Các doanh nghiệp cung cấp trái cây và rau quả cho bán lẻ thương mại thường được yêu cầu rửa và làm sạch sản phẩm trước khi giao hàng. Mặc dù có nhiều máy có thể làm được điều này, nhưng trước tiên người mua phải biết loại nào phù hợp nhất với nhu cầu cụ thể của mình.

Từ máy rửa nhỏ ở phân khúc thương mại thấp đến máy tích hợp trong dây chuyền chế biến, chúng ta sẽ xem xét những điều cơ bản về máy rửa trái cây và rau củ và cung cấp ví dụ về những máy tốt nhất hiện có cho các nhu cầu khác nhau.

Mục lục

Thị trường máy rửa trái cây và rau quả toàn cầu

Máy rửa trái cây và rau quả là gì?

Tại sao phải rửa trái cây và rau quả?

Các loại máy rửa trái cây và rau quả

Ví dụ về các loại máy rửa trái cây và rau quả khác nhau

Máy giặt bong bóng

Máy rửa bong bóng có băng tải

Bồn rửa bọt khí mở rộng

Máy giặt bong bóng với bàn chải lột

Dây chuyền chế biến rửa rau quả

Lời cuối

Thị trường máy rửa trái cây và rau quả toàn cầu

Việc bán trái cây và rau quả là một ngành công nghiệp toàn cầu khổng lồ, cung cấp cho một thế giới ngày càng khắt khe. Để theo kịp nhu cầu và đảm bảo năng suất cây trồng chất lượng cao nhất, nông dân dựa vào nhiều loại phân bón hóa học để thúc đẩy tăng trưởng và thuốc trừ sâu để giảm tác hại của côn trùng, vi khuẩn và nấm. Nhiều loại trong số này có thể gây hại cho người tiêu dùng và phải loại bỏ trước khi ăn.

Ngoài ra, do nông sản ngày càng được vận chuyển ra nước ngoài nên có nguy cơ gây ô nhiễm chéo đến các hệ sinh thái khác, đưa các sinh vật nguy hiểm vào nguồn cung cấp thực phẩm của chính họ.

Những yếu tố kết hợp này đang thúc đẩy nhu cầu toàn cầu ngày càng tăng đối với máy rửa trái cây và rau quả thương mại, với thị trường toàn cầu về máy rửa trái cây và rau quả đạt 3.97 tỷ USD vào năm 2023 và mong đợi được chứng kiến một Tỷ lệ tăng trưởng kép hàng năm 6.4% (CAGR) đến năm 2030.

Máy rửa trái cây và rau quả là gì?

Tại sao phải rửa trái cây và rau quả?

Cho dù sản phẩm được trồng ở trang trại hay trong vườn nhà, có một số lý do tại sao chúng ta nên rửa sạch trái cây và rau quả trước khi sử dụng.

Đầu tiên là rửa sạch đất và các chất bẩn khác vì lý do thẩm mỹ và vệ sinh. Ví dụ, cần loại bỏ côn trùng và vi khuẩn để ngăn ngừa ô nhiễm tiềm ẩn hoặc các bệnh do thực phẩm.

Ngoài ra, nhiều sản phẩm nông trại và vườn trồng ngày nay được xử lý bằng phân bón tự nhiên hoặc hóa học bổ sung chất dinh dưỡng cho đất và thúc đẩy tăng trưởng, cũng như thuốc trừ sâu để ngăn ngừa nhiều loại sinh vật phá hoại mùa màng. Những hóa chất này cũng phải được rửa sạch khỏi trái cây và rau quả trước khi bán và sử dụng.

Các loại máy rửa trái cây và rau quả

Các thành phần chính của máy rửa trái cây và rau quả thương mại bao gồm một bể rửa, được làm bằng thép không gỉ cấp thực phẩm, các tia nước để rửa và rửa sạch sản phẩm, một máy bơm xả và xả để loại bỏ nước đã qua sử dụng và một bảng điều khiển. Sản phẩm được cho vào bể nước hoặc bồn tắm – trong đó có chất tẩy rửa hoặc thuốc thử cấp thực phẩm – sau đó được ngâm và rửa sạch.

Có ba cách chính để rửa trái cây và rau quả: phun nước, ngâm sản phẩm vào nước hoặc kết hợp cả hai.

Việc ngâm có nguy cơ lây nhiễm chéo vì bất kỳ mầm bệnh nào hiện diện đều có thể lưu thông trong toàn bộ sản phẩm. Tuy nhiên, việc phun cũng có rủi ro vì việc bắn tung tóe có thể gây lây nhiễm chéo.

Những rủi ro tiềm ẩn này nhấn mạnh tầm quan trọng của việc thêm chất tẩy rửa phù hợp với trái cây và rau quả, đảm bảo lọc và thoát nước đã qua sử dụng đúng cách và rửa sạch sản phẩm.

Phương pháp giặt phổ biến nhất là phương pháp ngâm nước gọi là giặt bong bóng, sử dụng bong bóng để khuấy nước trong bể chứa, giúp hòa tan và kích hoạt chất tẩy rửa, đồng thời tạo điều kiện cho nước lưu thông.

Các thành phần bổ sung có thể tìm thấy trong máy giặt bao gồm:

- Vòi phun nước, trước, trong và sau khi rửa bọt

- Bàn chải để tăng thêm khả năng làm sạch hoặc thêm chức năng lột da

- Một băng chuyền để di chuyển sản phẩm qua bồn nước đến các quy trình khác

- Làm khô bằng không khí dọc theo đường đi của băng tải

Ví dụ về các loại máy rửa trái cây và rau quả khác nhau

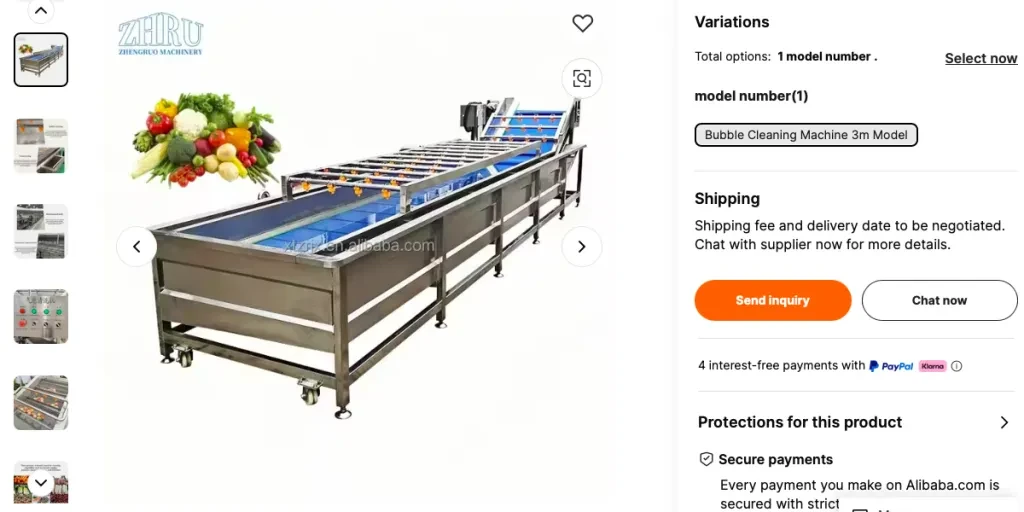

Máy giặt bong bóng

Một chức năng đơn giản máy giặt bong bóng, chẳng hạn như hình minh họa ở trên, hoạt động như một bể nước, có công tắc điều khiển để cài đặt nhiệt độ, thêm chất tẩy rửa hoặc chất khử trùng, bật và tắt chế độ khuấy bọt, lọc cặn và xả nước.

Có thể rửa sạch nhiều loại trái cây và rau quả bằng máy này, bao gồm cả rau củ có rễ cứng cũng như trái cây mềm và rau lá rời. Sản phẩm được đặt trong bồn và được rửa nhẹ nhàng trước khi xả nước và lấy sản phẩm ra.

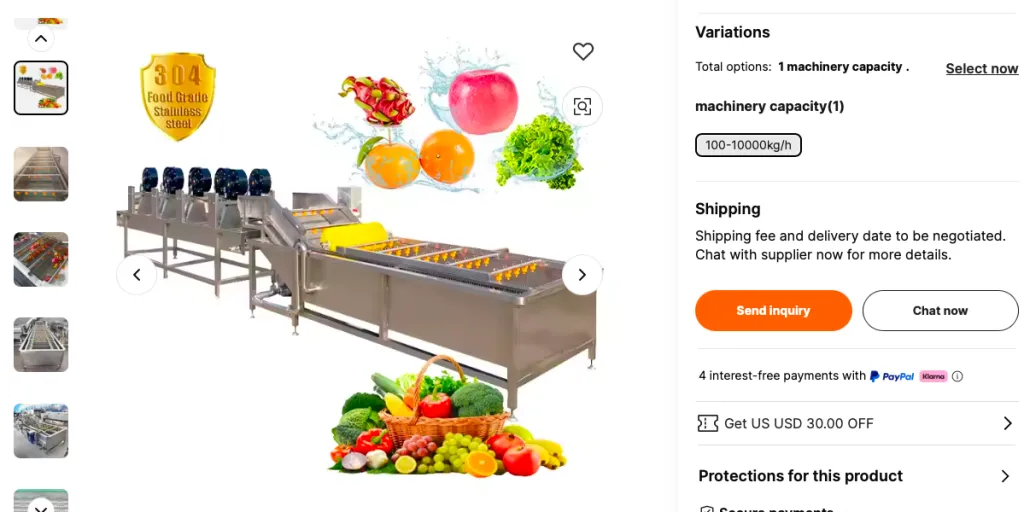

Máy rửa bong bóng có băng tải

Trong tạp chí máy rửa bong bóng tự động ở trên, nước khuấy được sử dụng để rửa, sau đó là một băng tải nhỏ để chiết xuất sản phẩm. Trái cây và rau quả được cho vào bồn tắm thủ công, tại đó các tia nước phun vào sản phẩm và được di chuyển chậm dọc theo băng tải trước khi được sấy khô bằng máy thổi khí.

Máy rửa này có cơ chế hoạt động nhẹ nhàng, phù hợp với các loại rau lá cũng như trái cây và rau củ mềm.

Bản đồ này cho thấy các thành phần riêng lẻ của cùng một máy, bao gồm các ống phun phía trên bể chứa nước và cửa thoát nước thải. Hệ thống điều khiển bao gồm một máy bơm nước, hệ thống chu trình nước (rửa bọt), một bộ biến tần và một máy thổi.

Hình ảnh trên cho thấy điều này máy rửa trái cây và rau quả Sức chứa. Những quả táo được đưa vào bồn nước, được rửa sạch bằng bọt khí trong khi di chuyển, sau đó được băng tải nâng lên và rửa sạch bằng các vòi phun được bố trí dọc theo băng tải.

Bồn rửa bọt khí mở rộng

Một số biến thể của máy rửa trái cây và rau quả có bồn rửa mở rộng và băng tải đầu ra ngắn. Mô hình trên là máy giặt trống quay thương mại, và có bồn tắm mở rộng với vòi phun rửa dọc theo chiều dài, cũng như vòi phun rửa ở phần nâng cao của băng tải (trống quay). Ở đầu băng tải, sản phẩm được thả vào thùng chứa phải được đổ thủ công khi đầy.

Vì đây là máy rửa ngập nước có băng tải ngắn và không có chổi vệ sinh nên phù hợp với nhiều loại trái cây và rau quả.

Tất cả các mô hình được đề cập ở trên đều sử dụng phương pháp rửa bong bóng tương tự, với chuyển động băng tải và sấy khô bằng không khí. Tuy nhiên, cũng có một số thiết kế khác nhau.

Ví dụ, mô hình trên được quảng cáo là máy rửa rau quả thương mại cho khách sạn và sử dụng cơ chế bốn bồn, bốn xô, với mỗi xô tự động nâng sản phẩm từ bồn này và đổ vào bồn tiếp theo, tiến triển từ rửa sang tráng. Vào cuối quy trình, sản phẩm đã rửa sẽ đi qua phễu dẫn hướng vào thùng có thể tháo rời hoặc thùng chứa khác.

Máy giặt bong bóng với bàn chải lột

Một số mẫu máy giặt cũng có bàn chải để làm sạch và lột thêm. Máy giặt ở trên, được mô tả như một máy rửa rau củ quả thương mại máy gọt vỏ Máy sử dụng phương pháp phun và nhúng để rửa sản phẩm, nhưng cũng có con lăn chải, giúp làm sạch và lột sâu hơn.

Vì quá trình này có tính mài mòn nên không phù hợp với các loại trái cây mềm và rau lá xanh, mà phù hợp với các loại rau củ có rễ cứng như khoai tây, khoai lang, cà rốt, củ cải, củ cải Thụy Điển và sắn.

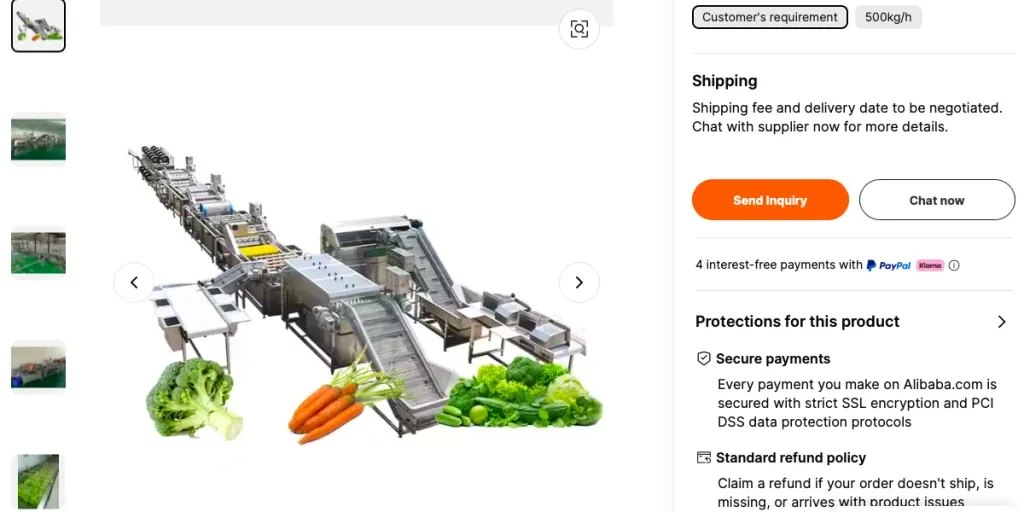

Dây chuyền chế biến rửa rau quả

Phía trên là một máy giặt có chứa trái cây và dây chuyền sản xuất rau quả có nhiều chức năngMáy rửa bọt khí sử dụng chuyển động lăn và chải bên trong bình chứa nước và có thêm vòi phun nước để rửa sạch.

Máy có thể được tùy chỉnh với một bàn sấy mở rộng phù hợp sau quá trình rửa. Cơ chế này đủ nhẹ nhàng để rửa rau lá và các sản phẩm mềm.

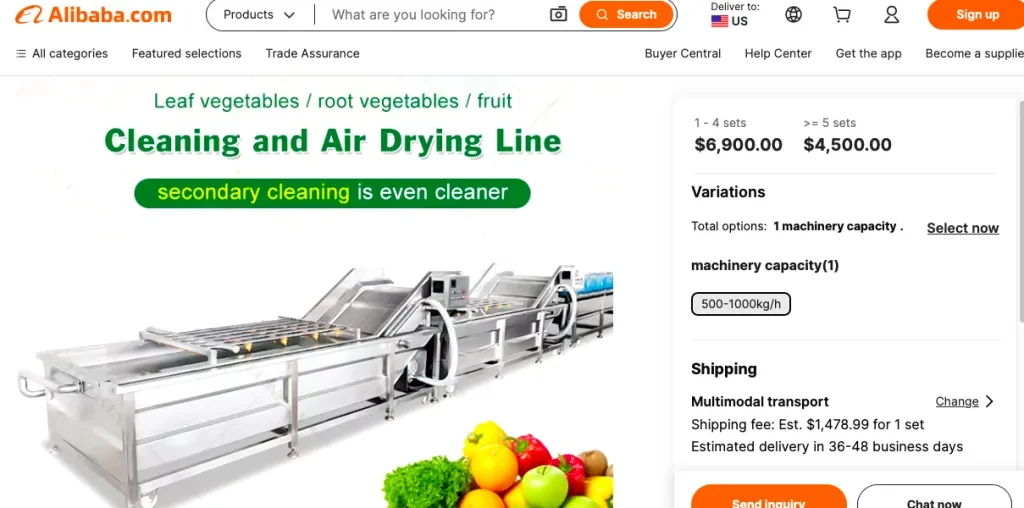

Máy rửa trái cây và rau quả có thể được tích hợp vào dây chuyền chế biến đa chức năng dài, như minh họa ở trên. Băng tải nạp liệu di chuyển sản phẩm đến bồn rửa, trong khi các trạm bổ sung phân loại và xử lý, trước khi băng tải mở rộng làm khô và thực hiện các xử lý khác.

Một dây chuyền sản xuất thay thế để rửa trái cây và rau quả là đặt máy rửa nối tiếp nhau theo phương pháp rửa tuần tự. Trong ví dụ trên, một dây rửa trái cây và rau quả di chuyển sản phẩm qua nhiều lần rửa, sau đó là dây phơi.

Phương pháp này cung cấp tính linh hoạt cao hơn, vì mỗi bồn rửa có thể được sử dụng để làm sạch và tách sản phẩm, giảm thiểu ô nhiễm. Quá trình rửa bong bóng ban đầu loại bỏ bụi bẩn và côn trùng, sau đó là bồn rửa thuốc thử để loại bỏ cặn thuốc trừ sâu, một giai đoạn để rửa sạch và một phần cuối cùng để sấy khô.

Lời cuối

Máy rửa trái cây và rau quả có nhiều kiểu dáng, phổ biến nhất là sự kết hợp giữa kiểu phun và kiểu ngâm. Một số mẫu chỉ có bồn rửa, và một số khác sử dụng hệ thống băng tải để di chuyển sản phẩm qua quá trình rửa và vào hệ thống con lăn ngắn hoặc dài. Hầu hết các mẫu băng tải này đều có hệ thống rửa phun và nhiều mẫu còn có quạt gió để làm khô sản phẩm. Một số phiên bản cũng bao gồm hệ thống chổi, sử dụng chổi lăn để làm sạch mài mòn hơn, cũng như chức năng lột vỏ.

Điều quan trọng là người mua phải xác định rõ loại trái cây và rau quả mà họ định rửa. Hệ thống ngâm thường khá nhẹ nhàng và phù hợp với hầu hết các loại trái cây và rau quả cứng và mềm. Trong khi đó, phun nước làm tăng thêm mức độ làm sạch và rửa sạch có thể hữu ích khi rửa các sản phẩm có hình dạng không đều như rau lá và rau họ cải. Cuối cùng, các máy có cơ chế chải phù hợp nhất với các loại rau củ cứng như cà rốt và khoai tây.

Các doanh nghiệp thương mại lớn hơn có thể lựa chọn máy sản xuất băng tải dài hơn, cho phép xử lý khối lượng lớn cũng như nhiều giai đoạn rửa hoặc sấy khô.

Để biết thêm thông tin về nhiều loại máy rửa trái cây và rau quả có sẵn, hãy xem AliExpress phòng trưng bày.

Afrikaans

Afrikaans አማርኛ

አማርኛ العربية

العربية বাংলা

বাংলা Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português Русский

Русский Español

Español Kiswahili

Kiswahili ไทย

ไทย Türkçe

Türkçe اردو

اردو Tiếng Việt

Tiếng Việt isiXhosa

isiXhosa Zulu

Zulu