerlendirilmesini gerektirir. Gelişmiş teknoloji ve pazar eğilimleri, şerit testerelerin geleceğini şekillendiriyor ve gelişmiş performans, hassasiyet ve sürdürülebilirlik sunuyor. Bu gelişmeler hakkında bilgi sahibi olarak, işletmeler bilinçli kararlar alabilir ve belirli ihtiyaçlarını karşılayan ve operasyonel verimliliği artıran şerit testerelere yatırım yapabilir.