Umrhwebi osebenzisa ivenkile okanye umzi-mveliso wesinyithi kufuneka atyale imali koomatshini abafanelekileyo ukuze aphumelele kushishino lwesinyithi. Ngenxa yenkqubela phambili yetekhnoloji, ezi zixhobo zoshishino ziye zavela, zenza kube lula ukwenza iindawo zentsimbi ezinqwenelekayo kuyo nayiphi na imilo kunye nobukhulu.

Ukuvela kwezi zixhobo kuye kwaba negalelo ekuyilweni koomatshini abaninzi abanokuvelisa iimilo ezintsonkothileyo zamalungu esinyithi ngokunciphisa umgudu womntu kunye nokusebenza okuphezulu. Kwaye ekubeni umntu unokukhetha kwiintsimbi ezahlukeneyo oomatshini abasebenza, kubalulekile ukuqonda iintlobo ezahlukeneyo zoomatshini phaya kunye nemisebenzi yabo. Unale nto engqondweni, eli nqaku liza kuxubusha 11 oomatshini eziqhelekileyo ezisetyenziswa kushishino metalworking, ukuze umthengi unako ngokuzithemba umthombo koomatshini abayifunayo.

Imarike yoomatshini bokwenza isinyithi kwihlabathi

Ubungakanani bemarike yehlabathi yoomatshini bokwenza isinyithi kuqikelelwa ukuba bunokwanda ngesantya sokukhula ngonyaka (CAGR) ye-9.4%, ukusuka kwi-US $ 230,48 yebhiliyoni ngo-2021 ukuya kwi-US $ 364.92 yebhiliyoni ngo-2026.

Oku kukhula kuphenjelelwa zizinto ezininzi, eziquka:

- Ukukhula koqoqosho oluzinzileyo kumazwe amaninzi asakhasayo naphuhlileyo, kukhuthaza utyalo-mali kwiimarike zabasebenzisi bokugqibela.

- Ukufumana kwakhona amaxabiso ezinto zorhwebo kulandela iziphumo ezibi ze-Covid-19.

- Ulawulo lwamanani oluphezulu lwekhompyuter (i-6-axis CNC) oomatshini bokungqusha, abaququzelela ukuguqulwa kweentsimbi ezikrwada zibe ngamacandelo okugqibela antsonkothileyo.

Uhlobo koomatshini besinyithi

Abo basebenza kumzi-mveliso wesinyithi bayazi ukuba iimveliso ezikumgangatho ophezulu zinokuvela kuphela kwizixhobo ezifanelekileyo zoshishino. Apha ngezantsi kukho uluhlu lweematshini eziqhelekileyo zesinyithi ezisetyenziselwa imisebenzi ethile, kubandakanywa ukusika isinyithi kunye nokubunjwa.

1. Umatshini we-lathe othe tye

Lo matshini udla ngokusetyenziswa ekujikelezweni isiqwenga semathiriyeli umntu asebenza kuyo. IiLathes ingasetyenziselwa ukusika, ukukruna, isanti, ukubhola, intambo, ukubhoboza, ukujika, kunye nobuso beplastiki, iinkuni, kunye namalungu esinyithi. Ziza kuluhlu lweesayizi kunye nolungelelwaniso kunye nezixhobo ezininzi ezihambayo zokuphucula imisebenzi yazo.

Uninzi lwabasebenzi bentsimbi abasebenza ngentsimbi echanekileyo bayakuvuyela ukusebenza kunye oomatshini bokuhlamba. Ngokomzekelo, iifektri ezivelisa oomatshini bokukhanya zinokusebenzisa oomatshini belaphu ukuphucula iimveliso zabo.

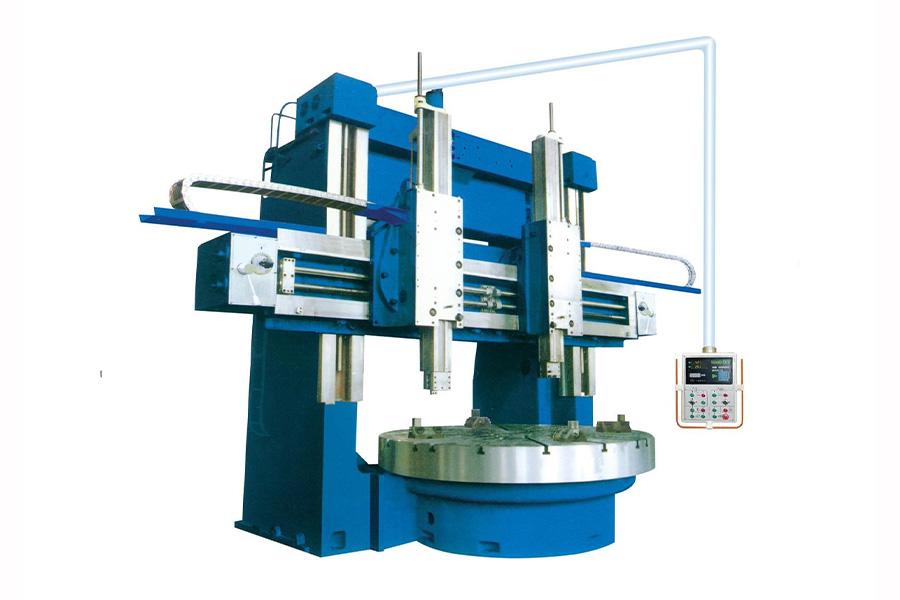

2. Oomatshini belathe nkqo (VTLs)

Ii-VTL sesinye sezona zixhobo zinemisebenzi emininzi kwishishini lesinyithi. Zihlala zisetyenziselwa ukwenza ii-alloys eziqinileyo, izixhobo zentsimbi ezinesantya esiphezulu, izixhobo ze-ceramic, kunye neentsimbi ezine-ferrous kunye ne-non-ferrous.

Ngaphezu koko, banokusebenza iindawo ezinkulu zetsimbi ezinobubanzi obusuka kwi-1 ukuya kwi-20 yeemitha. Bahambisa imisebenzi esebenzayo yokusika isinyithi kubandakanya ukudinwa kwecylindrical, ukujika, ukubheka phezulu, kunye nokucofa.

3. Oomatshini bokugaya

Oomatshini bokugaya zinemisebenzi emininzi xa kusetyenzwa imathiriyeli ezahlukeneyo kwimizi-mveliso nakwizicelo zokuvelisa. Basebenzisa izixhobo zokusika ezijikelezayo ukuze baphucule izixhobo zokusebenza ngokubhomba, ukungqusha, ukuphinda kuphinde kuphinde kuqhutyekwe nokucoca.

Oomatshini bokugaya zihlelwe ngokuxhomekeke kwicala lokujikeleza kwazo. Oomatshini abathe nkqo banama-spindle abo kwi-engile echanekileyo kwizinto zokusebenza. Oomatshini bokungqusha abathe tyaba banesixhobo sokusika esijikelezayo sijonge ngokuthe tye kwaye sisebenza ngaxeshanye kwindawo yokusebenza. Ngokwahlukileyo, umatshini wokusila jikelele unokuthe tyaba okanye ngokuthe nkqo, kuxhomekeke kwiimfuno zezicelo ezithile.

4. Oomatshini bokucoca

Umsebenzisi unokusebenzisa i-a umatshini wokuhlamba ukwenza, ukusika, kunye nokubumba izinto ezahlukeneyo. Umatshini usebenzisa i-broach okanye i-toothed isixhobo sokususa izinto kunye nokucoca i-workpiece. Inkqubo ingaba ngumgca okanye i-rotary, kuxhomekeke kwindlela umatshini obekwe ngayo kunye nomsebenzi.

Ngokomzekelo, xa ususa izinto zokusebenza kwi-workpiece, umatshini we-rotary broaching ujikeleza isixhobo samazinyo ukwenza iimveliso kwiingcali eziphethe iiprojekthi zetsimbi.

5. Umatshini wokugaya

Oomatshini bokugaya zizixhobo ezidumileyo kushishino lwesinyithi kuba zisetyenziselwa ukubumba okanye ukugqiba imiphezulu yesinyithi. Iigrinder zisebenzisa i-abrasion ukususa izinto ezingafunekiyo kwi-workpiece. Ekubeni inkqubo yokusila ivelisa ubushushu, oomatshini abaninzi bale mihla bafakelwe iisistim zokupholisa ngamanzi, izinto zokupholisa ezisekelwe kwioli, okanye iinkqubo zokupholisa umoya ukuze i-workpiece ipholile.

Uhlobo lomatshini wokugaya umntu kufuneka akhethe kuxhomekeke kwizinto ezisetyenzwayo kunye nesiphumo esijoliswe kuyo. Umzekelo, izinto ezingqongqo ngakumbi zinokufuna iipleyiti zokugaya intsimbi, ngelixa izinto ezithambileyo ziya kwenza kakuhle ngeepleyiti zealuminiyam.

Oomatshini bokugaya inokusetyenziswa njengezixhobo zokusika apho ezinye izixhobo zingakwazi ukuvelisa imilo efunekayo.

Ishishini lesinyithi lifuna iigrinder ezahlukeneyo ezilungele iinjongo ezahlukeneyo, ezifana nokubamba kunye nokwenza imilo ethile yomsebenzi.

6. Oomatshini bokwemba

Ishishini lokwenza isinyithi libandakanya ukugrumba imingxuma kwiintsimbi nezinye izinto ezifana nekhonkrithi, iplastiki kunye neenkuni. Oomatshini bokwemba nceda ukudala le mingxuma.

Zahlulwe zaba ziindidi ezimbini: oomatshini bemigulukudu kunye noomatshini bokwemba iradial. Oomatshini bokwemba imigulukudu banezijikelezo ezininzi ezixhonywe kwitafile engatshintshiyo. Kwelinye icala, oomatshini bokwemba iradial baxhonywe kwingalo ejikelezayo.

Nangona kukho oomatshini bokomba abaqhutywa ngesandla, abantu abaninzi bakhetha oomatshini abasebenza ngombane ngenxa yokuchaneka kwabo kunye nokukwazi ukusebenza ngomsebenzi ocekethekileyo. Nangona kunjalo, oomatshini bokomba abaqhutywa ngesandla baseluncedo, ngakumbi xa kufuneka ukuthwaleka okanye xa kusetyenzwa ngezinto ezithambileyo ngendlela emangalisayo.

7. Umatshini wokucheba

Nceda ungabhidani lo matshini nalawo asetyenziselwa ukucheba iigusha! Oku umatshini wokucheba isetyenziselwa ukusika amashiti esinyithi abe ngobungakanani obunqwenelekayo kunye neemilo ngaphandle kokwenza iitshiphusi okanye intsalela, ngaloo ndlela kuncitshiswe inkunkuma eyingozi emoyeni naphantsi. Oku isikhokelo sokuthenga sabaqalayo ukuya koomatshini bokucheba yindawo elungileyo yokuqalisa kwabo bangayaziyo into eyenziwa ngumatshini.

8. Oomatshini bokuhlamba

Amashishini ahlukeneyo asebenzisa isinyithi ukuvelisa iigiya ezikhethekileyo, i-splines, i-shafts echanekileyo ephezulu, kunye nezinye iindawo ze-cylindrical kwizicelo ezahlukeneyo. Oomatshini beHobbling ziluncedo ekulungiseni ezi mfuno. Ngethamsanqa, banohlahlo lwabiwo-mali kwaye bafuna abantu abambalwa ukuba baqhube, kodwa basavelisa ubuninzi beengxenye zetsimbi imihla ngemihla.

9. Cinezela isiqhoboshi

Cinezela iziqhoboshi ziye zasetyenziswa kangangeenkulungwane kushishino metalworking ukucubungula amacandelo metal. Nangona kunjalo, ngetekhnoloji ephezulu, cinezela iziqhoboshi ziye zaba zizixhobo ezintsonkothileyo ezisebenzisa ubugcisa bekhompyutha kunye neenkqubo zale hydraulic ukugoba amashiti esinyithi. Bangajika okanye isinyithi esisikiweyo kwiifom ezizodwa kunye neemilo usebenzisa i-die okanye i-punch iseti kwii-engile ezithile.

10. Iziko lomatshini

Amaziko Machining ngukumkanikazi nookumkani koomatshini kushishino lwesinyithi. Bangoomatshini abanemisebenzi emininzi abanceda ukuqhuba imisebenzi emininzi entsonkothileyo, kubandakanya ukucotha, ukugaya, ukubhola, kunye nokuthunga ngenxa yokuba baphatha izixhobo ezininzi kwitshintshi.

Amaziko omatshini ayahluka ngokuxhomekeke kwimisebenzi yawo, imilinganiselo yendawo yokusebenza, kunye nenani leezembe; nangona kunjalo, zahlulwe ikakhulu ngamaziko omatshini athe nkqo nathe tyaba, ngokuxhomekeke kwindawo ye-axis yokusonta.

11. IiSandblasters

A isantiblaster ihambisa amasuntswana esanti acolekileyo okanye imidiya erhabaxa ngesantya esiphezulu ukwenza imisebenzi emininzi. Isetyenziswa kwishishini lesinyithi ukucoca okanye ukususa iipeyinti zokupeyinta, ukudubula, okanye ukuphucula umphezulu wezinto ezahlukeneyo.

Abanini bamaziko, iikontraka, iiyadi zikaloliwe, iindawo zeenqanawa, kunye nokusetyenziswa okuhambahambayo okwahlukileyo bafuna oomatshini be-sandblaster eyomeleleyo ukuze balawule umhlwa kunye nokucoca. Nangona zifuna izakhono ezithile, umatshini womatshini kulula ukuqondwa.

IiSandblasters zinokusebenza ngesanti, isoda, okanye amaso ukucoca imiphezulu. Omnye unokusebenzisa umoya oxinzelelweyo, ulwelo, okanye umphunga ukuvelisa ukufunxa okutsalela imidiya erhabaxa kumlomo wompu phambi kokubetha umphezulu womsebenzi.

Into ekufuneka uyiqwalasele xa ukhetha oomatshini bokwenza isinyithi

Nangona abanye oomatshini bentsimbi besebenza ngeendlela ezininzi, usenokukhetha umatshini ongalunganga ukuba awusebenzisi lumkelo. Ngaloo nto engqondweni, ezi zezinye zezinto eziphambili ezifanele ukuphononongwa ngaphambi kokuba utyale imali kumatshini.

Izinto eziza kwenziwa

Ubukhulu, uhlobo, kunye nokungaguquguquki kwezinto ezisetyenzwayo kuthintela umatshini wesinyithi okhethwa ngumntu. Ngokomzekelo, i-aluminiyam ekhanyayo okanye i-metal gauge encinci ifuna umatshini wokucheba osebenza ngombane okanye ngomoya.

Ngaphandle kohlobo lwemathiriyeli, kukwabalulekile ukuqwalasela ubume bayo ukuze ubone ukuba ngowuphi umatshini oza kulungena kakuhle.

Uhlobo lomatshini ekufuneka lwenziwe

Ngelixa abanye oomatshini bentsimbi besebenza ngeendlela ezininzi, umqhubi unokufuna oomatshini abaqinileyo nabaphucukileyo bezicelo ezithile. Ngokomzekelo, oomatshini bokwemba bangasetyenziselwa ukugqobhoza, kodwa abafanelekanga ukugaya izixhobo zokusebenza.

imveliso

Ishishini ngalinye lifuna ukusebenza ngokugqibeleleyo kwaye liphucule imveliso yalo. Umatshini osebenzayo wesinyithi kufuneka uthembeke kwaye uhlale ixesha elide kwimveliso eqhubekayo. Kufuneka kwakhona ivelise inani eliphezulu leentsimbi zemihla ngemihla ukuphucula inzuzo. Umzekelo, iidrili ezisebenza ngombane zingcono ukomba ngobuninzi kunoomatshini bokomba ngesandla.

Imilinganiselo yee-workpieces

Izixhobo zokusebenza ezinkulu zifuna oomatshini abakhulu bentsimbi, ngelixa izinto ezincinci zinokufuna oomatshini abaphathwayo nabasebenza ngesandla. Ubume kunye nenani leezembe zesixhobo sokusebenza ziya kumisela uhlobo lwembono yomatshini wokusebenza ngetsimbi umntu afanele awusebenzise.

Amanqanaba okuchaneka

Inqanaba lokuchaneka kwintsimi yesinyithi kukukwazi umatshini ukufanisa imilinganiselo echaziweyo kuyilo. Ukuchaneka komatshini wokwenza isinyithi kunye namanqanaba achanekileyo abalulekile ekuqinisekiseni ukusebenza ngokufanelekileyo koomatshini bentsimbi kunye nokwaneliseka kwabathengi. Ngaphezu koko, ukuchaneka kunye nokuchaneka kunceda ukuqinisekisa ukuba iindawo zetsimbi eziveliswayo ziyahambelana.

isiphelo

Ishishini lesinyithi lizele ngoomatshini, nto leyo enokubhidanisa abathengi abaninzi. Nangona kunjalo, umntu unokwandisa amathuba abo okwenza isigqibo esilungileyo ngophando kunye neengcali zokubonisana. Olunye ukhetho olunoqoqosho kukuthenga oomatshini abaguquguqukayo abenza imisebenzi emininzi. Qinisekisa ukuba isixhobo sinemveliso ephezulu kunye namanqanaba okuchaneka ukwanelisa iimfuno zabathengi. Kwaye kwabo bafuna ukufunda ngakumbi, khangela kwakhona esi sikhokelo iingcebiso zokukhetha kwifektri esebenzayo yesinyithi.

Afrikaans

Afrikaans አማርኛ

አማርኛ العربية

العربية বাংলা

বাংলা Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch हिन्दी

हिन्दी Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Bahasa Melayu

Bahasa Melayu മലയാളം

മലയാളം پښتو

پښتو فارسی

فارسی Polski

Polski Português

Português Русский

Русский Español

Español Kiswahili

Kiswahili ไทย

ไทย Türkçe

Türkçe اردو

اردو Tiếng Việt

Tiếng Việt isiXhosa

isiXhosa Zulu

Zulu