The walking foot sewing machine market has seen significant advancements in 2025, driven by technological innovations and shifting consumer demands. This article will delve into key factors for selecting the best walking foot sewing machine, offering professional buyers valuable insights and comprehensive guidance.

Table of Contents:

1. Market Overview of Walking Foot Sewing Machine

2. Detailed Analysis of Walking Foot Sewing Machine Market

3. Key Factors When Selecting a Walking Foot Sewing Machine

4. Importance of Material Compatibility

5. Safety Standards and Certifications

6. Upgradability and Future-Proofing

7. Packaging Quality and Shipping Considerations

8. Summing Up

Market Overview of Walking Foot Sewing Machine

The walking foot sewing machine market has been experiencing steady growth and is expected to continue upward. As of 2024, the global sewing machine market size reached USD 6.8 billion, with a projected growth rate (CAGR) of 4.7% from 2023 to 2032. Walking foot sewing machines are known for their ability to handle multiple layers of fabric and heavy materials. They are increasingly in demand across various industries, including automotive, upholstery, and fashion.

The market shows significant regional variations. The Asia-Pacific region, particularly China, Japan, and India, dominates the manufacturing and consumption of sewing machines. In the Americas, the United States and Canada are key markets, driven by consumer preferences for quality and advanced features. In Europe, there is strong demand for high-quality, durable, and environmentally friendly sewing machines, reflecting the region’s commitment to sustainability.

Technological advancements, such as the integration of IoT and big data in sewing machines, are enhancing production efficiency and driving market growth. Innovations in computerized and embroidery machines are also contributing to the expanding market. The global sewing machine market is expected to reach USD 10.3 billion by 2032, highlighting the growing demand for advanced sewing solutions.

Detailed Analysis of Walking Foot Sewing Machine Market

Walking foot sewing machines are known for their robust performance, especially in handling thick and multiple layers of fabric. These machines are essential in industries requiring precision and consistency in stitching heavy materials. The market for walking foot sewing machines is influenced by several factors, including technological advancements, consumer behavior shifts, and economic influences.

Key performance benchmarks for walking foot sewing machines include stitch quality, speed, and durability. Manufacturers are enhancing these features to meet the growing demand for high-performance sewing machines. The market is also shifting towards digitalization, with computerized controls and automation improving efficiency and reducing manual intervention.

Consumer behavior is moving towards DIY fashion and home decor, driving demand for both basic and advanced sewing machines. The expanding global fashion sector necessitates efficient and high-quality sewing equipment to keep up with fast-changing trends. Distribution channels are evolving, with a growing preference for online platforms due to their convenience and broader reach.

Recent innovations in sewing machines include energy-efficient models and the use of sustainable materials, aligning with the global trend towards environmental sustainability. Manufacturers are focusing on longer-lasting and easily maintainable models to reduce environmental impact.

Customer pain points in the sewing machine market include the complexity of operating advanced machines and high initial costs. Manufacturers address these issues by offering user-friendly interfaces and financing options. Brand positioning strategies increasingly focus on quality, innovation, and sustainability to differentiate products in a competitive market.

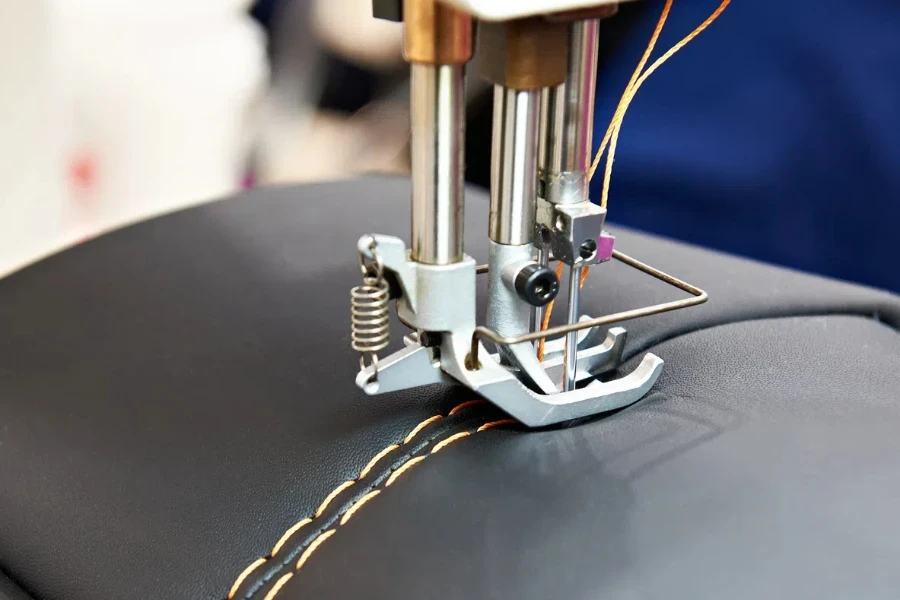

Niche markets for walking foot sewing machines include custom upholstery businesses, automotive seat manufacturing, and high-end fashion design. These markets demand specialized machines that offer high precision. Differentiation strategies in these markets include offering customized solutions and superior after-sales support.

Key Factors When Selecting a Walking Foot Sewing Machine

Performance and Functionality

When evaluating the performance and functionality of a walking foot sewing machine, consider the machine’s motor power and stitch capabilities. A robust motor ensures the machine can handle heavy-duty fabrics like leather and canvas without strain. Motors ranging from 1/4 hp to 1 hp are common in higher-end models, providing the necessary torque and consistent performance. Machines with a higher number of stitches per minute (SPM) can significantly increase productivity. Typical industrial walking foot sewing machines offer speeds up to 2,500 SPM, making them ideal for commercial applications.

Stitch length and width adjustments allow users to customize their stitching based on the material and project requirements. Machines with a maximum stitch length of up to 10 mm and adjustable stitch width provide greater versatility. Additionally, the reverse stitch function is crucial for reinforcing seams, ensuring durability and longevity of the finished product.

Build Quality and Durability

The build quality of a walking foot sewing machine directly impacts its durability and lifespan. Machines constructed with high-quality materials such as cast iron or heavy-duty aluminum are more robust and capable of withstanding rigorous use. Models with die-cast housings are known for their strength and stability, which is essential for maintaining precision during intensive sewing tasks.

Internal components, such as gears and bearings, should be made from durable materials like stainless steel to ensure smooth operation and reduce wear and tear. Regular maintenance, including lubrication and cleaning, is vital to prolong the machine’s life. Some machines come with built-in maintenance kits, making it easier for users to keep their equipment in optimal condition.

Latest Technology Features

Modern walking foot sewing machines often incorporate advanced technology to enhance functionality and ease of use. Features such as digital controls and programmable stitch patterns allow for greater precision and customization. Machines equipped with LCD screens provide clear visibility of settings and stitch options, making it easier for users to adjust parameters quickly.

Automatic thread trimming and needle positioning save time and improve efficiency. These functions allow the machine to cut threads and position the needle at the desired point automatically, reducing manual intervention. Some high-end models also offer integrated sewing lights, providing better illumination of the workspace and reducing eye strain during extended sewing sessions.

Ease of Use and Setup

The ease of use and initial setup complexity are significant considerations, especially for businesses that require quick deployment of new equipment. Machines with user-friendly interfaces and intuitive controls minimize the learning curve, allowing operators to start sewing with minimal training. Additionally, machines that come pre-assembled or with clear assembly instructions reduce setup time and potential errors.

Ergonomic design features, such as adjustable worktables and comfortable foot pedals, enhance user comfort and reduce fatigue during long sewing sessions. Machines with built-in storage compartments for accessories and tools also contribute to a more organized and efficient workspace.

Price Range and Budget

Walking foot sewing machines are available in various price ranges, catering to different budgets and requirements. Entry-level models suitable for small businesses or hobbyists typically start around $500, offering basic functionality and reliability. Mid-range machines, priced between $1,000 and $2,500, provide a balance of advanced features and robust performance, making them ideal for medium-sized enterprises.

High-end industrial machines, which can cost upwards of $3,000, are designed for heavy-duty use and come with premium features like automatic threading, multiple needle positions, and high-speed motors. When selecting a machine, consider the total cost of ownership, including maintenance, spare parts, and potential upgrades, to ensure it aligns with the business’s long-term financial plan.

Importance of Material Compatibility

Material compatibility is crucial when choosing a walking foot sewing machine, as it determines the machine’s ability to handle various fabrics and materials. Machines designed for industrial use must accommodate heavy-duty fabrics like leather, canvas, and denim, as well as lighter materials such as cotton and polyester. This versatility ensures the machine can be used for a wide range of projects, enhancing its value and utility.

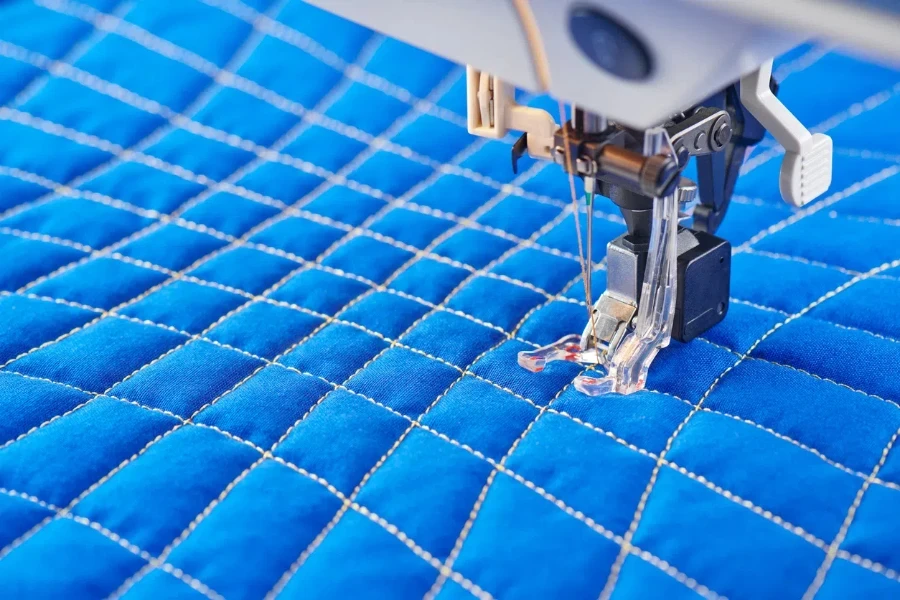

The walking foot mechanism provides even feeding of fabric layers, preventing slippage and ensuring consistent stitch quality. This feature is particularly important when working with multiple layers of fabric or thick materials, as it maintains alignment and reduces the risk of skipped stitches or uneven seams. Machines with a triple feed system, incorporating needle feed, walking foot, and bottom feed, offer superior material handling capabilities.

Safety Standards and Certifications

Adhering to safety standards and obtaining relevant certifications is essential for ensuring the safe operation of walking foot sewing machines. Machines that comply with international safety standards, such as CE (Conformité Européenne) and UL (Underwriters Laboratories), provide assurance of their safety and reliability. These certifications indicate that the machine has undergone rigorous testing and meets the required safety criteria, reducing the risk of accidents and injuries.

Safety features, such as automatic needle guards and emergency stop buttons, further enhance operator safety. Machines equipped with these features can prevent accidental needle punctures and allow users to quickly halt operation in case of an emergency. Regular safety inspections and maintenance are also crucial for identifying potential hazards and ensuring the machine remains in safe working condition.

Upgradability and Future-Proofing

Investing in a walking foot sewing machine with upgradability and future-proofing capabilities ensures the equipment remains relevant and functional as technology advances. Machines with modular designs allow users to upgrade components, such as motors and control systems, to enhance performance and add new features. This flexibility extends the machine’s lifespan and reduces the need for frequent replacements.

Compatibility with software updates and additional accessories, such as specialized presser feet and stitch pattern kits, further enhances the machine’s versatility and functionality. Some machines offer USB ports for importing custom stitch patterns, allowing users to expand their creative possibilities and keep up with evolving trends.

Packaging Quality and Shipping Considerations

The quality of packaging and shipping considerations play a significant role in ensuring the safe delivery of walking foot sewing machines. Machines should be securely packaged with protective materials, such as foam inserts and sturdy boxes, to prevent damage during transit. Detailed instructions for unpacking and assembly should be included to guide users through the setup process.

Reputable manufacturers and suppliers offer reliable shipping options, including tracking and insurance, to ensure the machine arrives in good condition. It is also beneficial to choose suppliers with responsive customer support, who can assist with any issues or questions that may arise during shipping and delivery.

Summing Up

In summary, selecting the right walking foot sewing machine involves considering various factors, including performance, build quality, technology features, ease of use, and budget. Ensuring material compatibility, safety standards, upgradability, and packaging quality further enhances the machine’s value and functionality. By carefully evaluating these aspects, businesses can make informed decisions and invest in equipment that meets their specific needs and requirements.