Rack and pinion systems are pivotal in the machinery world, translating rotational motion into linear motion with precision and efficiency. This guide aims to demystify the complexities surrounding these mechanisms, offering a deep dive into their operation, benefits, applications, and maintenance strategies. Whether you’re a seasoned engineer or a curious novice, understanding rack and pinion systems can significantly impact your approach to machinery design and functionality.

Table of Contents:

– What is a rack and pinion?

– Key applications of rack and pinion systems

– Benefits of using rack and pinion

– Maintenance tips for rack and pinion systems

– Future trends in rack and pinion technology

What is a rack and pinion?

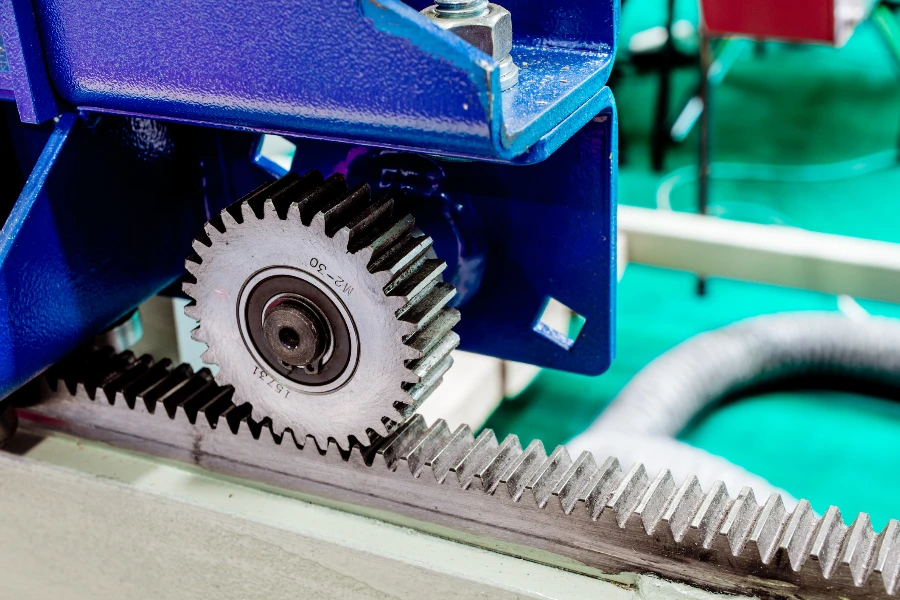

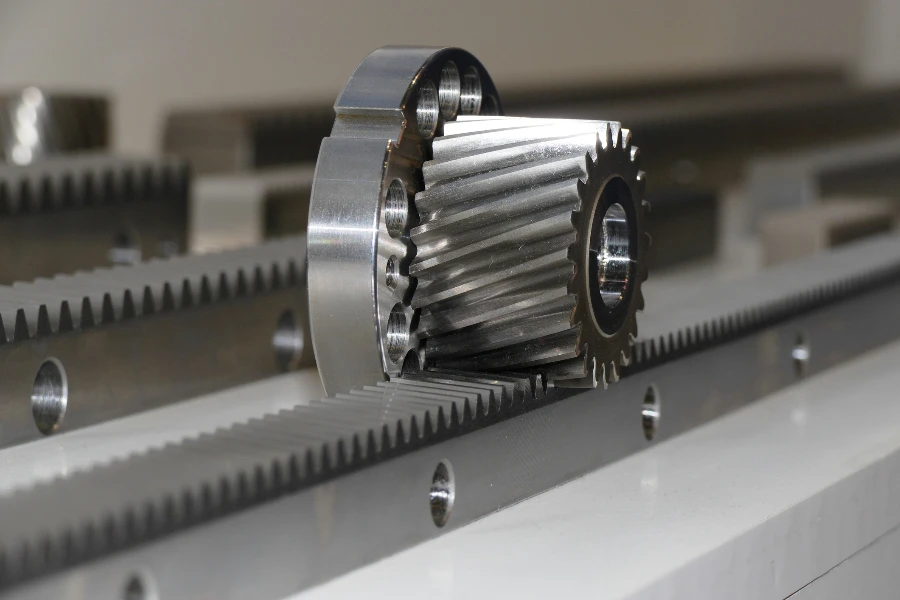

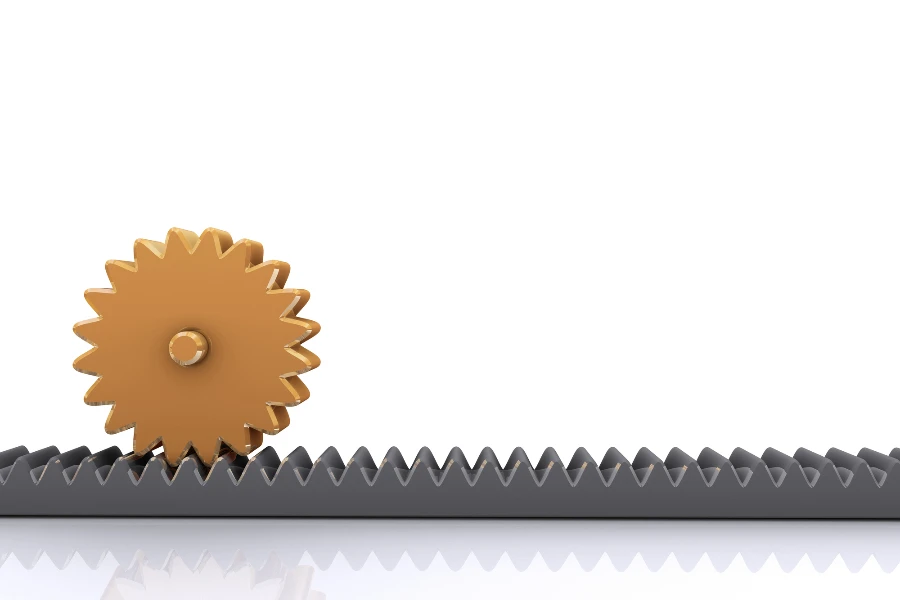

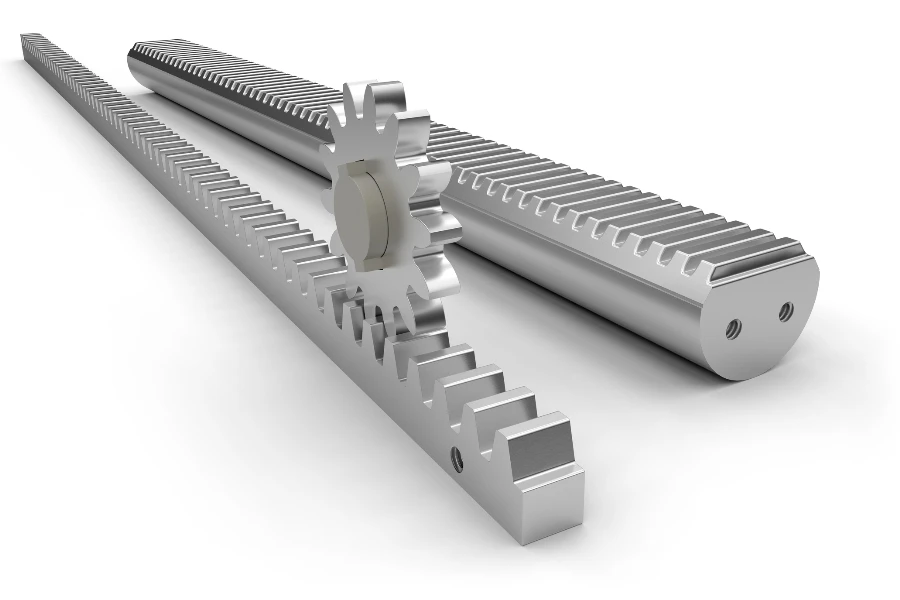

Rack and pinion systems are fundamental in converting rotational movements into linear motions. At the heart of this mechanism is the pinion, a small gear wheel that engages with a linear gear bar known as the rack. When the pinion rotates, it drives the rack to move linearly. This interaction forms the basis of many machines and devices, offering a simple yet effective solution for motion conversion.

Understanding the mechanics of rack and pinion systems is crucial for anyone involved in machinery design or maintenance. The precision and efficiency of these systems depend on several factors, including the materials used, the gear ratio, and the quality of the engagement between the rack and pinion. By grasping these concepts, one can appreciate the elegance and utility of rack and pinion systems in various applications.

The design considerations for rack and pinion systems are vast and varied. Engineers must account for factors such as load capacity, speed requirements, and environmental conditions. This ensures that the system not only performs optimally but also withstands the rigors of its intended application. The choice of materials, from hardened steel to plastic, plays a significant role in the system’s durability and performance.

Key applications of rack and pinion systems

Rack and pinion systems find their place in numerous applications, showcasing their versatility and reliability. One of the most common uses is in the automotive industry, where they serve as the core component of steering mechanisms. By converting the rotational motion of the steering wheel into the linear motion needed to turn the wheels, rack and pinion systems provide drivers with precise control over their vehicles.

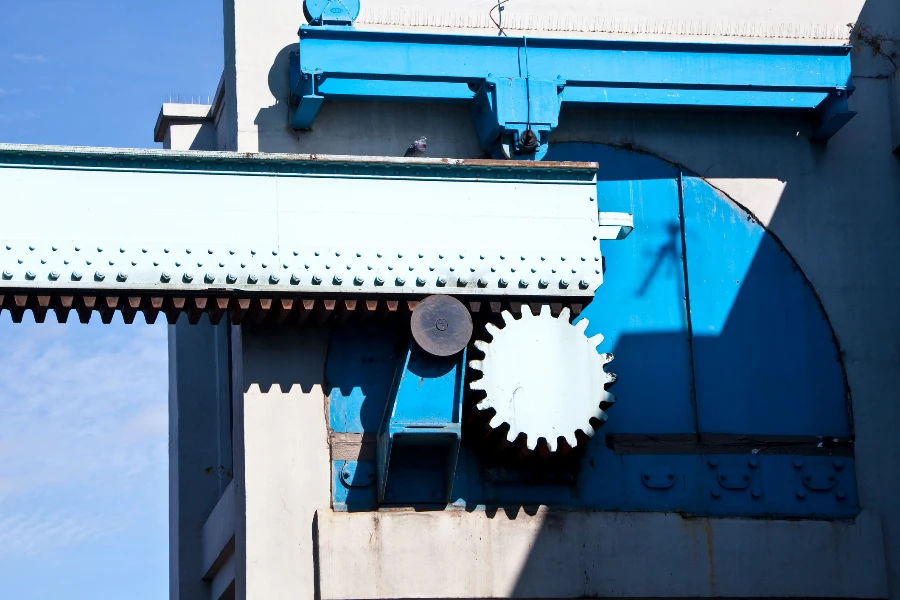

Another significant application is in the field of manufacturing and automation. Here, rack and pinion systems are integral to the movement of machinery and equipment, facilitating smooth and accurate positioning. Whether it’s in CNC machines or assembly lines, the precision afforded by these systems is indispensable for modern manufacturing processes.

In addition to automotive and manufacturing applications, rack and pinion systems are also prevalent in construction and entertainment industries. From moving heavy loads in construction equipment to creating dynamic stage effects in theaters, the applications of rack and pinion systems are as diverse as they are critical.

Benefits of using rack and pinion

The adoption of rack and pinion systems comes with a host of benefits. Primarily, these systems offer unmatched precision in motion control. The direct engagement between the rack and pinion allows for accurate and consistent movement, which is vital in applications requiring exact positioning.

Moreover, rack and pinion systems boast high efficiency and reliability. The simplicity of their design minimizes the risk of failure, ensuring long-term operation with minimal maintenance. This efficiency is particularly beneficial in high-speed applications, where the system’s ability to swiftly convert motion is paramount.

Lastly, the scalability of rack and pinion systems makes them suitable for a wide range of applications. From small gadgets to large industrial machines, the principles of rack and pinion can be applied universally, allowing for versatile design solutions that cater to specific needs.

Maintenance tips for rack and pinion systems

Maintaining rack and pinion systems is essential for ensuring their longevity and performance. Regular inspection is the first step in identifying potential issues, such as wear and tear on the teeth of the rack and pinion. Early detection of these problems can prevent more significant issues down the line.

Lubrication plays a critical role in the maintenance of rack and pinion systems. Proper lubrication reduces friction between the rack and pinion, minimizing wear and extending the system’s lifespan. Selecting the right type of lubricant, and applying it correctly, is crucial for effective maintenance.

Another important aspect of maintenance is alignment. Ensuring that the rack and pinion are correctly aligned prevents uneven wear and optimizes the system’s efficiency. Regular checks and adjustments can help maintain optimal alignment, contributing to the system’s overall reliability.

Future trends in rack and pinion technology

The evolution of rack and pinion technology is closely tied to advancements in materials science and manufacturing techniques. As these fields progress, we can expect to see rack and pinion systems that are lighter, stronger, and more efficient. The integration of smart technologies, such as sensors and IoT devices, will further enhance the capabilities of these systems, allowing for real-time monitoring and adjustment.

Sustainability is another area of focus for the future of rack and pinion systems. The development of eco-friendly materials and manufacturing processes will contribute to more sustainable machinery designs. This aligns with the broader industry trend towards reducing environmental impact and promoting sustainable practices.

In conclusion, rack and pinion systems are set to become even more integral to the machinery and technology of the future. Their simplicity, efficiency, and versatility make them indispensable in a wide range of applications. As technology advances, the potential for innovation in rack and pinion systems is boundless, promising exciting developments on the horizon.

Conclusion:

Rack and pinion systems are the unsung heroes of the machinery world, offering precision, efficiency, and versatility across a myriad of applications. From steering our cars to facilitating advanced manufacturing processes, these mechanisms play a crucial role in our daily lives and the economy. By understanding their operation, benefits, and maintenance, we can better appreciate the technology and anticipate future advancements. As we look towards a future of innovation, the humble rack and pinion system remains at the heart of mechanical design and functionality, promising to drive progress in countless fields.

বাংলা

বাংলা Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português Русский

Русский Español

Español Kiswahili

Kiswahili ไทย

ไทย Türkçe

Türkçe اردو

اردو Tiếng Việt

Tiếng Việt isiXhosa

isiXhosa Zulu

Zulu