Power trowels are devices used in construction to finish and smooth concrete surfaces. These mechanical wonders replace labor-intensive manual methods with rotating blades that level and polish freshly poured concrete. The global popularity of power trowels stems from their ability to drastically reduce labor, expedite projects, enhance durability, and ensure consistent quality finishes.

However, selecting a suitable power trowel can be challenging with so many available models. This guide gives insight into the different types of power trowels available and tells buyers how to buy suitable machines for their businesses.

Table of Contents

Power trowel market share

Types of power trowels

The ultimate guide to purchasing power trowel

Summary

Power trowel market share

The power trowel market has experienced robust growth due to increased construction activities globally, the need for efficient concrete surface finishing, and the drive for quicker project turnaround times. According to a report published by Expert Market Research, the global ride-on power trowel market is projected to grow at a CAGR of 4.4% from 2023 to 2028.

The demand for power trowels is exceptionally high in regions witnessing rapid urbanization and infrastructure development, such as North America, Europe, and Asia-Pacific, with countries like China and India.

Types of power trowels

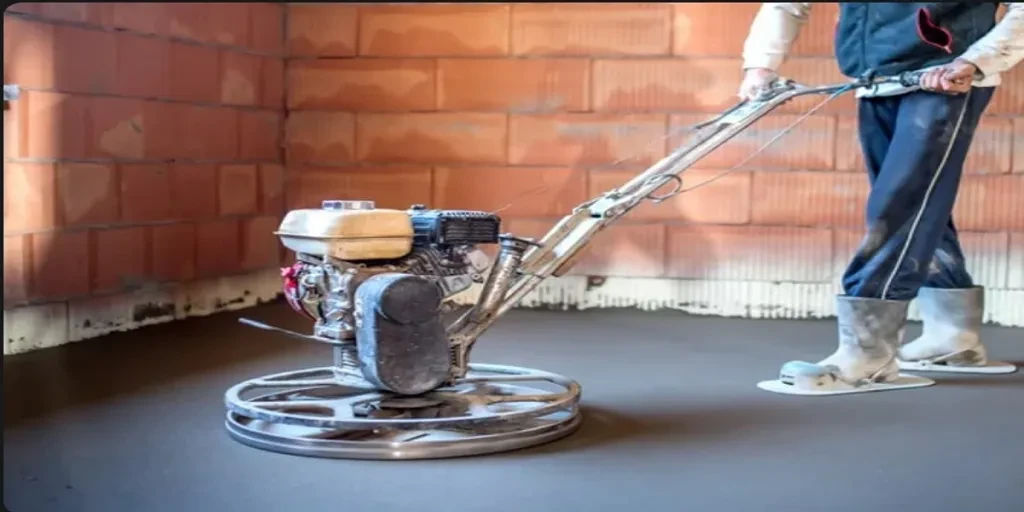

1. Walk-behind power trowel

Walk-behind power trowels are handheld and operated by a person walking behind them. They are perfect for smaller projects or areas where maneuverability is key. Walk-behind power trowels typically have one or two blades that rotate to smooth and level the concrete surface. They are commonly used for tasks like finishing garage floors, patios, and other confined spaces where larger equipment might struggle to reach.

Walk-behind power trowels handle approximately 100 to 200 square feet of concrete finishing per hour. They operate at speeds ranging from 60 to 100 RPM, with prices typically starting at around USD 1,000 for basic models and going up to USD 5,000 for more advanced options.

Pros

– Ideal for smaller projects and tight spaces

– Cost-effective and accessible for small contractors

– Lower fuel and maintenance costs

Cons

– Limited capacity for larger projects

– Operates at slower speeds, extending the finishing time

– Requires physical effort to walk behind the machine

2. Ride-on power trowel

Designed for larger projects, ride-on power trowels are operated by an operator who rides on the machine. They offer greater power and coverage, ideal for finishing vast concrete surfaces like warehouse floors, airport runways, and large industrial complexes. Ride-on power trowels often feature multiple blades that can be adjusted to achieve the desired smoothness and flatness across expansive areas.

Ride-on power trowels boast significantly higher capacities, averaging 250 to 500 square feet per hour. They operate at 25 to 150 RPM speeds, with prices starting at approximately USD 5,000 and reaching USD 10,000 or more for advanced models.

Pros

– High capacity for large projects

– Operates at faster speeds, reducing finishing time

– Operator comfort

Cons

– Higher upfront and operational costs

– Reduced maneuverability in confined spaces

– May require specialized operator training

3. Edging power trowel

Edging power trowels are specialized tools for achieving a polished finish along the edges of concrete slabs. Their smaller size and design allow them to work close to walls and corners precisely, ensuring that the edges match the quality of the central surface. These power trowels are valuable for maintaining consistency and aesthetic appeal in spaces with prominently visible edges.

Edging power trowels handle around 50 to 100 square feet of concrete finishing per hour. They typically operate at speeds between 60 and 120 RPM, and prices range from USD 500 to USD 1,500, depending on features.

Pros

– Precision for edge and corner work

– Maneuverable and cost-effective for specific tasks

– Affordable for specialized applications

Cons

– Limited capacity for large surfaces

– Operates at slower speeds compared to larger trowels

– Primarily designed for edging work

4. Finish power trowel

Also known as combination power trowels, finish power trowels offer versatility by allowing operators to switch between floating and finishing functions. They are equipped with adjustable pitch blades set to different angles, making them suitable for early-stage concrete leveling and final surface smoothing. This flexibility reduces the need for multiple passes, saving time and effort in achieving the desired concrete texture.

Finish power trowels achieve concrete finishing rates of about 300 to 500 square feet per hour, similar to ride-on trowels. They operate at speeds ranging from 40 to 150 RPM, with prices starting at USD 3,000 for basic models and going up to USD 8,000 or more for advanced options.

Pros

– Versatility with floating and finishing functions

– Efficient concrete leveling and smoothing in one machine

– Moderate capacity suitable for various projects

Cons

– Moderate capacity compared to dedicated ride-on trowels

– Price variability based on features and capabilities

– May require operator training for adjustable pitch blades

5. Helicopter power trowel

Helicopter power trowels cover extensive areas efficiently. They often have multiple sets of high-speed rotating blades that work together to provide a uniform finish across vast stretches of concrete. Helicopter power trowels are commonly employed in projects like highways, bridges, and airport runways, where achieving a consistently smooth surface is paramount.

Pros

– High capacity for large-scale projects

– Rapid finishing with multiple blade sets

– Achieves a consistently smooth surface for critical projects

Cons

– High initial cost due to power and capabilities

– Unsuitable for confined spaces or smaller projects

– Requires operator training for handling intricacies

The ultimate guide to purchasing power trowel

1. Power source

Power trowels come in electric, gas, or propane engines. Electric models shine indoors, offering an eco-friendly, low-noise option, though they require access to a power outlet. Meanwhile, gas and propane options flaunt mobility, suited for moving around like true adventurers. Admittedly, they are a touch louder and bring fumes into the scene. Ultimately, your chosen power source should harmonize with the project’s location, scale, and environmental considerations.

2. Cost

Think about how long the power trowel will last and how easy it is to maintain. Sometimes, putting your money into a dependable and long-lasting power trowel is the best move.

Power trowels can vary widely in price depending on the type and features. Walk-behind models could start at around USD 1,000 and go up to USD 5,000 or more. Ride-on power trowels, being larger and more powerful, can range from USD 6,000 to USD 15,000 or beyond.

3. Blade diameter

The size of the power trowel blade has a big say in how much ground it can cover and the quality of the finish. Bigger blades, for instance, can sweep through more area in a single go, which ramps up the efficiency. But, when dealing with cramped spaces or projects that require delicate detailing, a smaller blade diameter might be the wiser choice.

Walk-behind power trowels usually have blade diameters that range from around 24 to 46 inches. Conversely, ride-on power trowels can pack more blades, ranging from 46 to 96 inches.

4. Number of blades

The number of blades a power trowel rocks can be the deciding factor in achieving that sleek finish. More blades often mean high-shine polish, but the machine might need extra oomph.

The number of blades varies across trowel types: walk-behind models usually feature 2 to 4 blades, ride-on trowels can range from 4 to 8 blades, edging trowels typically have 1 to 2 blades, finish trowels often sport 4 to 6 blades, and larger ride-on variants, often termed as “helicopter” trowels, can incorporate 8 or more blades for expansive projects.

5. Suitability

Focus on the type of concrete the power trowels will be working on, the exact finish needed, how much space is available to move around, and how quickly things need to be done. A walk-behind trowel might be the best if it is a smaller gig. But if the area is sprawling, the ride-on models take the lead. Edging trowels are the go-to for those precise finishing touches along the edges.

Summary

The world of power trowels demands carefully considering factors that directly shape the concrete finishing success. Each choice molds the project’s outcome from power sources to blade details. Whether a small task or a grand project, grasping power trowel intricacies empowers intelligent decisions. For a diverse array of power trowel options, explore Chovm.com.

বাংলা

বাংলা Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português Русский

Русский Español

Español Kiswahili

Kiswahili ไทย

ไทย Türkçe

Türkçe اردو

اردو Tiếng Việt

Tiếng Việt isiXhosa

isiXhosa Zulu

Zulu